Keywords: Massachusetts, maintenance engineer, checklist, types Detailed Description: A Massachusetts Maintenance Engineer Checklist is a comprehensive document that outlines the essential tasks and actions that a maintenance engineer in Massachusetts should perform to ensure efficient operation and upkeep of various facilities. This checklist serves as a guide for maintenance engineers to inspect, repair, and maintain equipment, systems, and infrastructure. The checklist comprises a range of specific tasks, categorized into various sections, tailored to suit the specific needs of a maintenance engineer working in Massachusetts. These sections may include but are not limited to: 1. Electrical Maintenance: This section includes tasks related to electrical systems, such as inspecting circuit breakers, testing emergency power supplies, monitoring electrical panels, evaluating grounding systems, and ensuring proper functioning of electrical equipment. 2. HVAC Maintenance: This section focuses on heating, ventilation, and air conditioning (HVAC) systems. It includes tasks like inspecting HVAC units, cleaning air filters, checking for refrigerant leaks, calibrating thermostats, and ensuring optimal performance of HVAC systems to maintain a comfortable environment. 3. Plumbing Maintenance: Tasks related to plumbing systems are listed in this section. Maintenance engineers are responsible for inspecting water supply lines, drains, and pipes for leaks or blockages, checking water pressure, testing faucets and toilets, and ensuring proper functioning of plumbing fixtures and equipment. 4. Structural Maintenance: This section covers tasks related to the building's structural integrity. It includes inspecting walls, ceilings, floors, and roofs for any signs of damage, checking for leaks or cracks, evaluating the condition of doors and windows, and ensuring compliance with building codes and safety standards. 5. Equipment Maintenance: Maintenance engineers are responsible for inspecting and maintaining various equipment, such as generators, boilers, pumps, motors, and elevators. This section outlines specific tasks to ensure their proper functioning, including lubrication, filter replacement, alignment checks, and performance testing. Other types of Massachusetts Maintenance Engineer Checklists can be tailored for specific industries or environments. For example, there may be checklists specific to manufacturing facilities, hospitals, schools, commercial buildings, or residential complexes. These checklists may have additional tasks relevant to the respective setting, such as machine maintenance, medical equipment checks, fire safety inspections, or building security assessments. In conclusion, a Massachusetts Maintenance Engineer Checklist is a comprehensive guide that helps maintenance engineers perform their duties effectively and maintain the proper functioning of various systems and equipment. The checklist can be customized based on different industries and settings to ensure specific requirements are fulfilled.

Massachusetts Maintenance Engineer Checklist

Description

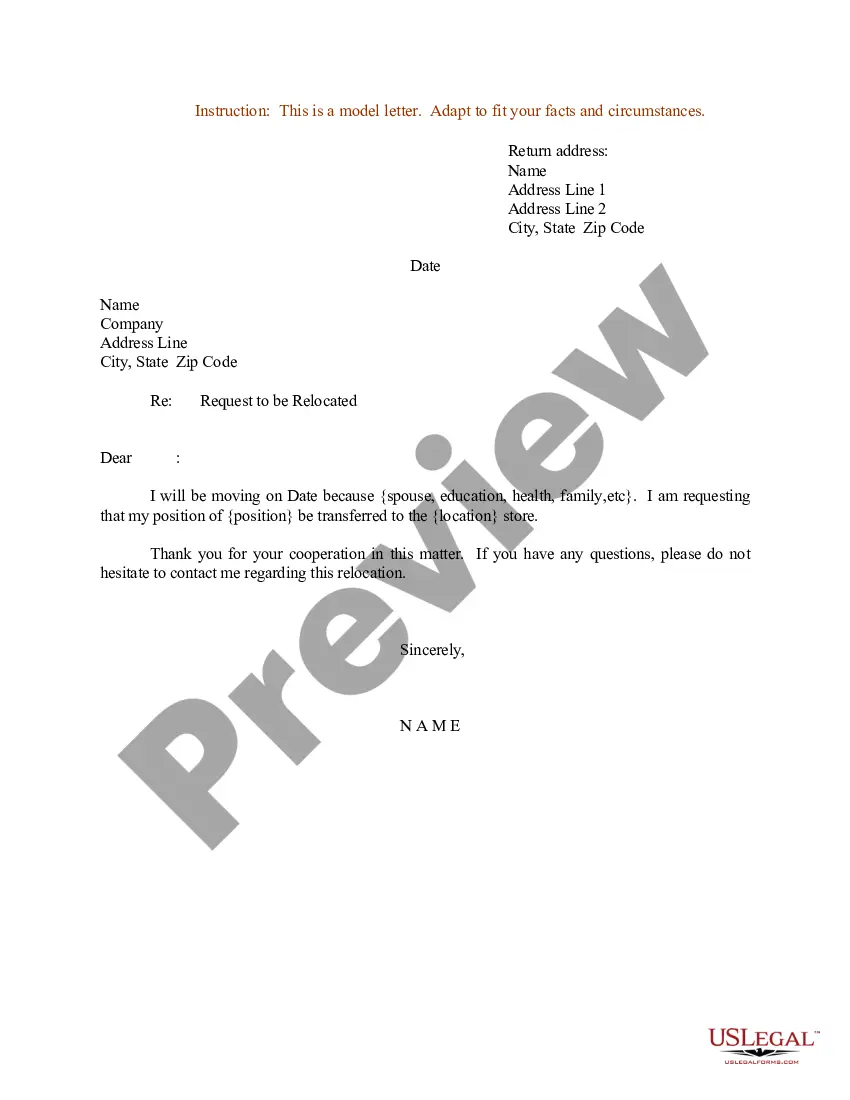

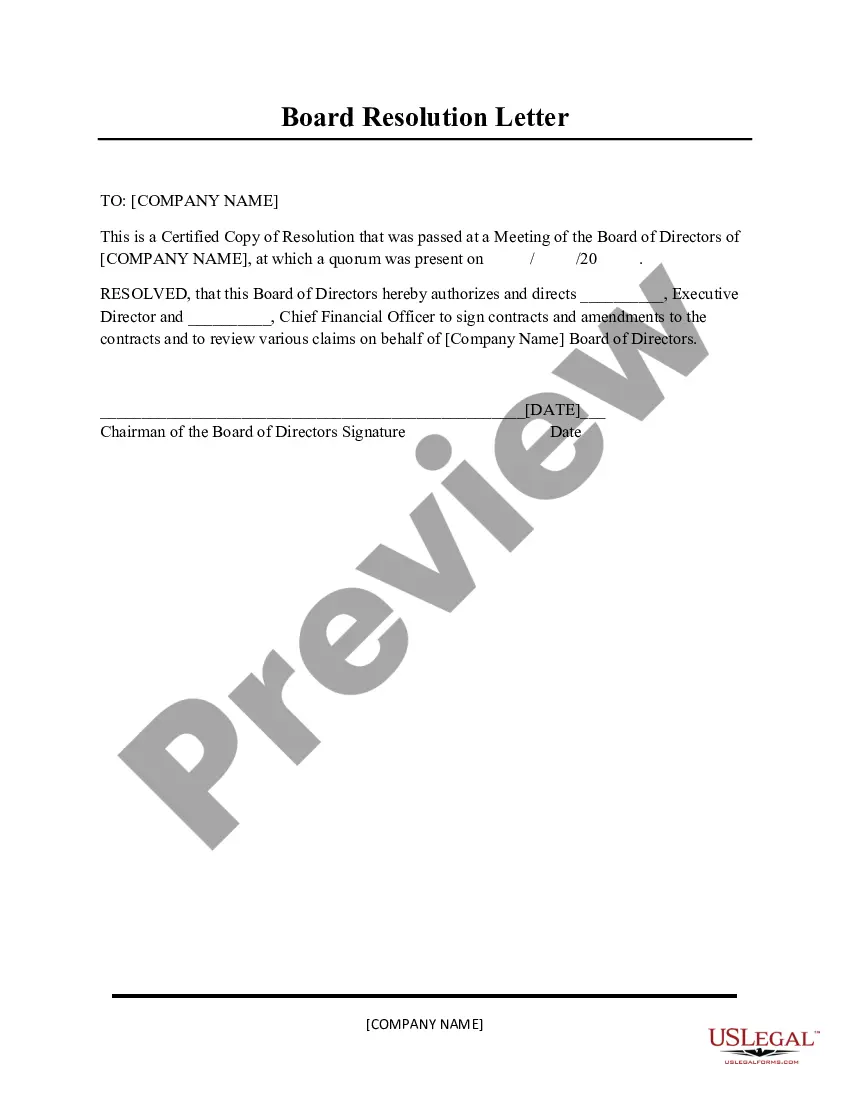

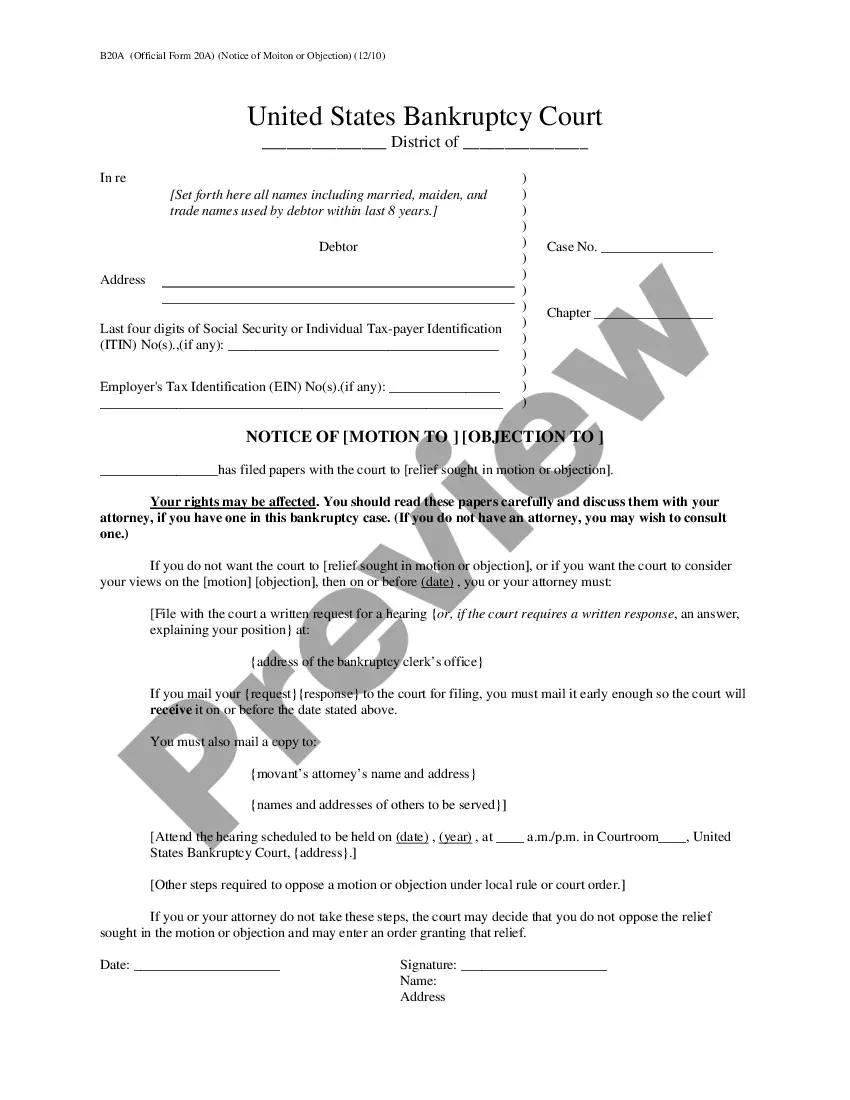

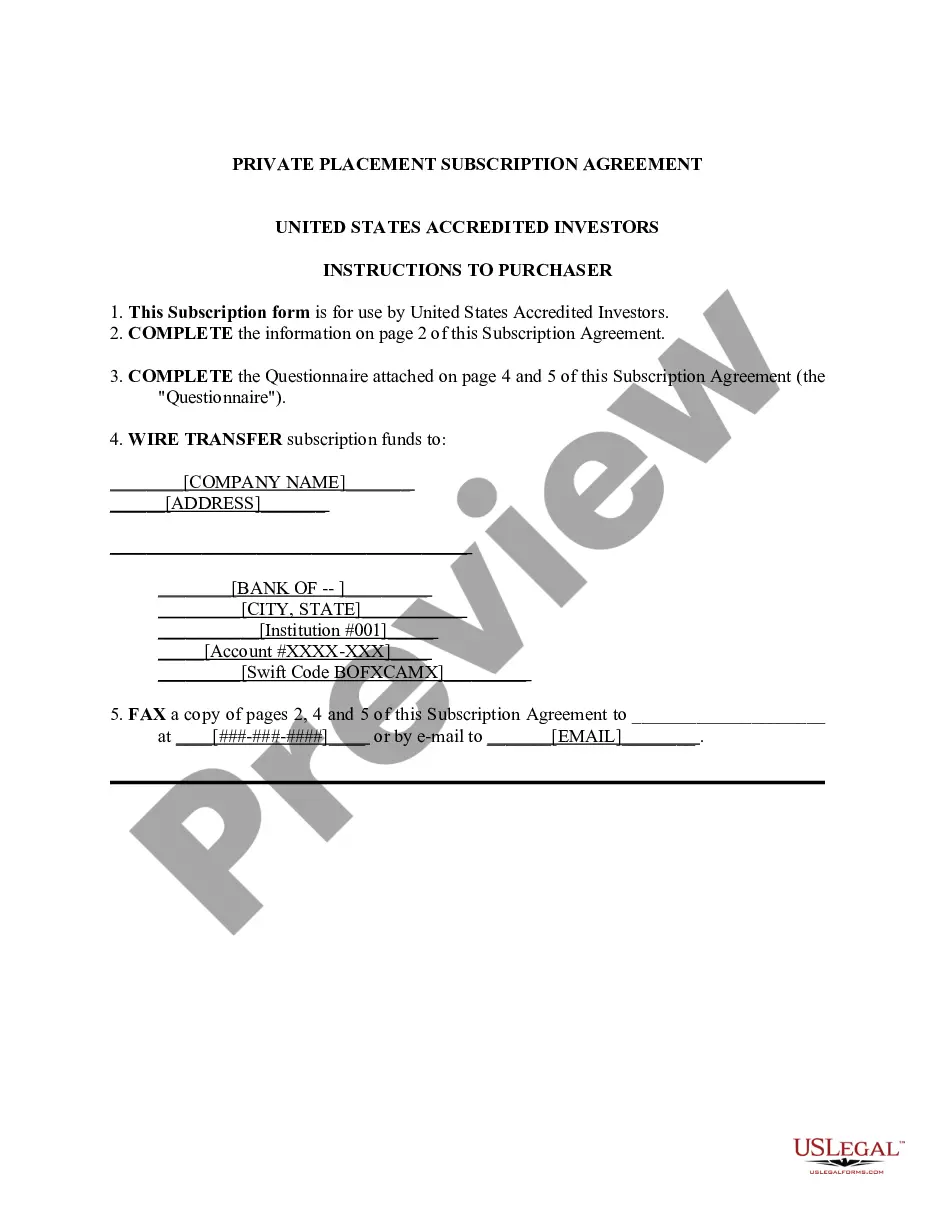

How to fill out Massachusetts Maintenance Engineer Checklist?

You can commit several hours on the Internet looking for the authorized record template which fits the federal and state demands you require. US Legal Forms offers a huge number of authorized kinds that happen to be reviewed by specialists. It is simple to down load or produce the Massachusetts Maintenance Engineer Checklist from our service.

If you already have a US Legal Forms profile, it is possible to log in and then click the Acquire key. Next, it is possible to comprehensive, revise, produce, or indication the Massachusetts Maintenance Engineer Checklist. Every authorized record template you acquire is your own permanently. To get yet another copy of any obtained develop, visit the My Forms tab and then click the related key.

If you work with the US Legal Forms internet site the first time, follow the basic instructions below:

- First, make certain you have chosen the right record template for your region/area that you pick. See the develop outline to make sure you have chosen the appropriate develop. If available, utilize the Preview key to appear from the record template too.

- If you wish to get yet another model of the develop, utilize the Look for field to get the template that suits you and demands.

- After you have discovered the template you desire, click on Acquire now to continue.

- Choose the costs strategy you desire, type your qualifications, and register for an account on US Legal Forms.

- Total the purchase. You may use your credit card or PayPal profile to fund the authorized develop.

- Choose the file format of the record and down load it to the system.

- Make alterations to the record if necessary. You can comprehensive, revise and indication and produce Massachusetts Maintenance Engineer Checklist.

Acquire and produce a huge number of record templates utilizing the US Legal Forms site, which provides the biggest variety of authorized kinds. Use specialist and state-certain templates to take on your small business or individual requirements.