Mississippi Maintenance Engineer Checklist is a comprehensive document that outlines the various tasks and responsibilities performed by maintenance engineers in the state of Mississippi. This checklist acts as a guide for maintenance engineers to ensure that all necessary procedures are followed, equipment is properly maintained, and safety standards are upheld. The checklist includes a wide range of maintenance tasks that should be performed regularly. These tasks can vary depending on the specific industry and facility where the maintenance engineer is employed. However, some common keywords and categories that are typically included in the Mississippi Maintenance Engineer Checklist are: 1. Equipment Maintenance: — Inspect and maintain machinery, tools, and equipment. — Check for any signs of wear and tear or damage. — Clean and lubricate equipment as necessary. — Ensure proper working condition and functionality. 2. Preventive Maintenance: — Perform routine inspections to identify potential issues. — Schedule regular maintenance tasks to prevent breakdowns. — Check and replace any worn-out parts— - Follow manufacturer guidelines for maintenance. 3. Safety Measures: — Follow established safety protocols and guidelines. — Conduct regular audits of safety equipment. — Ensure compliance with state and federal safety regulations. — Train staff on safety procedures. 4. Facility Maintenance: — Inspect and maintain the overall facility, including electrical systems, plumbing, HVAC systems, etc. — Repair or replace any faulty equipment or systems. — Monitor energy consumption and recommend energy-saving initiatives. — Oversee the cleanliness and organization of the facility. 5. Documentation: — Maintain detailed records of maintenance activities performed. — Document any repairs, replacements, or changes to equipment. — Keep an inventory of spare parts and supplies. — Create reports and summaries of maintenance work. In addition to the general Mississippi Maintenance Engineer Checklist, there may be specific checklists designed for different industries or types of facilities. For example: 1. Manufacturing Facility Maintenance Engineer Checklist: — Focuses on maintenance tasks specific to manufacturing equipment. — Includes tasks related to production line maintenance, calibration of machines, etc. 2. Healthcare Facility Maintenance Engineer Checklist: — Emphasizes maintenance tasks relevant to healthcare facilities, such as medical equipment, HVAC systems, and emergency generators. — Includes strict adherence to cleanliness and infection control standards. 3. Hospitality Facility Maintenance Engineer Checklist: — Highlights tasks relevant to hotels, resorts, or hospitality establishments. — Includes maintenance of guest rooms, common areas, swimming pools, HVAC systems, etc. Overall, the Mississippi Maintenance Engineer Checklist provides a detailed roadmap for maintenance engineers to ensure the efficient operation of various facilities in the state while prioritizing safety and equipment longevity.

Mississippi Maintenance Engineer Checklist

Description

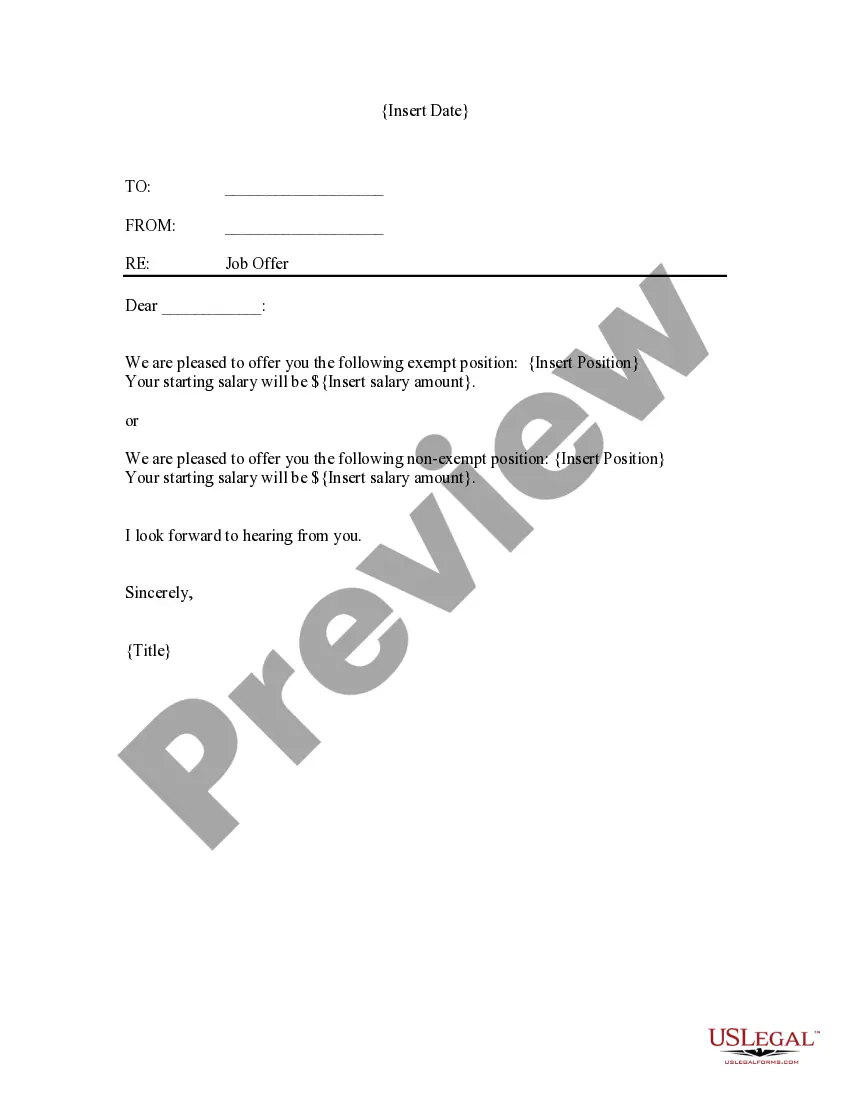

How to fill out Mississippi Maintenance Engineer Checklist?

Are you presently inside a situation the place you need files for possibly organization or specific uses nearly every day? There are a lot of legal file web templates available on the Internet, but discovering kinds you can depend on is not easy. US Legal Forms delivers thousands of form web templates, just like the Mississippi Maintenance Engineer Checklist, that happen to be published to meet state and federal needs.

Should you be presently knowledgeable about US Legal Forms internet site and get a free account, merely log in. Following that, it is possible to acquire the Mississippi Maintenance Engineer Checklist design.

Should you not provide an profile and want to start using US Legal Forms, abide by these steps:

- Obtain the form you will need and make sure it is to the appropriate city/area.

- Take advantage of the Review key to check the shape.

- Look at the description to ensure that you have chosen the appropriate form.

- If the form is not what you are seeking, utilize the Search field to obtain the form that meets your requirements and needs.

- If you obtain the appropriate form, simply click Get now.

- Choose the prices strategy you want, fill out the desired information to generate your money, and pay money for an order utilizing your PayPal or credit card.

- Select a handy data file formatting and acquire your duplicate.

Get all the file web templates you might have purchased in the My Forms menus. You may get a more duplicate of Mississippi Maintenance Engineer Checklist any time, if required. Just select the needed form to acquire or printing the file design.

Use US Legal Forms, one of the most considerable collection of legal forms, in order to save efforts and steer clear of faults. The service delivers appropriately created legal file web templates which you can use for a range of uses. Produce a free account on US Legal Forms and commence generating your way of life a little easier.