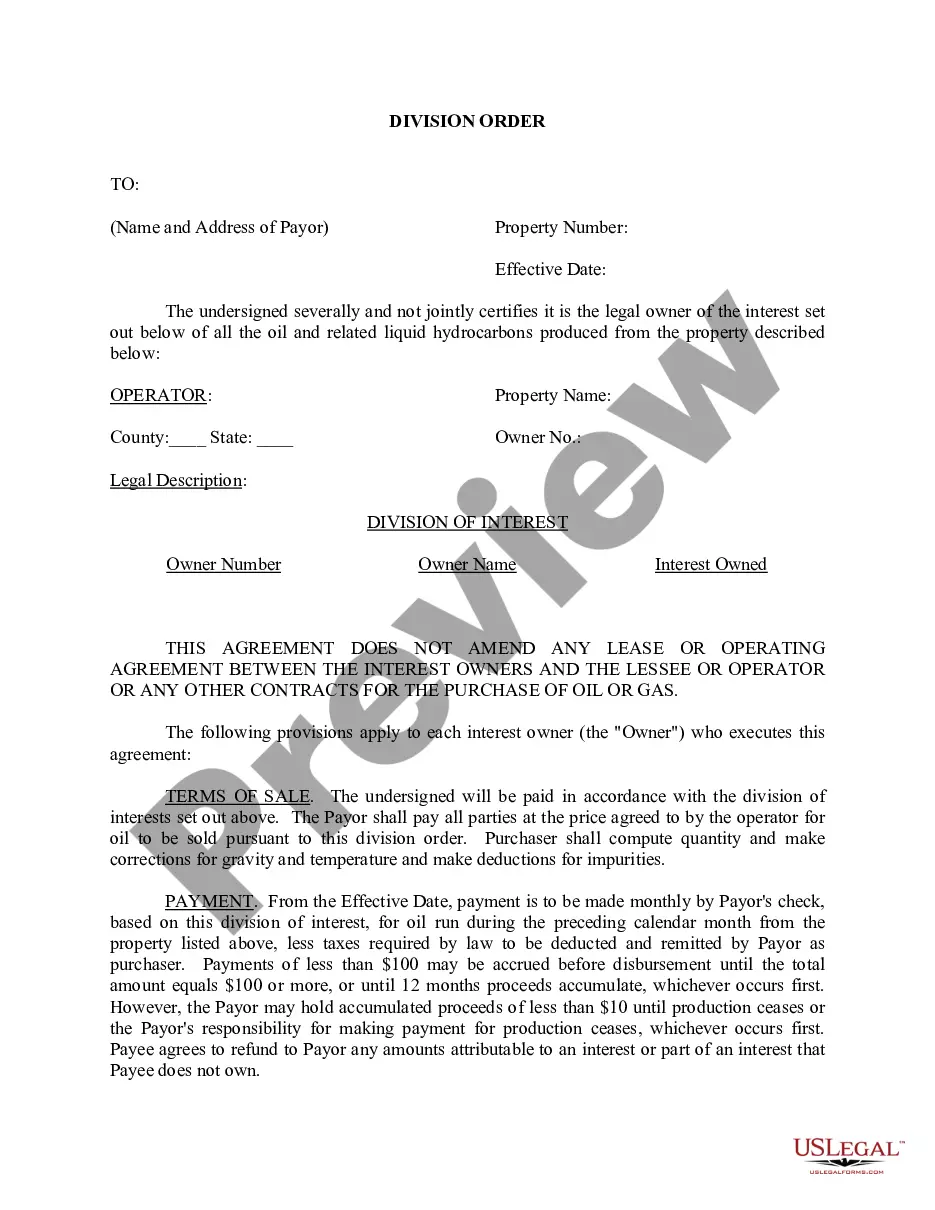

This office lease form states that the landlord shall install a freight elevator that will be adjacent to the tenant's exclusive loading dock. Upon completion of the installation of the tenant's freight elevator, the tenant, at its sole cost and expense, shall maintain the tenant's freight elevator in good working order.

Minnesota Specification for Freight Elevator Service

Description

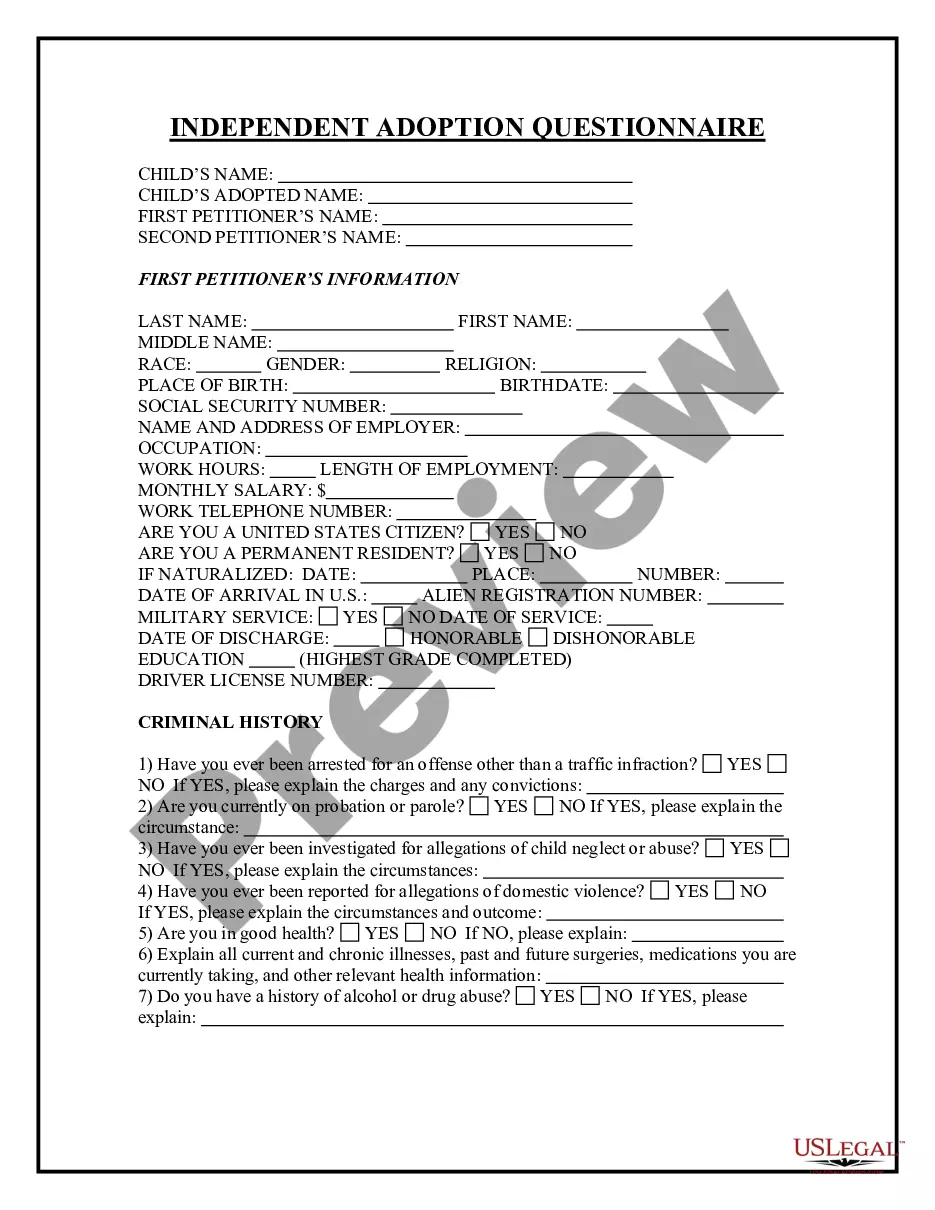

How to fill out Specification For Freight Elevator Service?

Choosing the right authorized papers design could be a have difficulties. Of course, there are tons of themes available on the net, but how can you find the authorized type you require? Take advantage of the US Legal Forms site. The service provides thousands of themes, like the Minnesota Specification for Freight Elevator Service, which can be used for company and personal demands. Each of the forms are checked out by experts and fulfill state and federal requirements.

Should you be currently registered, log in to your account and then click the Download switch to obtain the Minnesota Specification for Freight Elevator Service. Make use of account to look with the authorized forms you might have ordered earlier. Proceed to the My Forms tab of your own account and have another backup of your papers you require.

Should you be a whole new user of US Legal Forms, allow me to share basic guidelines that you can follow:

- Initially, make sure you have selected the right type to your city/state. It is possible to examine the form using the Review switch and browse the form outline to make certain this is basically the best for you.

- In the event the type does not fulfill your expectations, make use of the Seach field to obtain the right type.

- Once you are positive that the form is acceptable, go through the Get now switch to obtain the type.

- Choose the pricing strategy you need and type in the required info. Design your account and pay for your order utilizing your PayPal account or charge card.

- Pick the file file format and down load the authorized papers design to your gadget.

- Comprehensive, modify and print out and signal the received Minnesota Specification for Freight Elevator Service.

US Legal Forms may be the most significant catalogue of authorized forms in which you can discover a variety of papers themes. Take advantage of the company to down load expertly-manufactured documents that follow status requirements.

Form popularity

FAQ

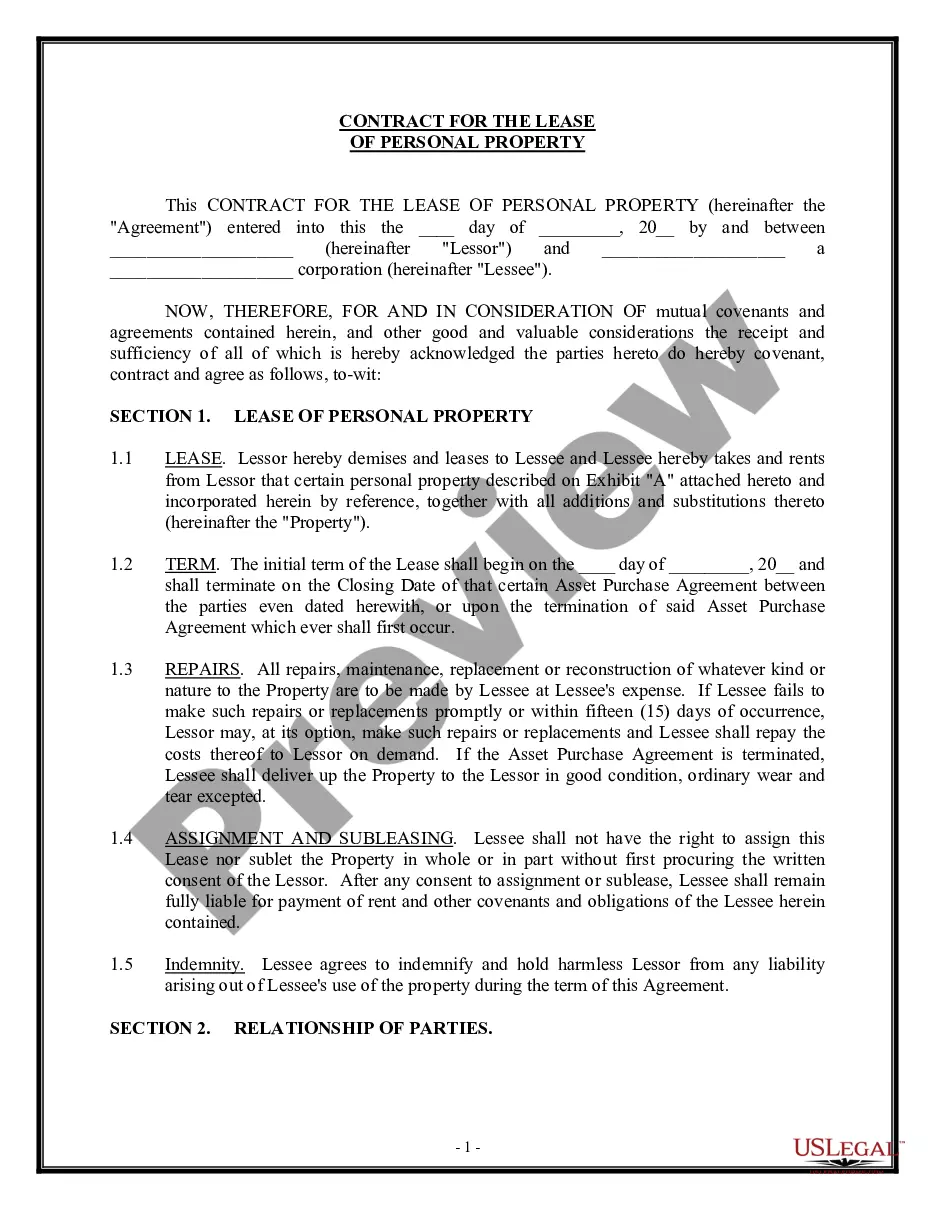

What are the Minimum Space Requirements for a Home Elevator? In general, you need at least 20 to 25 square feet of space to a residential elevator. You might also need about 8 inches of pit space dug into the ground beneath the elevator, depending on the style of residential elevator you plan to use.

The average cost to a freight elevator is between $65,000 and $150,000.

Freight Elevator Dimensions The cabin of a freight elevator is required to have a minimum height of 8 feet (2.4 m), width of 6 feet (1.8 m), and depth of 5 feet (1.5 m) to accommodate large items.

The width of the elevator car is a minimum of 68 inches (1730 mm). The depth of the elevator car measured from the back wall to the elevator door is a minimum of 54 inches (1370 mm). The depth of the elevator car measured from the back wall to the control panel is a minimum of 51 inches (1291 mm).

What is a Freight Elevator? Freight elevators are designed to move goods and materials throughout a building. Compared to passenger elevators, freight cars travel at slower speeds, can carry much heavier loads and are designed to withstand tougher working conditions.

The Safety Code for Elevators ASME A17. 1-2022, as a code, is intended to provide safety of life and limb and promote public welfare. It covers not only elevators, escalators, moving walks, dumbwaiters, material lifts, and related equipment, but also their associated parts, rooms, spaces, and hoistways.

Freight elevators allow for much larger equipment such as forklifts or even entire vehicles to drive into an elevator. While the capacity of service elevators typically maxes out at 5000 lbs., freight elevators can often carry loads up to 100,000 lbs.!