Massachusetts Maintenance Supervisor Checklist

Description

How to fill out Maintenance Supervisor Checklist?

Selecting the appropriate authorized document template can be challenging.

Certainly, numerous templates are accessible online, but how can you obtain the authorized form you require.

Utilize the US Legal Forms website.

If you are currently registered, Log In to your account and click on the Download button to receive the Massachusetts Maintenance Supervisor Checklist. Use your account to browse the authorized forms you have previously acquired. Navigate to the My documents tab of your account to obtain another copy of the document you desire. If you are a new user of US Legal Forms, here are simple instructions to follow: First, ensure you have chosen the correct form for your city/region. You can preview the form using the Preview button and read the form details to ensure it suits your needs. If the form does not meet your requirements, utilize the Search area to find the correct form. Once you confirm that the form is suitable, click the Purchase now button to acquire the form. Select your preferred payment plan and enter the necessary information. Create your account and complete the transaction using your PayPal account or credit card. Choose the file format and download the authorized document template to your device. Finally, complete, modify, print, and sign the acquired Massachusetts Maintenance Supervisor Checklist. US Legal Forms is the largest collection of authorized forms where you can find various document templates. Utilize the service to obtain professionally crafted documents that adhere to state regulations.

- The service offers thousands of templates, such as the Massachusetts Maintenance Supervisor Checklist, for both business and personal needs.

- All of the forms are reviewed by experts and comply with federal and state regulations.

Form popularity

FAQ

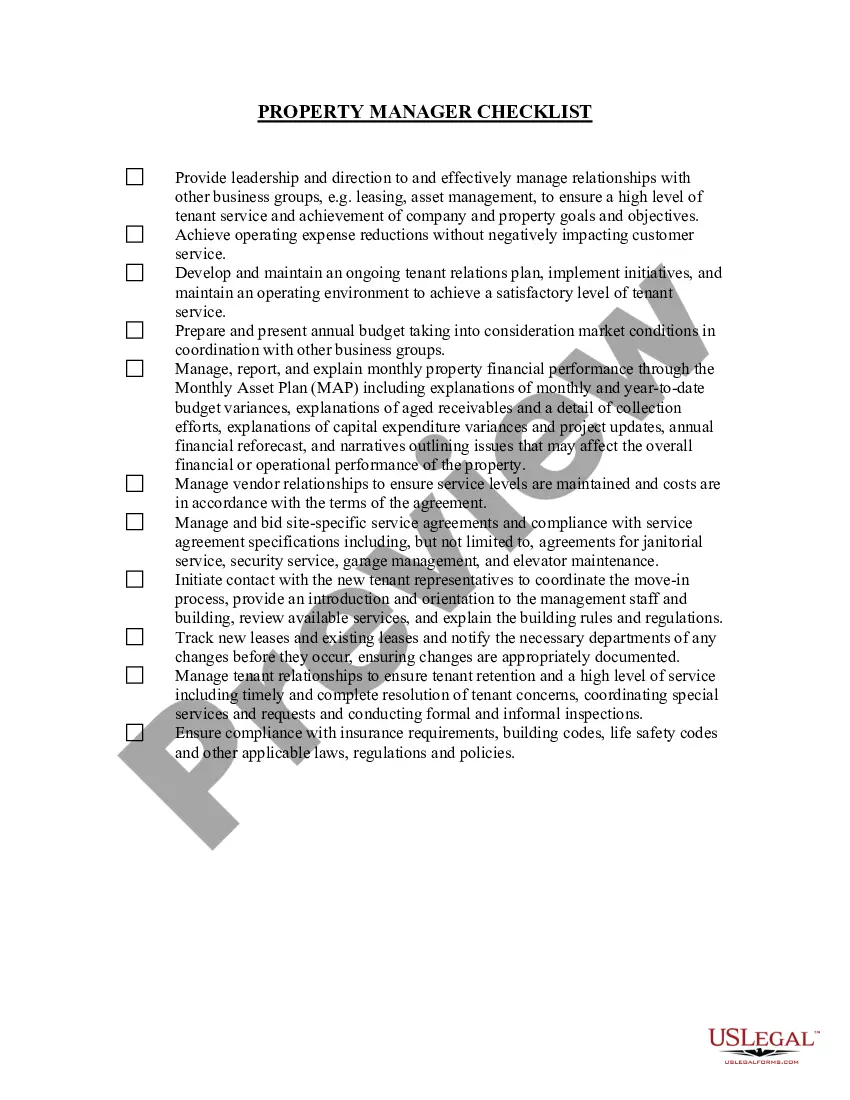

A general maintenance check refers to an essential review of a property's systems and components to ensure they function properly. This process includes inspecting items such as plumbing, electrical systems, and HVAC units. Utilizing the Massachusetts Maintenance Supervisor Checklist can greatly enhance the efficiency of this check, allowing supervisors to easily track issues and prioritize repairs. A thorough checklist streamlines maintenance tasks and promotes a safer living environment.

Key elements of a maintenance report typically include a summary of the tasks performed, time and date of service, any parts used, and recommendations for future maintenance. Documenting this information effectively aids in communication and planning. The Massachusetts Maintenance Supervisor Checklist can ensure you cover all essential components in a maintenance report.

A preventive maintenance checklist is an itemized list of written tasks that guide technicians through a process of asset's preventive maintenance (PM).

For example: performing regular business and equipment inspections, cleaning and lubricating essential equipment, and tidying your business's grounds are all examples of preventive maintenance. The goal of preventive maintenance is to prevent equipment failure before it occurs, and to reduce the risk of accidents.

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

What to Include in Your Preventive Maintenance ScheduleTake Inventory. The first step is to take careful inventory of your machinery, equipment, resources, and vehicles that need regular attention.Prioritize Maintenance.List Specific Maintenance Tasks Create a Schedule.Tracking & Modifying.

In order to build a most effective checklist that fits their enterprise, businesses should first:Delegate maintenance duties to relevant people.Set preventive maintenance program goals.Gether information about existing equipment.Shortlist equipment before including in the checklist.More items...?

Simply put, maintenance performed on a regular basis to reduce the likelihood of failure is preventive maintenance. Also called planned or preventative maintenance, PM is conducted throughout an asset's normal operating conditions.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...