This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

Louisiana Salt Water - Disposal, Storage, and Handling

Description

How to fill out Salt Water - Disposal, Storage, And Handling?

Are you presently in the place the place you need to have documents for sometimes company or individual purposes nearly every day? There are a lot of legitimate document layouts available on the net, but locating types you can rely is not easy. US Legal Forms gives a large number of develop layouts, just like the Louisiana Salt Water - Disposal, Storage, and Handling, which can be composed to fulfill state and federal demands.

When you are presently informed about US Legal Forms internet site and get your account, simply log in. Afterward, you can acquire the Louisiana Salt Water - Disposal, Storage, and Handling format.

Unless you have an bank account and want to begin using US Legal Forms, follow these steps:

- Obtain the develop you will need and make sure it is for your appropriate area/area.

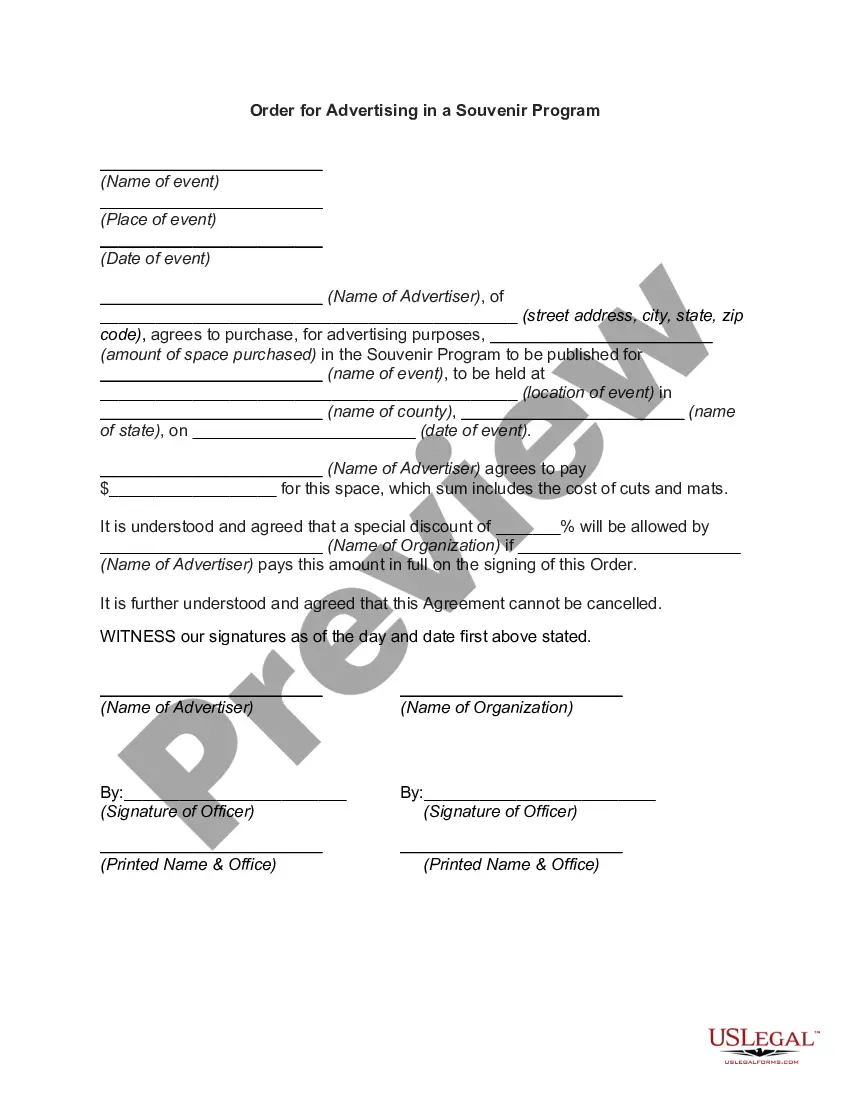

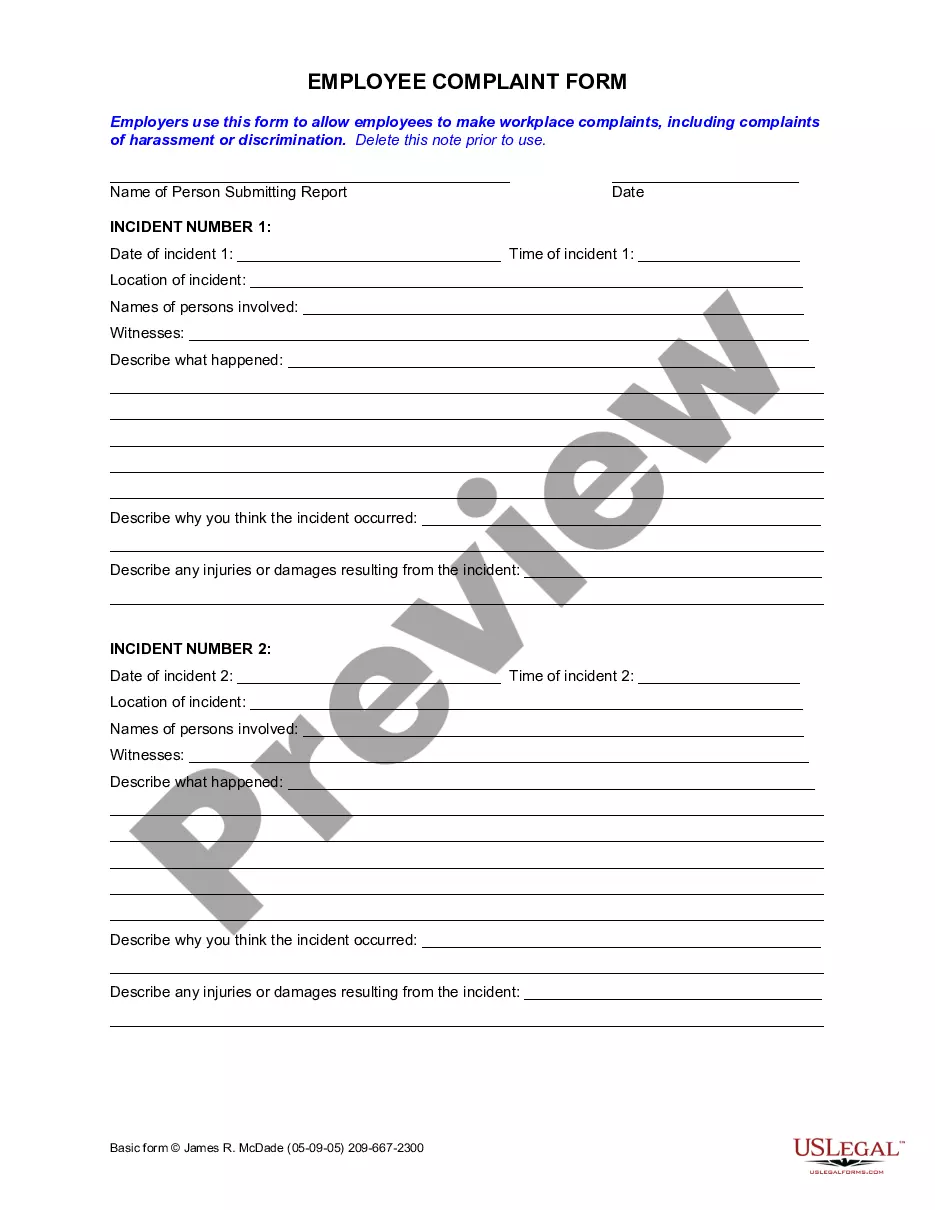

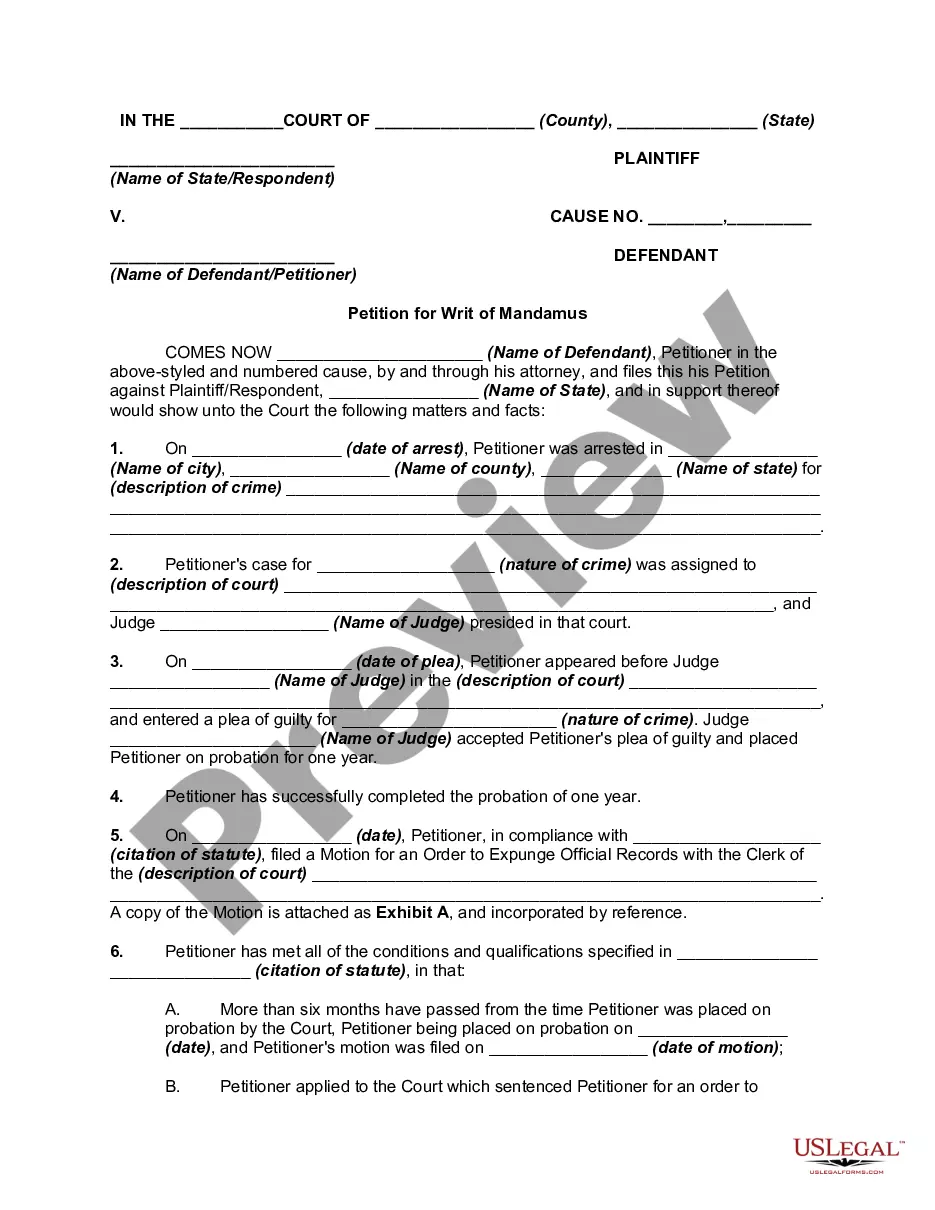

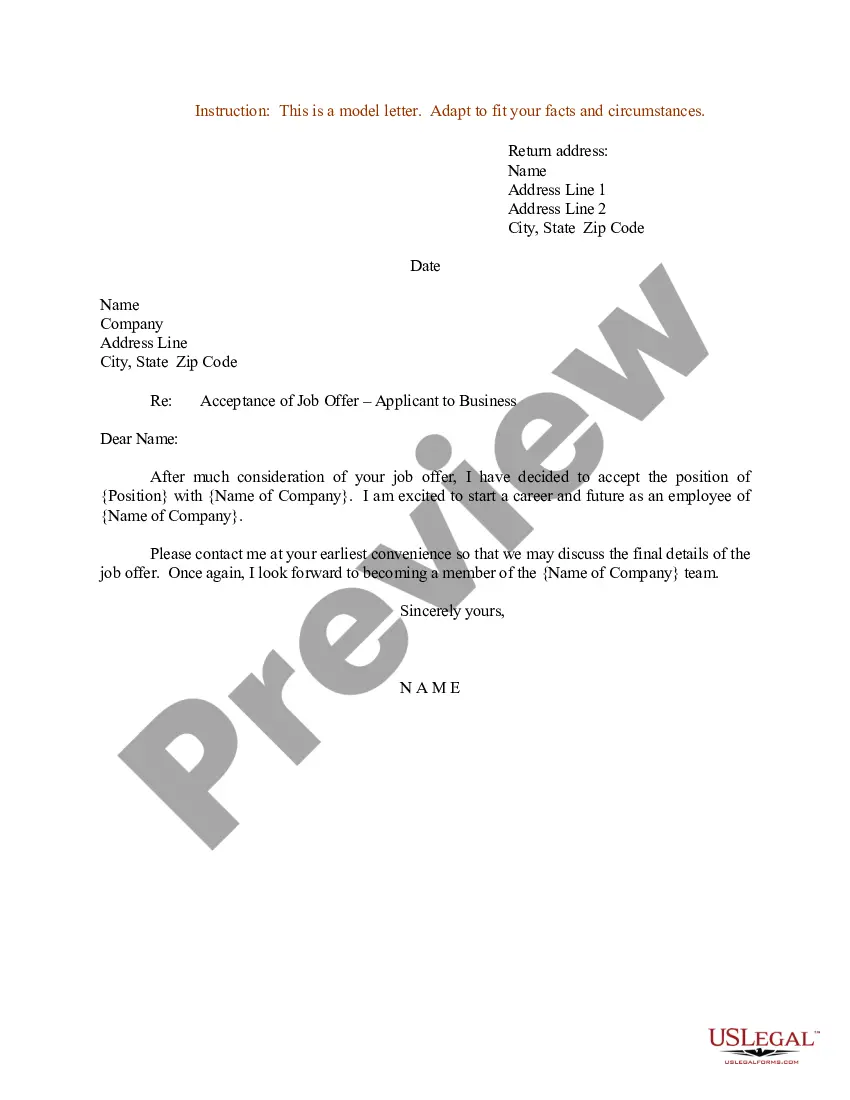

- Take advantage of the Review option to review the shape.

- Browse the outline to actually have selected the right develop.

- When the develop is not what you are searching for, make use of the Search area to find the develop that meets your requirements and demands.

- When you find the appropriate develop, click on Buy now.

- Select the rates strategy you would like, fill in the desired details to generate your account, and pay for your order with your PayPal or bank card.

- Pick a handy data file file format and acquire your backup.

Locate all of the document layouts you possess bought in the My Forms food selection. You can aquire a extra backup of Louisiana Salt Water - Disposal, Storage, and Handling any time, if required. Just go through the necessary develop to acquire or print the document format.

Use US Legal Forms, probably the most substantial selection of legitimate varieties, in order to save efforts and steer clear of faults. The services gives skillfully produced legitimate document layouts that you can use for a selection of purposes. Produce your account on US Legal Forms and initiate creating your way of life easier.

Form popularity

FAQ

Disposal wells may be used to inject mineralized water produced with oil and gas into underground zones for the purpose of safely and efficiently disposing of the fluid. Typically, the underground interval is one that is not productive of oil and gas.

A salt water disposal (SWD) well is a disposal site for water produced as a result of the oil and gas extraction process. Produced water, also referred to as salt water, contains particulate which can cause problems for the pump bringing water into the well.

The oil and gas industry faces many challenges, including the availability of fresh water for making fracturing fluids, especially in the Arabian peninsula and other arid regions. Using seawater to make fracturing fluid can help address several obstacles and reduce costs.

Saltwater drilling fluid finds primary use in drilling through salt strata that is prone to dissolution when other types of drilling fluids are used.

The process of oil and gas production creates millions of gallons of hazardous brine, also known as salt water, every day. This salt water contains various chemicals for extracting impurities out of the oil and gas and has an extremely high salt content, making it dangerous.

The primary benefit of drinking salt water pertains to increasing hydration. Some have claimed that it can also help with detoxing your body and aiding in digestion, but the truth isn't that simple.

While some particularly arid regions allow for disposal via evaporation from large holding pits, most salt water is disposed of at specialty disposal sites where the salt water is injected by way of a disposal well (salt water disposal, or SWD wells) into natural underground formations.

Healthy Uses for Salt Canker Sores. 1/12. Rinsing your mouth with salt water can ease the pain and help you heal faster. ... Ingrown Toenail. 2/12. ... Stuffy or Runny Nose. 3/12. ... Psoriasis and Eczema. 4/12. ... Heartburn. 5/12. ... Bug Bites or Stings. 6/12. ... Sore Throat. 7/12. ... Tired Feet. 8/12.