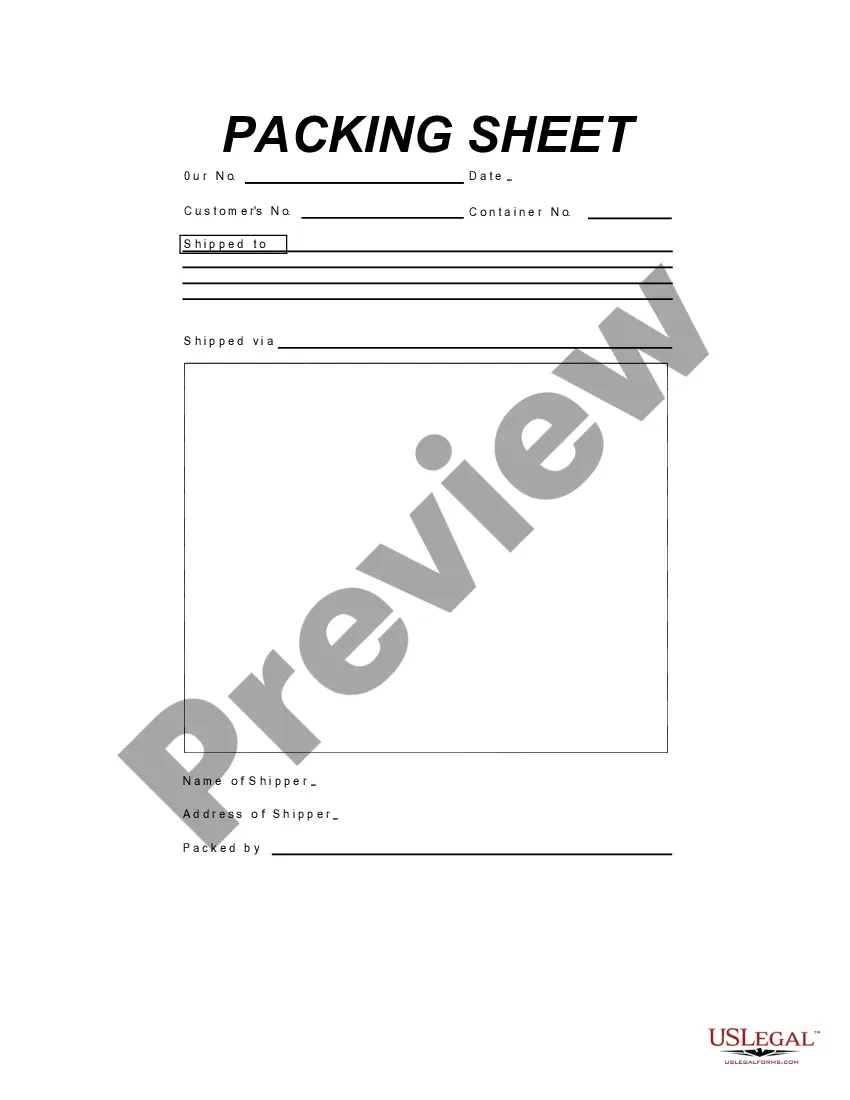

Minnesota Packing Sheet is a versatile and indispensable tool used in the packaging industry. It is specifically designed to ensure a secure and systematic packaging process, contributing to the smooth transportation of goods. Made from high-quality materials, it offers exceptional durability and reliability. The primary purpose of a Minnesota Packing Sheet is to provide a protective layer between the product being packaged and the packaging material. It helps cushion the product, preventing any potential damage that may occur during handling, storage, or shipping. This sheet acts as a buffer, absorbing shocks and minimizing the risk of breakage, scratches, or dents. Minnesota Packing Sheet features various types, each tailored to meet specific packaging needs. Some commonly known types are: 1. Corrugated Cardboard Packing Sheet: This type offers excellent strength and rigidity due to its corrugated construction. It is ideal for packaging fragile items that require enhanced protection. 2. Foam Packing Sheet: Designed with foam padding, this sheet provides superior cushioning properties. The foam absorbs impacts, ensuring that the products remain intact during transit. It is commonly used for electronics, glassware, and other delicate items. 3. Bubble Wrap Packing Sheet: Recognized for its air-filled bubbles, this sheet acts as a protective layer against shocks and vibrations. It is an excellent choice for wrapping fragile items, offering an extra layer of cushioning. 4. Kraft Paper Packing Sheet: Made from durable, recyclable material, this sheet provides a cost-effective solution for packaging needs. It offers moderate protection against minor impacts and is commonly used for wrapping lightweight goods. 5. Polyethylene (PE) Packing Sheet: This type of packing sheet excels at moisture resistance, making it an ideal choice for packaging products vulnerable to water damage. It provides a reliable barrier against humidity and external factors. When selecting the appropriate Minnesota Packing Sheet, it is crucial to consider factors such as product fragility, transportation conditions, and budget constraints. By choosing the right type of packing sheet, businesses can enhance the safety and protection of their products, minimize losses, and ensure customer satisfaction.

Minnesota Packing Sheet

Description

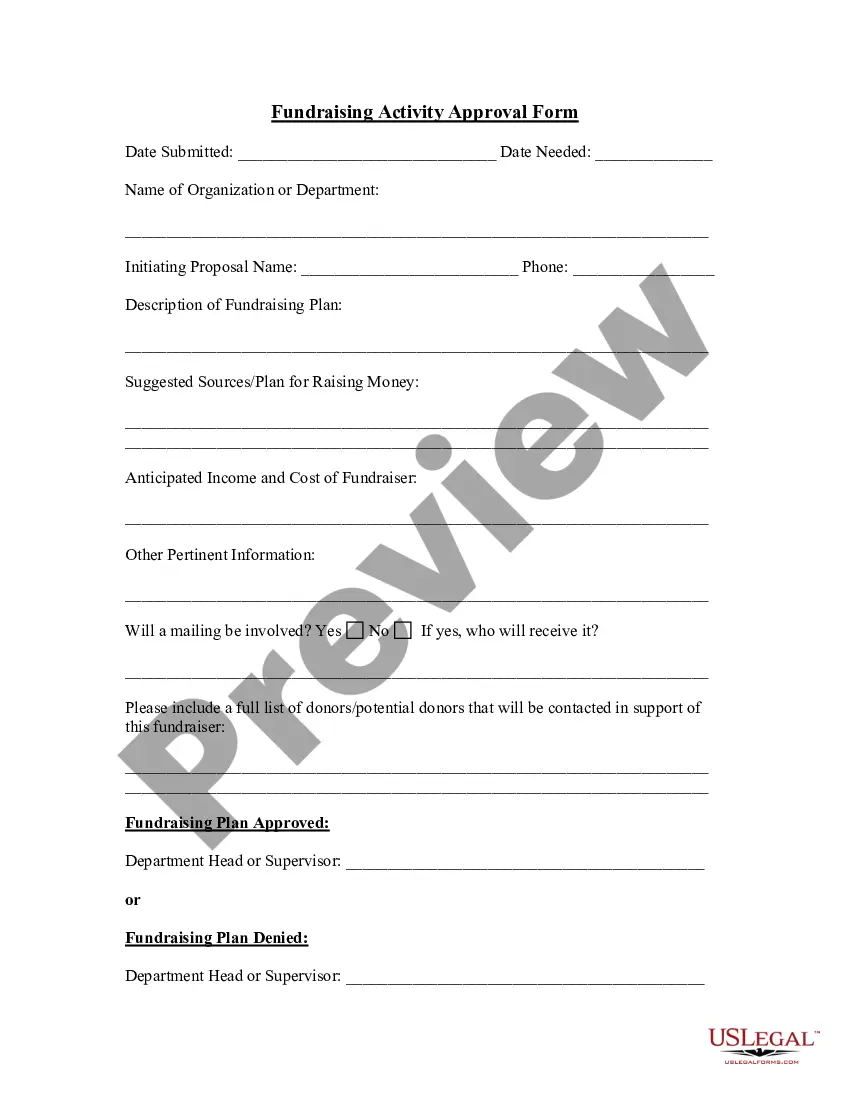

How to fill out Minnesota Packing Sheet?

US Legal Forms - among the biggest libraries of authorized forms in the States - offers a wide array of authorized file layouts you can download or print out. While using internet site, you will get thousands of forms for organization and specific functions, categorized by classes, suggests, or keywords.You will discover the most recent versions of forms much like the Minnesota Packing Sheet within minutes.

If you have a registration, log in and download Minnesota Packing Sheet through the US Legal Forms local library. The Down load key will show up on every develop you view. You gain access to all earlier downloaded forms from the My Forms tab of your own accounts.

If you want to use US Legal Forms for the first time, allow me to share easy directions to help you get started off:

- Ensure you have picked the best develop for the metropolis/area. Select the Preview key to analyze the form`s content. Read the develop explanation to actually have chosen the proper develop.

- If the develop does not suit your specifications, utilize the Lookup discipline towards the top of the display to discover the one that does.

- When you are satisfied with the shape, confirm your decision by clicking the Buy now key. Then, pick the rates prepare you like and supply your accreditations to register for an accounts.

- Procedure the purchase. Utilize your Visa or Mastercard or PayPal accounts to perform the purchase.

- Choose the formatting and download the shape on your own gadget.

- Make changes. Fill up, modify and print out and sign the downloaded Minnesota Packing Sheet.

Each web template you put into your bank account does not have an expiry day and is yours eternally. So, if you want to download or print out an additional backup, just proceed to the My Forms area and click on in the develop you will need.

Get access to the Minnesota Packing Sheet with US Legal Forms, one of the most extensive local library of authorized file layouts. Use thousands of skilled and condition-particular layouts that meet your small business or specific requirements and specifications.