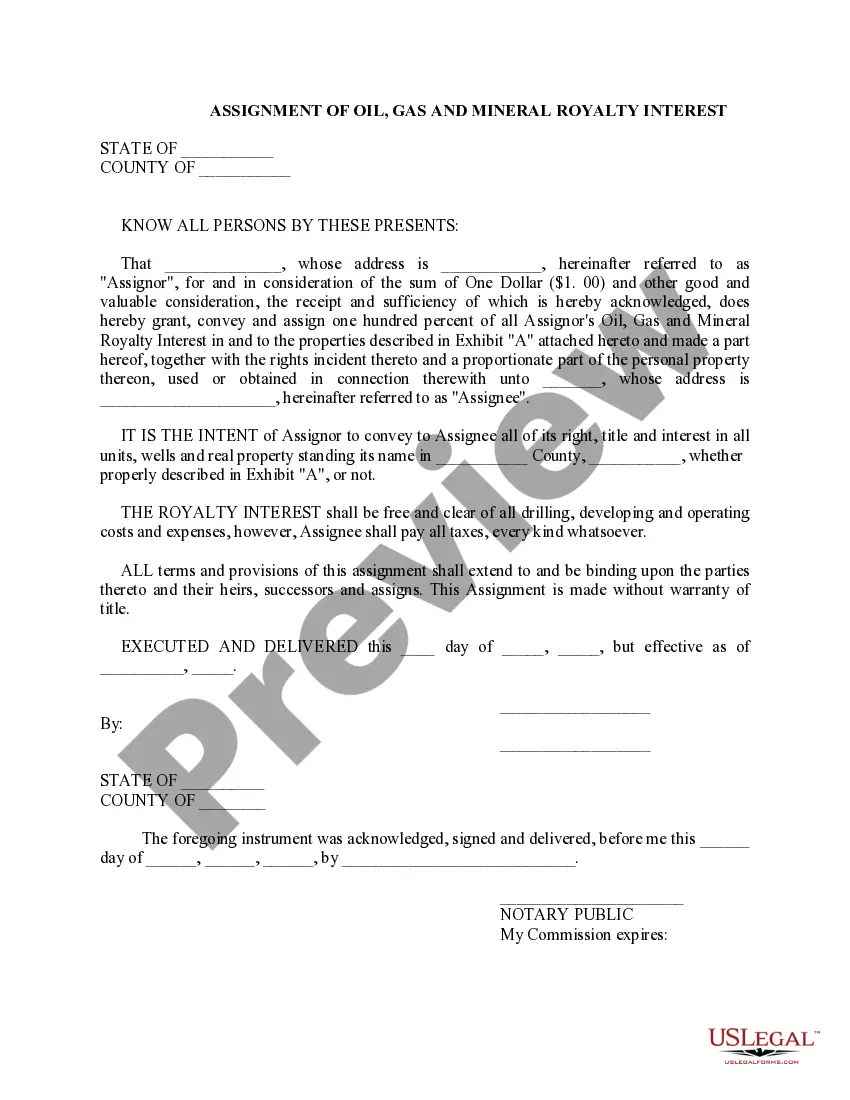

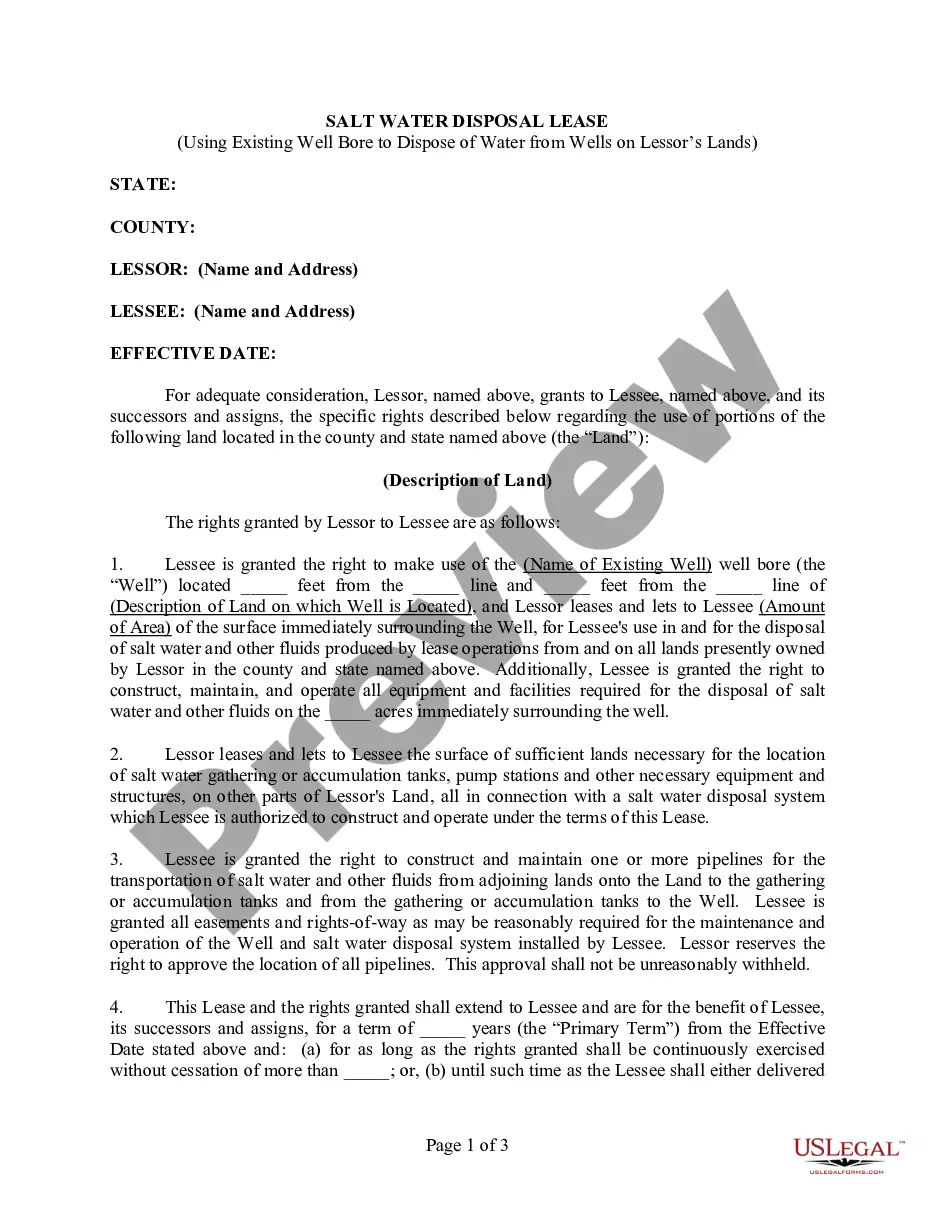

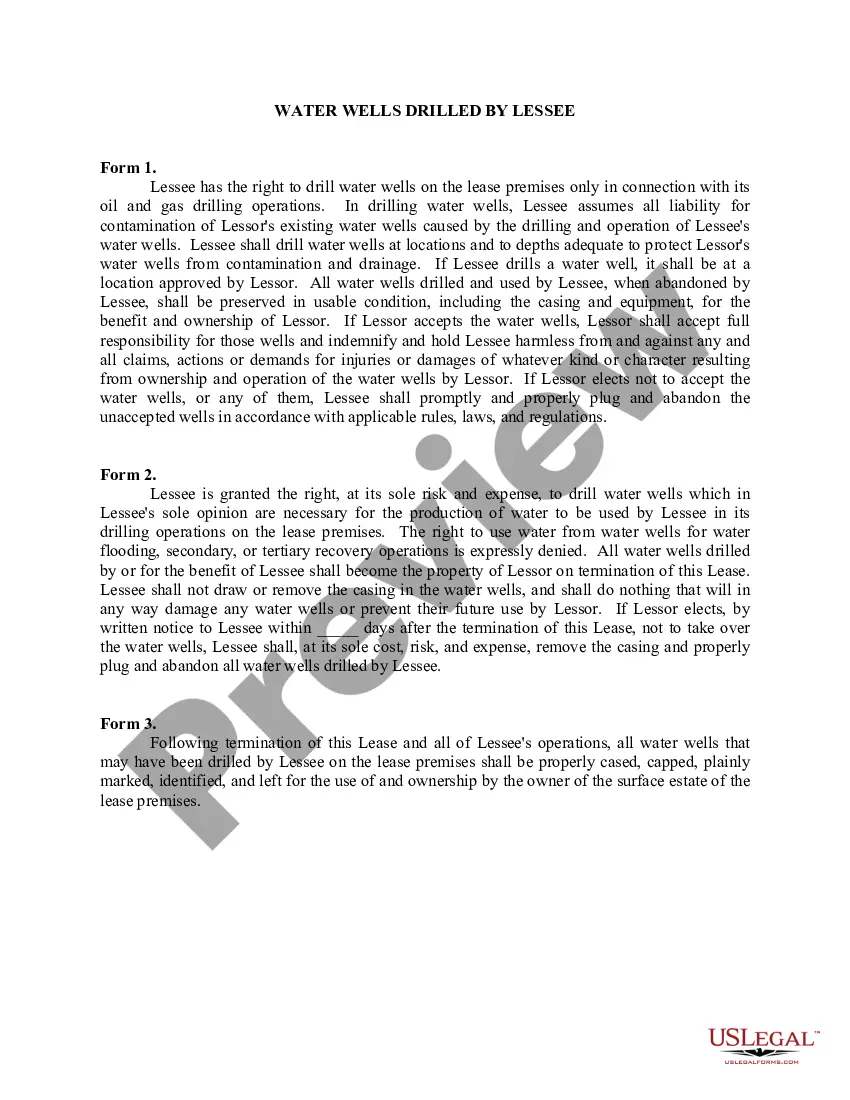

This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

Mississippi Conversion of An Oil Or Gas Well to An injection Or Water Well

Description

How to fill out Conversion Of An Oil Or Gas Well To An Injection Or Water Well?

Choosing the right legitimate document web template can be a battle. Naturally, there are a lot of layouts available online, but how can you obtain the legitimate form you require? Utilize the US Legal Forms website. The support gives thousands of layouts, including the Mississippi Conversion of An Oil Or Gas Well to An injection Or Water Well, which can be used for enterprise and personal demands. Every one of the forms are examined by pros and meet federal and state specifications.

If you are currently signed up, log in to the account and click on the Download button to find the Mississippi Conversion of An Oil Or Gas Well to An injection Or Water Well. Utilize your account to search through the legitimate forms you may have acquired previously. Check out the My Forms tab of your respective account and obtain another version in the document you require.

If you are a new consumer of US Legal Forms, here are basic directions that you should adhere to:

- First, make certain you have chosen the correct form for the city/county. It is possible to examine the form utilizing the Preview button and look at the form information to make certain this is the right one for you.

- In case the form fails to meet your expectations, make use of the Seach area to get the correct form.

- Once you are certain that the form is acceptable, click the Buy now button to find the form.

- Select the prices plan you need and enter the required info. Make your account and purchase the transaction with your PayPal account or charge card.

- Pick the data file file format and down load the legitimate document web template to the product.

- Full, revise and print and sign the acquired Mississippi Conversion of An Oil Or Gas Well to An injection Or Water Well.

US Legal Forms may be the biggest collection of legitimate forms in which you will find numerous document layouts. Utilize the company to down load expertly-manufactured papers that adhere to state specifications.

Form popularity

FAQ

To shut in a well means to make it not produce, so we'll start with a primer on production. When a well is ?producing? it means the well has been drilled, completed in a reservoir, and oil and/or gas is somehow moving up the wellbore and to the surface facility. What does it mean to shut-in a well? - Pecan Tree Oil & Gas Pecan Tree Oil & Gas ? blog ? 2020-5-29-wh... Pecan Tree Oil & Gas ? blog ? 2020-5-29-wh...

To shut in a well is to close off a well so that it stops producing. An emergency shutdown valve was installed on the wellhead to shut in the well at any time. The company had to shut in a well that began producing water in order to prevent contamination of the dry oil from other wells when production was commingled.

It can be proven that, for common types of pipe sticking (e.g., differential pressure, heaving, or sloughing shale), it is better to close in the well quickly, reduce the kick influx, and, thereby, reduce the chances of pipe sticking. Shut-in procedures for well control - PetroWiki PetroWiki ? Shut-in_procedures_for_we... PetroWiki ? Shut-in_procedures_for_we...

In the petroleum industry, shutting-in is the implementation of a production cap set lower than the available output of a specific site. This may be part of an attempt to constrict the oil supply or a necessary precaution when crews are evacuated ahead of a natural disaster. Shut-in (oil drilling) - Wikipedia wikipedia.org ? wiki ? Shut-in_(oil_drilling) wikipedia.org ? wiki ? Shut-in_(oil_drilling)

Impact on wells Any cessation of the extraction process may result in the clogging of this porous rock with sediment or paraffin, which means that production may permanently be reduced by half, or even stop completely, when pumping resumes.