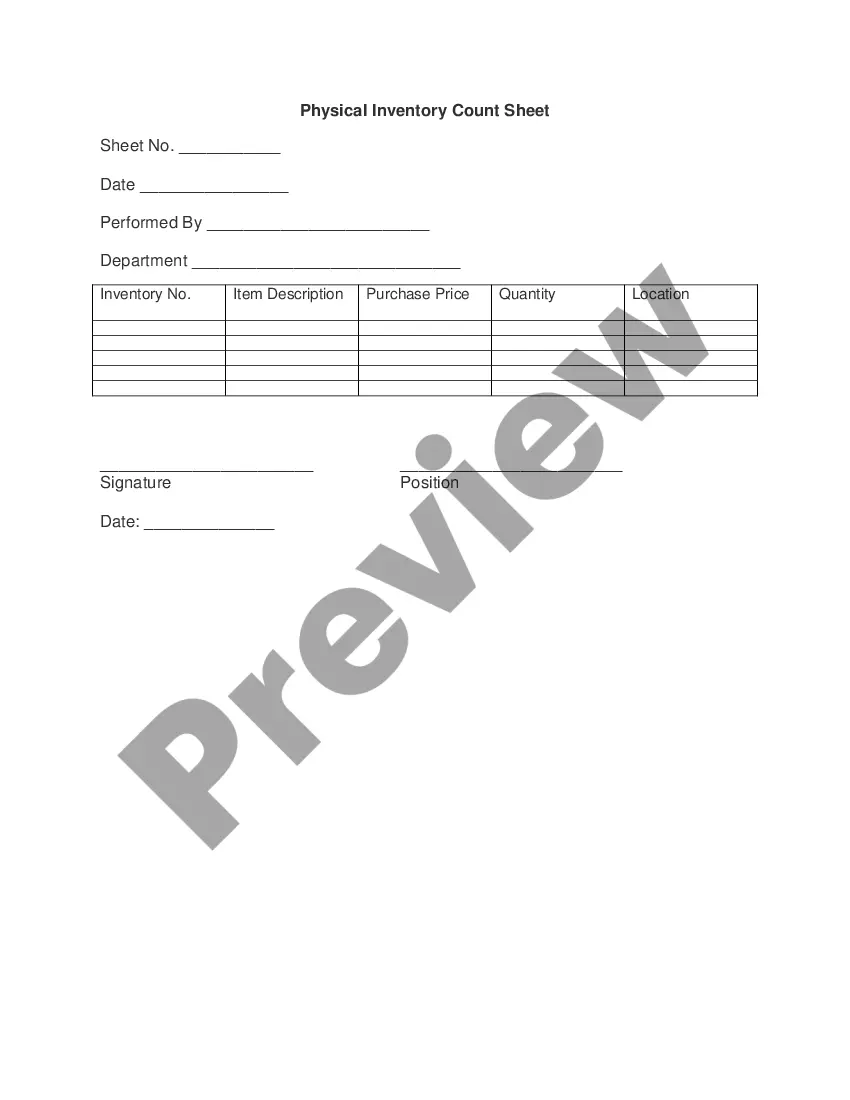

Mississippi Physical Inventory Count Sheet

Description

How to fill out Physical Inventory Count Sheet?

If you need to thoroughly review, obtain, or print authentic document templates, utilize US Legal Forms, the premier collection of legal forms, available online.

Take advantage of the site’s user-friendly and efficient search function to find the documents you need.

Many templates for business and personal purposes are organized by categories and states, or keywords.

Step 4. After locating the form you need, click the Purchase now button. Choose the pricing plan that suits you and enter your details to register for an account.

Step 5. Complete the transaction. You can use your credit card or PayPal account to finalize the purchase.

- Utilize US Legal Forms to access the Mississippi Physical Inventory Count Sheet with just a few clicks.

- If you are already a US Legal Forms customer, Log In to your account and click on the Download button to locate the Mississippi Physical Inventory Count Sheet.

- You can also access forms you have previously downloaded under the My documents section of your account.

- If you are using US Legal Forms for the first time, follow the instructions below.

- Step 1. Make sure you have selected the form for the appropriate city/state.

- Step 2. Use the Preview feature to review the form's content. Don’t forget to read the description.

- Step 3. If you are unhappy with the form, utilize the Search field at the top of the screen to find alternate versions of the legal form template.

Form popularity

FAQ

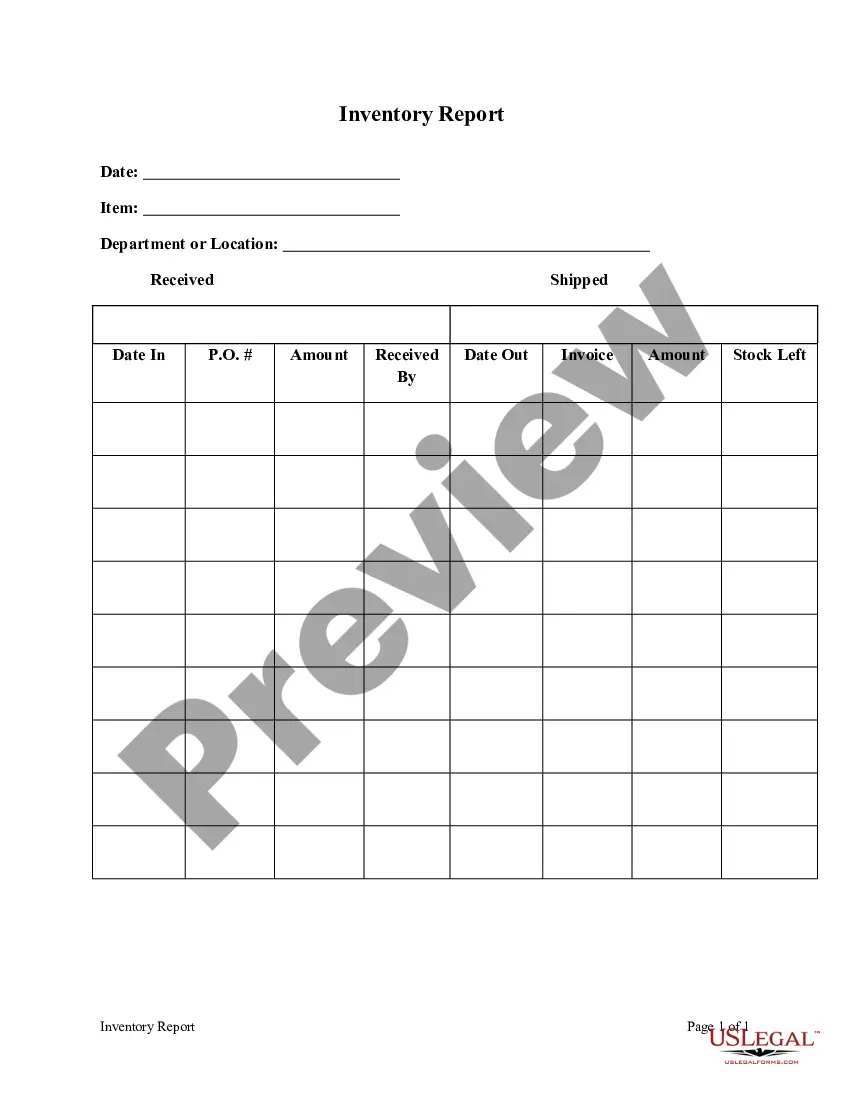

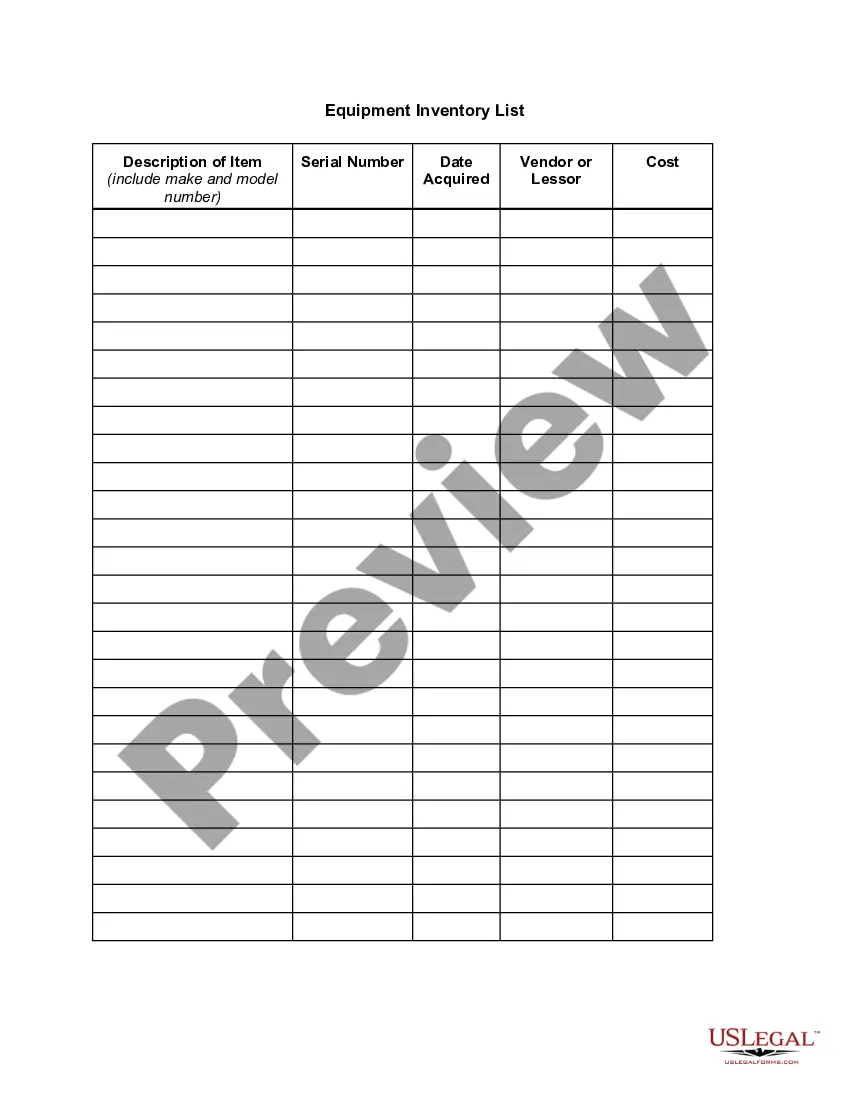

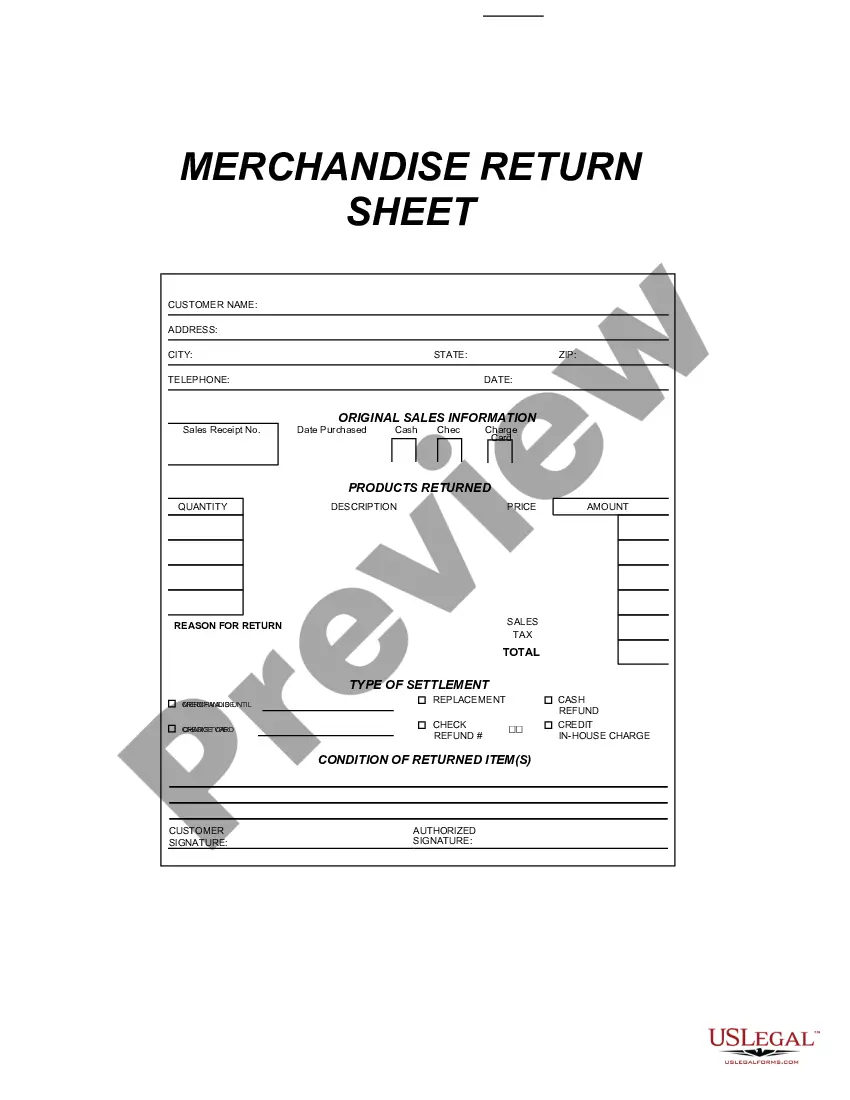

Filling out an inventory sheet, such as the Mississippi Physical Inventory Count Sheet, requires a systematic approach. Begin by entering basic identifying information like item names and SKU numbers in designated columns. As you count, write the corresponding quantities next to each item, ensuring that all entries are accurate and legible. Finally, review the completed sheet for any mistakes before submitting it into your inventory system.

To conduct inventory counts, establish a clear plan using the Mississippi Physical Inventory Count Sheet. Organize your items logically so team members can count them quickly and efficiently. Distribute the counting responsibilities among your staff and monitor progress to reduce confusion. Consistency in your counting methodology enhances accuracy and provides reliable data for inventory management.

When conducting a physical count of inventory, consider several key factors for an accurate count. First, ensure you have the right tools like the Mississippi Physical Inventory Count Sheet. Next, evaluate the time of year you choose for your count, as busy seasons may affect accuracy. It's crucial to involve trained staff who can identify discrepancies and manage the counting process efficiently.

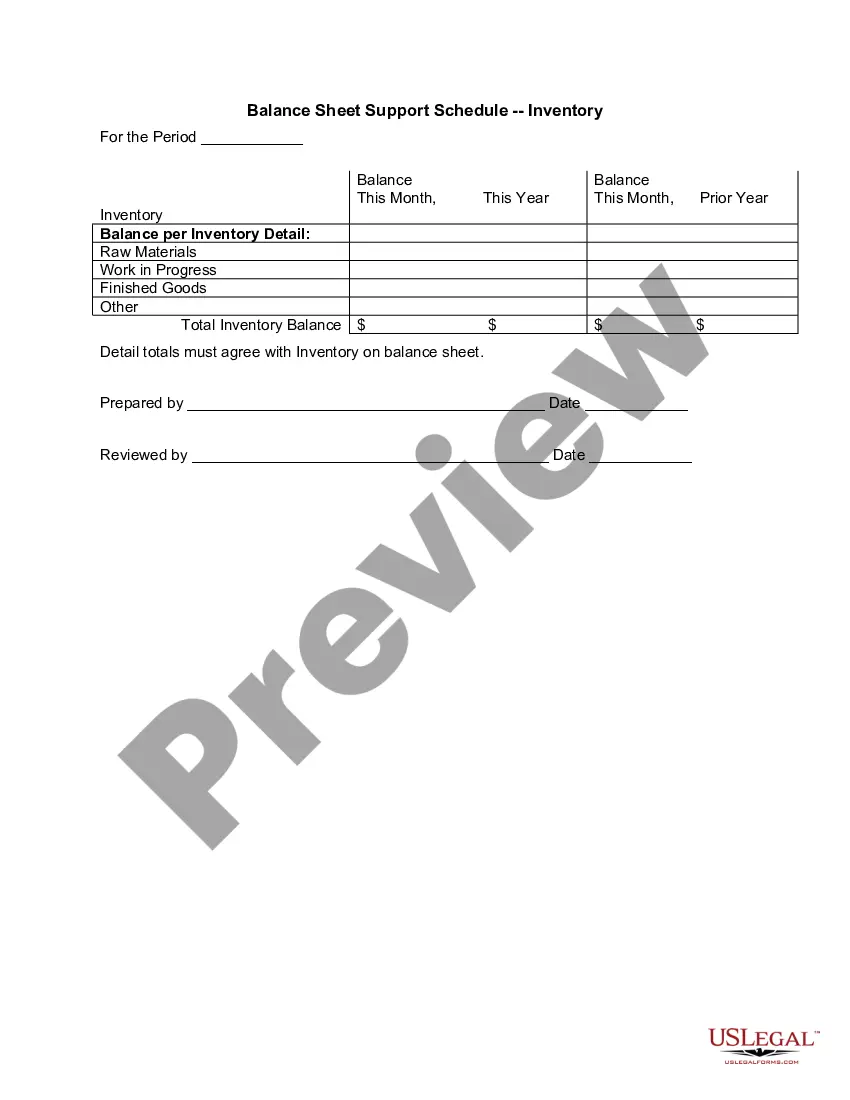

Calculating physical inventory involves summing total quantities of products observed during the count. Using the Mississippi Physical Inventory Count Sheet, write down the counts for each item and total them at the end. You may also factor in previous records to identify any variances, which can help manage future inventory purchases. This calculation leads to better financial assessments and inventory control.

Doing a physical inventory involves systematically counting all items in your inventory to ensure accuracy. With the Mississippi Physical Inventory Count Sheet in hand, you can create a structured process by grouping similar items together. You should assign teams to different sections of the inventory and tally items, making it easier to track totals and correct any errors as you go. This process helps maintain precise inventory records.

To conduct an effective physical inventory count using the Mississippi Physical Inventory Count Sheet, you should follow four key steps. First, prepare your inventory area by organizing products and materials for easy access. Second, count each item and record the quantities on your count sheet. Third, compare your counts to your inventory records to identify discrepancies. Lastly, update your inventory system with the newly verified figures.

The procedure for a physical inventory count involves several key steps, starting with planning and preparation. First, choose a suitable time for the count, such as outside of peak business hours, and then use a Mississippi Physical Inventory Count Sheet to document your findings. Count all items meticulously and compare them against your records to identify discrepancies. Finally, review the inventory count for accuracy before finalizing the data.

To create a physical inventory, gather all relevant stock items and prepare your materials, like a Mississippi Physical Inventory Count Sheet. Start by counting each item systematically, documenting quantities carefully. It’s recommended to conduct this process regularly to ensure data accuracy and consistency in inventory levels. Regular review and updates can help prevent discrepancies.

Organizing physical inventory starts with categorizing items based on type, size, or frequency of use. Employing a Mississippi Physical Inventory Count Sheet can help maintain clarity in your organization. It's beneficial to label storage locations and ensure that all team members are aware of the layout. This systematic approach minimizes errors and enhances efficiency during inventory counts.

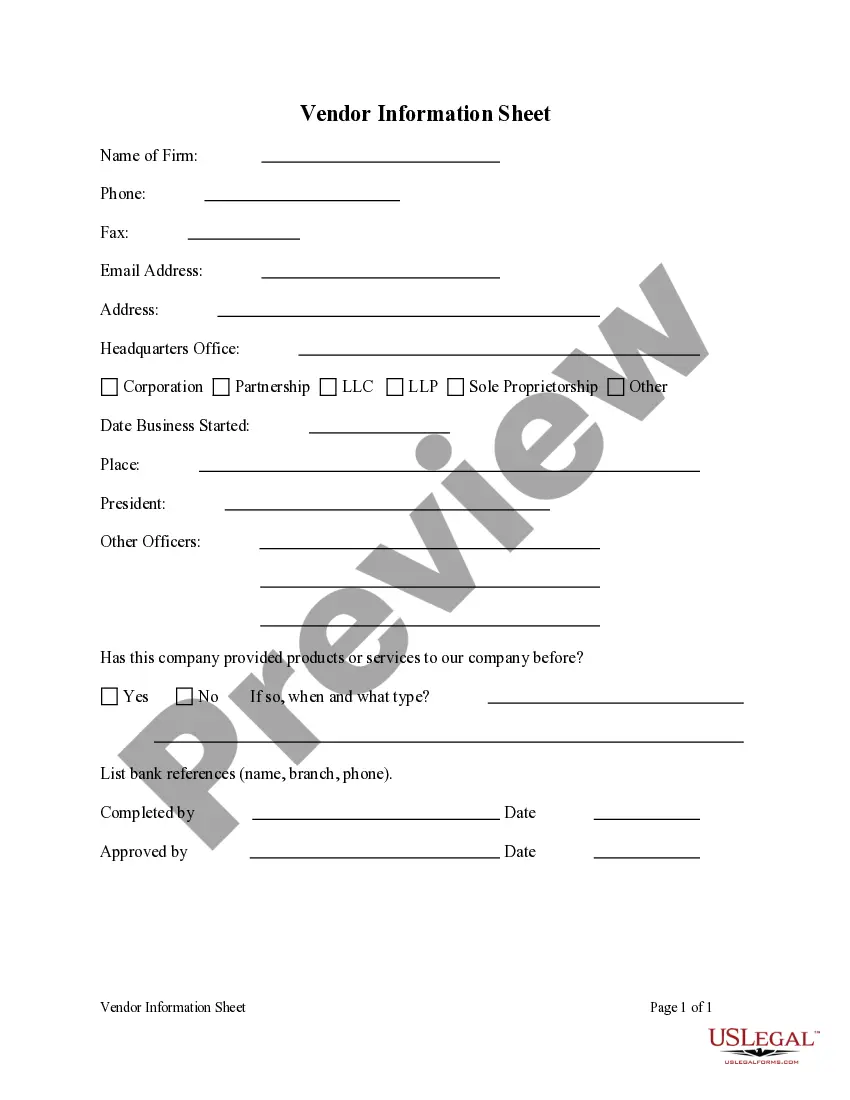

Typically, the responsibility of conducting a physical inventory count falls on the inventory manager or a designated team. This individual's role includes ensuring accuracy and consistency throughout the counting process. Using a Mississippi Physical Inventory Count Sheet can facilitate better teamwork and communication among staff members. Clear assignments and roles can lead to a more streamlined inventory process.