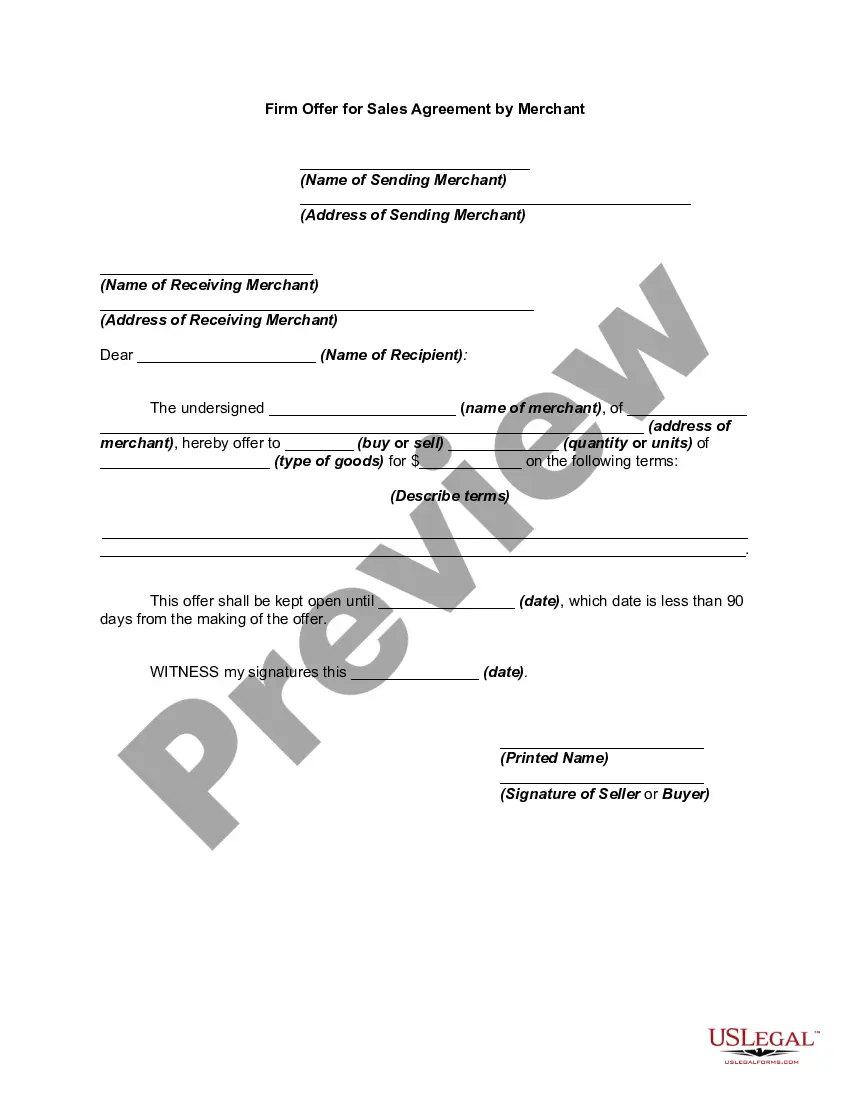

A purchase order represents the formal and final agreement to a purchasing transaction with a vendor. It identifies:

1. the vendor,

2. the material to be ordered (which in this form is described in Exhibit A),

3. the quantity (which in this form is described in Exhibit A),

4. the price (which in this form is described in Exhibit A),

5. the delivery date and terms of delivery (which in this form is described in Exhibit A), and

6. the terms of payment (which in this form is described in Exhibit A).

The Louisiana Purchase Order of Aluminum Extrusions is a procurement document used in the state of Louisiana to acquire aluminum extrusion products. Aluminum extrusions are profiles created by squeezing aluminum alloy through a specific shape in a die. These extrusions are widely used in various industries for applications such as construction, automotive, aerospace, and manufacturing. The Louisiana Purchase Order of Aluminum Extrusions serves as a legal contract between the buyer and the supplier. It outlines the specific requirements, quantities, quality standards, and delivery terms for the aluminum extrusion products being ordered. This order ensures that the desired aluminum extrusions meet the buyer's specifications and are delivered within the agreed-upon timeframe. There are different types of Louisiana Purchase Order of Aluminum Extrusions, categorized based on their specific usage or characteristics: 1. Standard Extrusions: These are the most commonly ordered aluminum extrusions, available in various shapes such as T-sections, angles, channels, and rods. Standard extrusions are often used in general construction, architectural applications, and framing systems. 2. Custom Extrusions: These are tailored aluminum extrusions specifically designed to meet unique project requirements. Custom extrusions can be produced in complex profiles and intricate shapes, allowing precise customization according to the buyer's specifications. They find applications in specialized industries like transportation, electronics, and marine sectors. 3. Heat Sink Extrusions: These extrusions are designed to dissipate heat generated by electronic components. They often feature specialized fins or grooves, enhancing thermal conductivity and efficiency. Heat sink extrusions are extensively utilized in electronic devices, LED lighting, telecommunications, and power distribution systems. 4. Industrial Extrusions: These extrusions are primarily used for industrial applications, such as conveyor systems, machine frames, and material handling equipment. Industrial extrusions possess high strength and durability, making them suitable for heavy-duty operations and demanding environments. 5. Architectural Extrusions: These extrusions are meant for enhancing the aesthetics and functionality of architectural structures. They can be custom-designed to fit specific building purposes, such as windows, doors, curtain walls, façades, and decorative elements. Architectural extrusions contribute to energy efficiency, design flexibility, and sustainability in construction projects. It is worth noting that the Louisiana Purchase Order of Aluminum Extrusions can be further categorized based on alloys, finishing options (such as powder coating or anodizing), and dimensional specifications. However, these classifications may vary based on the specific needs of the buyer and the supplier.