This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

Minnesota Conversion of An Oil Or Gas Well to An injection Or Water Well

Description

How to fill out Conversion Of An Oil Or Gas Well To An Injection Or Water Well?

Are you presently inside a position the place you require files for either enterprise or individual uses just about every working day? There are tons of lawful document layouts available online, but getting types you can depend on is not straightforward. US Legal Forms provides a huge number of develop layouts, like the Minnesota Conversion of An Oil Or Gas Well to An injection Or Water Well, which are published to fulfill federal and state needs.

Should you be presently knowledgeable about US Legal Forms web site and get an account, merely log in. Afterward, it is possible to acquire the Minnesota Conversion of An Oil Or Gas Well to An injection Or Water Well web template.

Should you not come with an accounts and want to start using US Legal Forms, adopt these measures:

- Find the develop you need and ensure it is to the proper town/county.

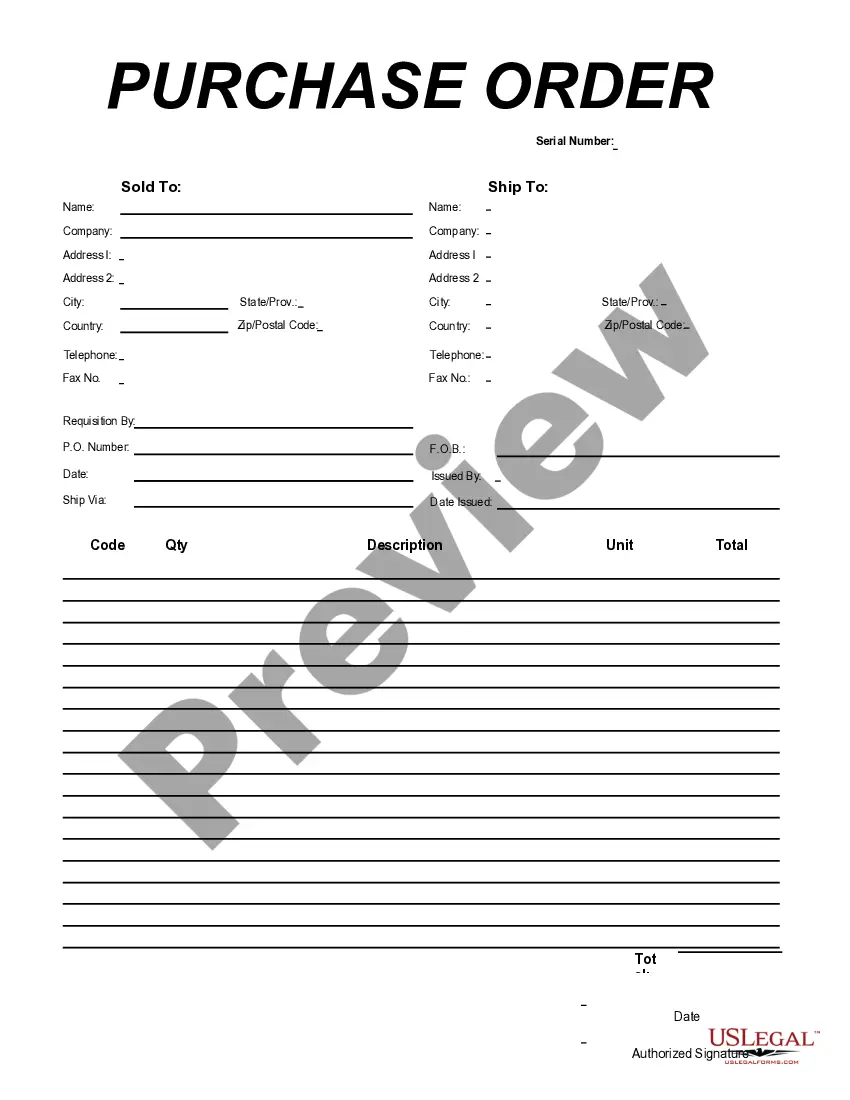

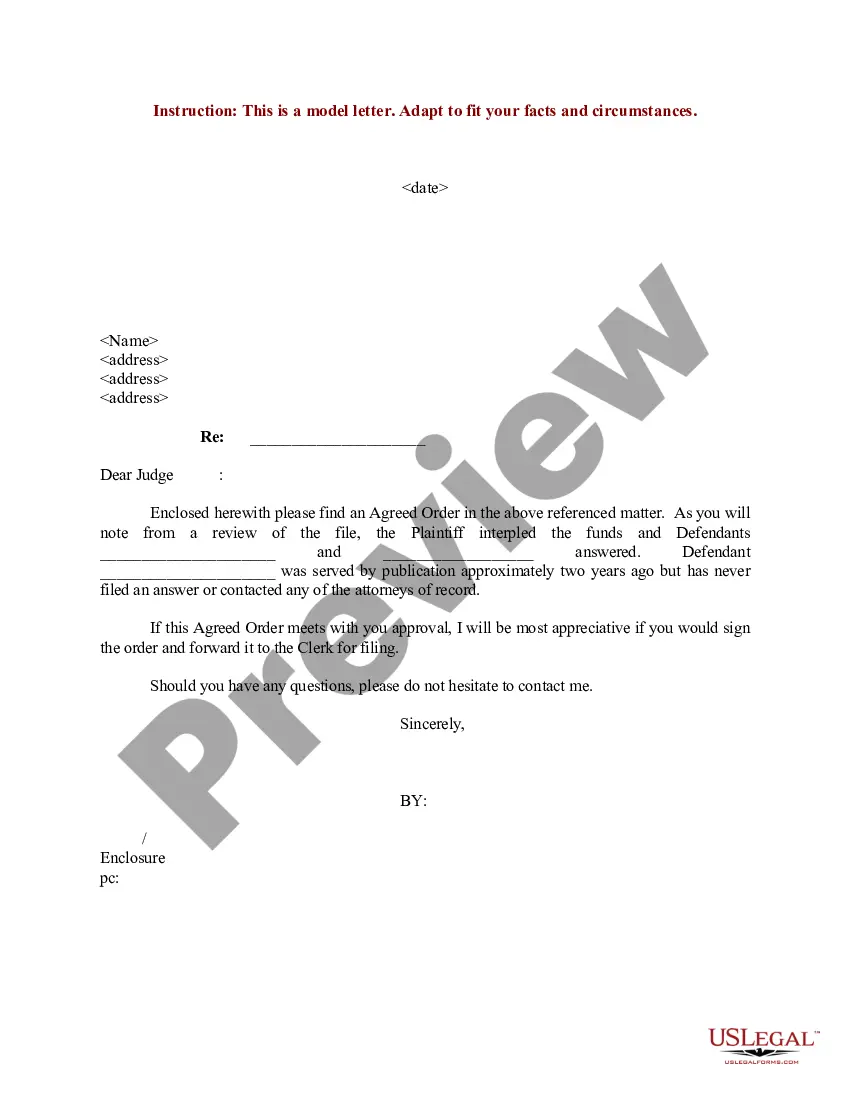

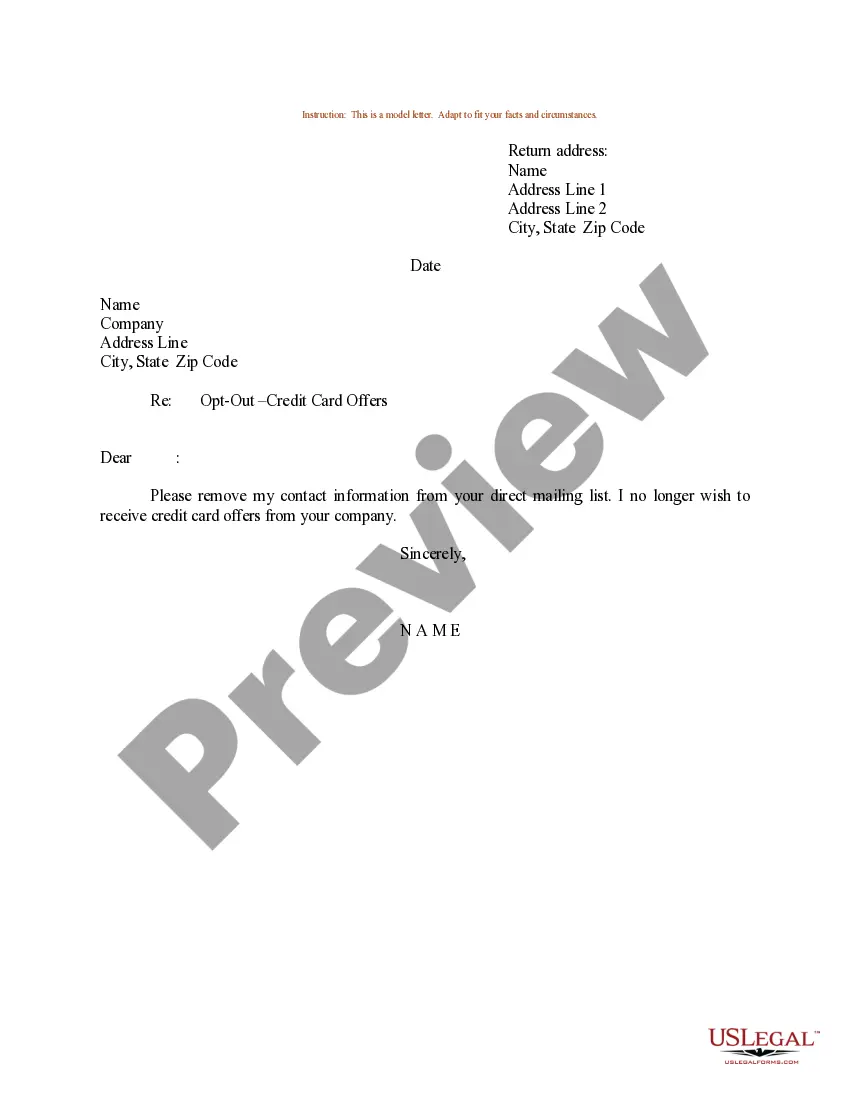

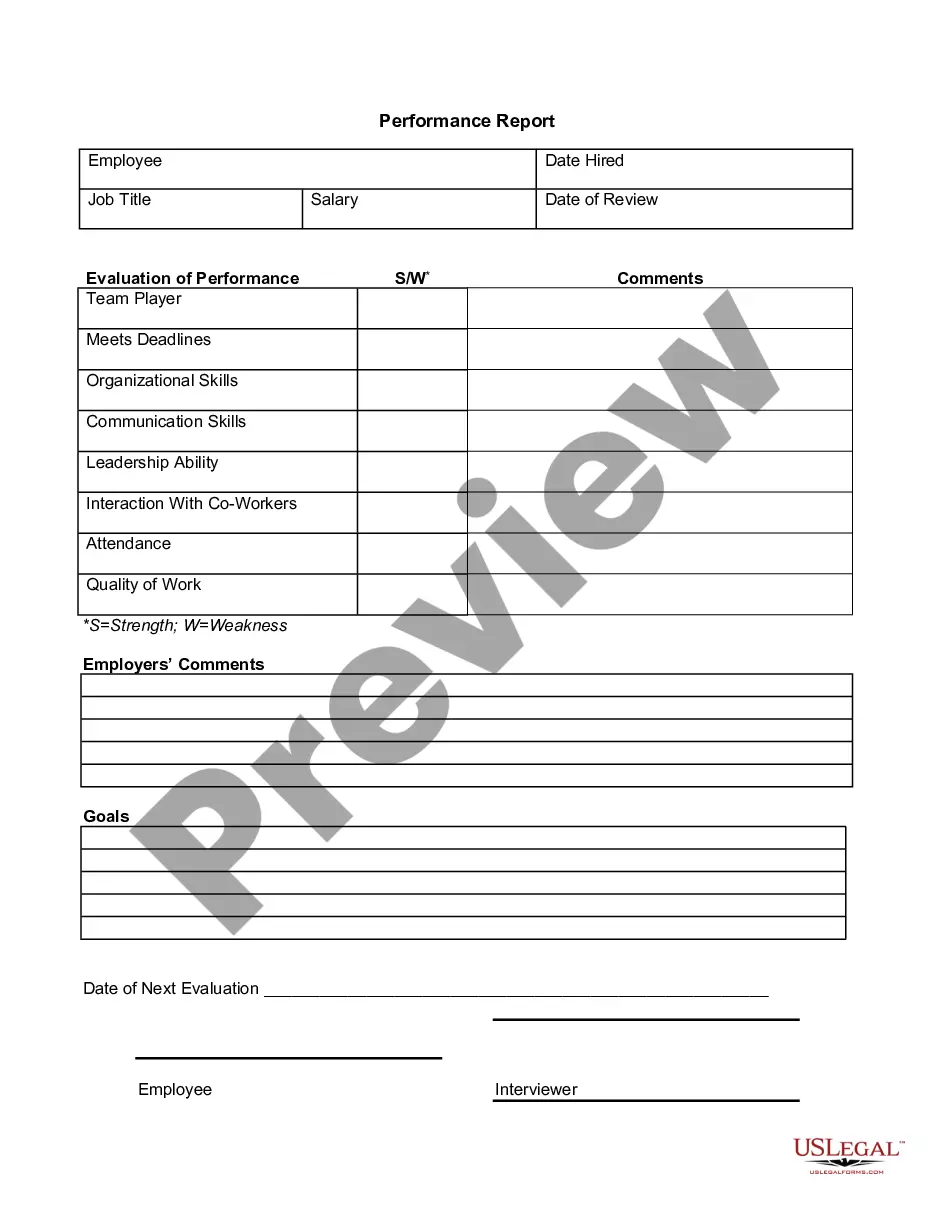

- Utilize the Review option to analyze the form.

- Read the outline to ensure that you have chosen the appropriate develop.

- In the event the develop is not what you`re seeking, utilize the Research industry to get the develop that suits you and needs.

- Whenever you get the proper develop, click Purchase now.

- Choose the pricing program you want, submit the desired information and facts to make your money, and buy the order using your PayPal or charge card.

- Choose a handy file structure and acquire your duplicate.

Get all of the document layouts you possess purchased in the My Forms menus. You can get a extra duplicate of Minnesota Conversion of An Oil Or Gas Well to An injection Or Water Well at any time, if needed. Just click the necessary develop to acquire or print out the document web template.

Use US Legal Forms, by far the most substantial selection of lawful types, in order to save time as well as steer clear of faults. The support provides expertly manufactured lawful document layouts which can be used for a variety of uses. Create an account on US Legal Forms and start generating your way of life a little easier.

Form popularity

FAQ

Well conversion is when an existing water-supply well is converted from private to public use.

In Minnesota, all wells must be installed by contractors licensed by the Minnesota Department of Health (MDH), except that an individual may construct a well for personal use on land owned or leased by that individual, and used by the individual for farming or agricultural purposes or for the individual's place of ...

The typical depth of a well for a private residence ranges anywhere from 100 to 800 feet. If the geology of your region is different from that of another part of the country, you might need a well that is either deeper or shallower.

Drilling a residential water well costs $25 to $65 per foot or $3,750 to $15,300 on average for a complete system and installation. Prices include the drilling, a pump, casing, wiring, and more.

Driven wells are constructed by driving pipe into the ground. Driven wells are cased continuously and shallow (approximately 30 to 50 feet deep). Though driven wells are cased, they can be contaminated easily because they draw water from aquifers near the surface.

In Minnesota, all wells must be installed by contractors licensed by the Minnesota Department of Health (MDH), except that an individual may construct a well for personal use on land owned or leased by that individual, and used by the individual for farming or agricultural purposes or for the individual's place of ...

The depth to which wells are constructed is determined by factors such as 1) depth to groundwater, 2) the groundwater quality, and 3) the geologic conditions at the well site. Wells in Minnesota range in depth from 15 feet to over 1,000 feet.

How to seal a well? Wells need to be sealed by a licensed well contractor. This service can cost between $500 to $1,500 or more for sealing an average four-inch diameter domestic well. Our grant program can cover as much as 50% of the total well sealing costs, up to $750 per well.