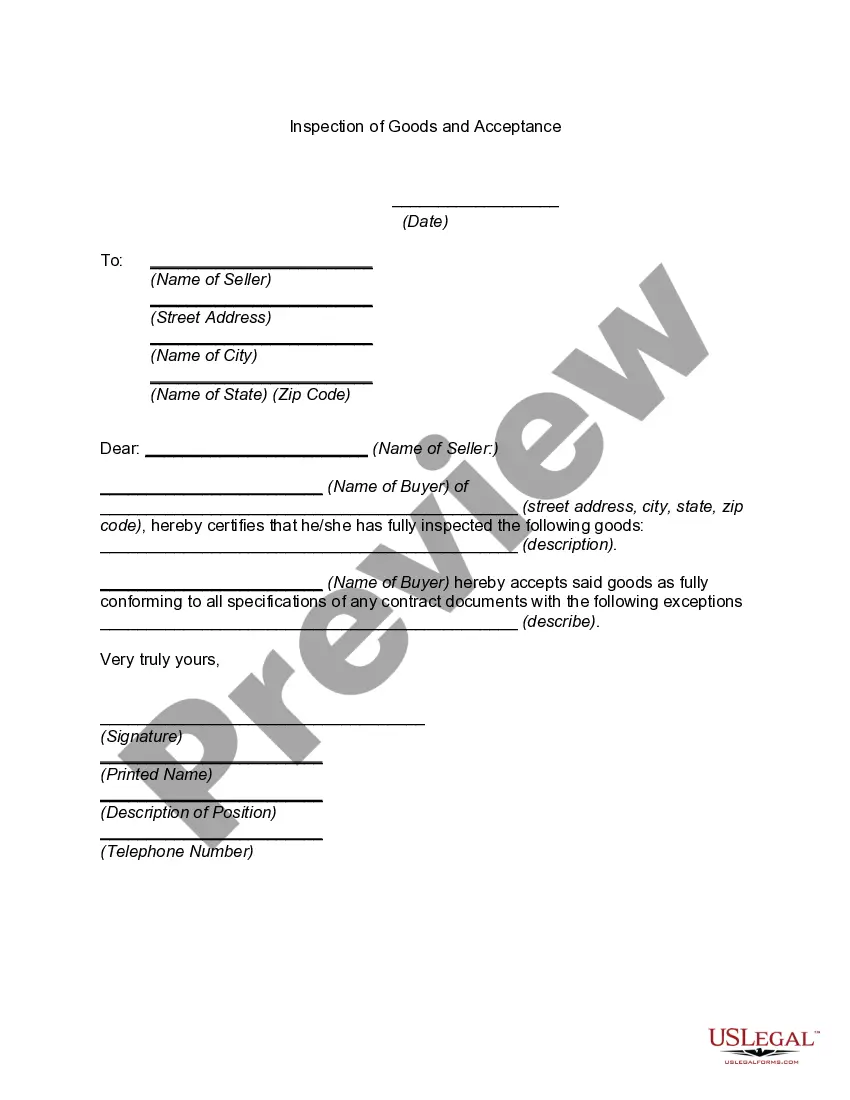

Mississippi Inspection of Goods and Acceptance

Description

How to fill out Inspection Of Goods And Acceptance?

Are you currently in a position where you require documents for either business or personal purposes almost every workday.

There are numerous legitimate document templates available online, but finding reliable versions is not easy.

US Legal Forms offers thousands of form templates, including the Mississippi Inspection of Goods and Acceptance, which are designed to comply with federal and state regulations.

Once you find the appropriate document, click Get now.

Select your preferred payment plan, enter the necessary information to create your account, and complete your purchase using PayPal or a credit card. Choose a convenient document format and download your copy. Access all the document templates you have purchased in the My documents section. You can obtain another copy of the Mississippi Inspection of Goods and Acceptance at any time if required. Just click the desired form to download or print the document template. Utilize US Legal Forms, the most comprehensive collection of legitimate documents, to save time and prevent errors. The service offers professionally crafted legal document templates that can be used for a variety of purposes. Create an account on US Legal Forms and start simplifying your life.

- If you are already familiar with the US Legal Forms website and possess an account, simply Log In.

- After that, you can download the Mississippi Inspection of Goods and Acceptance template.

- If you do not have an account and wish to start using US Legal Forms, follow these steps.

- Locate the form you need and verify it is suitable for your specific state/region.

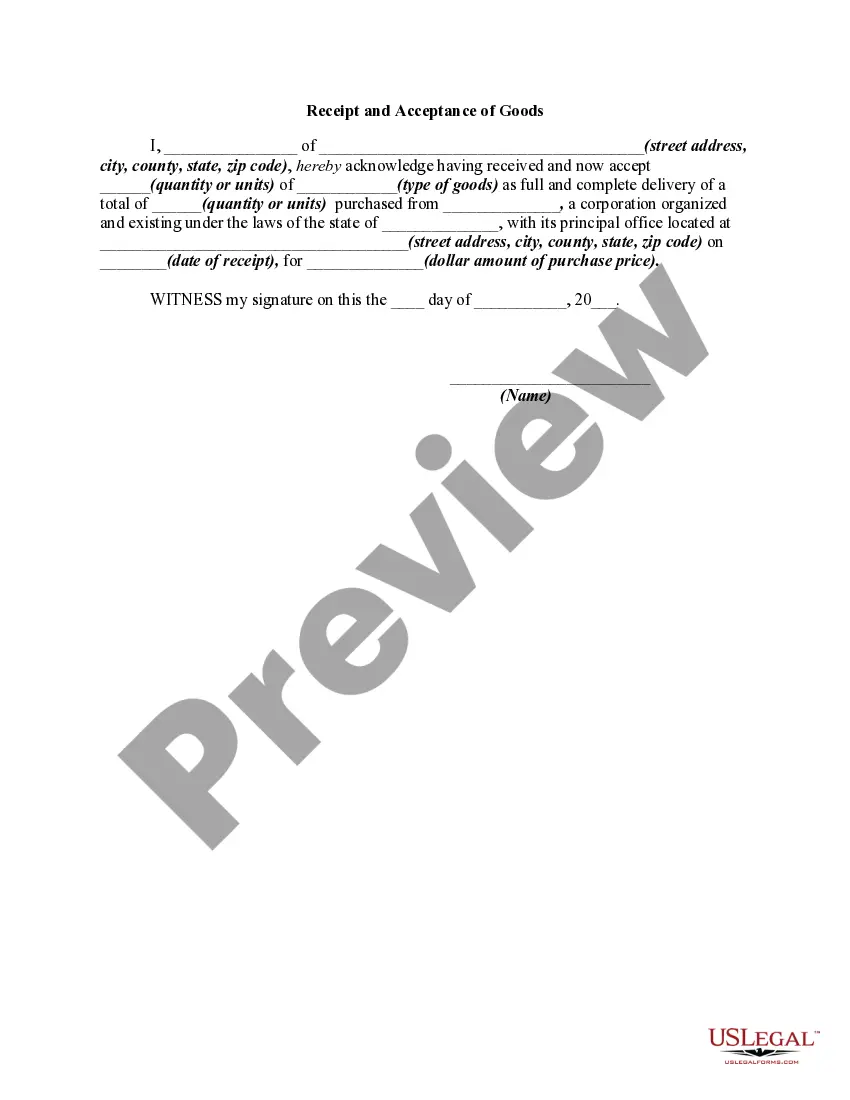

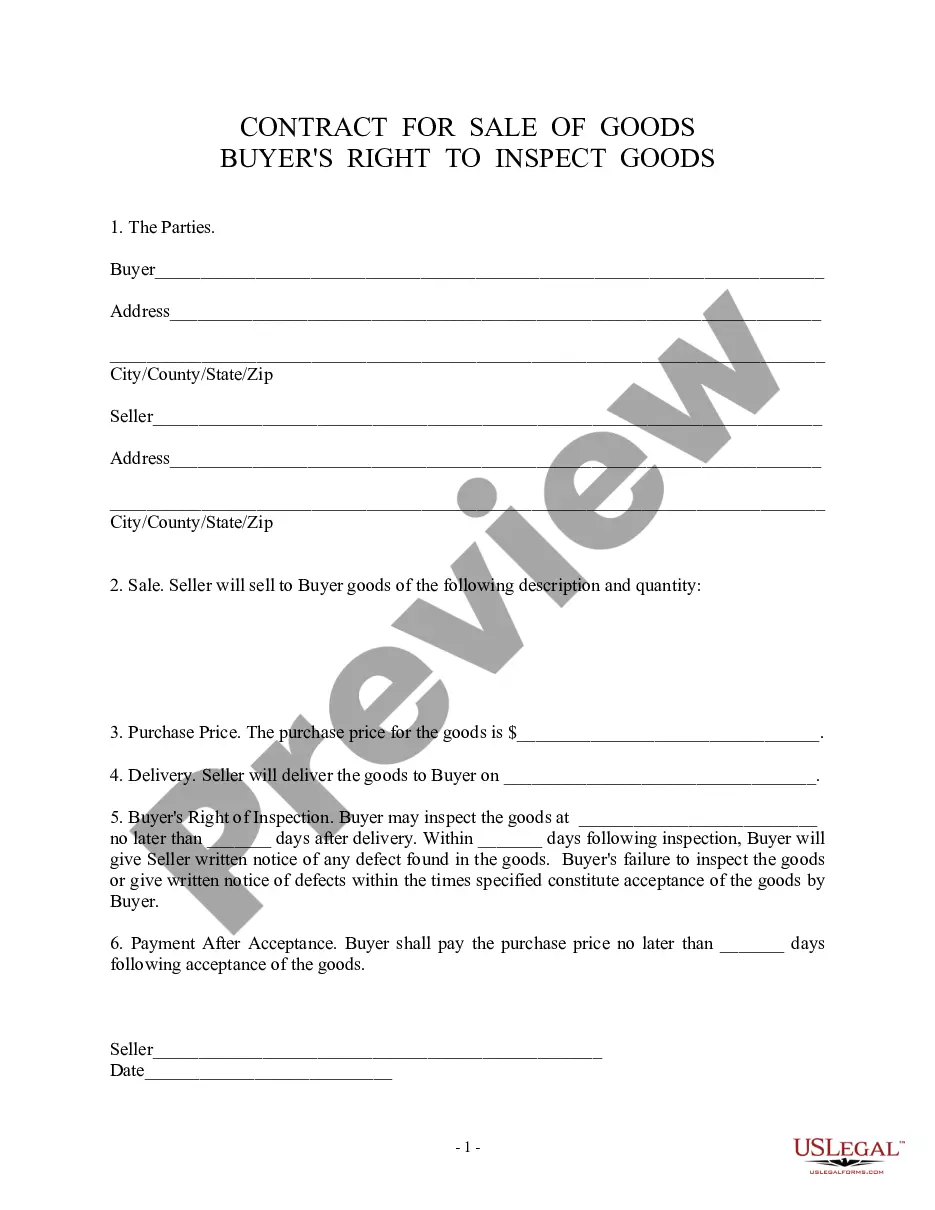

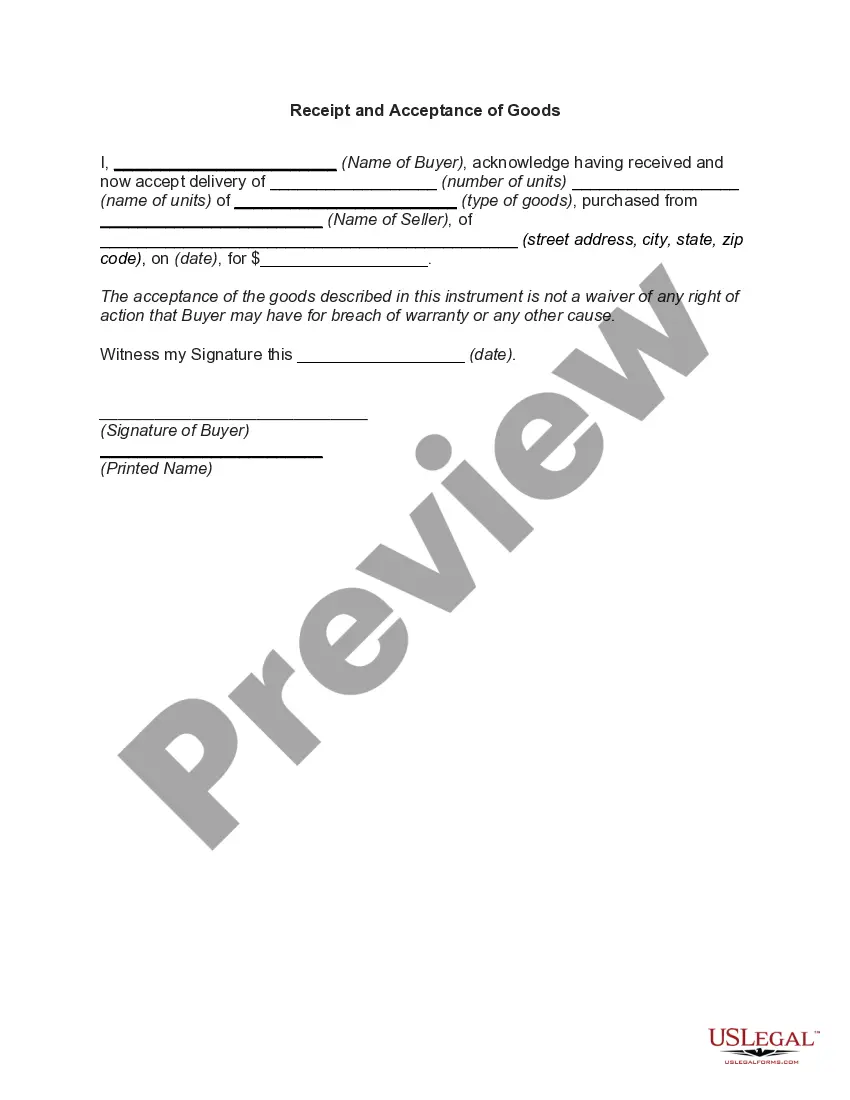

- Utilize the Review button to examine the document.

- Check the description to confirm that you have chosen the correct form.

- If the form is not what you are looking for, use the Search field to find the template that fits your requirements.

Form popularity

FAQ

Under Article 2, if the goods 'fail in any respect to conform to the contract,' then the buyer can reject the goods. Rejection simply means that the buyer refuses, or doesn't keep, the goods.

Under the UCC, the primary obligation of a buyer of goods is to pay for the goods. The general rule is that the buyer must accept and pay for the goods when the seller has deliveredor, to use more technical language, tendered delivery ofthe goods.

Rejection and a Buyer's Duties after Rejection Under UCC, Section 2-601(a), rejection is allowed if the seller fails to make a perfect tender. The rejection must be made within a reasonable time after delivery or tender. Once it is made, the buyer may not act as the owner of the goods.

If no such period has been agreed, the buyer must inspect the goods in a timely manner and notify the seller of any defects within a reasonable period after he has discovered or ought to have discovered them, at the latest within two years of receipt of the goods.

(1) Unless otherwise agreed and subject to subsection (3), where goods are tendered or delivered or identified to the contract for sale, the buyer has a right before payment or acceptance to inspect them at any reasonable place and time and in any reasonable manner.

1) Where the seller delivers to the buyer a quantity of goods less than he contracted to sell, the buyer may reject them, but if the buyer accept the goods so delivered he shall pay for them at the contract rate.

(2) Revocation of acceptance must occur within a reasonable time after the buyer discovers or should have discovered the ground for it and before any substantial change in condition of the goods which is not caused by their own defects. It is not effective until the buyer notifies the seller of it.

The rejection must be made within a reasonable time after delivery or tender. Once it is made, the buyer may not act as the owner of the goods. If he has taken possession of the goods before he rejects them, he must hold them with reasonable care to permit the seller to remove them.

In the absence of an express or fixed time established by the parties to an agreement or contract (especially one that falls under the purview of the UNIFORM COMMERCIAL CODE UCC), any time which is not manifestly unreasonable under the circumstances.

According to the UCC, acceptance occurs when the buyer: after a reasonable opportunity to inspect the goods indicates to the seller that the goods are conforming or that he or she will take them in spite of any non-conformity. does not reject the goods after a reasonable time for inspection has passed; or.