This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

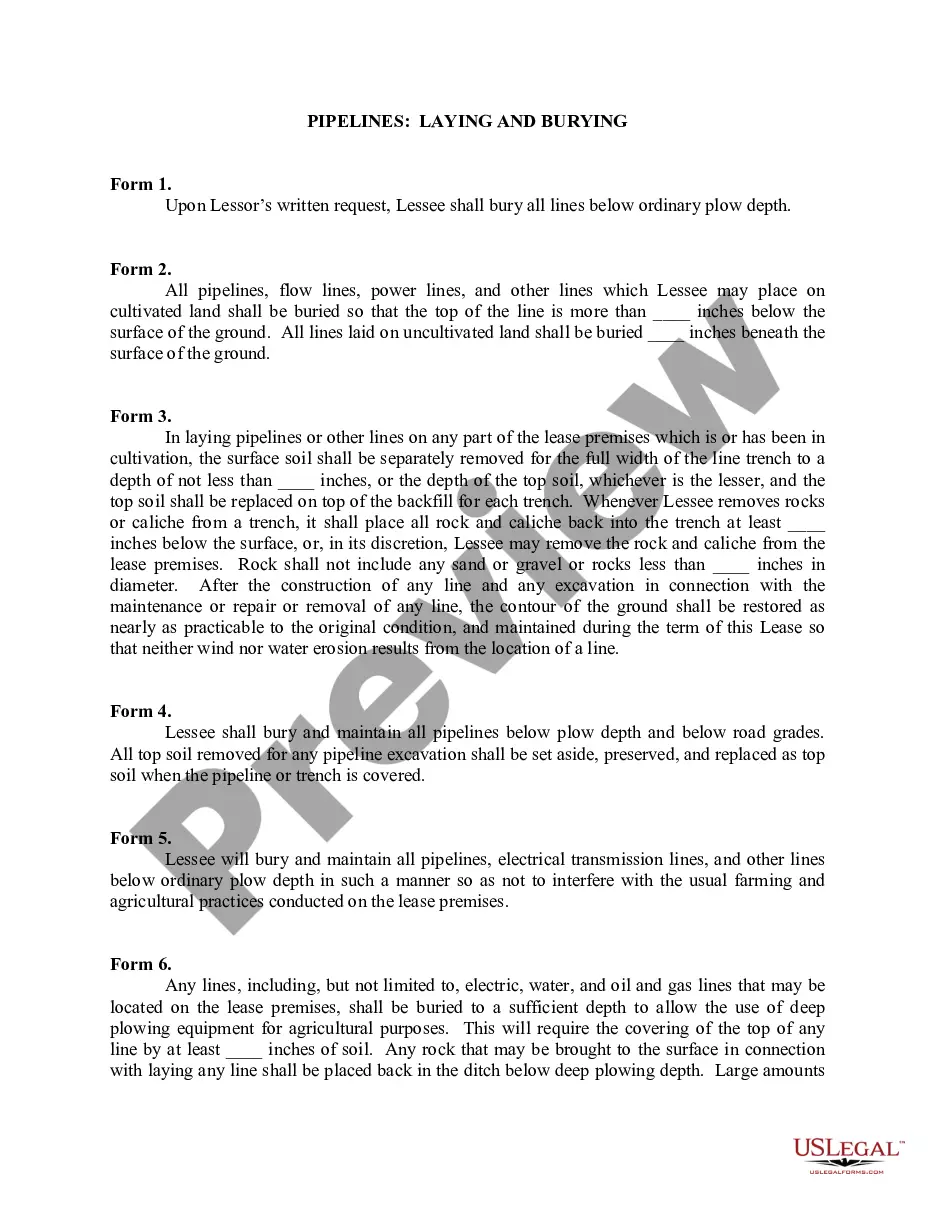

Michigan Pipelines - Laying and Burying

Description

How to fill out Pipelines - Laying And Burying?

If you want to full, download, or print lawful record layouts, use US Legal Forms, the largest selection of lawful varieties, which can be found on the web. Make use of the site`s simple and convenient lookup to discover the paperwork you need. Numerous layouts for organization and person uses are sorted by classes and claims, or keywords and phrases. Use US Legal Forms to discover the Michigan Pipelines - Laying and Burying in just a few mouse clicks.

Should you be currently a US Legal Forms buyer, log in to your accounts and click the Download option to find the Michigan Pipelines - Laying and Burying. You can even access varieties you in the past saved from the My Forms tab of your respective accounts.

If you work with US Legal Forms the first time, follow the instructions below:

- Step 1. Make sure you have chosen the shape for your proper metropolis/region.

- Step 2. Utilize the Preview solution to look through the form`s content. Never overlook to learn the description.

- Step 3. Should you be not satisfied together with the kind, utilize the Look for discipline at the top of the monitor to locate other types in the lawful kind design.

- Step 4. After you have discovered the shape you need, go through the Get now option. Pick the rates prepare you like and add your references to register for the accounts.

- Step 5. Method the transaction. You can use your charge card or PayPal accounts to accomplish the transaction.

- Step 6. Choose the formatting in the lawful kind and download it on the gadget.

- Step 7. Full, change and print or sign the Michigan Pipelines - Laying and Burying.

Every single lawful record design you get is your own permanently. You may have acces to each and every kind you saved within your acccount. Select the My Forms area and choose a kind to print or download once more.

Contend and download, and print the Michigan Pipelines - Laying and Burying with US Legal Forms. There are millions of professional and condition-distinct varieties you can use for your personal organization or person requires.

Form popularity

FAQ

In the United States, a gas line should be between 18 and 24 inches deep. Most of the time, the main gas lines are at least 24 inches deep.

Overhead power lines are moved underground and buried at least 24 inches deep. Depending on the project, this includes converting the primary and/or secondary electrical system but does not move the service wires attached to your home or business underground.

In the United States, a gas line should be between 18 and 24 inches deep. Usually, the main gas lines are at least 24 inches deeper than service gas lines found at a depth of 18 inches underground.

Since 1953, the Line 5 pipeline has been transporting oil and natural gas through Wisconsin, Michigan and Canada. The pipeline, run by energy company Enbridge, transports over 22 million gallons of light crude oil and natural gas liquids per day.

Enbridge's Line 5 pipeline transports 22 million gallons of crude oil and natural gas liquids across 645 miles of countryside every day. This aging oil pipeline violates tribal treaty rights and poses catastrophic risks to the drinking water for 40 million people and one-fifth of the world's surface freshwater.

Pipelines are generally laid underground because temperature is less variable. Because pipelines are usually metal, this helps to reduce the expansion and shrinkage that can occur with weather changes. However, in some cases it is necessary to cross a valley or a river on a pipeline bridge.

Underground piping shall be buried not less than 18 inches below the surface of the ground unless otherwise protected. All underground piping shall be protected from corrosion by coating in compliance with Section 533(b) or equivalent.

The horizontal line under the ground will be a continuous run of polyethylene pipe without any joints except at the ends. At each end, it will attach to an ?anodeless riser?. These are ?L-shaped? steel sleeves that connect to the horizontal line underground and transition the plastic line to steel piping above-ground.