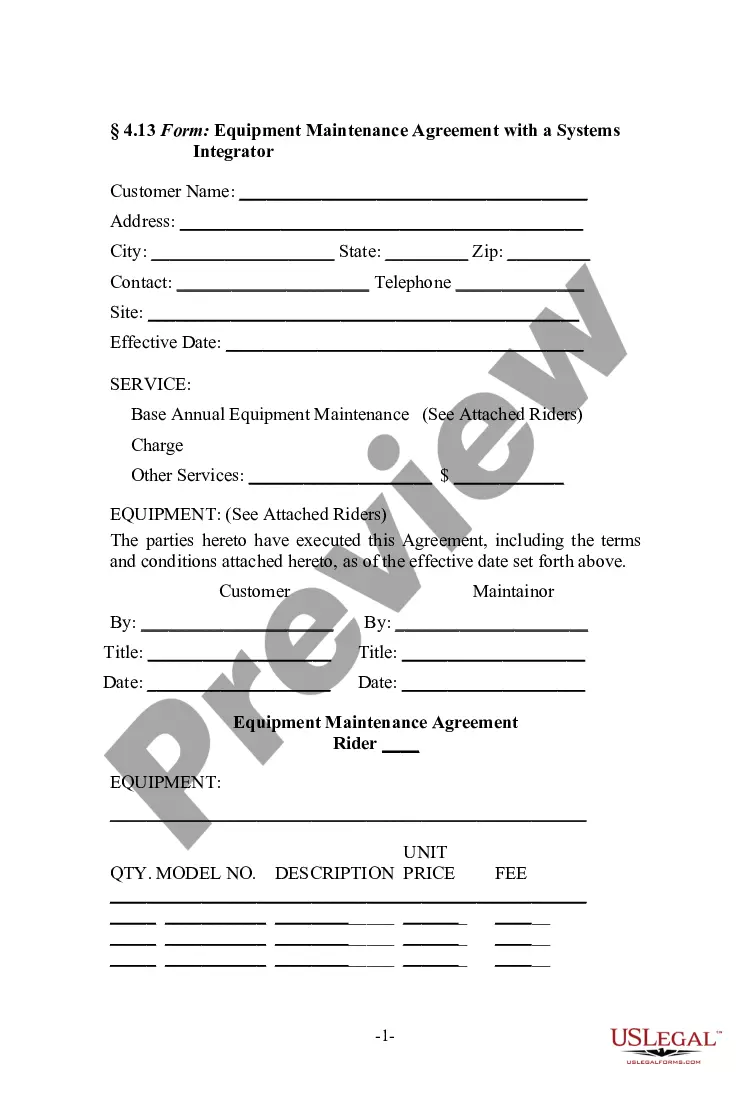

Michigan Equipment Maintenance Agreement with a Manufacturer

Description

How to fill out Equipment Maintenance Agreement With A Manufacturer?

Selecting the appropriate legal document format can be quite a challenge. Certainly, there are numerous web templates accessible online, but how can you acquire the legal form you require? Utilize the US Legal Forms website.

The services provide thousands of templates, such as the Michigan Equipment Maintenance Agreement with a Manufacturer, that can be utilized for business and personal purposes. All of the forms are reviewed by experts and comply with federal and state regulations.

If you are already registered, Log In to your account and click the Obtain button to download the Michigan Equipment Maintenance Agreement with a Manufacturer. Use your account to review the legal forms you have previously purchased. Proceed to the My documents section of your account and acquire another copy of the document you need.

US Legal Forms is the largest collection of legal forms where you can find numerous document templates. Utilize the service to download properly structured papers that adhere to state regulations.

- First, ensure you have selected the correct form for your city/county. You can examine the document using the Preview option and read the form description to verify this is suitable for you.

- If the document does not meet your needs, use the Search field to find the appropriate form.

- Once you are convinced the document is suitable, click on the Buy now button to acquire the form.

- Select the payment plan you prefer and input the required information. Create your account and complete an order using your PayPal account or credit card.

- Choose the document format and download the legal document format to your device.

- Complete, modify, print, and sign the received Michigan Equipment Maintenance Agreement with a Manufacturer.

Form popularity

FAQ

When writing a contract for an independent maintenance contractor, include the hourly pay rate, methods of payment, and any provisions for additional compensation. With contracts for larger service providers, include all agreed-upon provisions such as compensation, price discounts or early payment, and credit terms.

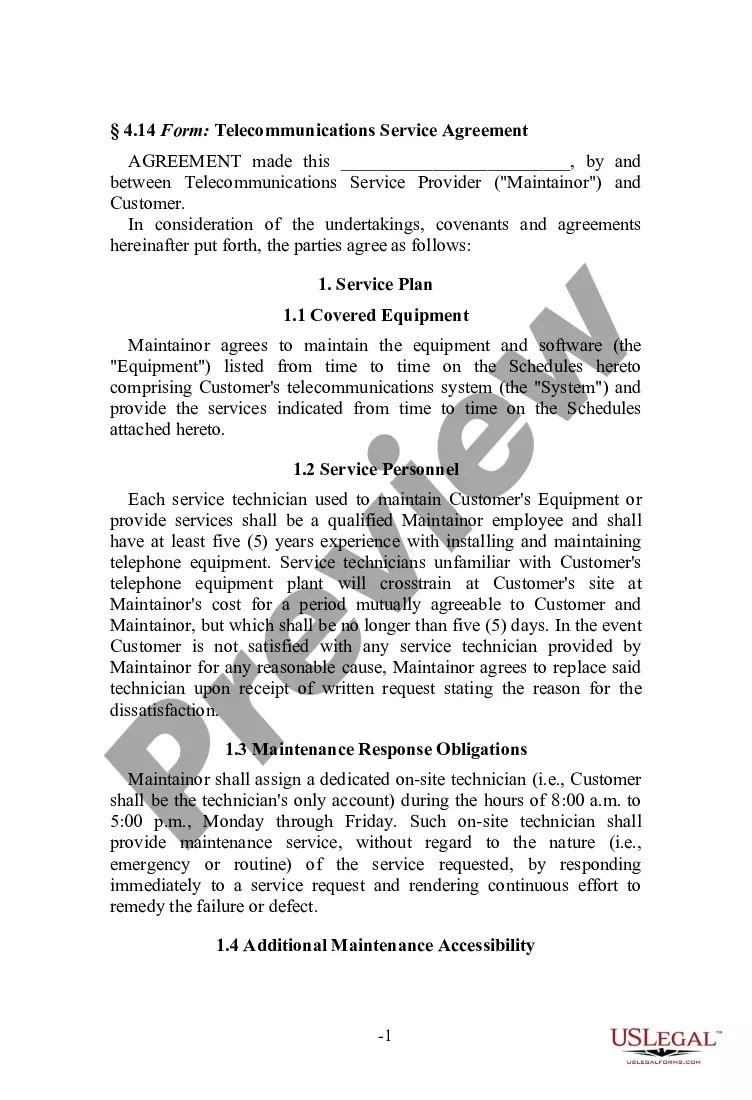

A service maintenance contract is a legal agreement between a company and a maintenance service provider. It specifies the terms and conditions of the agreement between the two parties.

What is an Equipment Service Agreement? An Equipment Service Agreement is a program of pre-scheduled maintenance calls for your HVAC or Plumbing equipment based on a contract between Indoor Elements Mechanical and you, our valued customer.

Maintenance agreements provide routine maintenance, access to emergency repairs, and constant upgrades to software and your system's hardware. More importantly, the agreement make you a priority and allows you to build a relationship with your maintenance provider.

A service maintenance contract is a legal agreement between a company and a maintenance service provider. It specifies the terms and conditions of the agreement between the two parties.

It has three parts: objective, strategy and resource. B. Equipment Maintenance: A set of activities conducted to keep an equipment in optimum working condition and consists of periodic inspection, preventive maintenance, and corrective maintenance.

Draw up a section for official definitions at the beginning of the contract.Lay out the maintenance services to be performed early in the contract.Discuss the compensation structure agreed upon for services.Draft a section discussing any warranties or promises made by either party.More items...

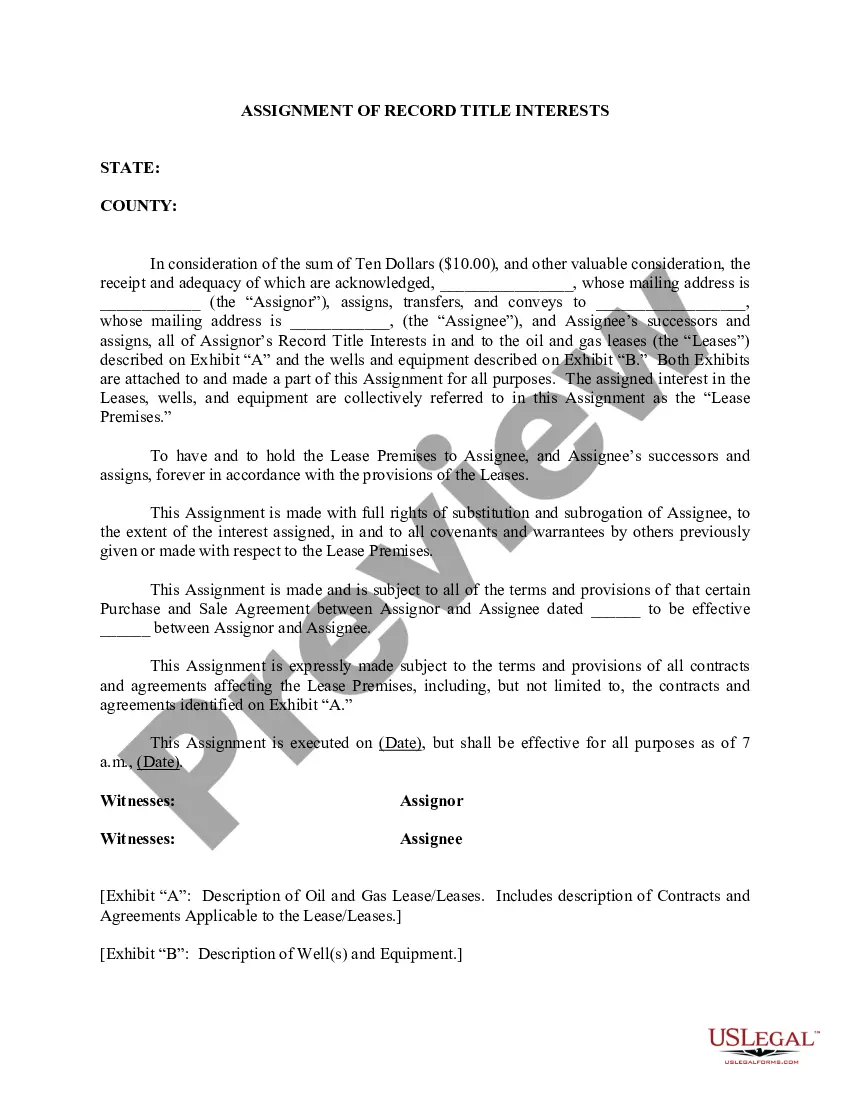

A maintenance contract, defined as the contract between 2 parties which creates the agreement that one party will maintain an asset owned by another party, is common across many industries. Maintenance contracts can exist for equipment, a building, landscape, computers and other information technologies, and more.

In your maintenance agreement, you will need to include:A section that defines both the provider and the client including their full legal names and any terms that need to be defined in the contract.A list of the services that will be performed in detail.The compensation for the agreed upon services.More items...