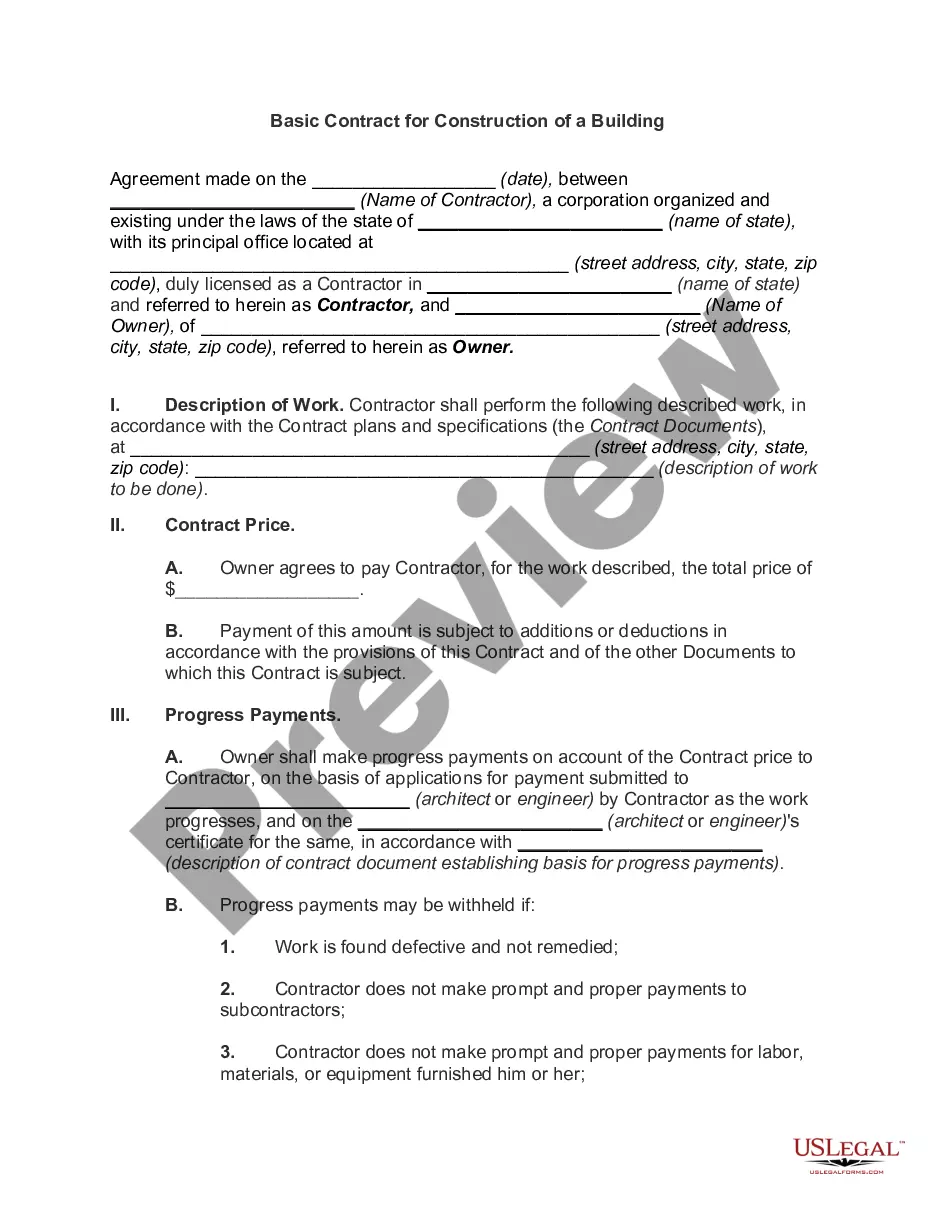

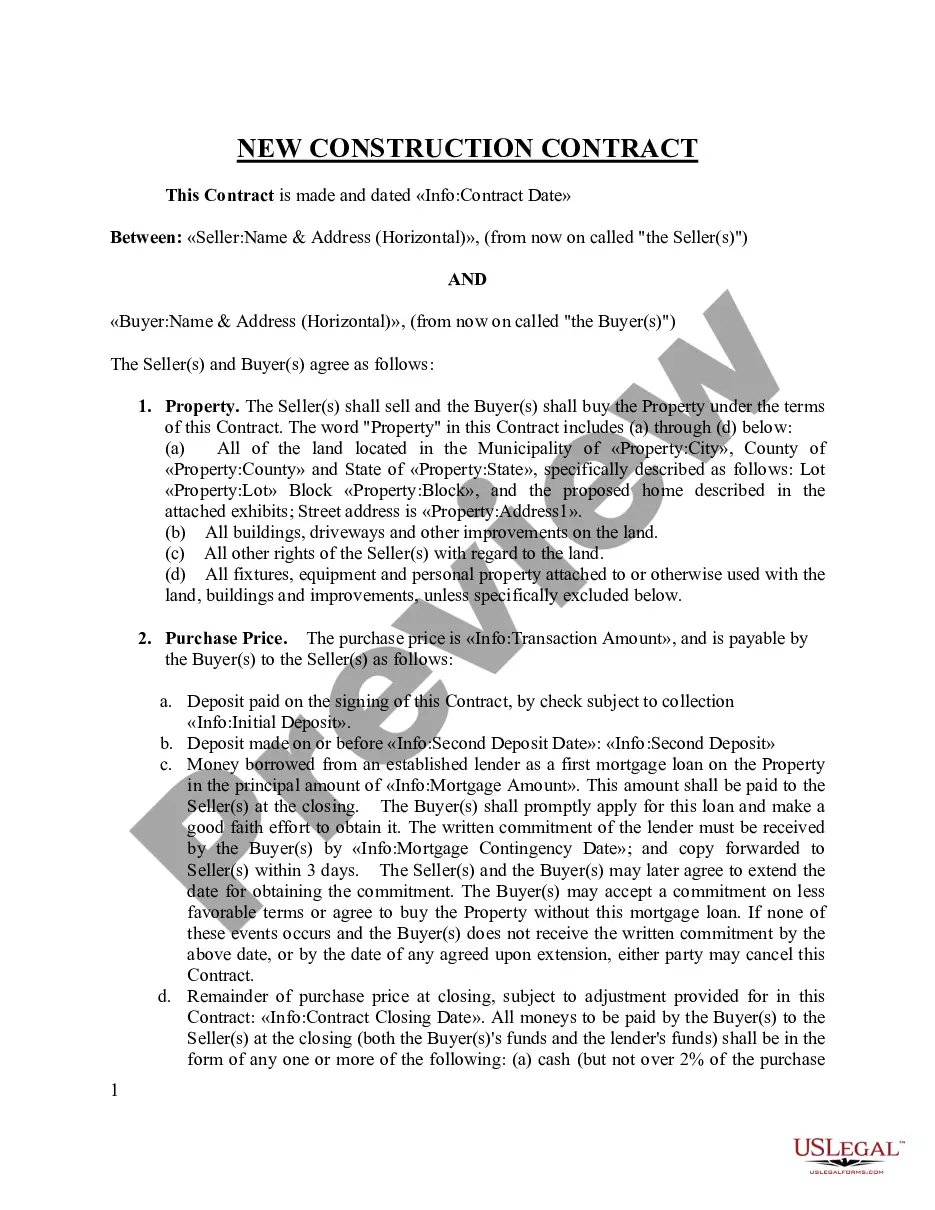

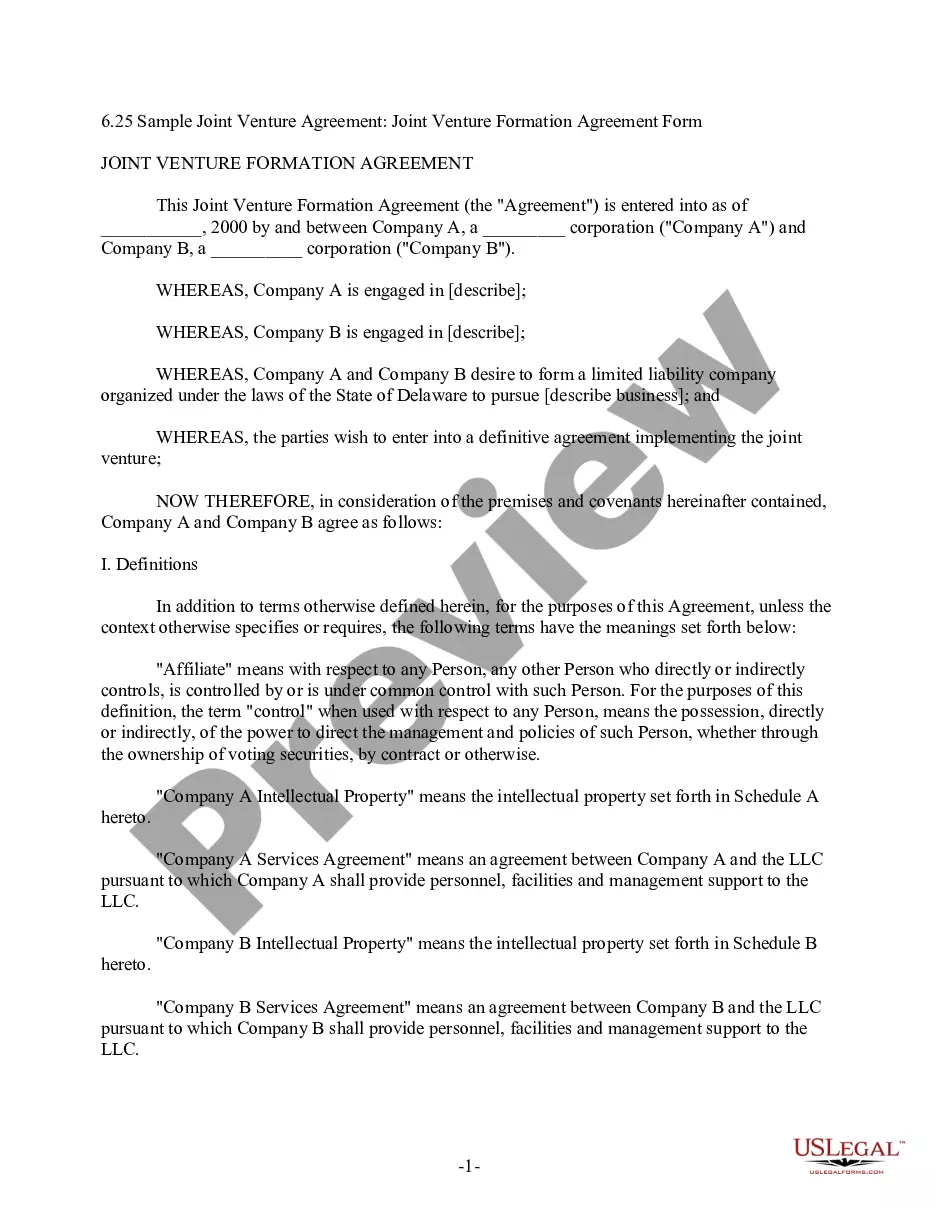

This form is a contract for the design and construction of a manufacturing facility that will be engaged in a particular manufacturing process. This form is a generic example that may be referred to when preparing such a form for your particular state. It is for illustrative purposes only. Local laws should be consulted to determine any specific requirements for such a form in a particular jurisdiction.

Massachusetts Contract for Design and Construction of Manufacturing Facility

Description

How to fill out Contract For Design And Construction Of Manufacturing Facility?

You are capable of spending numerous hours online attempting to locate the legal document format that fulfills the state and federal requirements you need.

US Legal Forms provides an extensive selection of legal templates that have been evaluated by experts.

You can conveniently download or print the Massachusetts Contract for Design and Construction of Manufacturing Facility from the platform.

If available, use the Preview button to view the document format as well.

- If you already have a US Legal Forms account, you can Log In and click the Download button.

- Afterward, you can complete, modify, print, or sign the Massachusetts Contract for Design and Construction of Manufacturing Facility.

- Each legal document format you acquire is yours permanently.

- To obtain an additional copy of a purchased document, navigate to the My documents tab and click the corresponding button.

- If you are visiting the US Legal Forms website for the first time, follow the simple instructions provided below.

- First, ensure that you have chosen the correct document format for your selected county/area.

- Review the document description to confirm you have chosen the correct template.

Form popularity

FAQ

Securing your first contracting client can be achieved through networking and showcasing your expertise. Build a strong online presence by creating a portfolio highlighting previous work and engaging with potential clients on platforms like social media. Utilizing the resources from uslegalforms can assist you in preparing necessary documents and contracts for your Massachusetts Contract for Design and Construction of a Manufacturing Facility, making your offerings more professional.

Yes, you can act as your own general contractor in Massachusetts, but this comes with challenges. You must handle all aspects of the project, including hiring subcontractors and obtaining necessary permits for your Massachusetts Contract for Design and Construction of a Manufacturing Facility. Ensure that you have adequate knowledge and resources, as managing a construction project requires careful planning and oversight.

Operating as a contractor without a formal contract is risky and generally discouraged. A contract provides legal protection and clarifies responsibilities for both parties involved. In the context of a Massachusetts Contract for Design and Construction of a Manufacturing Facility, a written agreement outlines project specifications, payment terms, and timelines, promoting accountability and reducing misunderstandings.

To secure a contract with a construction company, start by researching firms that specialize in projects similar to your Massachusetts Contract for Design and Construction of a Manufacturing Facility. Build a strong proposal that clearly outlines your project, budget, and timeline. Networking within the industry also helps, as personal connections can lead to recommendations and opportunities to collaborate.

When communicating with a contractor for your Massachusetts Contract for Design and Construction of a Manufacturing Facility, avoid sharing vague or unverified information. Do not express personal preferences that could mislead the project scope, such as stating you are open to any budget without a limit. Clear and honest communication fosters a productive relationship, encouraging contractors to provide tailored and effective solutions.

The five design process procedures include defining the problem, researching, brainstorming solutions, prototyping, and testing. Each step is critical for developing a robust approach to a Massachusetts Contract for Design and Construction of Manufacturing Facility. These procedures guide you through a systematic exploration of design possibilities. By incorporating these steps into your project, you enhance creativity while mitigating risks, leading to successful outcomes.

Typically, the design process can be categorized into four types: conceptual design, detailing, final design, and implementation. In the context of a Massachusetts Contract for Design and Construction of Manufacturing Facility, these processes systematically transition from initial ideas to tangible solutions. Each type serves a distinct purpose, ensuring thorough exploration and development of each aspect of the project. Understanding these types aids in better project planning and execution.

Design guidelines encompass a set of standards and best practices tailored for projects involving the Massachusetts Contract for Design and Construction of Manufacturing Facility. These guidelines address various aspects such as sustainability, safety, accessibility, and aesthetics. Following them not only ensures compliance with state regulations but also fosters efficient project execution. They serve as a roadmap for achieving a seamless transition from design to construction.

Design guidance refers to the overarching principles and recommendations that inform the design and construction of a manufacturing facility under the Massachusetts Contract for Design and Construction of Manufacturing Facility. This guidance aids designers in making informed decisions that align with project objectives and community standards. By utilizing design guidance, you enhance the likelihood of achieving a successful and compliant project outcome. It promotes consistency and clarity throughout the design process.

The designer guidelines and procedures for a Massachusetts Contract for Design and Construction of Manufacturing Facility focus on ensuring compliance with local regulations and industry standards. These guidelines help to streamline the design process, providing a framework for effective collaboration among all stakeholders. By following established procedures, designers can ensure that their projects meet both functional and aesthetic requirements. This ultimately leads to higher quality results and increased client satisfaction.