North Carolina Maintenance Assistance — Technician Checklist is a comprehensive document designed to ensure timely and efficient maintenance of equipment and machinery across various industries in the state of North Carolina. It provides a detailed outline of tasks and procedures to be followed by maintenance technicians to guarantee the proper functioning and longevity of equipment. Key tasks covered in the North Carolina Maintenance Assistance — Technician Checklist include: 1. Conducting regular equipment inspections: Technicians must inspect machinery and equipment regularly to identify potential issues and address them promptly. This ensures uninterrupted workflow and minimizes any risks associated with malfunctioning equipment. 2. Lubrication and greasing: Proper lubrication is essential for the smooth operation of machinery. The checklist outlines the recommended lubrication schedule and types of lubricants to be used for specific equipment, assisting technicians in maintaining optimal performance. 3. Cleaning and dusting: Regular cleaning and dusting of equipment prevent the accumulation of debris and prolong their lifespan. The checklist specifies the cleaning procedures, suitable cleaning agents, and frequency required for different types of machinery. 4. Calibration and adjustments: Technicians must periodically calibrate and make necessary adjustments to maintain the accuracy and precision of equipment. The checklist provides guidelines for calibration procedures and highlights the importance of maintaining equipment within specified tolerances. 5. Component inspection and replacement: Wear and tear of components can lead to reduced efficiency and potential breakdowns. The checklist instructs technicians on inspecting critical components, such as belts, filters, seals, and bearings, identifying signs of damage or wear, and replacing them if necessary. 6. Electrical system checks: Technicians perform inspections and tests to ensure the electrical system is safe and functioning correctly. This includes verifying wiring connections, checking for electrical faults, inspecting circuit breakers, and assessing grounding systems. Types of North Carolina Maintenance Assistance — Technician Checklists may vary depending on the specific industry or equipment being serviced. Some examples include: 1. Manufacturing Maintenance Assistance — Technician Checklist: Tailored for maintenance technicians in manufacturing plants, this checklist may cover specialized equipment, such as CNC machines, presses, conveyors, and robotics. 2. Facility Maintenance Assistance — Technician Checklist: Focused on maintenance tasks required for commercial buildings, this checklist may include HVAC systems, plumbing, lighting, fire safety equipment, and general facility maintenance. 3. Automotive Maintenance Assistance — Technician Checklist: Primarily designed for automotive repair shops, this checklist guides technicians in conducting routine maintenance, inspections, and repairs on vehicles, including engine diagnostics, brake systems, and suspension components. These are just a few examples, and North Carolina Maintenance Assistance — Technician Checklists can be adapted to various industries and equipment categories, ensuring that maintenance technicians have a structured and organized approach to keep equipment in optimal condition.

North Carolina Maintenance Assistance - Technician Checklist

Description

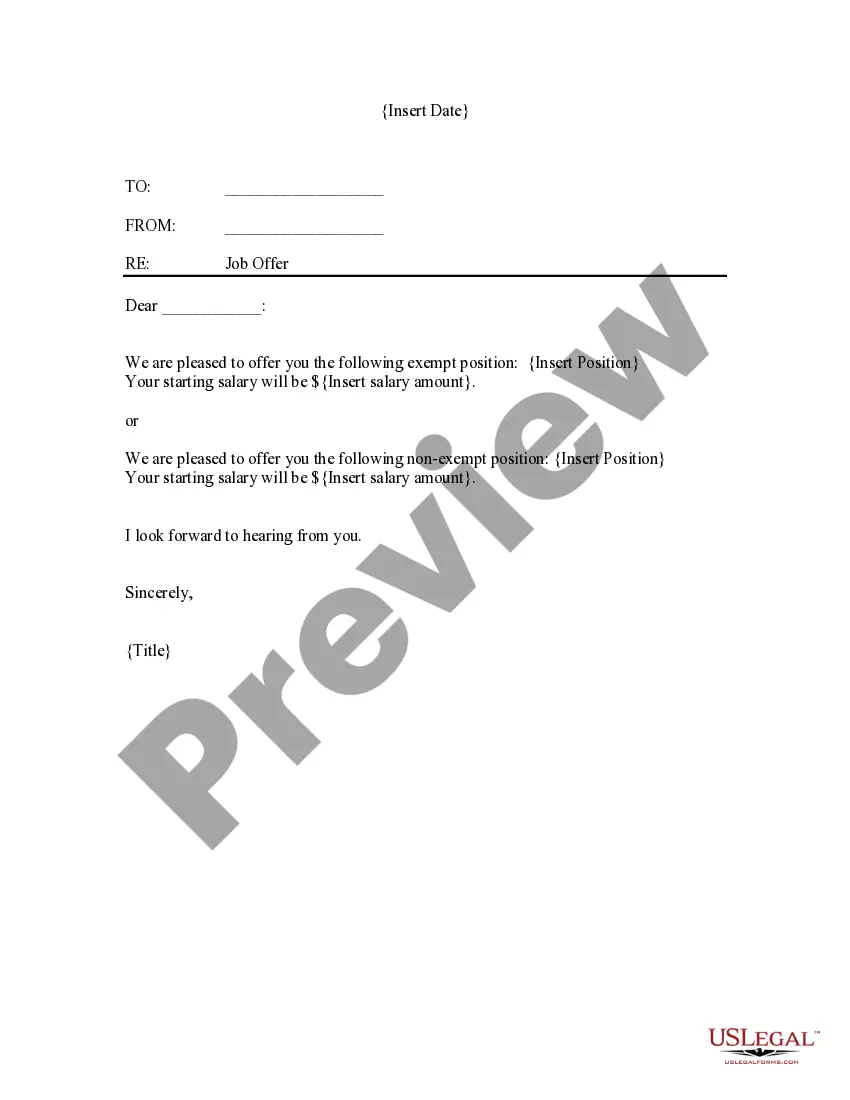

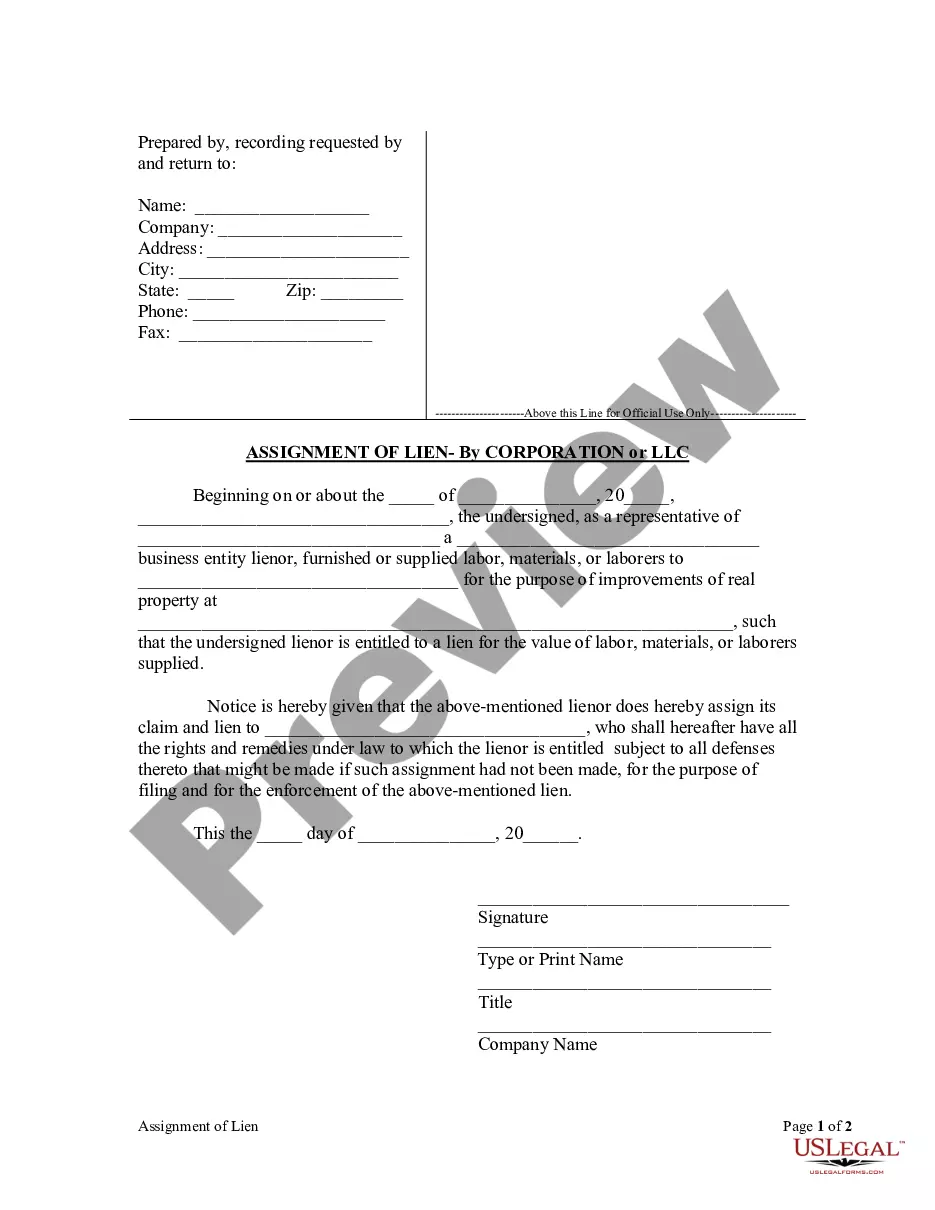

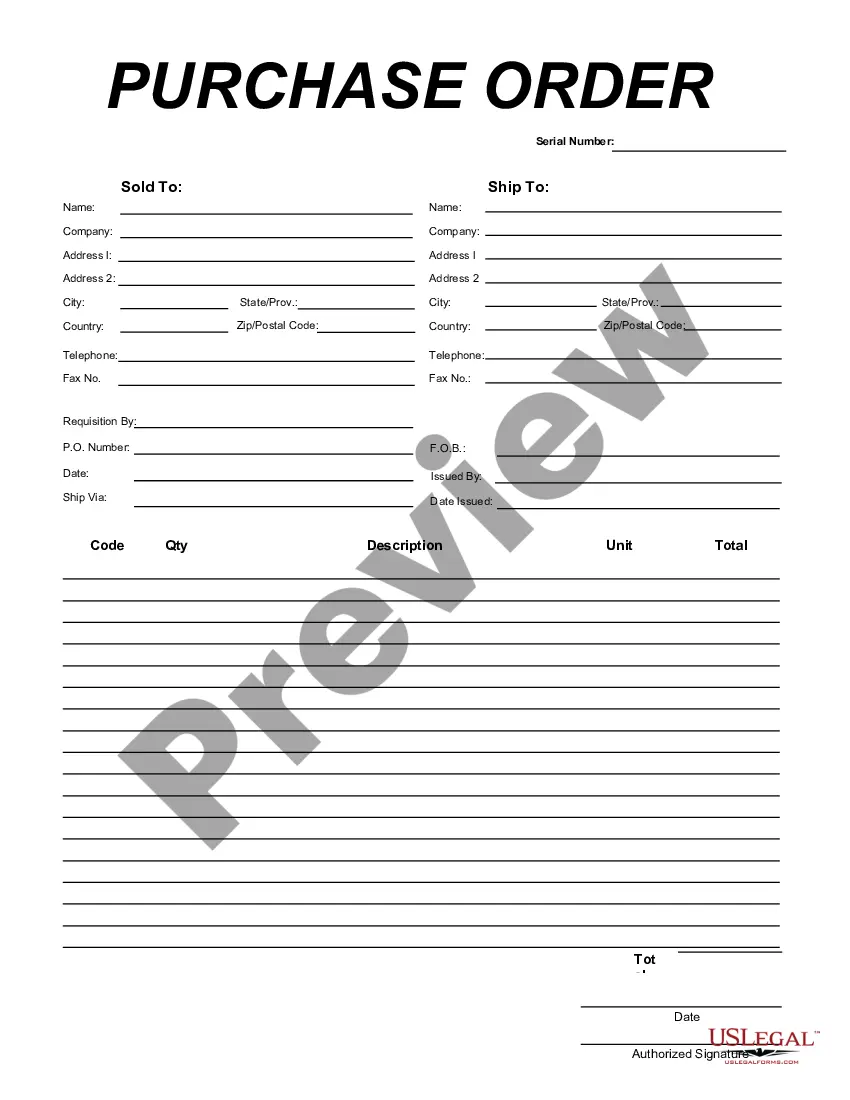

How to fill out North Carolina Maintenance Assistance - Technician Checklist?

You are able to spend hrs on the web attempting to find the authorized papers design that fits the federal and state needs you need. US Legal Forms provides 1000s of authorized types that are reviewed by experts. It is simple to obtain or print the North Carolina Maintenance Assistance - Technician Checklist from our services.

If you currently have a US Legal Forms accounts, it is possible to log in and then click the Acquire switch. After that, it is possible to full, modify, print, or signal the North Carolina Maintenance Assistance - Technician Checklist. Each and every authorized papers design you buy is your own eternally. To obtain yet another version associated with a acquired form, go to the My Forms tab and then click the corresponding switch.

If you work with the US Legal Forms web site the first time, follow the easy instructions beneath:

- Very first, make certain you have chosen the correct papers design for your area/area of your choice. Look at the form description to make sure you have selected the proper form. If offered, use the Preview switch to look from the papers design also.

- If you would like discover yet another model of the form, use the Research industry to find the design that meets your requirements and needs.

- After you have located the design you would like, just click Acquire now to move forward.

- Choose the rates strategy you would like, type in your qualifications, and register for a free account on US Legal Forms.

- Complete the financial transaction. You may use your charge card or PayPal accounts to cover the authorized form.

- Choose the structure of the papers and obtain it for your gadget.

- Make modifications for your papers if necessary. You are able to full, modify and signal and print North Carolina Maintenance Assistance - Technician Checklist.

Acquire and print 1000s of papers web templates utilizing the US Legal Forms website, which provides the most important variety of authorized types. Use professional and status-distinct web templates to take on your business or individual needs.

Form popularity

FAQ

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

A preventive maintenance checklist is an itemized list of written tasks that guide technicians through a process of asset's preventive maintenance (PM).

Preventive maintenance, when performed regularly, can extend the lifespan of diesel trucks and improve fuel economy. It can also play an important role in sustaining a truck's value in resale, as buyers usually want to see the vehicle's full maintenance record before making their purchase.

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

For proper vehicle maintenance, inspect the following:OIL AND COOLANT LEVELS.AIR FILTER.TIRE PRESSURE AND TREAD DEPTH.HEADLIGHTS, TURN SIGNALS, BRAKE, AND PARKING LIGHTS.OIL & FILTER.ROTATE TIRES.WAX VEHICLE.TRANSMISSION FLUID.More items...?

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

The maintenance plan's contents, which include the actual work, instructions, schedule, workers, spare parts, and contractors, guide all the maintenance work activities. Read on to learn what you need to include in the plan and how to make it efficient.

In his book Uptime, author John Dixon Campbell defines the six steps of the maintenance planning and control cycle as follows:Identify the problem.Plan the maintenance task.Schedule the work.Allocate the task to specific people.Ensure the work is executed properly.More items...