Michigan Corrective Action - Problem Solution

Description

How to fill out Corrective Action - Problem Solution?

Locating the appropriate sanctioned document template can be challenging.

Clearly, there is a multitude of templates accessible online, but how do you find the official form you need.

Utilize the US Legal Forms website. This service offers an extensive collection of templates, including the Michigan Corrective Action - Problem Solution, which can be utilized for both business and personal purposes.

First, verify that you have selected the correct form for your city/state. You can preview the form using the Preview button and review the form description to ensure it is the right one for you.

- All forms are reviewed by experts and comply with federal and state regulations.

- If you are already registered, Log Into your account and click the Download button to obtain the Michigan Corrective Action - Problem Solution.

- Use your account to browse through the legal forms you have previously purchased.

- Go to the My documents tab in your account and retrieve another copy of the document you need.

- If you are a new user of US Legal Forms, here are some simple guidelines for you to follow.

Form popularity

FAQ

To answer a corrective action form, start by thoroughly reading each question to understand the context. Provide clear and concise answers, citing specific details about the issue and corrective measures taken. Ensure your responses reflect a commitment to addressing problems, which is vital in the Michigan Corrective Action - Problem Solution process. This clarity demonstrates accountability and a proactive attitude.

The problem-solving initiative in Michigan law is designed to address complex issues through collaborative approaches among stakeholders. This initiative focuses on utilizing Michigan Corrective Action - Problem Solution strategies to enhance legal processes and improve outcomes. By working collectively, individuals and organizations can resolve disputes more effectively and foster a more stable environment.

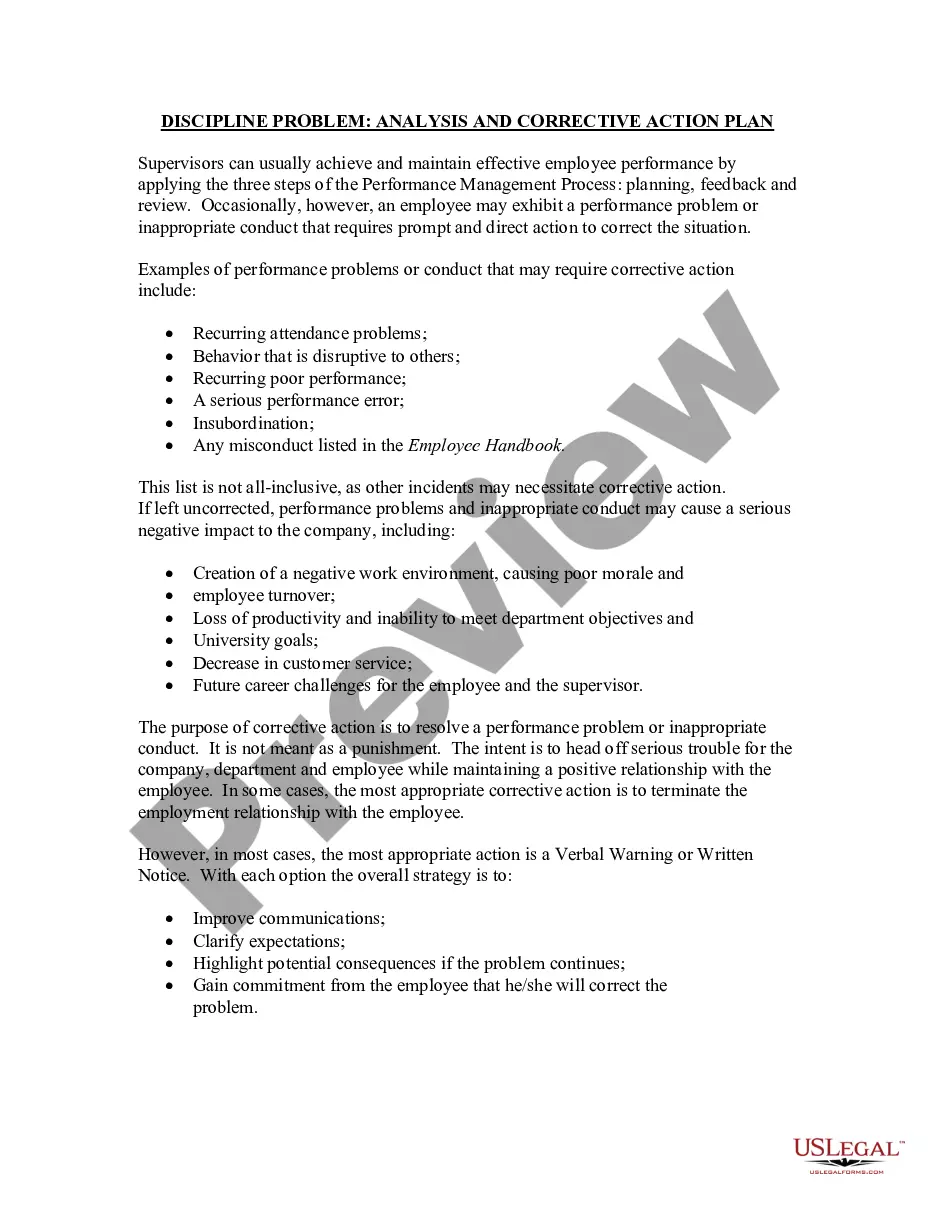

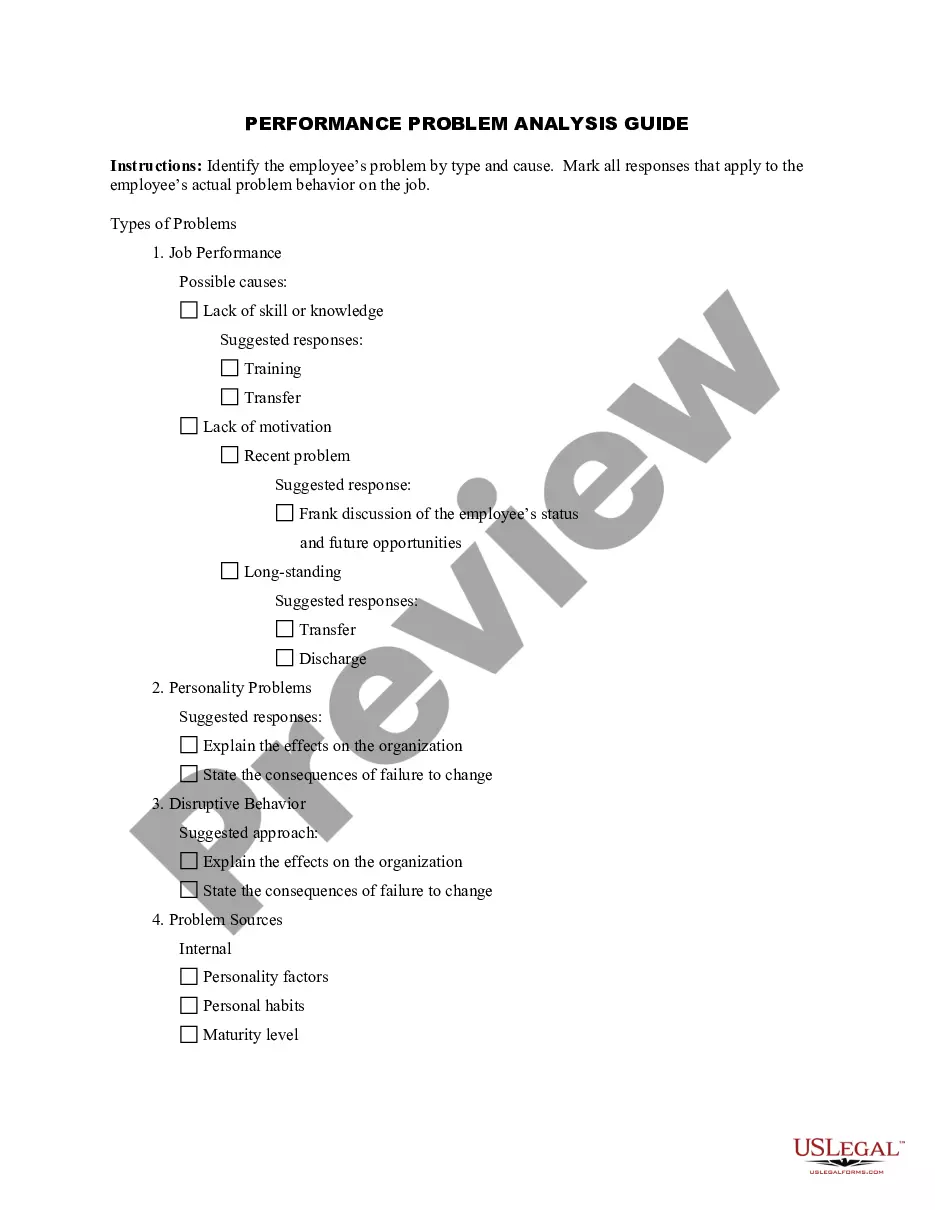

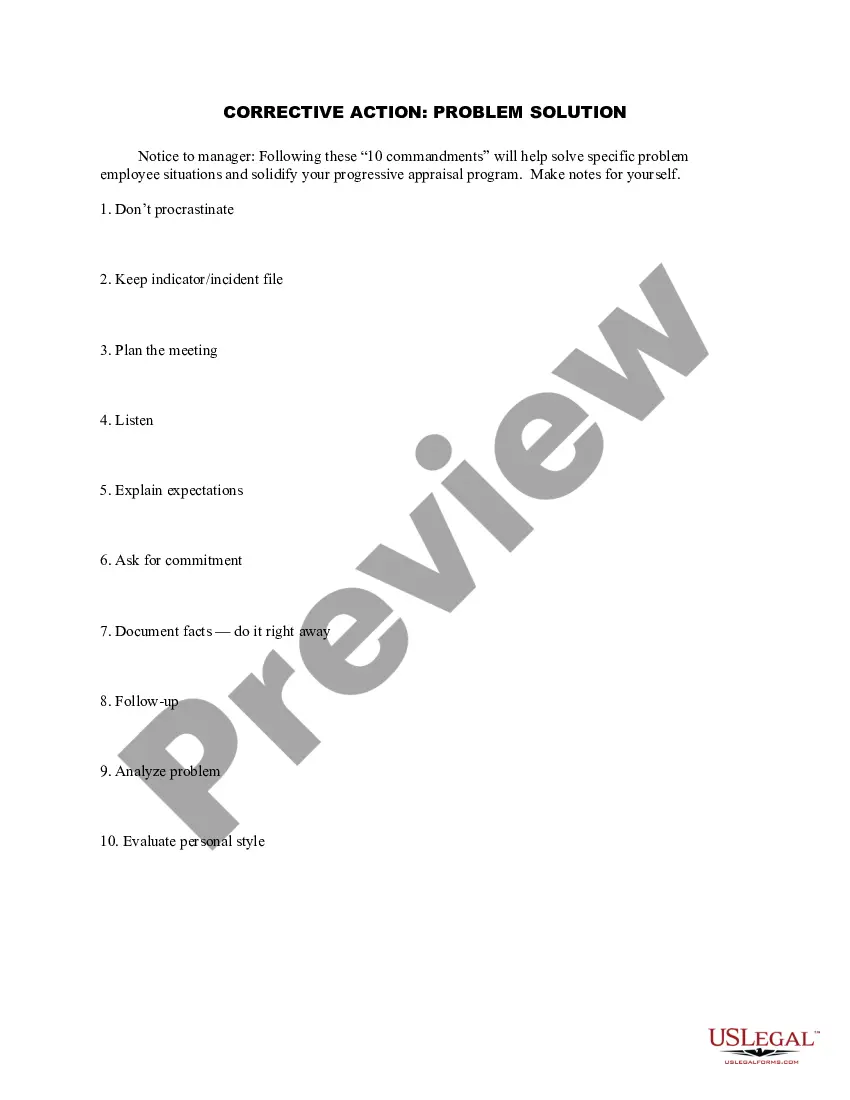

Corrective and preventive action (CAPA or simply corrective action) consists of improvements to an organization's processes taken to eliminate causes of non-conformities or other undesirable situations.

Corrective Action ExamplesInstalling alarms.Redesigning or replacing equipment.Recalibrating tools.Updating work processes.Retraining employees on policies and procedures.

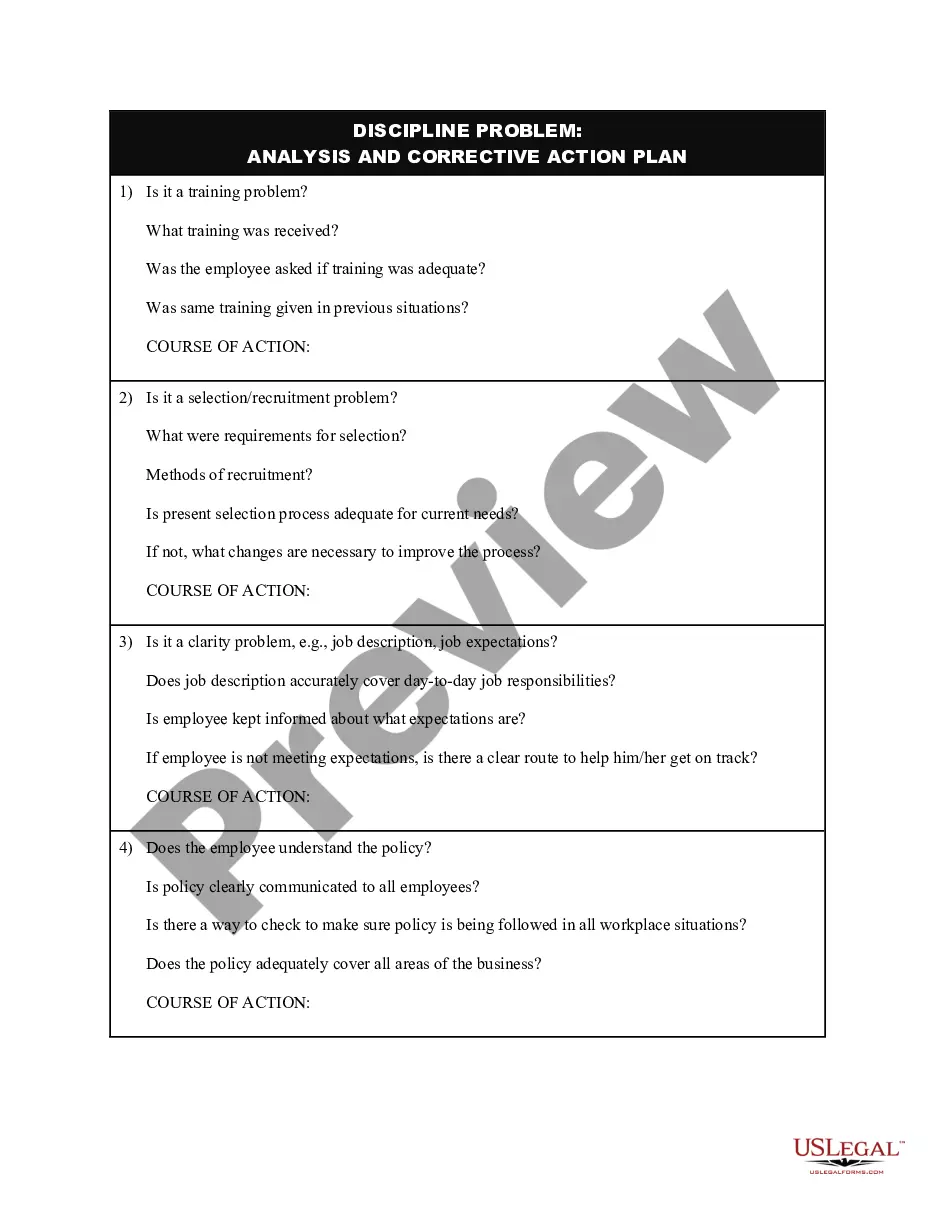

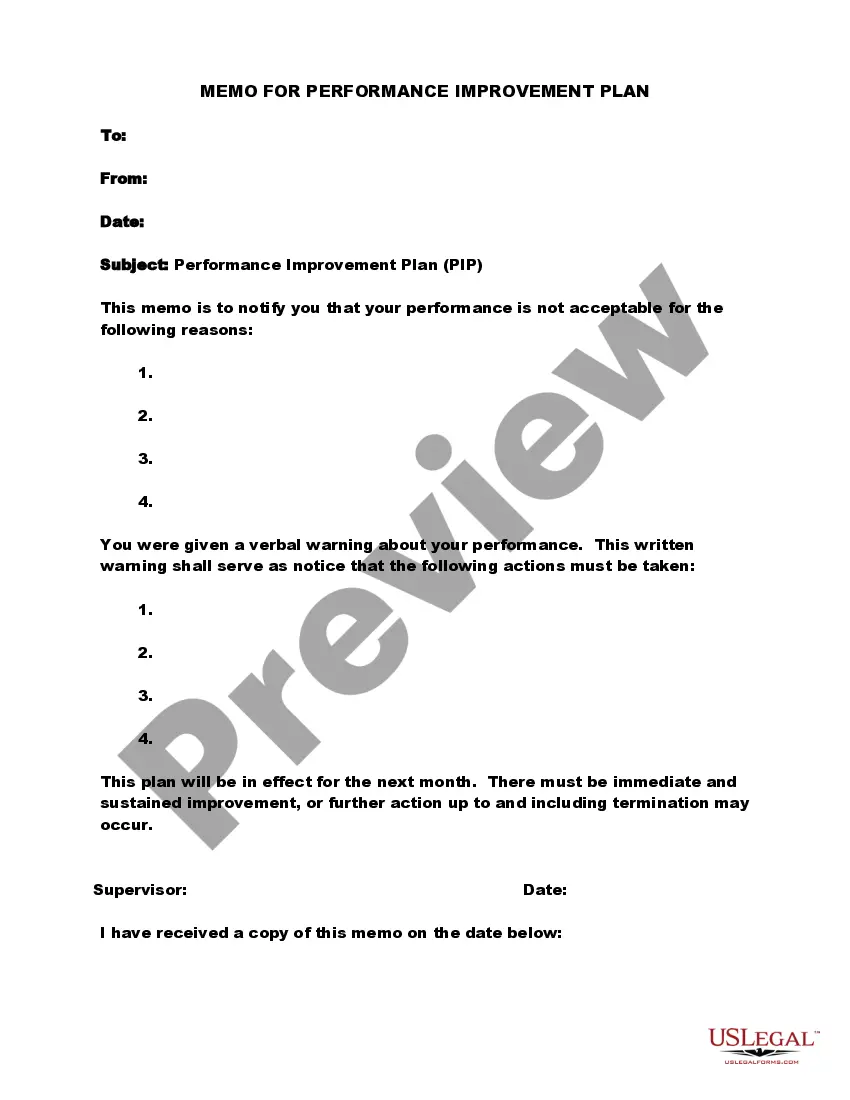

What Should Be in a Corrective Action Form?Information about the employee, including his name, the date and the name of his supervisor.Details about the rule violation that occurred.Details about the violation, such as the date and time and the place it occurred.The supervisor's statement about the incident.More items...

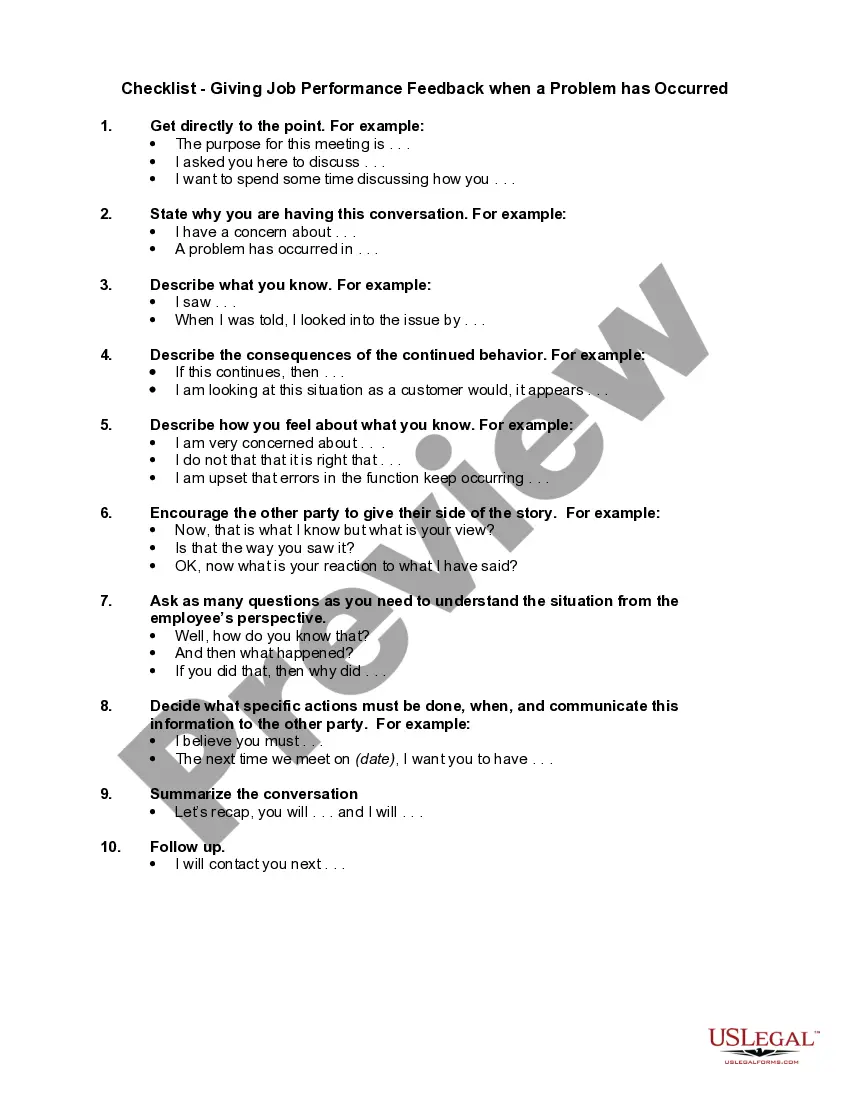

Explain clearly why the behavior or performance is a concern, including how it is impacting operations and other employees. Use direct and descriptive examples. Explain clearly the expected performance or behavior. Describe what will happen next if the performance is not corrected.

Corrective Action ExamplesInstalling alarms.Redesigning or replacing equipment.Recalibrating tools.Updating work processes.Retraining employees on policies and procedures.

There are two types of corrective action: immediate and preventative.

Basic corrective action looks at how and why performance deviated before correcting the source of deviation. It's not unusual for managers to rationalize that they don't have time to find the source of a problem and continue to perpetually put out fires with immediate corrective action.

Steps to prepare CARDefine corrective action for the problem occurred.Identify the root cause.Identify when to issue CARs.Define levels of corrective action.Identify contractual requirements impacting the schedule and delivery of the products.Continuous follow ups.Recording of the end result for future reference.