The Massachusetts Manufacturer Analysis Checklist is a comprehensive assessment tool designed to analyze and evaluate the operations, productivity, and compliance of manufacturing companies in the state of Massachusetts. This checklist aims to identify areas of improvement, regulatory compliance, and potential opportunities for growth within the manufacturing sector. With the goal of enhancing efficiency and competitiveness, this checklist examines various key aspects of manufacturing operations, including facility management, production processes, supply chain management, quality control, workforce management, environmental compliance, and safety protocols. By systematically evaluating these crucial areas, the checklist enables manufacturers to pinpoint their strengths and weaknesses and devise effective strategies for continuous improvement. The Massachusetts Manufacturer Analysis Checklist encompasses a range of different types, each focusing on specific areas to provide a comprehensive evaluation of a manufacturer's operations. These various types of checklists may include: 1. Facility Management Checklist: This type of checklist assesses the overall condition, layout, and organization of manufacturing facilities. It examines factors such as equipment maintenance, space utilization, waste management, energy efficiency, and overall facility cleanliness. 2. Production Processes Checklist: This checklist type scrutinizes the manufacturing processes employed by companies, ensuring that they are optimized for maximum output and minimal waste. It evaluates aspects such as workflow efficiency, technology integration, inventory management, and adherence to industry-specific best practices. 3. Supply Chain Management Checklist: This type of checklist delves into the management of the manufacturing company's supply chain and logistics. It evaluates supplier relationships, inventory management, transportation and distribution methods, demand forecasting, and risk mitigation plans. 4. Quality Control Checklist: This checklist focuses on the manufacturing company's overall quality control measures and adherence to regulatory standards and industry certifications. It examines aspects such as product testing procedures, documentation practices, defect management systems, and continuous improvement processes. 5. Workforce Management Checklist: This type of checklist assesses the human resource management practices within the manufacturing company. It examines aspects such as workforce training and development programs, employee safety protocols, performance evaluation systems, and employee retention strategies. 6. Environmental and Safety Compliance Checklist: This checklist ensures that manufacturing companies adhere to environmentally-friendly practices and comply with safety regulations. It assesses waste management protocols, air and water pollution control measures, hazardous material handling processes, and workplace safety policies. The Massachusetts Manufacturer Analysis Checklist acts as a valuable tool for manufacturers, enabling them to identify areas that require improvement, enhance productivity and efficiency, achieve regulatory compliance, and foster continuous growth within the challenging and ever-evolving manufacturing industry.

Massachusetts Manufacturer Analysis Checklist

Description

How to fill out Massachusetts Manufacturer Analysis Checklist?

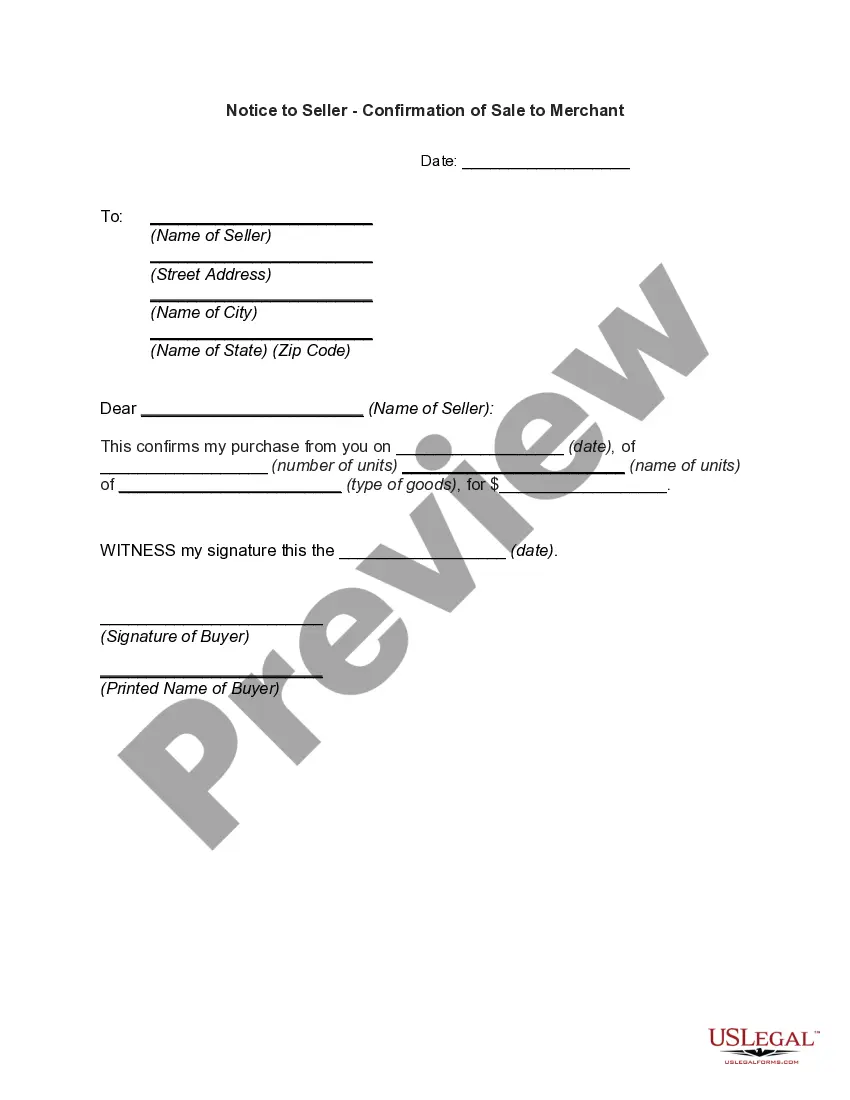

Are you presently within a situation where you require papers for either organization or personal reasons nearly every day time? There are a variety of legal record themes available online, but discovering types you can depend on isn`t simple. US Legal Forms delivers 1000s of develop themes, just like the Massachusetts Manufacturer Analysis Checklist, which are published to meet state and federal needs.

Should you be already informed about US Legal Forms internet site and also have a merchant account, basically log in. Following that, you may download the Massachusetts Manufacturer Analysis Checklist design.

Should you not come with an accounts and want to begin to use US Legal Forms, abide by these steps:

- Obtain the develop you want and make sure it is for that appropriate town/area.

- Utilize the Preview option to analyze the shape.

- Look at the information to ensure that you have selected the right develop.

- In case the develop isn`t what you`re seeking, utilize the Lookup discipline to discover the develop that fits your needs and needs.

- If you get the appropriate develop, simply click Acquire now.

- Opt for the costs strategy you desire, submit the specified information and facts to make your money, and pay for the transaction making use of your PayPal or charge card.

- Select a hassle-free document file format and download your backup.

Discover every one of the record themes you may have bought in the My Forms menus. You may get a more backup of Massachusetts Manufacturer Analysis Checklist at any time, if required. Just go through the required develop to download or print out the record design.

Use US Legal Forms, probably the most extensive selection of legal varieties, to save lots of time and steer clear of faults. The service delivers professionally made legal record themes that you can use for a selection of reasons. Create a merchant account on US Legal Forms and initiate producing your daily life a little easier.

Form popularity

More info

Program Tables SNAP Tables Puerto Rico Tables Home The most important factors in deciding which plant based meals should be served to your children are, 1. Nutritional value, 2. Ease of digestion, 3. Appearance and flavor. The choice can really be made with the help of food experts at our USDA Nutrient Database! Nutrition value is the value of the nutrient in foods. It may be expressed as percent DV (Difference), grams (ounces, 2 Tablespoons; 8 ounces or 1 pound) or milligrams (mg). The Food Guide Pyramid, a food guide designed and shared by The United States Department of Agriculture, provides nutritional requirements for healthy eating. Some of the most important numbers in The Food Guide Pyramid are: Protein: 10%, Fat: 20% and Carbohydrate: 15%. You can learn more about this food plan here. How To Select A Plant Based Diet Dietary guideline recommends that every child gets an adequate amount of vitamins and minerals.