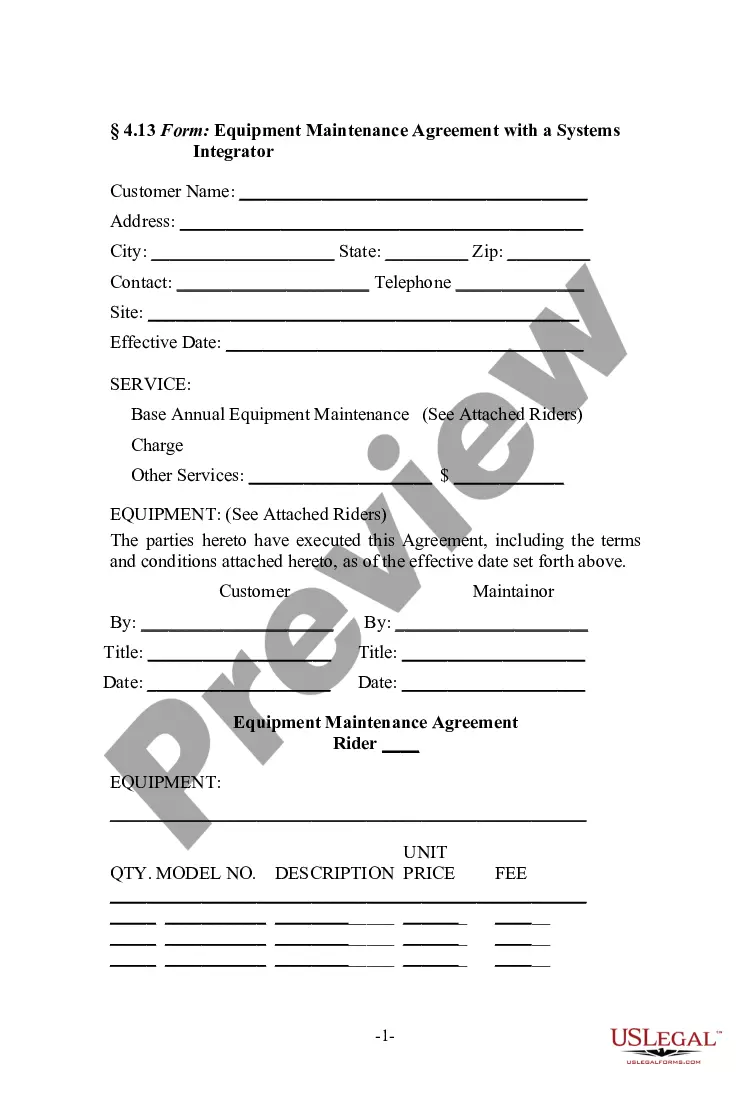

Maine Equipment Maintenance Agreement with a Systems Integrator

Description

How to fill out Equipment Maintenance Agreement With A Systems Integrator?

If you wish to complete, acquire, or produce lawful papers templates, use US Legal Forms, the most important variety of lawful forms, that can be found on the Internet. Make use of the site`s simple and easy convenient search to discover the papers you require. Numerous templates for enterprise and person functions are categorized by groups and suggests, or keywords and phrases. Use US Legal Forms to discover the Maine Equipment Maintenance Agreement with a Systems Integrator within a number of click throughs.

When you are currently a US Legal Forms client, log in to your profile and click the Obtain key to have the Maine Equipment Maintenance Agreement with a Systems Integrator. You can also gain access to forms you previously delivered electronically within the My Forms tab of your own profile.

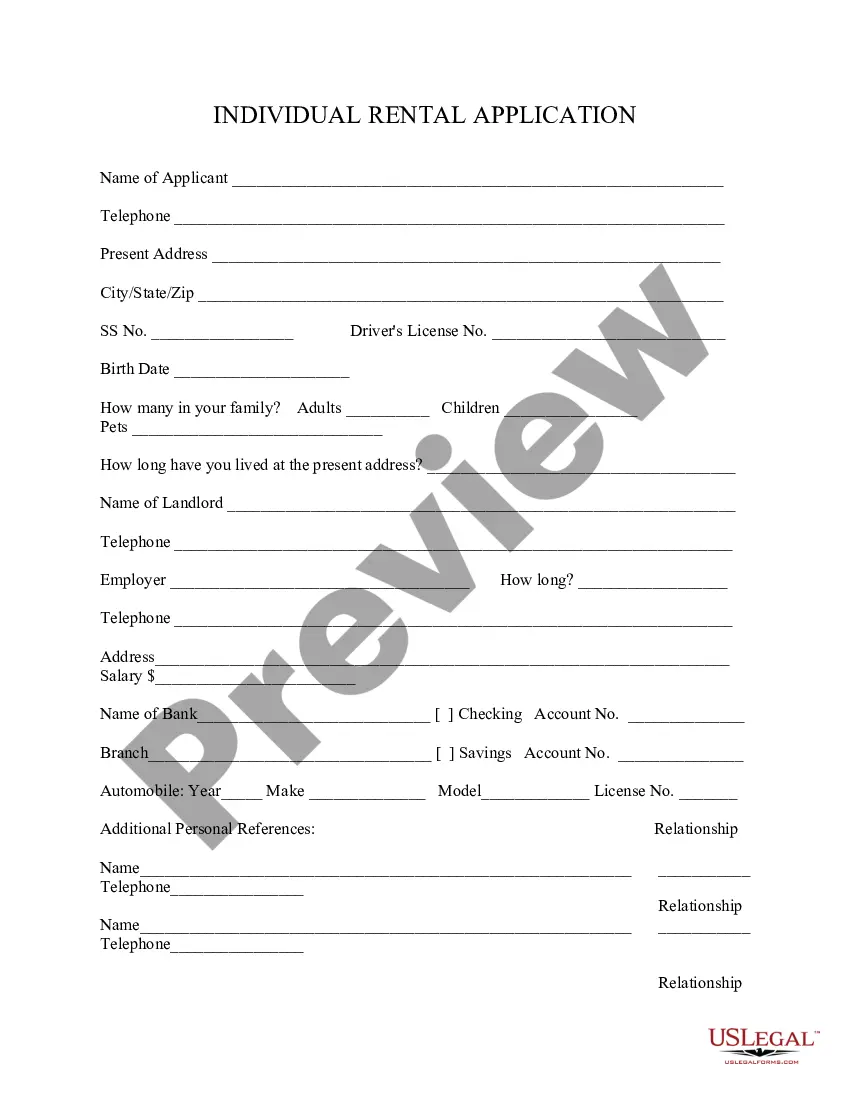

If you use US Legal Forms the first time, follow the instructions below:

- Step 1. Ensure you have selected the shape to the appropriate town/region.

- Step 2. Utilize the Review method to check out the form`s content. Do not forget to read the explanation.

- Step 3. When you are unsatisfied together with the form, utilize the Lookup industry at the top of the screen to get other variations of your lawful form web template.

- Step 4. After you have located the shape you require, select the Purchase now key. Opt for the costs prepare you like and add your references to register to have an profile.

- Step 5. Procedure the transaction. You can use your bank card or PayPal profile to perform the transaction.

- Step 6. Find the file format of your lawful form and acquire it on your own device.

- Step 7. Full, modify and produce or sign the Maine Equipment Maintenance Agreement with a Systems Integrator.

Every lawful papers web template you acquire is your own eternally. You possess acces to each and every form you delivered electronically within your acccount. Click on the My Forms portion and choose a form to produce or acquire yet again.

Contend and acquire, and produce the Maine Equipment Maintenance Agreement with a Systems Integrator with US Legal Forms. There are thousands of expert and condition-specific forms you can use to your enterprise or person requires.

Form popularity

FAQ

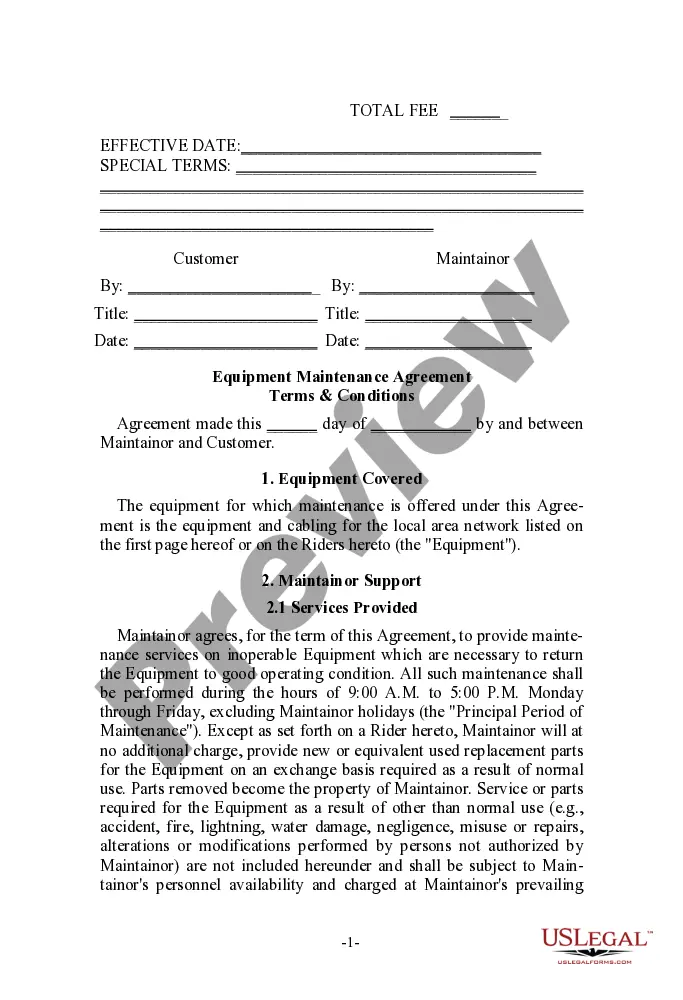

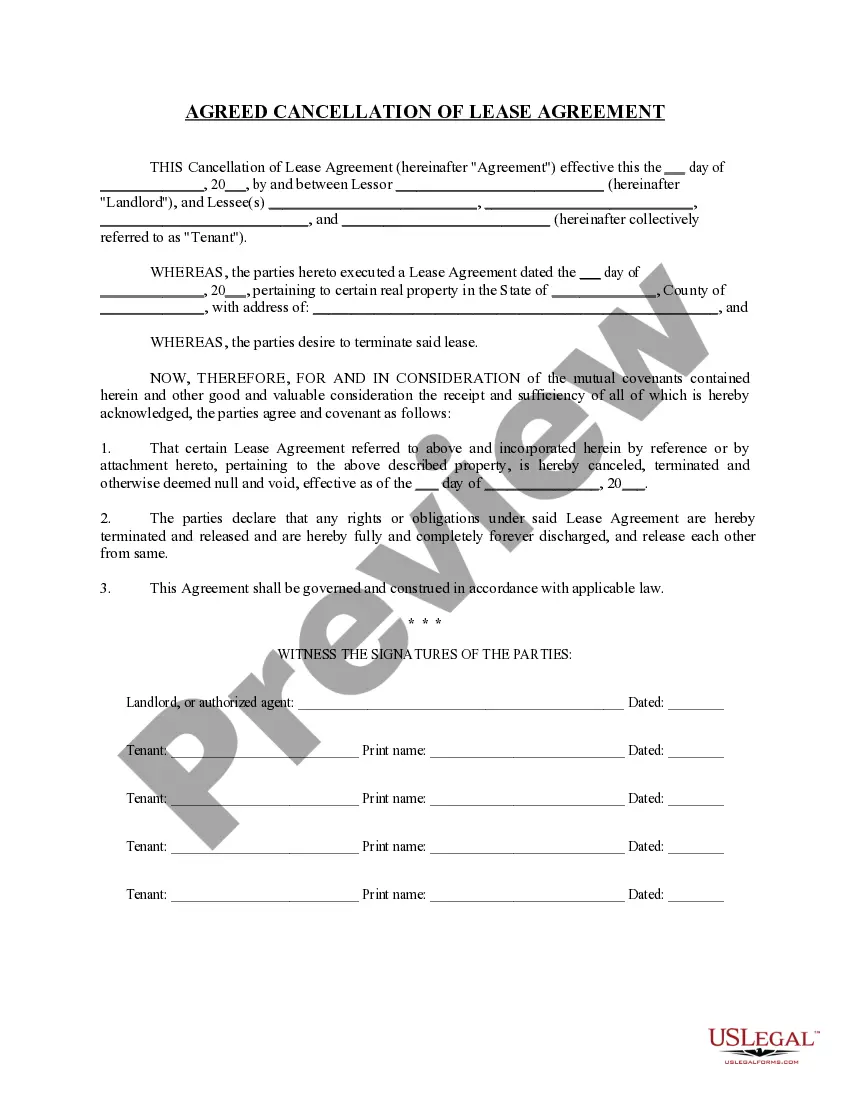

A maintenance contract is an agreement between you and your service provider that outlines the tasks, schedules, and frequency of the maintenance services they provide.

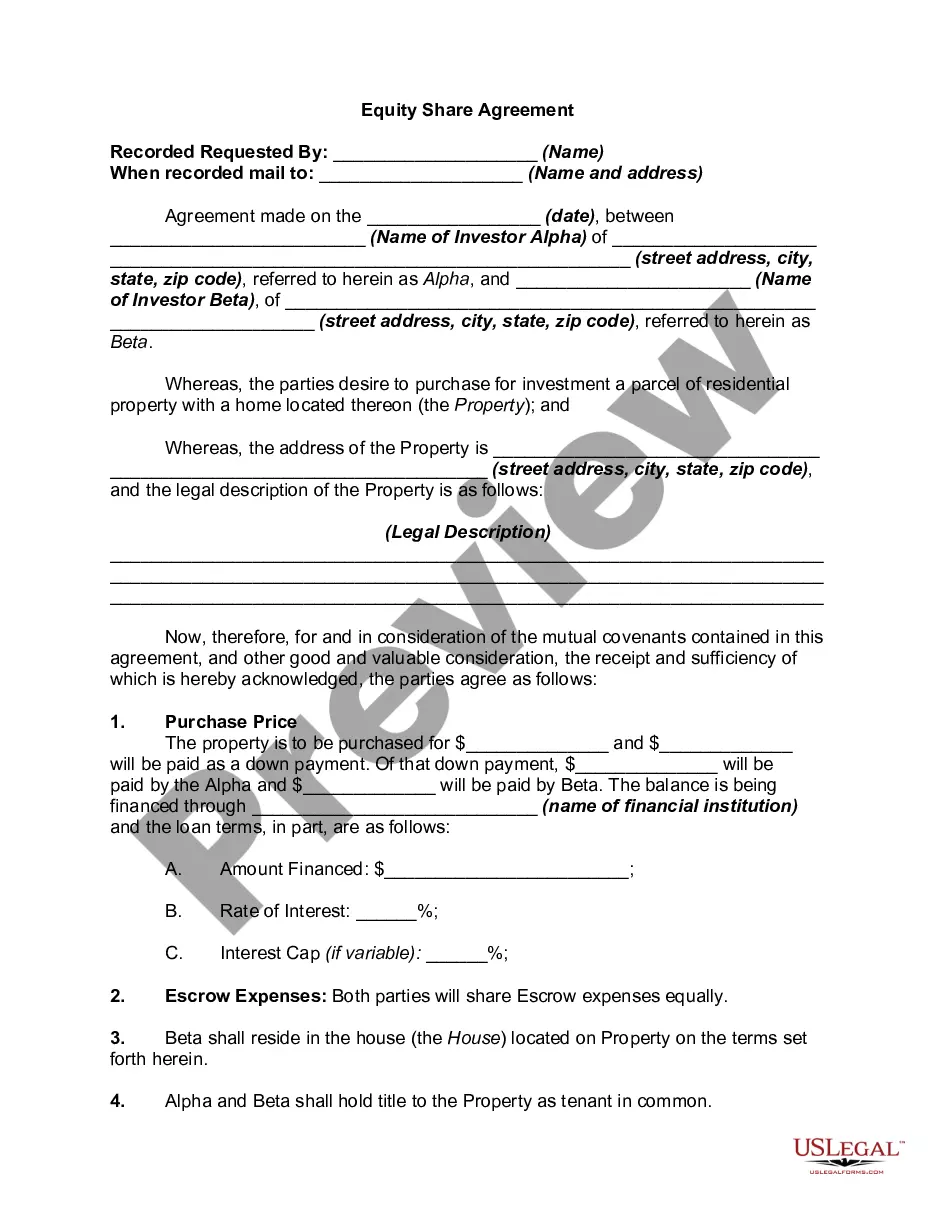

The term systems integration agreement is used to describe a contract for the acquisition, development and integration of hardware and software which is necessary to produce, in conjunction with the customer's business data, an entire computer system.

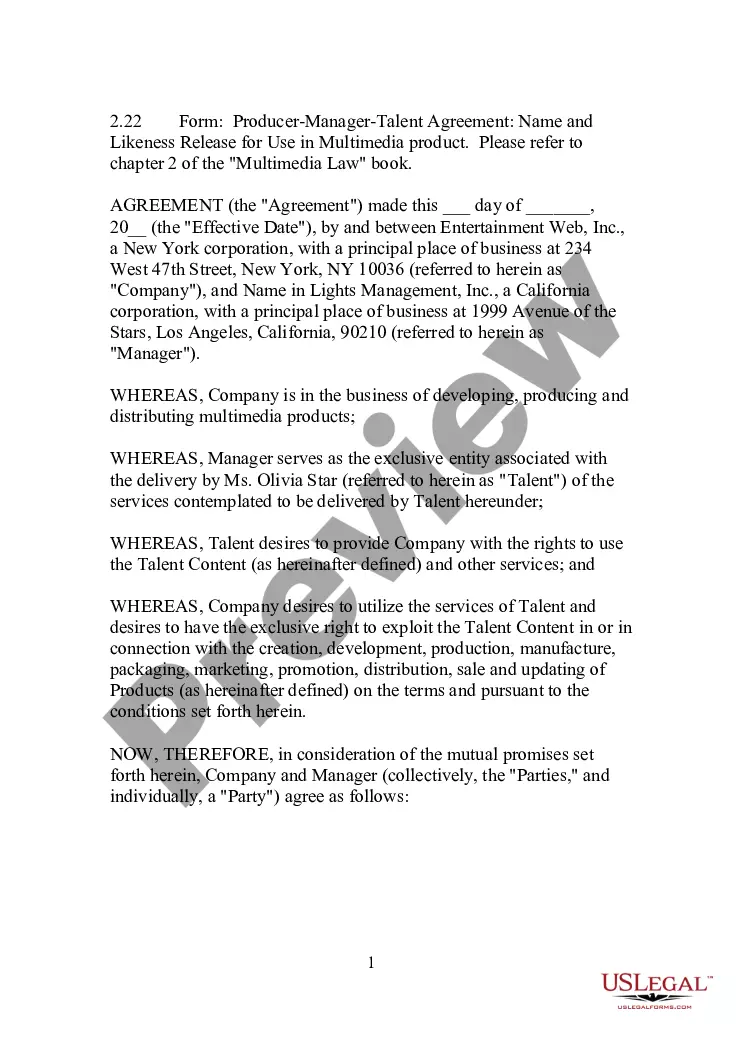

By Practical Law Commercial. A B2B agreement in which the supplier agrees to provide a maintenance and support service for equipment. The agreement is drafted to be broadly neutral between the parties. To access this resource, sign in below or register for a free, no-obligation trial.

A maintenance contract, defined as the contract between 2 parties which creates the agreement that one party will maintain an asset owned by another party, is common across many industries. Maintenance contracts can exist for equipment, a building, landscape, computers and other information technologies, and more.

Service contracts and warranties both provide some element of repair or maintenance for a specific period of time. The main difference is that warranties are included in the purchase price and service contracts cost extra.

A maintenance agreement outlines the steps one party will undertake to insure the upkeep, repair, serviceability of another party's property. Maintenance contracts are commonly used by companies that take care of vehicle fleets, industrial equipment, office and apartment buildings, computer networks, etc.