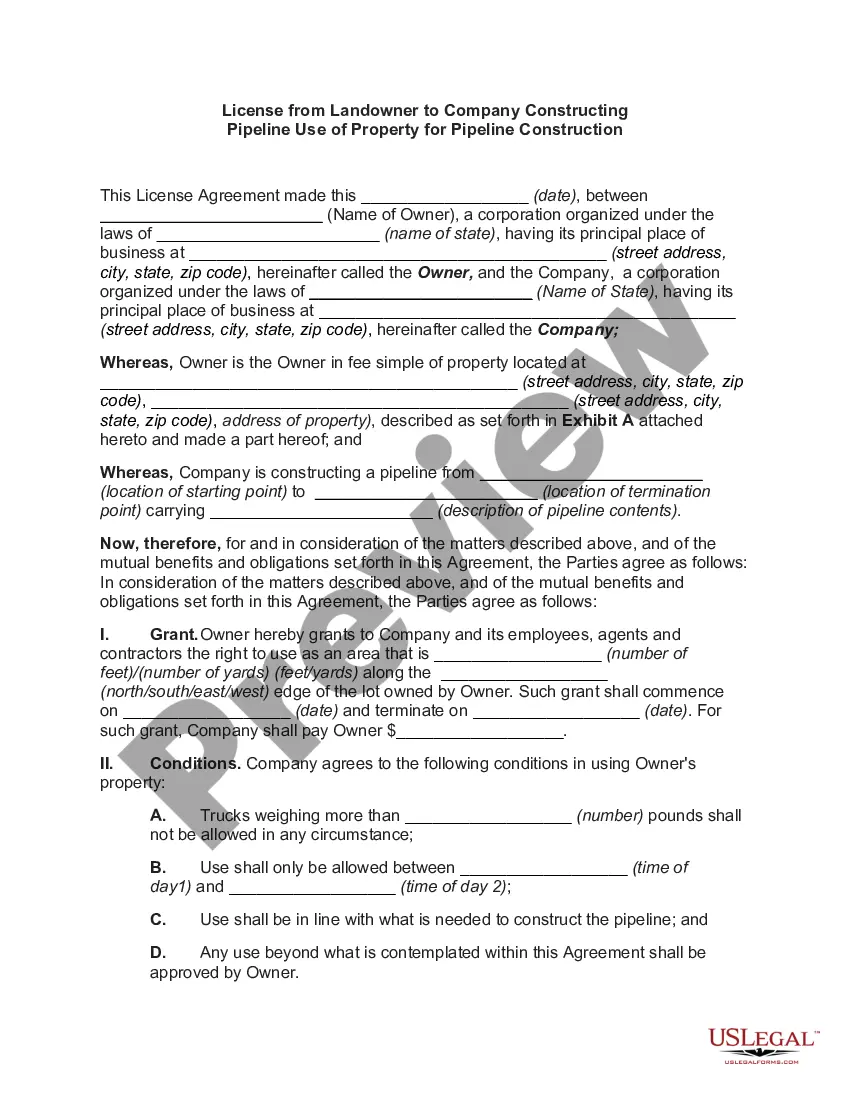

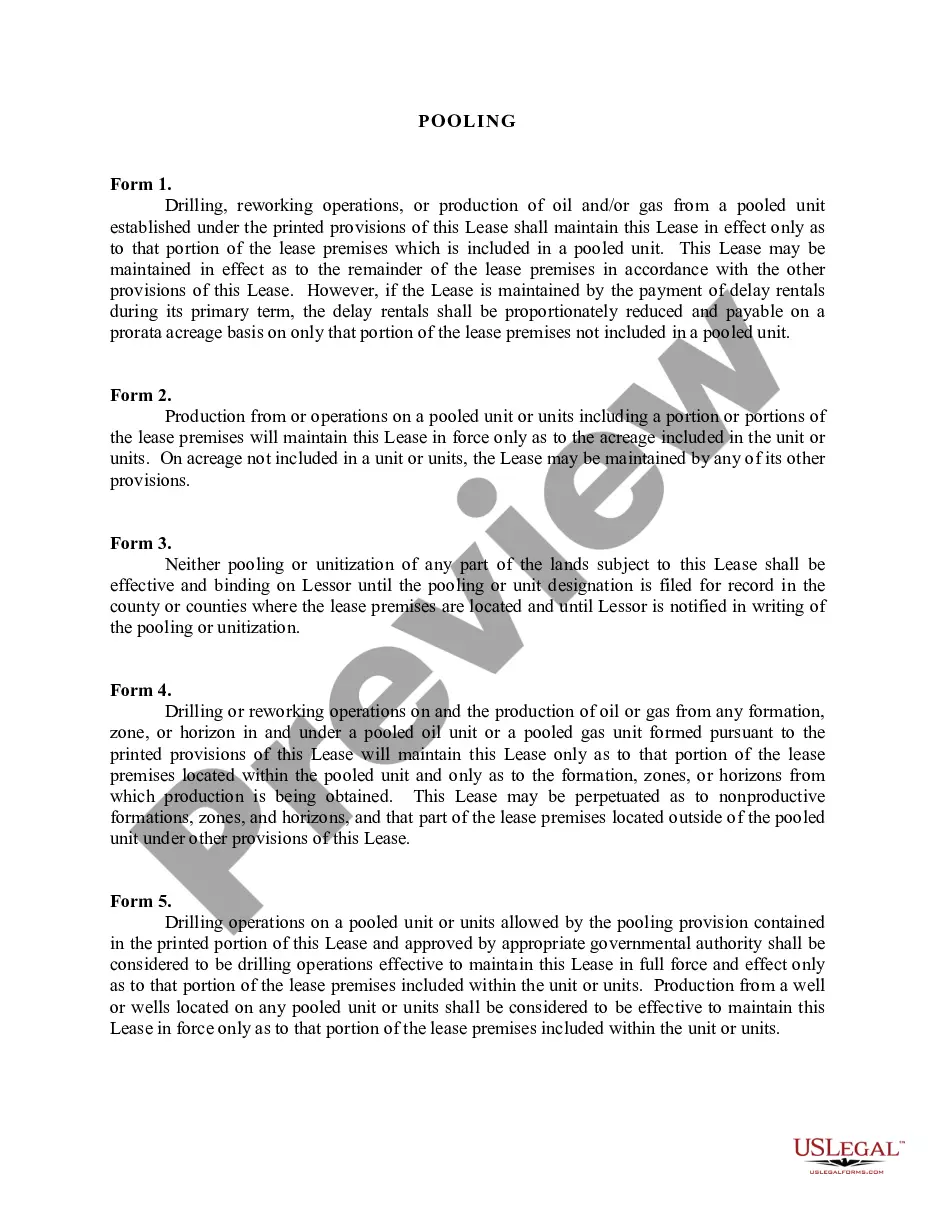

This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

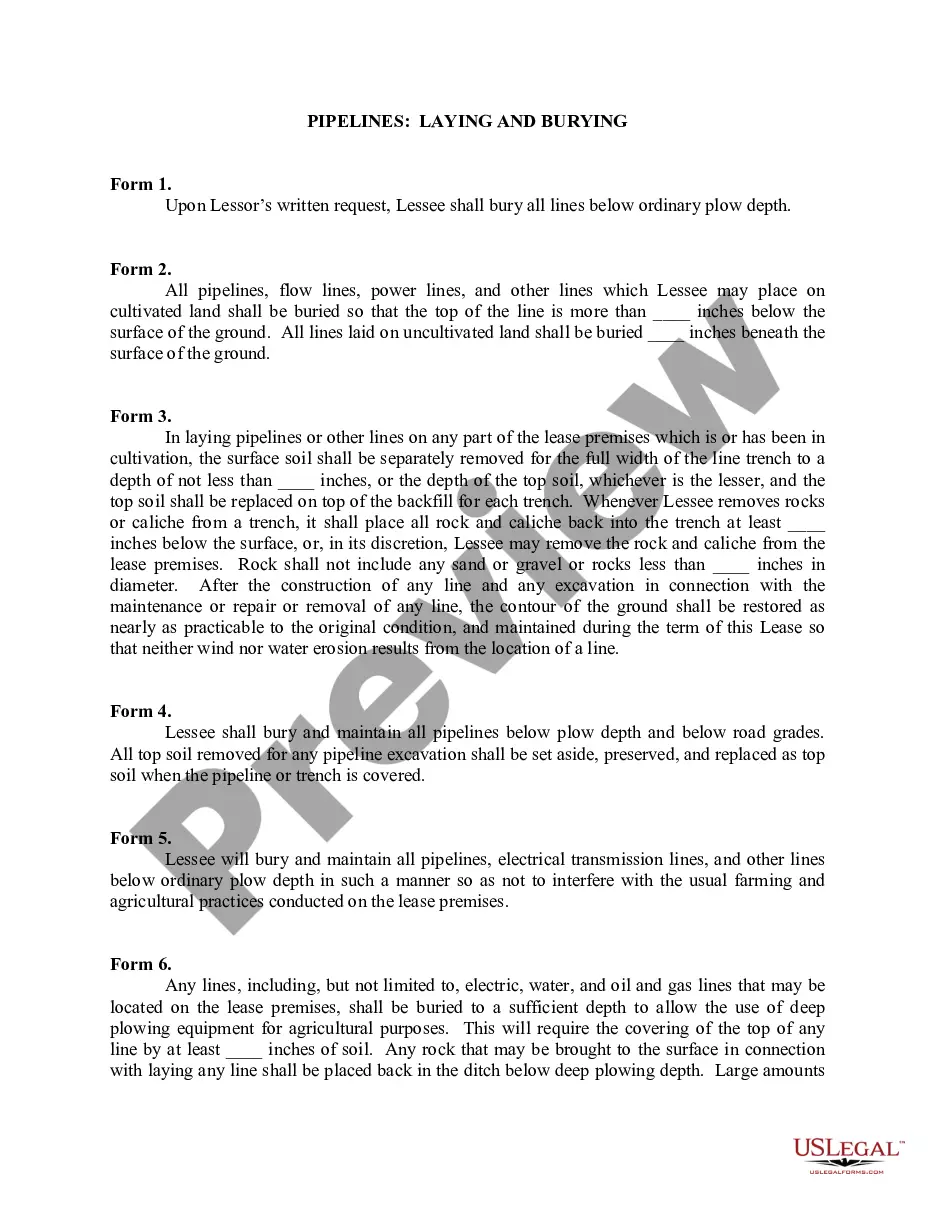

Massachusetts Pipelines - Laying and Burying

Description

How to fill out Pipelines - Laying And Burying?

You may commit time on the web attempting to find the legitimate papers template that suits the state and federal specifications you want. US Legal Forms provides a huge number of legitimate forms that happen to be evaluated by specialists. You can actually acquire or printing the Massachusetts Pipelines - Laying and Burying from your services.

If you have a US Legal Forms profile, you can log in and then click the Acquire option. Next, you can full, change, printing, or indicator the Massachusetts Pipelines - Laying and Burying. Each and every legitimate papers template you purchase is your own eternally. To have an additional version of any bought type, go to the My Forms tab and then click the related option.

If you work with the US Legal Forms site for the first time, stick to the straightforward recommendations under:

- Very first, make sure that you have chosen the proper papers template for the area/area that you pick. Read the type description to ensure you have picked the right type. If accessible, use the Preview option to search with the papers template at the same time.

- If you wish to locate an additional variation of the type, use the Search area to obtain the template that fits your needs and specifications.

- Upon having located the template you need, just click Get now to carry on.

- Select the rates strategy you need, type in your credentials, and register for a merchant account on US Legal Forms.

- Comprehensive the transaction. You should use your bank card or PayPal profile to fund the legitimate type.

- Select the structure of the papers and acquire it to the device.

- Make alterations to the papers if possible. You may full, change and indicator and printing Massachusetts Pipelines - Laying and Burying.

Acquire and printing a huge number of papers themes making use of the US Legal Forms site, that offers the biggest assortment of legitimate forms. Use professional and express-specific themes to handle your company or personal requirements.

Form popularity

FAQ

Gas pipelines transporting natural gas are typically buried just a few feet below the ground, while those carrying liquefied natural gas may be buried up to 100 feet deeper underground.

Pipelines are generally laid underground because temperature is less variable. Because pipelines are usually metal, this helps to reduce the expansion and shrinkage that can occur with weather changes. However, in some cases it is necessary to cross a valley or a river on a pipeline bridge.

And the deeper the technician must dig to get to your broken or otherwise compromised line, the higher the cost. The nationwide average water service line depth is 4.58 feet, and Massachusetts water lines are right about there ? 4.79 feet.

While most natural gas pipelines are buried under the ground, there are some that do their work above ground, and these are particularly susceptible to influence and damage from exterior factors.

In the United States, a gas line should be between 18 and 24 inches deep. Usually, the main gas lines are at least 24 inches deeper than service gas lines found at a depth of 18 inches underground. The depth of a gas line depends on a few factors, including the type of gas and the pipeline's purpose.

Within 36 inches of the outer edge of the pipe (on all sides), only hand excavation, air cutting, vacuum excavation, or potholing techniques are permitted.

Federal regulations require that transmission pipelines and regulated type A gathering lines be buried at least 30 inches below the surface in rural areas and deeper (36 inches) in more populated areas.

Pipeline systems are, in most cases, buried underground. Because they often carry environmentally harmful substances, such as waste or oil, they must be carefully constructed of the materials most appropriate for the substance being transported.