Maryland Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

US Legal Forms - one of the largest collections of legal documents in the USA - offers an extensive variety of legal document templates that you can download or print.

By using the website, you can access thousands of forms for business and personal purposes, organized by categories, states, or keywords. You can find the most recent versions of forms like the Maryland Aseptic Techniques in just a few minutes.

If you already have an account, Log In and download Maryland Aseptic Techniques from the US Legal Forms library. The Download button will appear on every form you view. You can access all previously downloaded forms in the My documents section of your account.

Complete the transaction. Use your credit card or PayPal account to finalize the purchase.

Select the format and download the form to your device. Edit the document. Complete, modify, print, and sign the downloaded Maryland Aseptic Techniques. Each template you added to your account has no expiration date and is yours indefinitely. Therefore, if you wish to download or print another copy, just go to the My documents section and click on the form you need. Access the Maryland Aseptic Techniques with US Legal Forms, one of the most extensive collections of legal document templates. Utilize thousands of professional and state-specific templates that meet your business or personal needs and requirements.

- If you are using US Legal Forms for the first time, here are simple steps to get started.

- Ensure you have selected the appropriate form for your city/state.

- Use the Preview button to check the content of the form.

- Review the form description to confirm you have chosen the correct document.

- If the form does not meet your needs, utilize the Search bar at the top of the screen to find one that does.

- Once you are satisfied with the form, confirm your choice by clicking the Get now button.

- Next, select your preferred pricing plan and provide your information to create an account.

Form popularity

FAQ

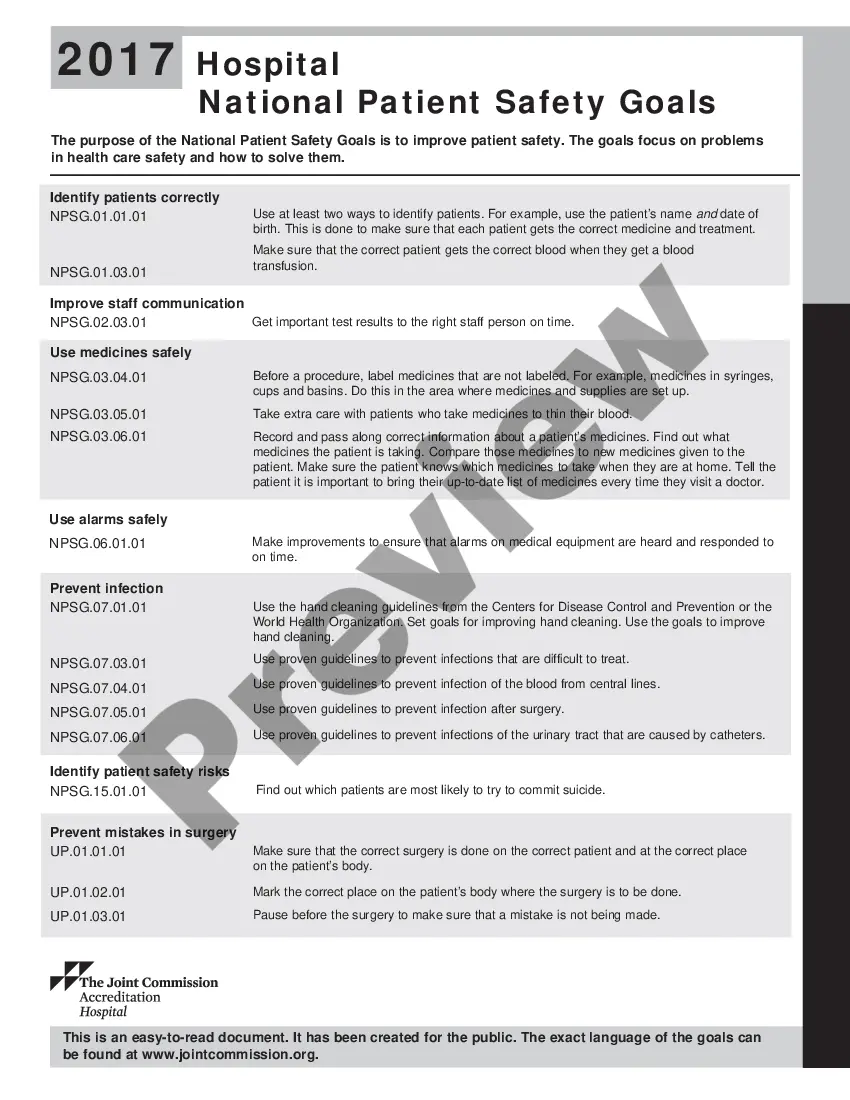

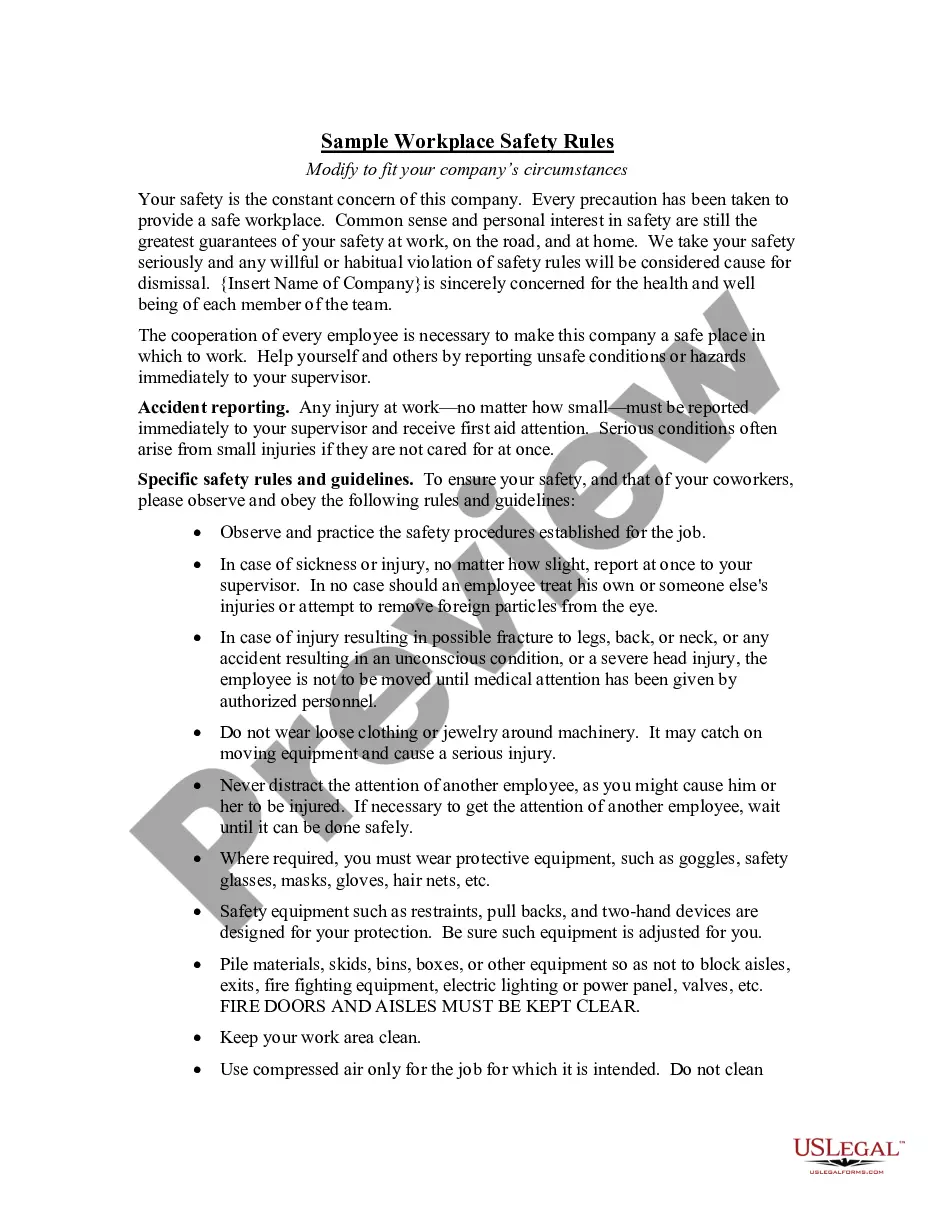

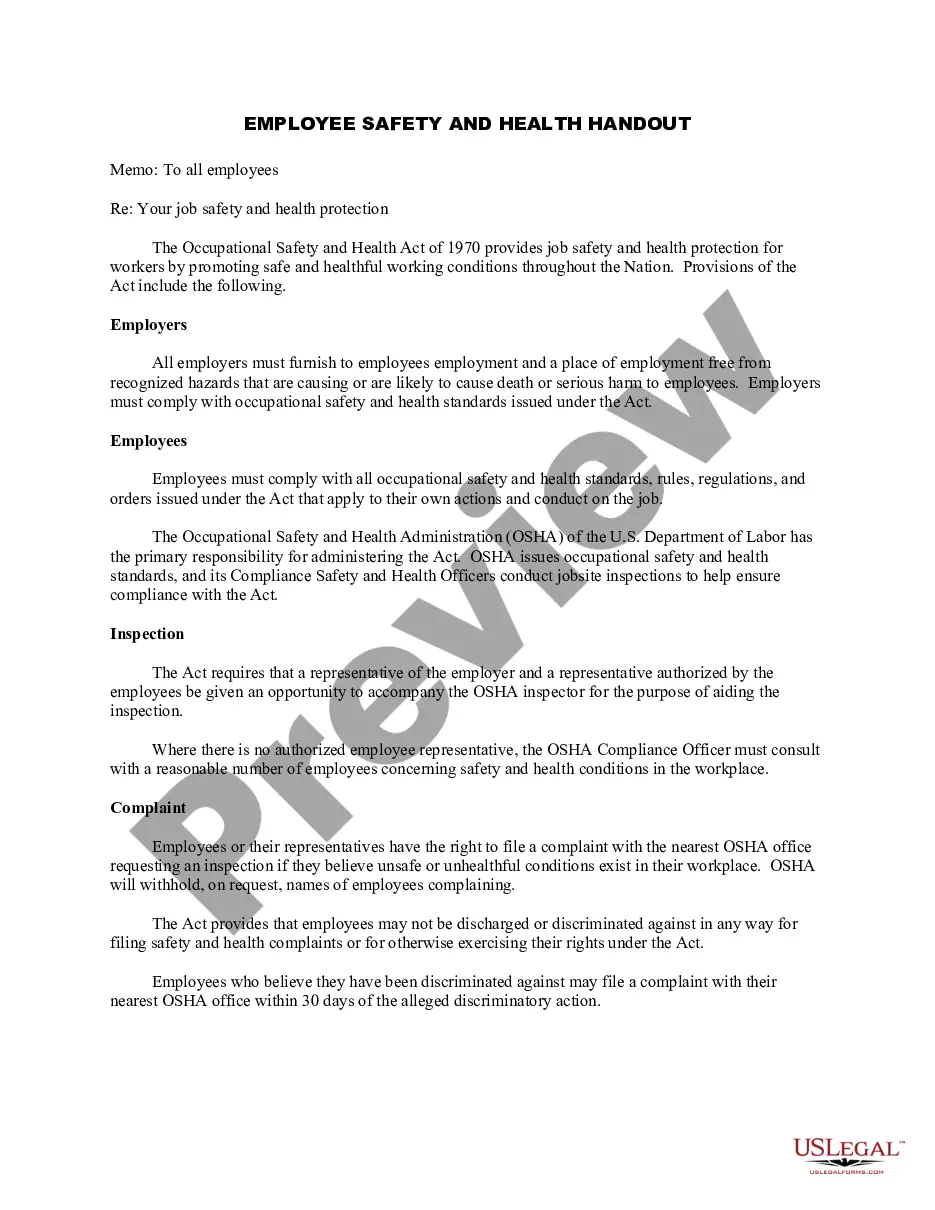

The primary difference between aseptic and non-sterile techniques is their approach to contamination prevention. Maryland Aseptic Techniques focus on minimizing the risk of infection, while non-sterile methods do not implement strict contamination controls. Understanding this distinction is crucial for healthcare providers when selecting the appropriate technique for various procedures. Awareness of these differences can help improve patient safety.

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

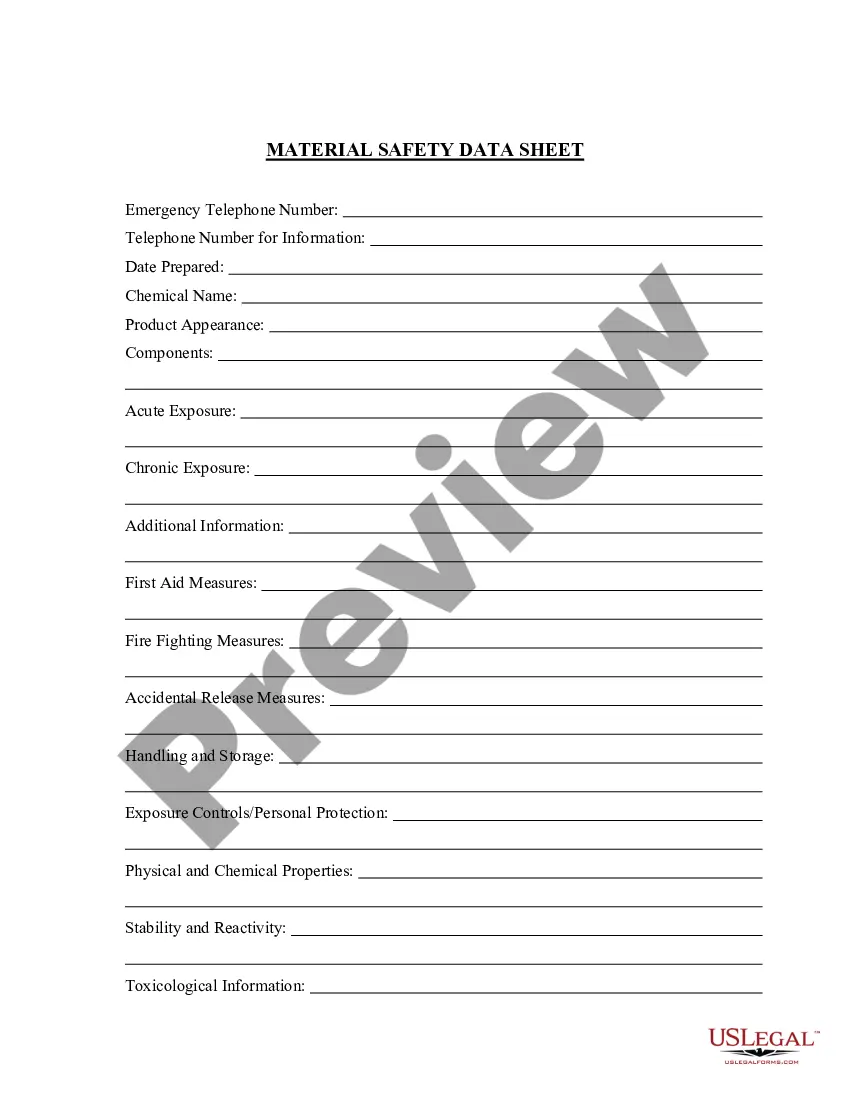

The intent of USP 797 is to prevent patient harm and death through minimum practice and quality standards expected of any entity or individual involved in storage, handling, preparation and transportation of CSPs.

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.

Aseptic technique is classified into two different categories: standard aseptic technique and surgical aseptic technique.

Aseptic technique is a collection of medical practices and procedures that helps protect patients from dangerous germs. Bacteria, viruses, and microorganisms are everywhere, so using aseptic technique can help keep important equipment from being contaminated.

What does it actually mean to be USP 797 compliant? First implemented in 2004, USP (United States Pharmacopeial) establishes(d) a standard of practice designed to prevent patient harm and fatality from contamination. More specifically, it's focused on guidelines for proper sterilization of facilities and equipment.

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

As a standard established by the United States Pharmacopeia Convention (USP), a scientific nonprofit organization dedicated to ensuring the quality of the American drug supply, USP 797 also outlines the required procedures for compounding sterile drug preparations.

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.