A Michigan Equipment Maintenance Agreement with a Systems Integrator is a comprehensive contract between a company or organization in Michigan and a professional Systems Integrator. This agreement outlines the terms and conditions for the ongoing maintenance and support of various equipment and systems utilized by the company. It ensures that the equipment functions optimally, minimizing downtime, and maximizing productivity. In such agreements, several types can exist, varying based on the specific nature of the equipment and systems being maintained. Some examples include: 1. IT Equipment Maintenance Agreement: This type of agreement focuses on the maintenance and support of computer hardware, software, network infrastructure, and related IT systems. It is crucial for organizations heavily relying on technology to ensure uninterrupted operations. 2. Industrial Equipment Maintenance Agreement: Companies operating in industries like manufacturing, construction, or logistics may have specific industrial equipment that requires regular maintenance. This type of agreement covers maintenance, repair, and inspection of machinery such as conveyor systems, production lines, forklifts, and heavy-duty vehicles. 3. HVAC Systems Maintenance Agreement: Heating, Ventilation, and Air Conditioning (HVAC) systems are crucial for maintaining a comfortable and functional environment in various buildings. This agreement involves the regular inspection, cleaning, and repair of HVAC equipment to ensure proper functioning and energy efficiency. 4. Security Systems Maintenance Agreement: Businesses with sophisticated security systems, including surveillance cameras, access control systems, fire alarms, and intrusion detection systems, can benefit from this type of agreement. It covers the monitoring, maintenance, and repair of security equipment to ensure the safety and protection of the premises. 5. Medical Equipment Maintenance Agreement: Hospitals, clinics, and medical facilities need to ensure the proper functioning and reliability of critical medical equipment. This agreement encompasses the regular servicing, calibration, and repair of medical devices such as X-ray machines, MRI scanners, ultrasound equipment, and anesthesia machines. In each of these agreements, certain keywords come into play: — Preventive Maintenance: Scheduled inspections and maintenance activities carried out to prevent equipment failures and minimize the chances of unexpected issues. — Corrective Maintenance: Repairs and fixes performed to resolve any equipment malfunctions or breakdowns promptly. — Service Level Agreement (SLA): A defined set of metrics and expectations regarding the response time, resolution time, and overall service quality provided by the Systems Integrator. — Spare Parts Management: The process of managing the inventory of spare parts required for equipment repairs and replacements to ensure minimal downtime. — Software Upgrades: The installation of the latest software updates, patches, and security enhancements to ensure optimal system performance and minimize vulnerabilities. — Service Call Reporting: The documentation of service requests, response times, and resolution details to maintain transparency and accountability between the company and the Systems Integrator. These keywords highlight the essential aspects of a Michigan Equipment Maintenance Agreement with a Systems Integrator, covering various types of equipment and systems commonly found in different industries.

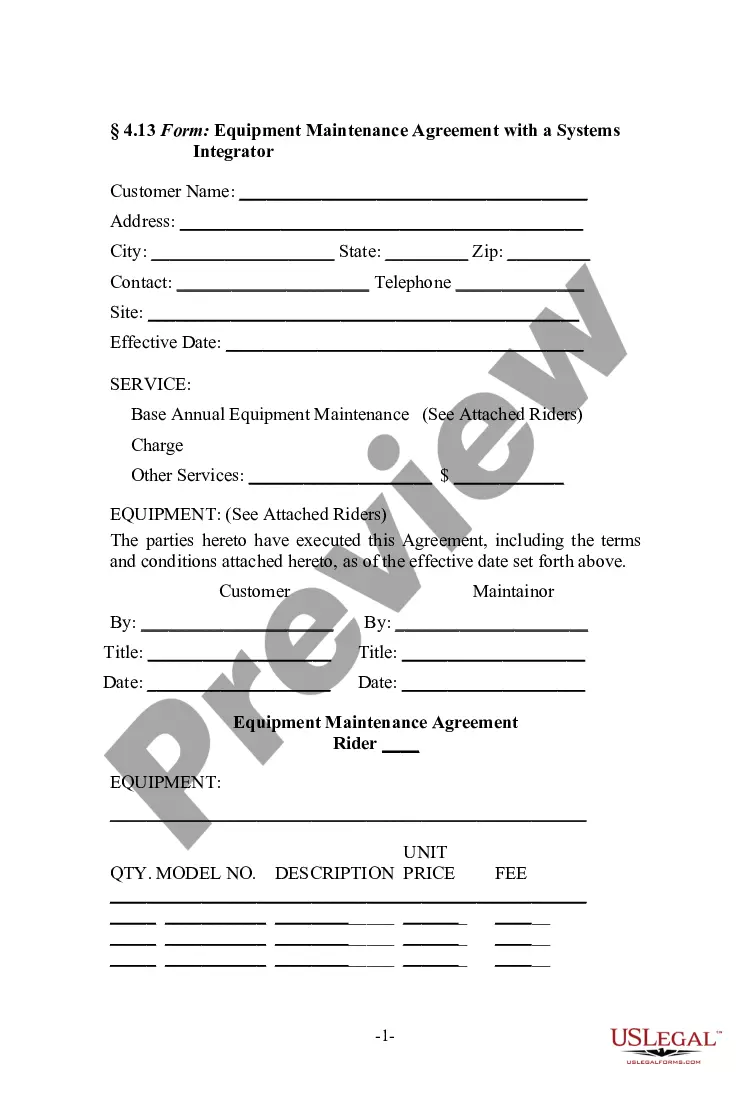

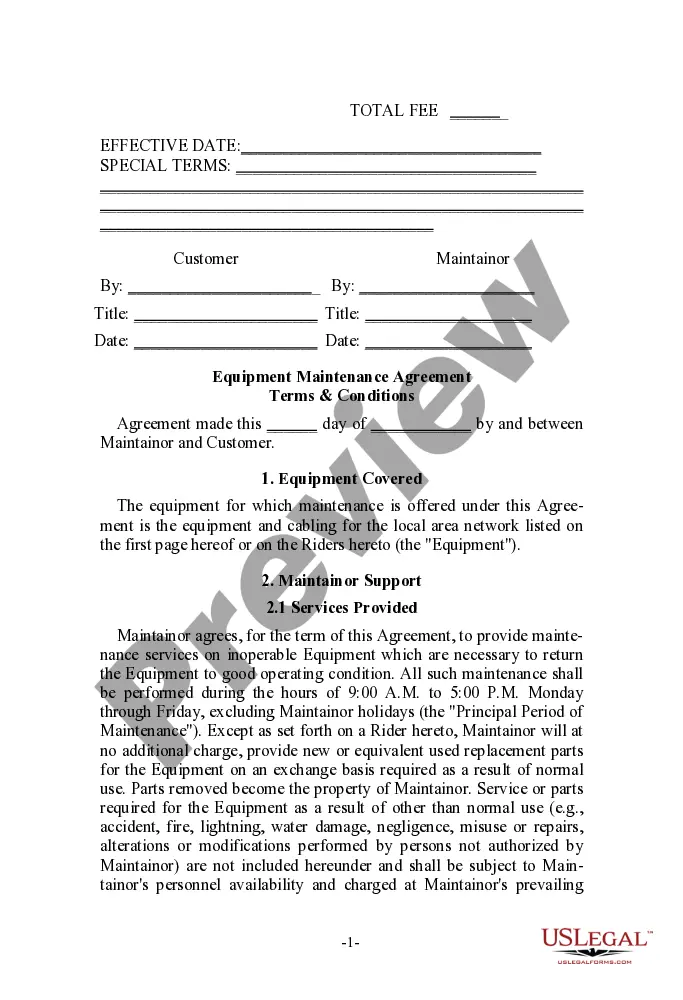

Michigan Equipment Maintenance Agreement with a Systems Integrator

Description

How to fill out Michigan Equipment Maintenance Agreement With A Systems Integrator?

If you have to total, obtain, or printing authorized papers themes, use US Legal Forms, the greatest variety of authorized varieties, which can be found on-line. Take advantage of the site`s easy and hassle-free search to discover the paperwork you will need. A variety of themes for business and individual reasons are categorized by groups and says, or key phrases. Use US Legal Forms to discover the Michigan Equipment Maintenance Agreement with a Systems Integrator with a number of clicks.

When you are previously a US Legal Forms consumer, log in in your accounts and click the Download key to obtain the Michigan Equipment Maintenance Agreement with a Systems Integrator. You may also accessibility varieties you previously saved within the My Forms tab of your respective accounts.

If you work with US Legal Forms initially, follow the instructions beneath:

- Step 1. Make sure you have chosen the form to the appropriate metropolis/country.

- Step 2. Take advantage of the Review method to check out the form`s information. Never neglect to read the information.

- Step 3. When you are unsatisfied with all the kind, make use of the Search field towards the top of the display screen to get other variations from the authorized kind template.

- Step 4. Once you have identified the form you will need, click the Buy now key. Choose the rates plan you choose and include your accreditations to register on an accounts.

- Step 5. Process the financial transaction. You can use your Мisa or Ьastercard or PayPal accounts to perform the financial transaction.

- Step 6. Choose the structure from the authorized kind and obtain it in your system.

- Step 7. Complete, modify and printing or indicator the Michigan Equipment Maintenance Agreement with a Systems Integrator.

Every single authorized papers template you purchase is your own property permanently. You have acces to each and every kind you saved inside your acccount. Click the My Forms area and select a kind to printing or obtain once more.

Contend and obtain, and printing the Michigan Equipment Maintenance Agreement with a Systems Integrator with US Legal Forms. There are millions of skilled and condition-particular varieties you can utilize for the business or individual demands.