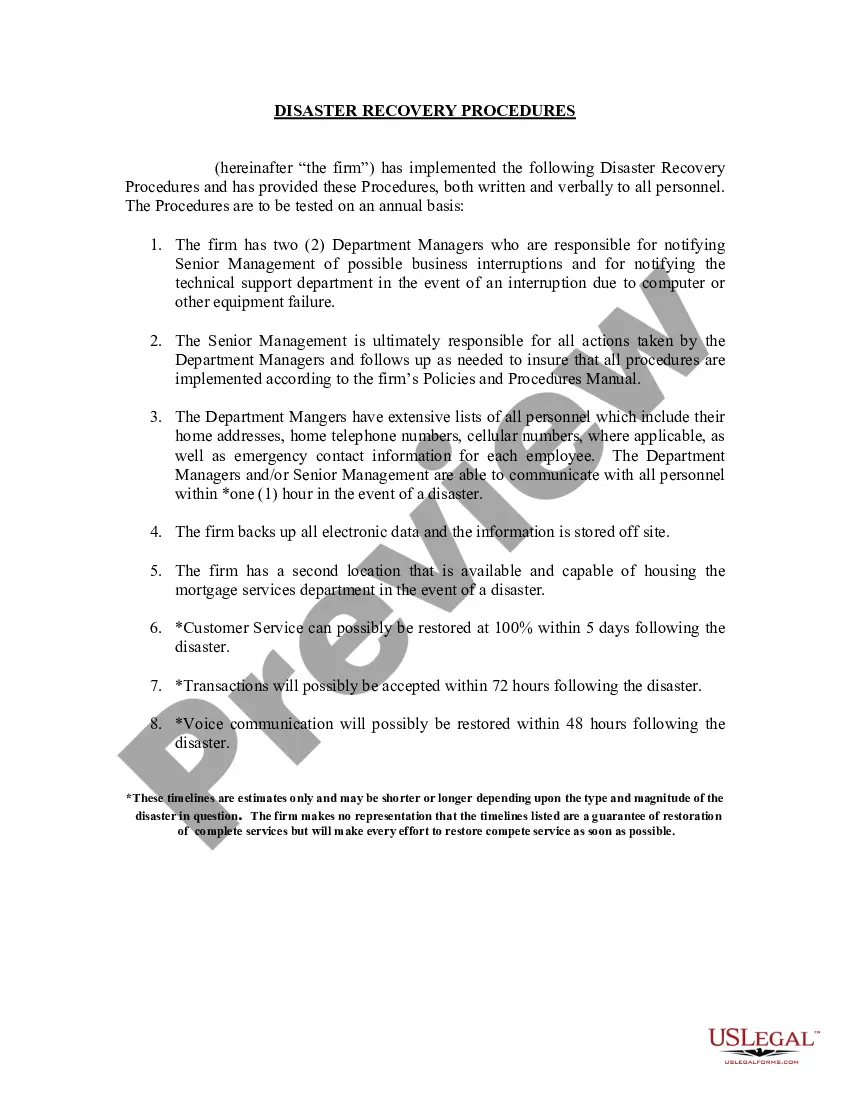

Maine Model Plans and Programs for the OSHA Bloodborne Pathogens and Hazard Communications Standards

Description

How to fill out Model Plans And Programs For The OSHA Bloodborne Pathogens And Hazard Communications Standards?

Are you presently in a scenario where you require documents for either business or personal purposes almost every day.

There are numerous legal document templates accessible online, yet finding reliable ones can be challenging.

US Legal Forms provides thousands of form templates, such as the Maine Model Plans and Programs for the OSHA Bloodborne Pathogens and Hazard Communications Standards, which are designed to comply with federal and state regulations.

Select the pricing plan you prefer, provide the necessary details to create your account, and complete the payment with your PayPal or credit card.

Choose a convenient document format and download your version. Access all the document templates you have purchased in the My documents section. You can obtain another copy of the Maine Model Plans and Programs for the OSHA Bloodborne Pathogens and Hazard Communications Standards anytime if needed. Simply click on the desired form to download or print the document template. Use US Legal Forms, the most extensive collection of legal forms, to save time and avoid errors. The service provides professionally crafted legal document templates suitable for a variety of purposes. Create an account on US Legal Forms and start simplifying your life.

- If you are already acquainted with the US Legal Forms website and have an account, simply sign in.

- Then, you can download the Maine Model Plans and Programs for the OSHA Bloodborne Pathogens and Hazard Communications Standards form.

- If you do not have an account and wish to start using US Legal Forms, follow these steps.

- Obtain the form you need and ensure it corresponds to your specific city/county.

- Utilize the Preview button to review the document.

- Check the description to confirm that you have selected the correct form.

- If the form is not what you are looking for, use the Search section to locate the document that meets your needs and requirements.

- Once you find the appropriate form, click Get now.

Form popularity

FAQ

For any inquiries about the exposure control plan and bloodborne pathogen training available around-the-clock, you have the option to contact your organization’s safety team or centralized OSHA hotline. With services like those provided by USLegalForms, you can access expert advice whenever necessary. This ensures constant support and guidance as you navigate these important compliance aspects.

For consistent support regarding the exposure control plan and bloodborne pathogen training, you can reach out to your local OSHA representative or the specific team at your organization. In addition, many organizations, like USLegalForms, provide dedicated resources and assistance through various channels to answer your questions anytime. This way, you can always stay informed about best practices and compliance requirements.

Contact the Office of Risk Management for questions.Step 1: Required Personal Protective Equipment.Step 2: Equipment.Step 3: Decontamination Procedures.Step 4: Disposal.Step 5: Decontaminate Re-useable Equipment.Step 6: Wash Your Hands.

To effectively eliminate or minimize exposure to bloodborne pathogens, Standard Precautions, instituted by the Centers for Disease Control and Prevention (CDC) will be followed. These include the use of Universal Precautions, Engineering Controls, Work Practice Controls, PPE, and Housekeeping Procedures.

Elements of an Exposure Control PlanStatement of purpose.Responsibilities of the owner, prime, employer, designated resources (i.e. H&S Manager), supervisors, and workers.Health hazards and risk categories for each product in your worksite.Written work procedures and practices.More items...

What is an Exposure Control Plan? The Exposure Control Plan consists of the employer's policy and procedures, defining the protective measures that will be taken by the employer to eliminate or minimize any risk of employee exposure to blood, bodily fluids or other potentially infectious material (OPIM).

The plan must also describe how an employer will use engineering and work practice controls, personal protective clothing and equipment, employee training, medical surveillance, hepatitis B vaccinations, and other provisions as required by OSHA's Bloodborne Pathogens Standard (29 CFR 1910.1030).

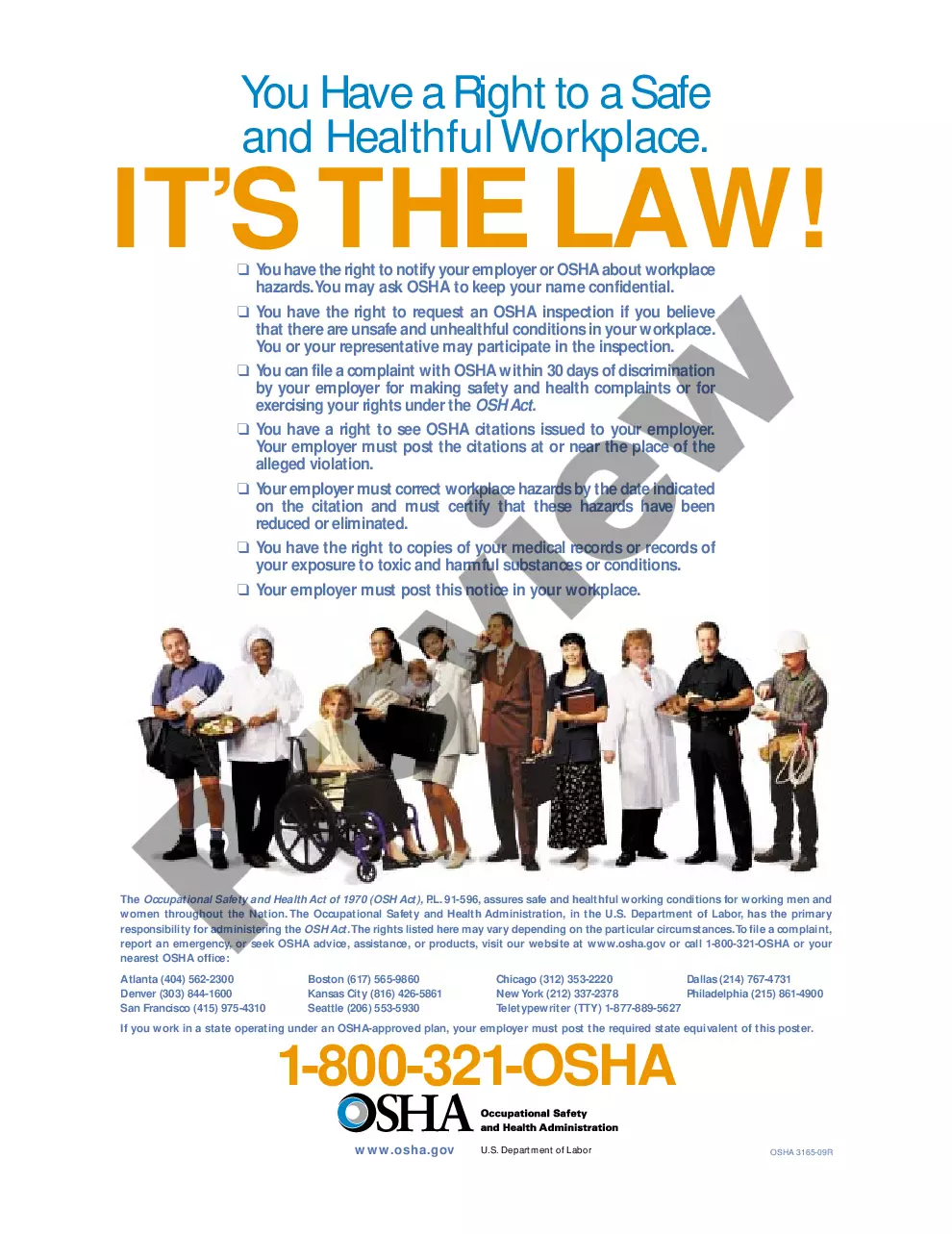

OSHA'S bloodborne pathogens standard protects employees who work in occupations where they are at risk of exposure to blood or other potentially infectious materials. OSHA's hazard com- munication standard protects employees who may be exposed to hazardous chemicals.

The OSHA Bloodborne Pathogens Standard emphasizes personal protective equipment or PPE. PPE includes gowns, gloves, eye protection, and masks. As the employer, you are responsible for cleaning, repairing, and replacing PPE as needed. And you must do so at no cost to your employees.

What is the Bloodborne Pathogens Standard? OSHA's Bloodborne Pathogens Standard (29 CFR 1910.1030) as amended pursuant to the 2000 Needlestick Safety and Prevention Act, is a regulation that prescribes safeguards to protect workers against health hazards related to bloodborne pathogens.