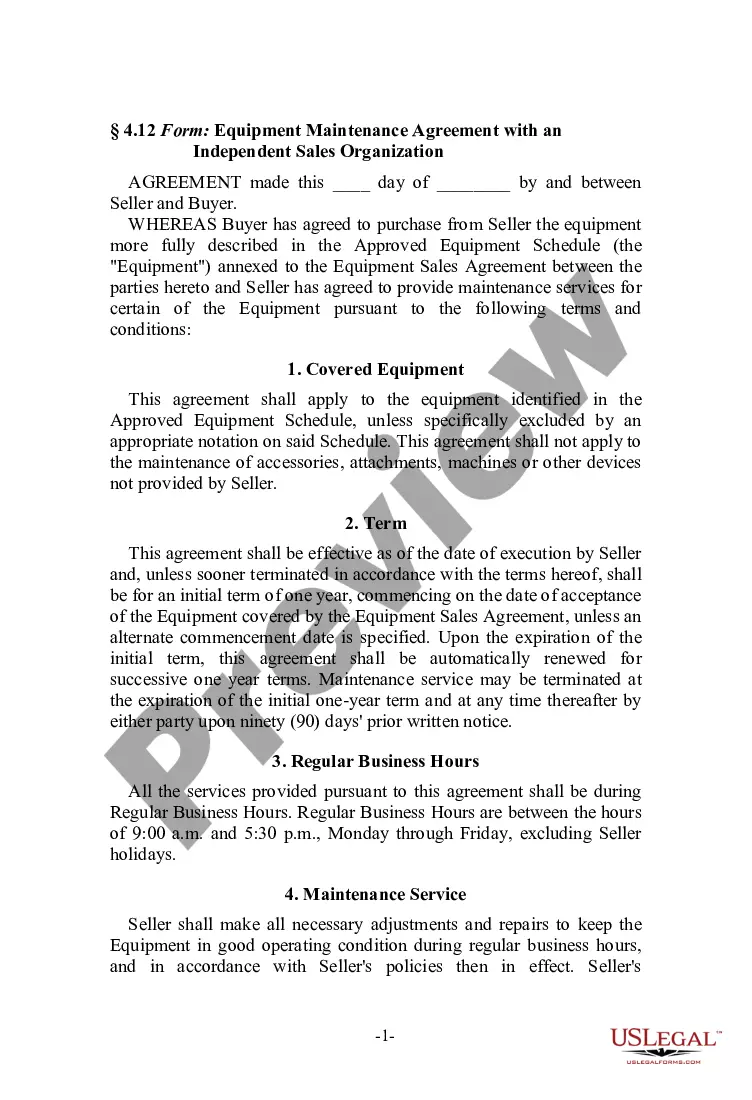

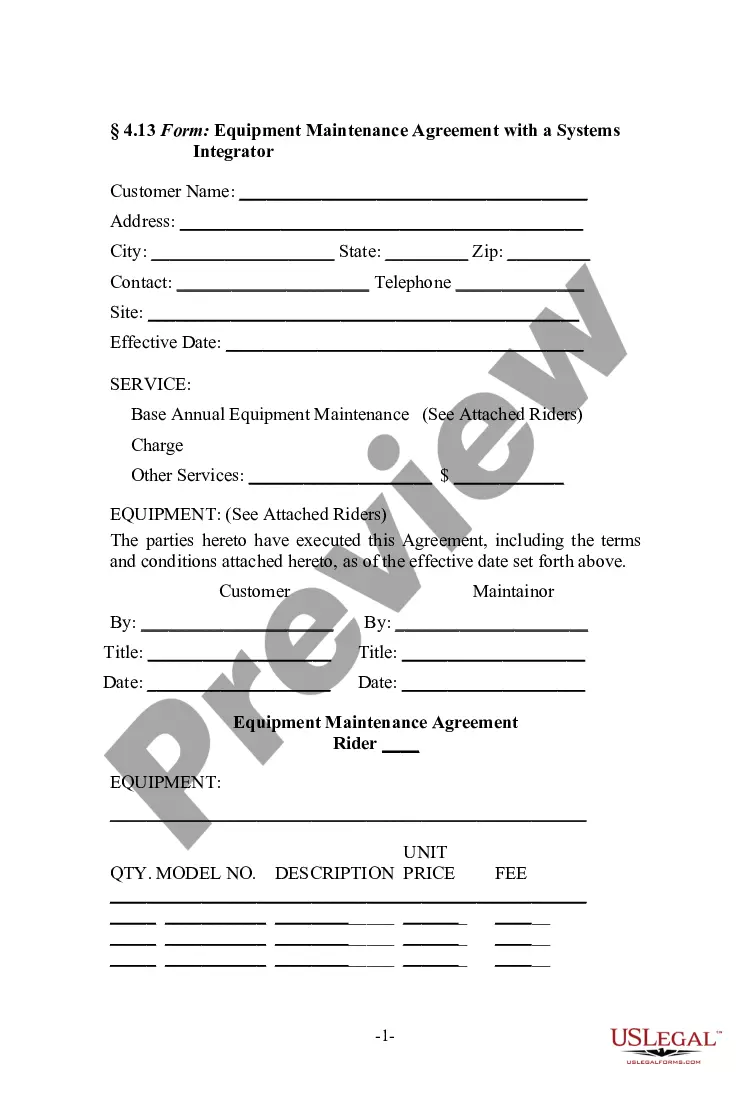

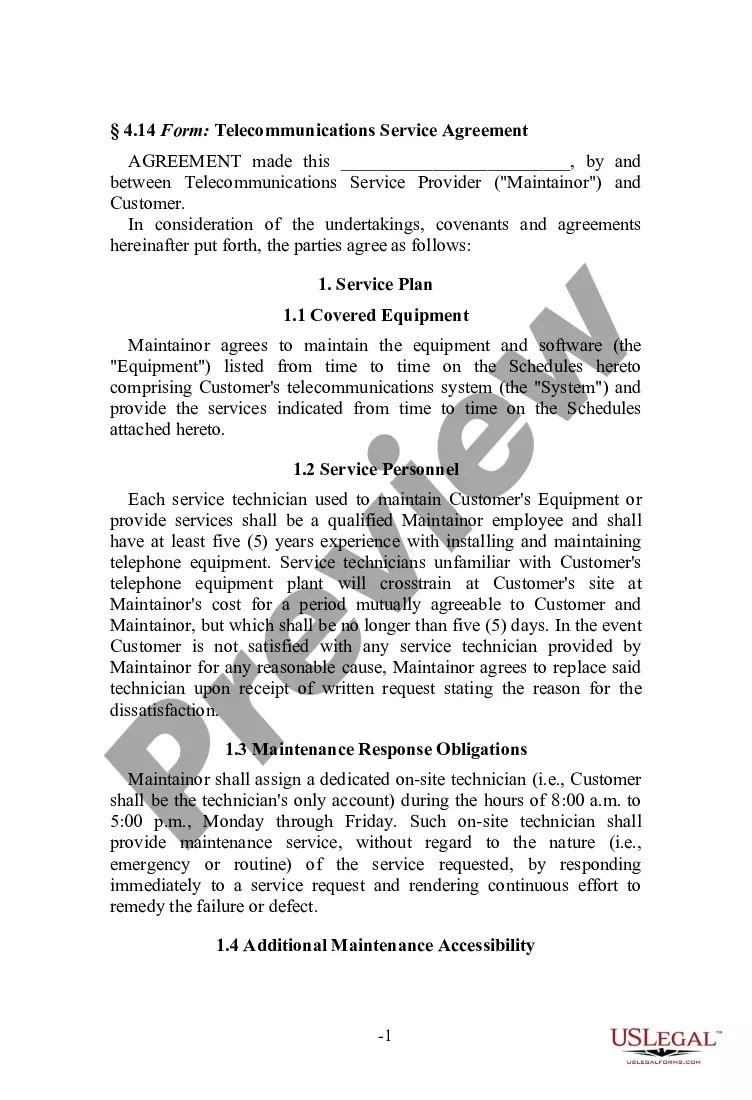

North Carolina Equipment Maintenance Agreement with a Manufacturer

Description

How to fill out Equipment Maintenance Agreement With A Manufacturer?

Are you within a place in which you need to have papers for sometimes business or individual functions just about every time? There are a variety of legal document templates available on the Internet, but locating ones you can trust is not easy. US Legal Forms offers a large number of form templates, like the North Carolina Equipment Maintenance Agreement with a Manufacturer, which are written to fulfill federal and state requirements.

In case you are presently acquainted with US Legal Forms internet site and get an account, just log in. After that, it is possible to acquire the North Carolina Equipment Maintenance Agreement with a Manufacturer design.

Should you not have an bank account and want to start using US Legal Forms, follow these steps:

- Get the form you want and ensure it is to the right metropolis/county.

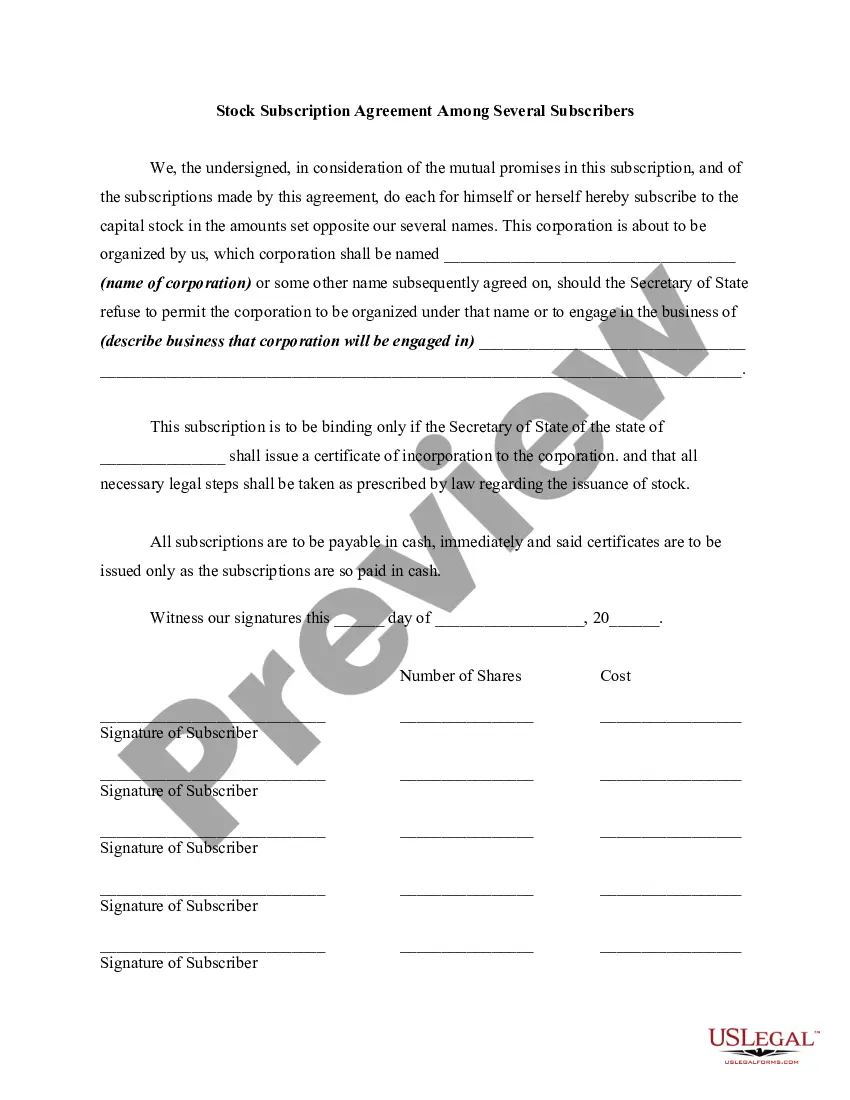

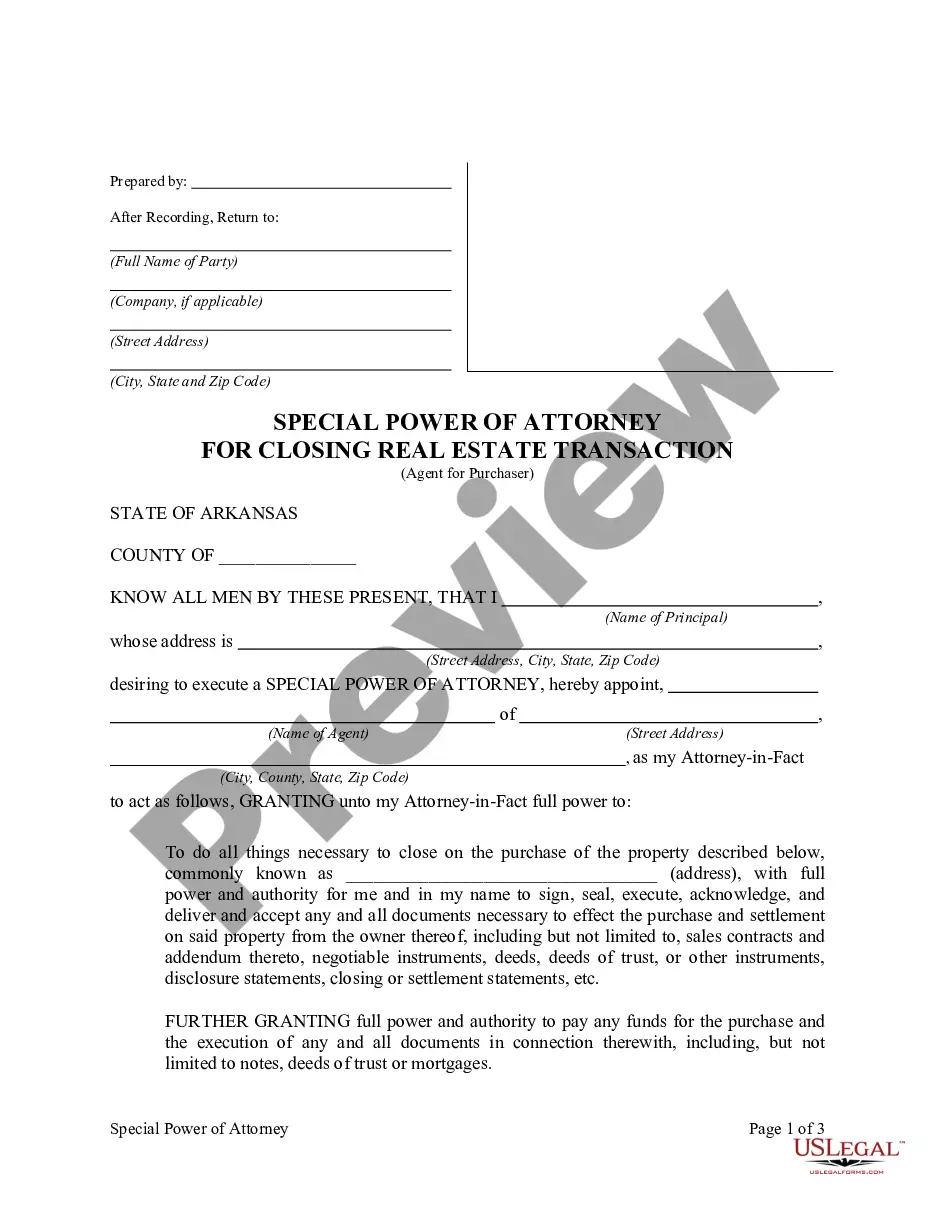

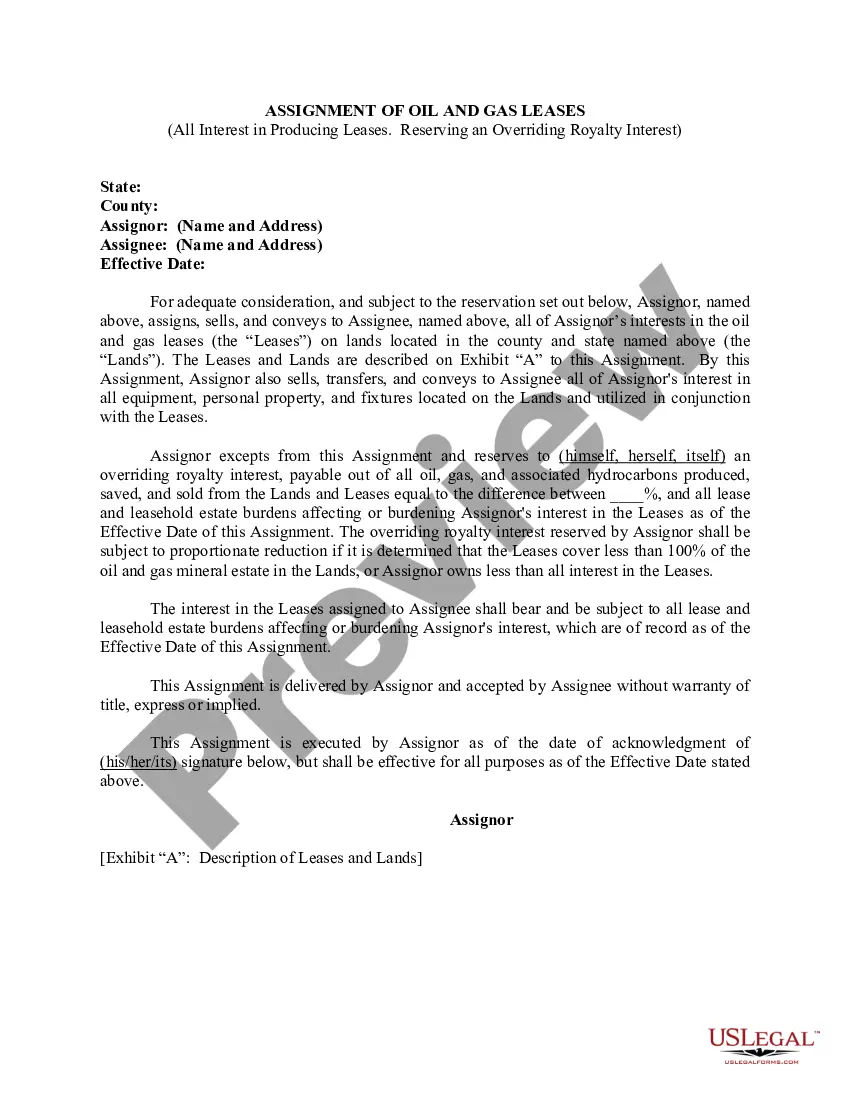

- Take advantage of the Review switch to check the form.

- Look at the information to actually have chosen the correct form.

- When the form is not what you are searching for, utilize the Search industry to get the form that fits your needs and requirements.

- Once you discover the right form, click on Buy now.

- Opt for the rates prepare you desire, submit the necessary information and facts to produce your account, and pay for the transaction utilizing your PayPal or bank card.

- Decide on a practical file formatting and acquire your version.

Get each of the document templates you have purchased in the My Forms food list. You may get a additional version of North Carolina Equipment Maintenance Agreement with a Manufacturer any time, if required. Just select the needed form to acquire or print the document design.

Use US Legal Forms, by far the most substantial collection of legal types, in order to save time and prevent blunders. The support offers skillfully manufactured legal document templates that you can use for a selection of functions. Generate an account on US Legal Forms and start making your life easier.

Form popularity

FAQ

A maintenance agreement outlines the steps one party will undertake to insure the upkeep, repair, serviceability of another party's property. Maintenance contracts are commonly used by companies that take care of vehicle fleets, industrial equipment, office and apartment buildings, computer networks, etc.

Preventive maintenance (PM) is the regular and routine maintenance of equipment and assets in order to keep them running and prevent any costly unplanned downtime from unexpected equipment failure. A successful maintenance strategy requires planning and scheduling maintenance of equipment before a problem occurs.

By Practical Law Commercial. A B2B agreement in which the supplier agrees to provide a maintenance and support service for equipment. The agreement is drafted to be broadly neutral between the parties. To access this resource, sign in below or register for a free, no-obligation trial.

Ways to create an equipment maintenance schedule Schedule work by date. We schedule maintenance work orders every ?X? days, weeks or months. ... Schedule work by meter reading. There are two different meter types. ... Schedule work by equipment alarms. ... Schedule work based on completion of other work.

A maintenance contract, defined as the contract between 2 parties which creates the agreement that one party will maintain an asset owned by another party, is common across many industries. Maintenance contracts can exist for equipment, a building, landscape, computers and other information technologies, and more.