Maine Maintenance Engineer Checklist is a comprehensive and structured document that contains a list of tasks and responsibilities for maintenance engineers operating in the state of Maine. This detailed checklist acts as a guide to ensure that all necessary maintenance procedures and protocols are followed effectively and efficiently. Keywords: Maine, Maintenance Engineer, Checklist, tasks, responsibilities, maintenance procedures, protocols, effective, efficient. There are different types of Maine Maintenance Engineer Checklists, each focusing on specific areas and aspects of maintenance engineering. Some notable types include: 1. Facility Maintenance Checklist: This type of checklist outlines tasks related to the general maintenance of facilities, such as inspecting HVAC systems, performing electrical and plumbing maintenance, checking fire safety equipment, monitoring security systems, and ensuring compliance with building codes. 2. Equipment Maintenance Checklist: This checklist is designed to address equipment-specific maintenance tasks. It includes activities like regular inspection, lubrication, calibration, repair and replacement, ensuring proper functioning, and minimizing downtime. 3. Preventive Maintenance Checklist: This checklist emphasizes the importance of proactive maintenance to prevent costly breakdowns and extend the lifespan of equipment and systems. It involves regular inspections, lubrication, testing, adjusting, and replacing components as needed to avoid unforeseen failures. 4. Safety Maintenance Checklist: Safety is a paramount concern in maintenance engineering. This checklist focuses on identifying potential safety hazards, adhering to safety regulations, conducting routine safety checks, maintaining safety equipment, and implementing corrective actions to eliminate risks. 5. Environmental Maintenance Checklist: Maintenance engineers in Maine need to adhere to environmental regulations and promote sustainable practices. This checklist covers tasks such as waste management, energy efficiency audits, pollution control measures, and adherence to environmental standards. 6. Documentation and Record-Keeping Checklist: Maintenance engineers are required to maintain accurate records of inspections, repairs, maintenance schedules, and any other relevant information. This checklist ensures the proper documentation of maintenance activities, allowing for traceability, reference, and future analysis. By utilizing the Maine Maintenance Engineer Checklist, maintenance engineers can effectively streamline their work processes, prioritize tasks, maintain compliance with regulations, improve efficiency, reduce costs, and ultimately ensure the smooth operation of various systems, facilities, and equipment in the state.

Maine Maintenance Engineer Checklist

Description

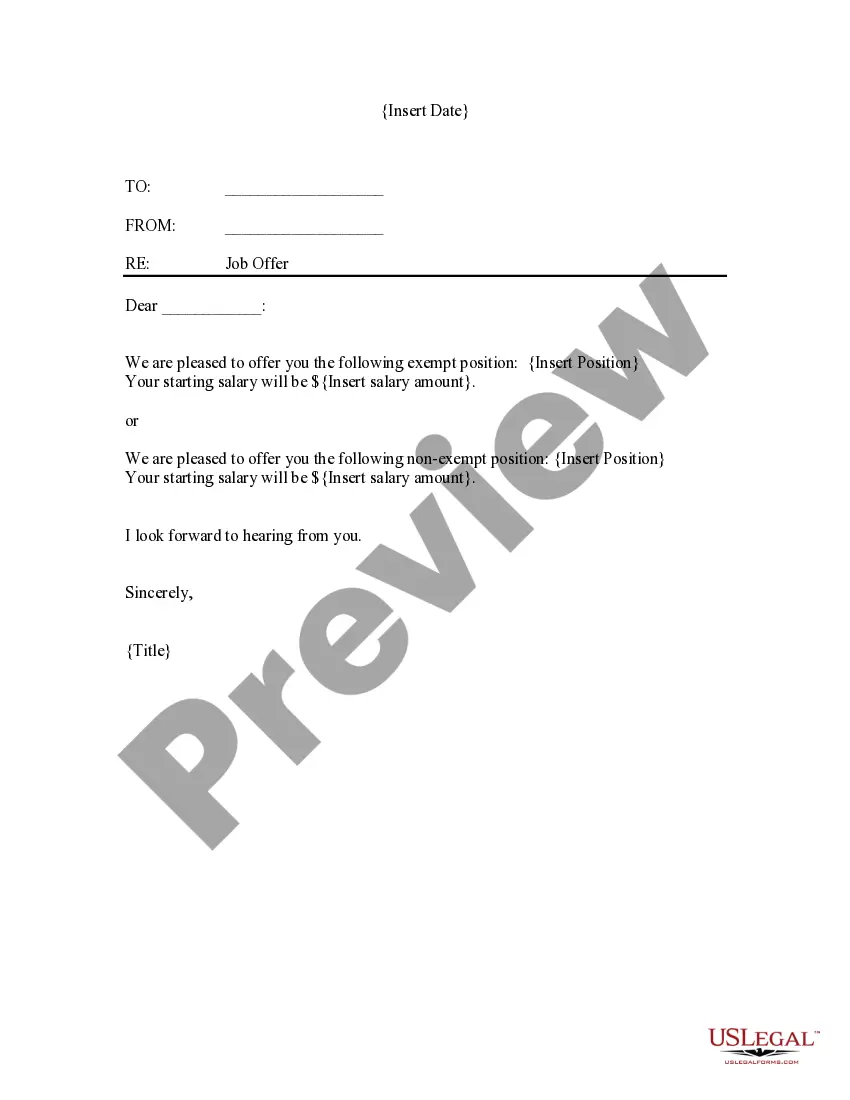

How to fill out Maine Maintenance Engineer Checklist?

Are you inside a place where you need to have documents for either organization or individual purposes virtually every day? There are tons of authorized record themes accessible on the Internet, but getting versions you can rely isn`t easy. US Legal Forms delivers a large number of kind themes, such as the Maine Maintenance Engineer Checklist, that are composed to meet federal and state requirements.

In case you are presently acquainted with US Legal Forms site and possess an account, simply log in. After that, you can download the Maine Maintenance Engineer Checklist template.

If you do not offer an bank account and wish to start using US Legal Forms, follow these steps:

- Find the kind you will need and make sure it is for the correct city/area.

- Take advantage of the Preview button to examine the shape.

- Read the information to actually have selected the correct kind.

- In the event the kind isn`t what you`re looking for, utilize the Lookup industry to get the kind that suits you and requirements.

- Whenever you discover the correct kind, click on Get now.

- Opt for the costs prepare you want, fill in the specified information to create your account, and purchase your order using your PayPal or credit card.

- Pick a handy data file file format and download your version.

Get all of the record themes you might have purchased in the My Forms menu. You can get a extra version of Maine Maintenance Engineer Checklist anytime, if needed. Just click on the necessary kind to download or print out the record template.

Use US Legal Forms, by far the most extensive collection of authorized types, in order to save time as well as stay away from faults. The support delivers expertly produced authorized record themes that can be used for an array of purposes. Make an account on US Legal Forms and initiate creating your lifestyle a little easier.