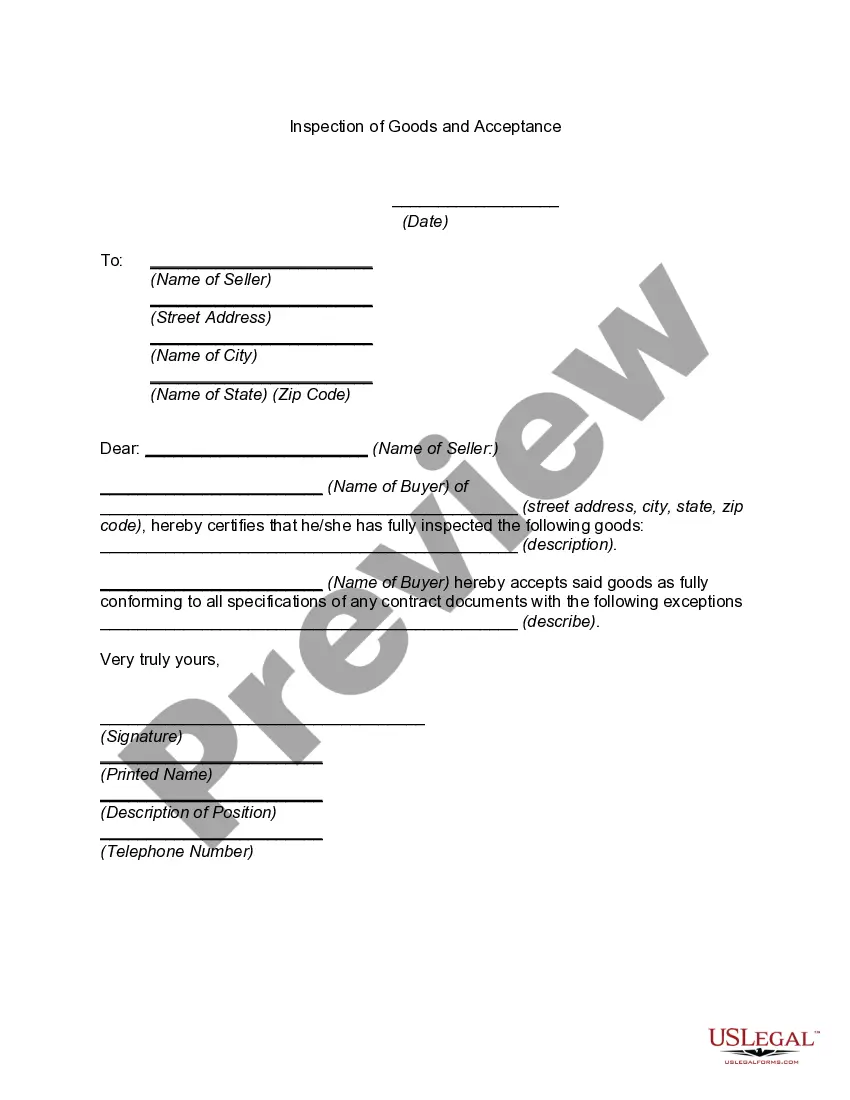

North Carolina Inspection of Goods and Acceptance plays a vital role in ensuring the quality, compliance, and safety of goods within the state. This process involves the examination, verification, and acceptance of various types of goods and materials to ensure they meet the required standards and specifications. The primary objective of North Carolina Inspection of Goods and Acceptance is to safeguard consumers, businesses, and the overall market integrity. It helps in preventing the distribution and sale of substandard or defective products, thereby ensuring customer satisfaction and trust. There are several types of inspections conducted under the North Carolina Inspection of Goods and Acceptance: 1. Pre-shipment Inspection: This type of inspection takes place before the goods are shipped to their final destination. Inspectors examine the goods and ensure that they meet the agreed-upon quality, quantity, and packing requirements. Pre-shipment inspection helps in minimizing the risk of receiving faulty or damaged goods. 2. In-process Inspection: This inspection occurs during the manufacturing or production process. Inspectors assess the goods at various stages to ensure compliance with specified standards, materials, and procedures. In-process inspection helps manufacturers identify and rectify any quality issues, ensuring that the final products meet the required specifications. 3. Post-arrival Inspection: This inspection happens after goods have arrived at their destination in North Carolina. Inspectors examine the goods for damage that may have occurred during transportation and verify their compliance with regulations and contractual agreements. Post-arrival inspection aims to identify any discrepancies or issues arising during transportation or handling. 4. Periodic Inspection: This type of inspection occurs periodically in businesses to ensure the continuing compliance of goods with regulations and standards. Inspectors assess the quality, safety, and reliability of products over time to maintain consumer protection and market integrity. During the North Carolina Inspection of Goods and Acceptance, inspectors evaluate various aspects such as product quality, labeling, packaging, weight, dimensions, and safety standards. They may also conduct tests, review documentation, and examine samples to ascertain compliance. Keywords: North Carolina, inspection of goods, acceptance, quality control, compliance, safety standards, pre-shipment inspection, in-process inspection, post-arrival inspection, periodic inspection, consumer protection, market integrity, product quality, labeling, packaging, weight, dimensions, testing, documentation, samples.

North Carolina Inspection of Goods and Acceptance

Description

How to fill out North Carolina Inspection Of Goods And Acceptance?

You may commit several hours on-line searching for the legal document design which fits the federal and state requirements you want. US Legal Forms supplies a large number of legal forms which can be examined by experts. You can actually obtain or printing the North Carolina Inspection of Goods and Acceptance from my services.

If you have a US Legal Forms profile, you can log in and click on the Obtain option. After that, you can complete, revise, printing, or indicator the North Carolina Inspection of Goods and Acceptance. Every single legal document design you buy is yours for a long time. To obtain yet another version of the acquired develop, visit the My Forms tab and click on the related option.

If you work with the US Legal Forms web site the very first time, adhere to the easy recommendations listed below:

- First, make sure that you have chosen the right document design to the area/town of your choice. Browse the develop explanation to make sure you have chosen the correct develop. If accessible, take advantage of the Review option to check with the document design too.

- If you wish to find yet another version of the develop, take advantage of the Look for discipline to obtain the design that fits your needs and requirements.

- Once you have found the design you want, click on Purchase now to carry on.

- Choose the costs strategy you want, enter your qualifications, and sign up for an account on US Legal Forms.

- Comprehensive the purchase. You should use your credit card or PayPal profile to fund the legal develop.

- Choose the formatting of the document and obtain it to your gadget.

- Make modifications to your document if needed. You may complete, revise and indicator and printing North Carolina Inspection of Goods and Acceptance.

Obtain and printing a large number of document layouts making use of the US Legal Forms Internet site, that provides the most important collection of legal forms. Use specialist and condition-certain layouts to handle your company or person demands.