North Dakota Contract Manufacturing Statement of Work is a legally binding document that outlines the specific scope, deliverables, timelines, and expectations for a manufacturing project conducted in North Dakota. This statement of work establishes a clear and detailed agreement between the manufacturer and the client, ensuring that both parties have a shared understanding of the project's objectives and requirements. Keywords: North Dakota, Contract Manufacturing, Statement of Work, legally binding, scope, deliverables, timelines, expectations, manufacturing project, agreement, objectives, requirements. Types of North Dakota Contract Manufacturing Statement of Work: 1. Product Manufacturing Statement of Work: This type of statement of work is used when a manufacturer is contracted to produce a specific product. It includes details about the product specifications, quality standards, production process, materials required, and any testing or quality assurance procedures. Additionally, it outlines the expected production quantities, packaging requirements, shipping terms, and other relevant components specific to the manufacturing of the product. 2. Assembly and Packaging Statement of Work: When a manufacturer is engaged to assemble components and package products, this type of statement of work comes into play. It outlines the scope of assembly work, ensuring that the manufacturer understands the precise steps and procedures required for assembling the product correctly. It also specifies the packaging and labeling requirements, ensuring that the finished product meets the client's expectations in terms of appearance and presentation. 3. Prototyping Statement of Work: In cases where a client requires the development of a prototype or a sample product before commencing full-scale manufacturing, a prototyping statement of work is utilized. This type of statement of work outlines the requirements for creating the prototype, including design specifications, materials to be used, proposed timeline, and any specific testing or qualification criteria. It serves as a blueprint for the manufacturer to follow in order to produce an accurate prototype that meets the intended functionality and appearance. 4. Contract Packaging Statement of Work: This type of statement of work is specific to contract packaging services. It outlines the terms, expectations, and responsibilities related to packaging products on behalf of a client. It includes details such as packaging specifications, labeling requirements, quality control procedures, storage and shipping instructions, and any additional services, like bundling or kitting, that may be required. Every type of North Dakota Contract Manufacturing Statement of Work aims to establish a comprehensive agreement between the manufacturer and the client, ensuring clarity, accountability, and alignment throughout the manufacturing process.

North Dakota Contract Manufacturing Statement of Work

Description

How to fill out North Dakota Contract Manufacturing Statement Of Work?

Finding the right legal file format could be a struggle. Naturally, there are a lot of themes available on the Internet, but how would you find the legal form you require? Use the US Legal Forms site. The assistance gives thousands of themes, for example the North Dakota Contract Manufacturing Statement of Work, which you can use for business and private needs. All the kinds are checked by experts and fulfill federal and state needs.

In case you are already authorized, log in for your account and click the Down load button to find the North Dakota Contract Manufacturing Statement of Work. Make use of account to look throughout the legal kinds you have ordered formerly. Proceed to the My Forms tab of your own account and get yet another copy in the file you require.

In case you are a whole new end user of US Legal Forms, listed here are basic recommendations for you to stick to:

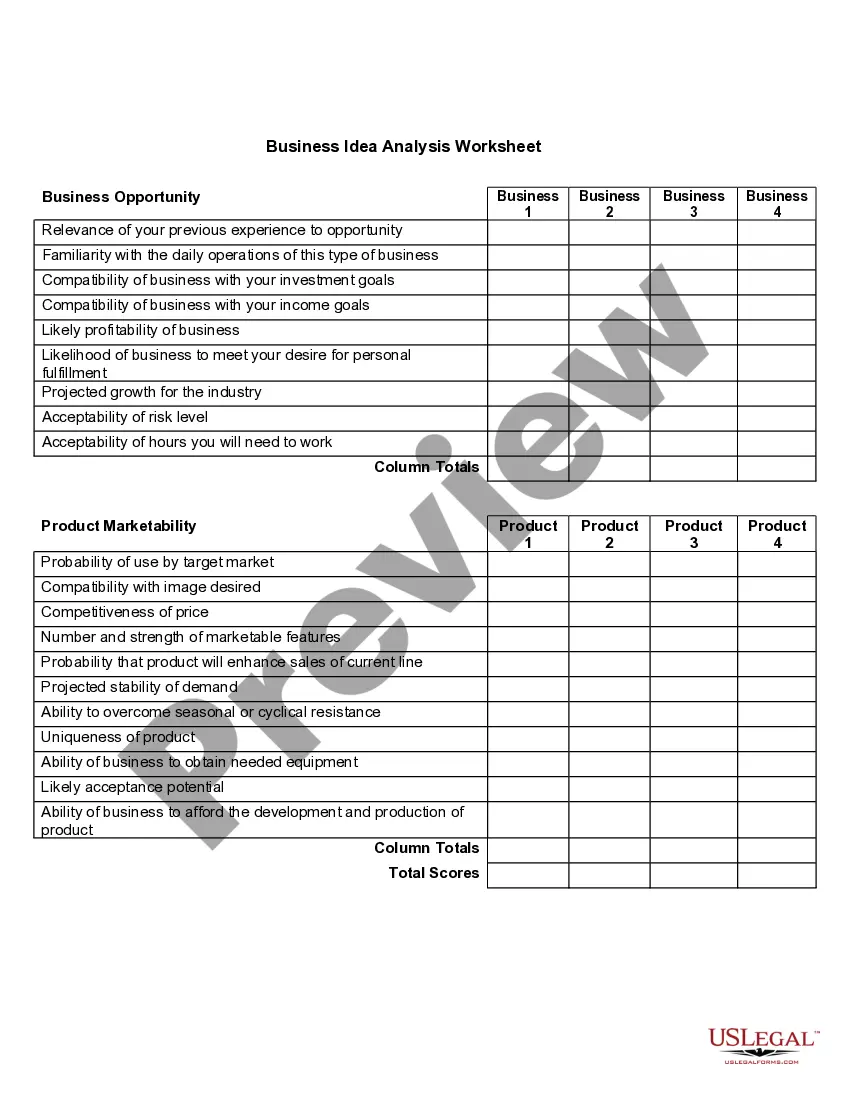

- Initially, ensure you have selected the appropriate form for your personal area/state. You may check out the shape using the Review button and study the shape outline to make sure it will be the best for you.

- When the form is not going to fulfill your expectations, use the Seach field to discover the appropriate form.

- When you are certain that the shape is acceptable, click on the Get now button to find the form.

- Select the pricing prepare you want and enter the essential information. Design your account and buy an order using your PayPal account or credit card.

- Pick the submit structure and obtain the legal file format for your gadget.

- Full, modify and print and indication the obtained North Dakota Contract Manufacturing Statement of Work.

US Legal Forms is the most significant catalogue of legal kinds in which you can see a variety of file themes. Use the service to obtain appropriately-made documents that stick to state needs.