Louisiana Equipment Maintenance Agreement with a Systems Integrator is a contract that outlines the terms and conditions of maintaining various equipment used by businesses or organizations. This agreement ensures that the systems' integrator is responsible for the upkeep, repair, and support of the specified equipment during the agreed-upon timeframe. The primary goal of this agreement is to maintain the efficiency, reliability, and functionality of equipment critical to the operation of the business. Keywords: Louisiana, equipment maintenance agreement, systems integrator, contract, terms and conditions, maintenance, repair, support, efficiency, reliability, functionality, operation, business. Different types of Louisiana Equipment Maintenance Agreements with a Systems Integrator may include: 1. Preventive Maintenance Agreement: This type of agreement focuses on regular inspection, cleaning, and maintenance to prevent equipment breakdowns. The systems' integrator performs routine check-ups and addresses any emerging issues before they become significant problems. 2. Corrective Maintenance Agreement: In this agreement, the systems' integrator is responsible for repairing and restoring equipment functionality when a breakdown or malfunction occurs. They provide prompt support to resolve technical issues and ensure minimal downtime. 3. Comprehensive Maintenance Agreement: This comprehensive agreement covers both preventive and corrective maintenance. It includes regular inspections, scheduled maintenance, repairs, and technical support whenever needed. This type of agreement offers comprehensive coverage for various equipment types and helps businesses minimize unexpected breakdowns. 4. On-demand Maintenance Agreement: This agreement allows businesses to request maintenance services on an as-needed basis. The systems' integrator provides support and repairs whenever the equipment faces issues, without any fixed maintenance schedule. 5. Parts and Labor Agreement: This type of agreement covers the cost of replacement parts and labor required for the maintenance and repair of equipment. It ensures that businesses have access to necessary components and professional expertise without additional costs. 6. Emergency Maintenance Agreement: This agreement focuses on immediate response and support in case of equipment emergencies. The systems' integrator guarantees rapid assistance for critical situations where equipment failure can significantly impact business operations. 7. Extended Maintenance Agreement: This agreement extends the maintenance coverage beyond the manufacturer's warranty period. The systems' integrator takes responsibility for the equipment's upkeep and support, providing peace of mind to businesses even after the warranty expires. By entering into a Louisiana Equipment Maintenance Agreement with a Systems Integrator, businesses can ensure that their equipment remains in optimal condition, reducing downtime, maximizing productivity, and extending the lifespan of their assets.

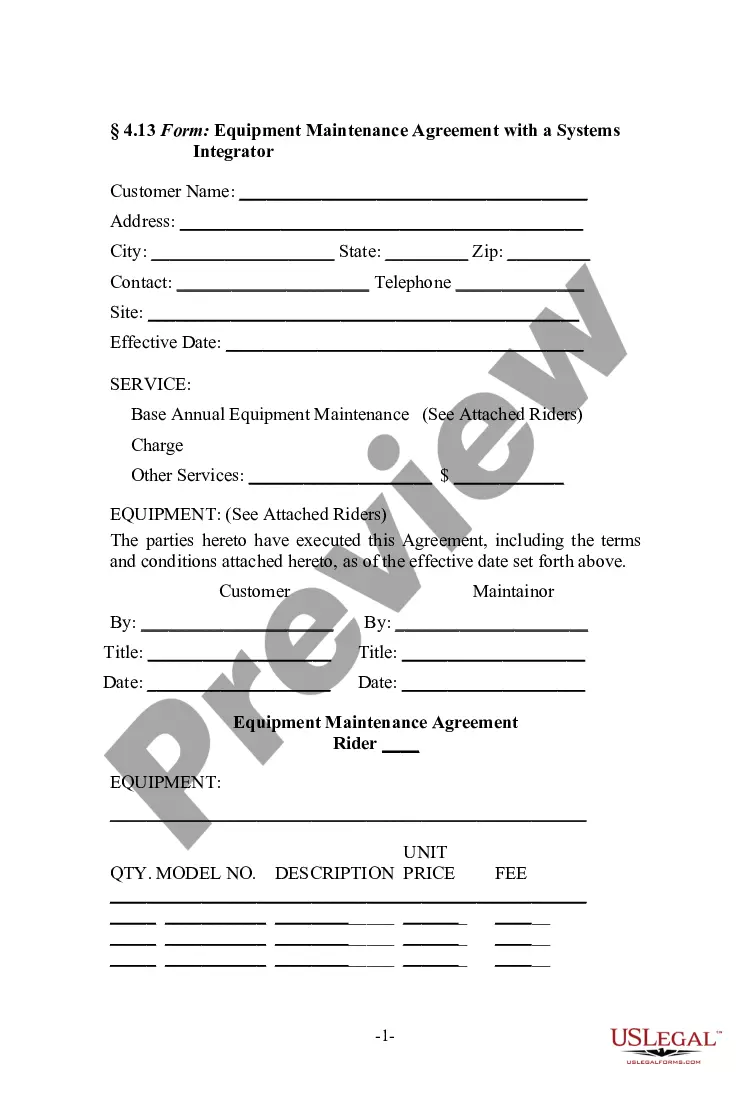

Louisiana Equipment Maintenance Agreement with a Systems Integrator

Description

How to fill out Louisiana Equipment Maintenance Agreement With A Systems Integrator?

You can spend several hours on the Internet trying to find the legal file format which fits the state and federal needs you will need. US Legal Forms supplies thousands of legal forms that happen to be examined by experts. You can actually obtain or print out the Louisiana Equipment Maintenance Agreement with a Systems Integrator from our services.

If you already possess a US Legal Forms accounts, it is possible to log in and then click the Obtain button. Following that, it is possible to full, modify, print out, or indication the Louisiana Equipment Maintenance Agreement with a Systems Integrator. Each legal file format you buy is yours for a long time. To acquire yet another copy for any bought type, visit the My Forms tab and then click the corresponding button.

If you work with the US Legal Forms web site initially, keep to the basic instructions beneath:

- Initial, be sure that you have selected the correct file format to the county/metropolis of your choosing. Browse the type explanation to ensure you have picked out the correct type. If readily available, use the Preview button to check from the file format also.

- If you wish to locate yet another edition from the type, use the Search industry to find the format that fits your needs and needs.

- After you have found the format you would like, click on Purchase now to move forward.

- Find the rates plan you would like, enter your accreditations, and sign up for a free account on US Legal Forms.

- Total the transaction. You can utilize your credit card or PayPal accounts to fund the legal type.

- Find the format from the file and obtain it to the system.

- Make alterations to the file if required. You can full, modify and indication and print out Louisiana Equipment Maintenance Agreement with a Systems Integrator.

Obtain and print out thousands of file web templates utilizing the US Legal Forms Internet site, which offers the greatest selection of legal forms. Use expert and state-certain web templates to handle your business or specific requires.