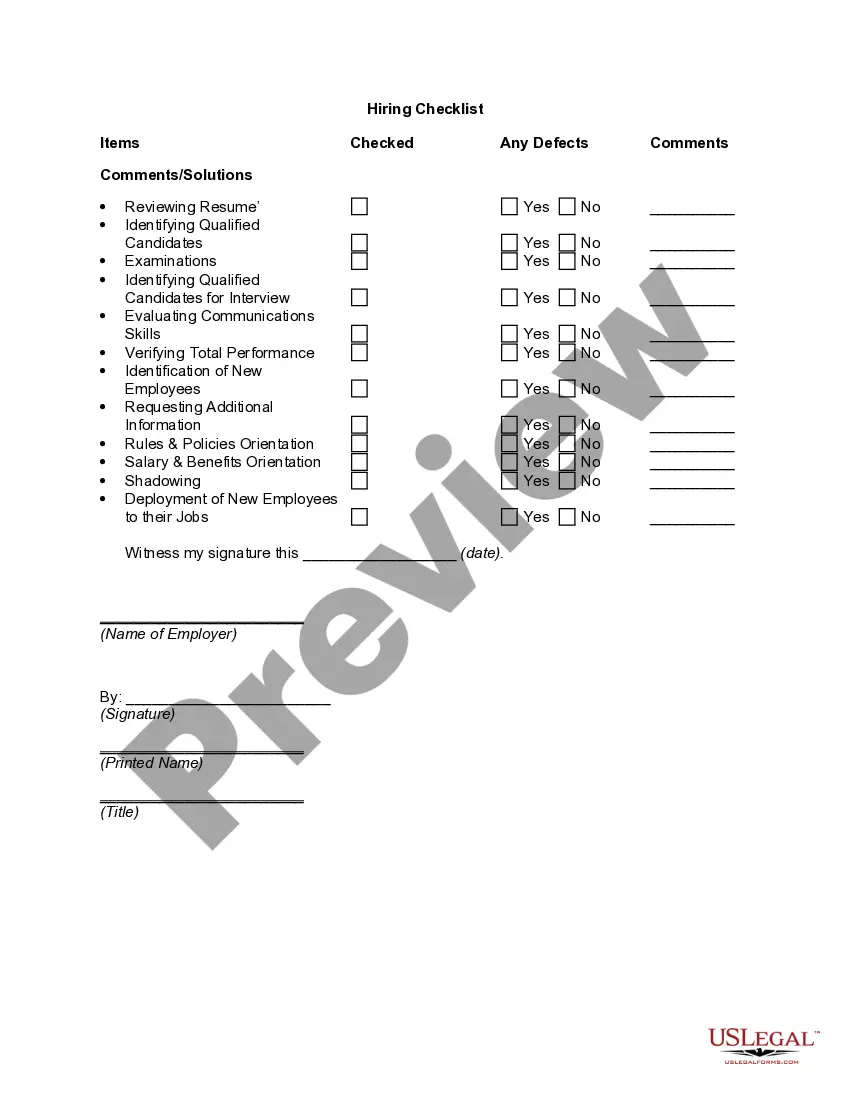

Montana Maintenance Assistance - Technician Checklist

Description

How to fill out Maintenance Assistance - Technician Checklist?

Discovering the right legitimate document web template can be quite a struggle. Naturally, there are a lot of layouts available online, but how do you get the legitimate form you require? Take advantage of the US Legal Forms site. The assistance offers thousands of layouts, like the Montana Maintenance Assistance - Technician Checklist, which can be used for organization and private requirements. Every one of the types are examined by experts and meet up with federal and state requirements.

In case you are already signed up, log in for your account and then click the Download button to have the Montana Maintenance Assistance - Technician Checklist. Make use of your account to search from the legitimate types you may have ordered previously. Proceed to the My Forms tab of the account and have another duplicate of the document you require.

In case you are a fresh consumer of US Legal Forms, listed here are straightforward instructions so that you can comply with:

- First, be sure you have selected the right form to your metropolis/region. You are able to examine the shape using the Review button and look at the shape information to make certain it is the best for you.

- If the form fails to meet up with your expectations, utilize the Seach field to find the appropriate form.

- Once you are positive that the shape is proper, select the Acquire now button to have the form.

- Opt for the rates strategy you desire and enter the necessary information. Build your account and purchase your order utilizing your PayPal account or Visa or Mastercard.

- Select the submit format and download the legitimate document web template for your device.

- Comprehensive, revise and print and sign the attained Montana Maintenance Assistance - Technician Checklist.

US Legal Forms is the largest catalogue of legitimate types in which you can find a variety of document layouts. Take advantage of the company to download expertly-produced paperwork that comply with state requirements.