North Dakota Physical Inventory Count Sheet

Description

How to fill out Physical Inventory Count Sheet?

If you need to compile, acquire, or create sanctioned document templates, utilize US Legal Forms, the foremost repository of legal documents available online.

Make use of the website's straightforward and convenient search feature to find the documents you require.

A selection of templates for business and personal purposes is organized by categories and states, or keywords.

Step 4. After locating the document you need, click the Download now button. Choose the payment plan you prefer and input your details to register for an account.

Step 5. Process the payment. You can use your credit card or PayPal account to complete the transaction.

- Employ US Legal Forms to obtain the North Dakota Physical Inventory Count Sheet with just a few clicks.

- If you are already a US Legal Forms user, Log In to your account and click on the Download button to acquire the North Dakota Physical Inventory Count Sheet.

- You can also access documents you previously received from the My documents section of your account.

- If this is your first time using US Legal Forms, follow the guide below.

- Step 1. Ensure you've chosen the form for the correct city/state.

- Step 2. Use the Preview option to examine the document's details. Don't forget to review the summary.

- Step 3. If you're not satisfied with the document, use the Search field at the top of the screen to find alternative templates within the legal forms repository.

Form popularity

FAQ

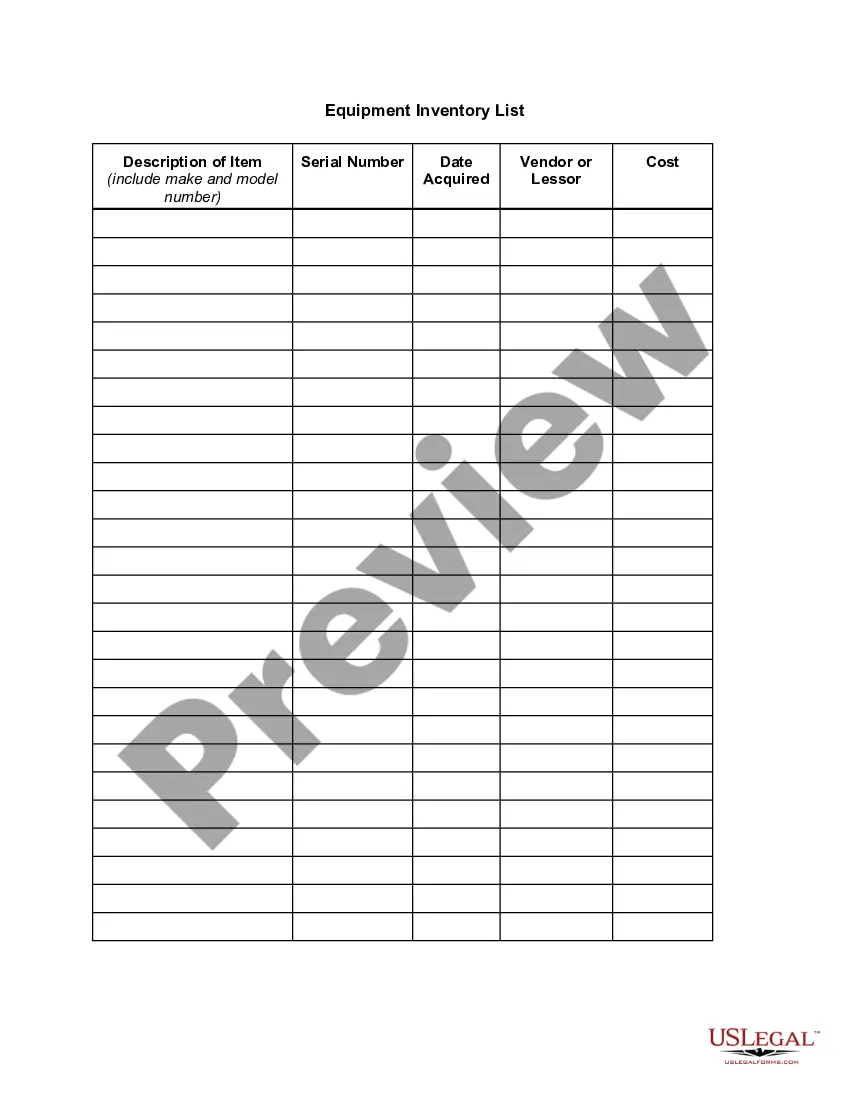

A physical count of inventory can identify discrepancies between recorded and actual stock levels, such as overages and shortages. This process also highlights areas for improvement in inventory management and helps prevent issues like stockouts or excess inventory. Utilizing a North Dakota Physical Inventory Count Sheet ensures these observations are documented and analyzed, leading to improved operations.

The physical count of inventory refers to the actual count of goods a business has in stock, independent of what records indicate. This process helps ensure that your inventory system is accurate and up-to-date. By using a North Dakota Physical Inventory Count Sheet, businesses can systematically track the physical counts and address any variances right away.

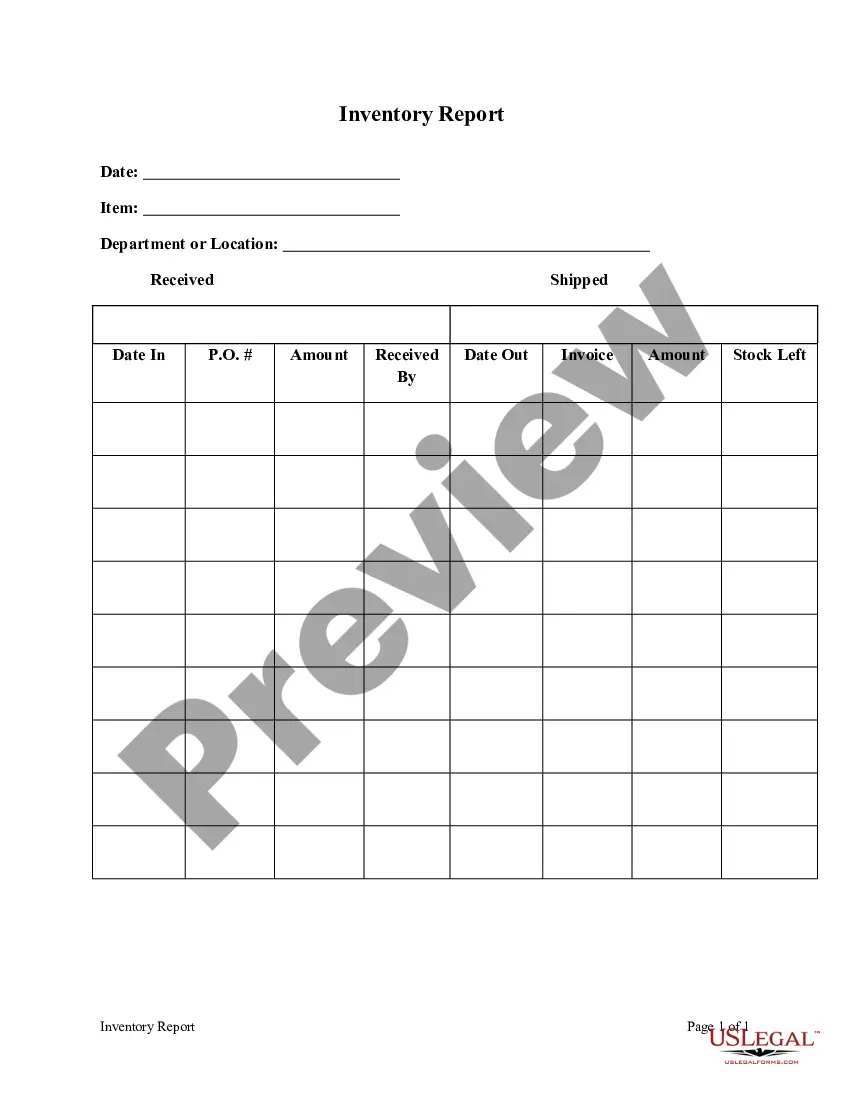

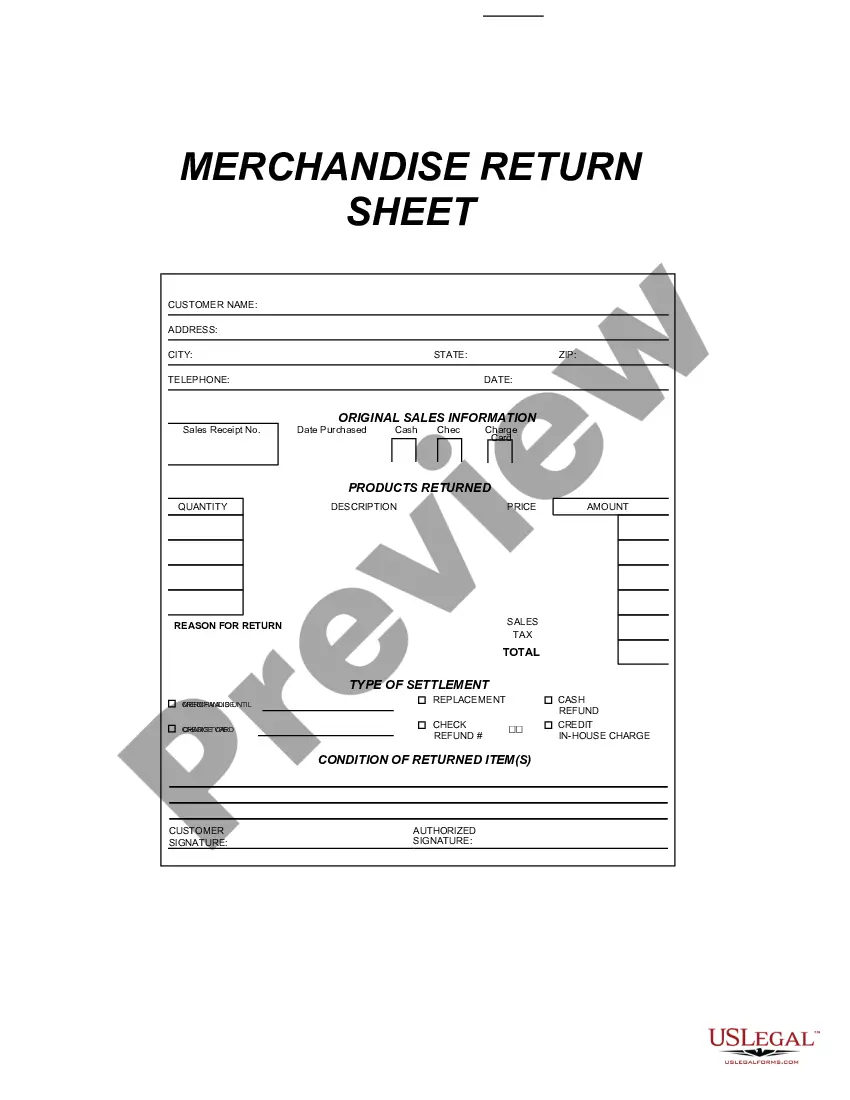

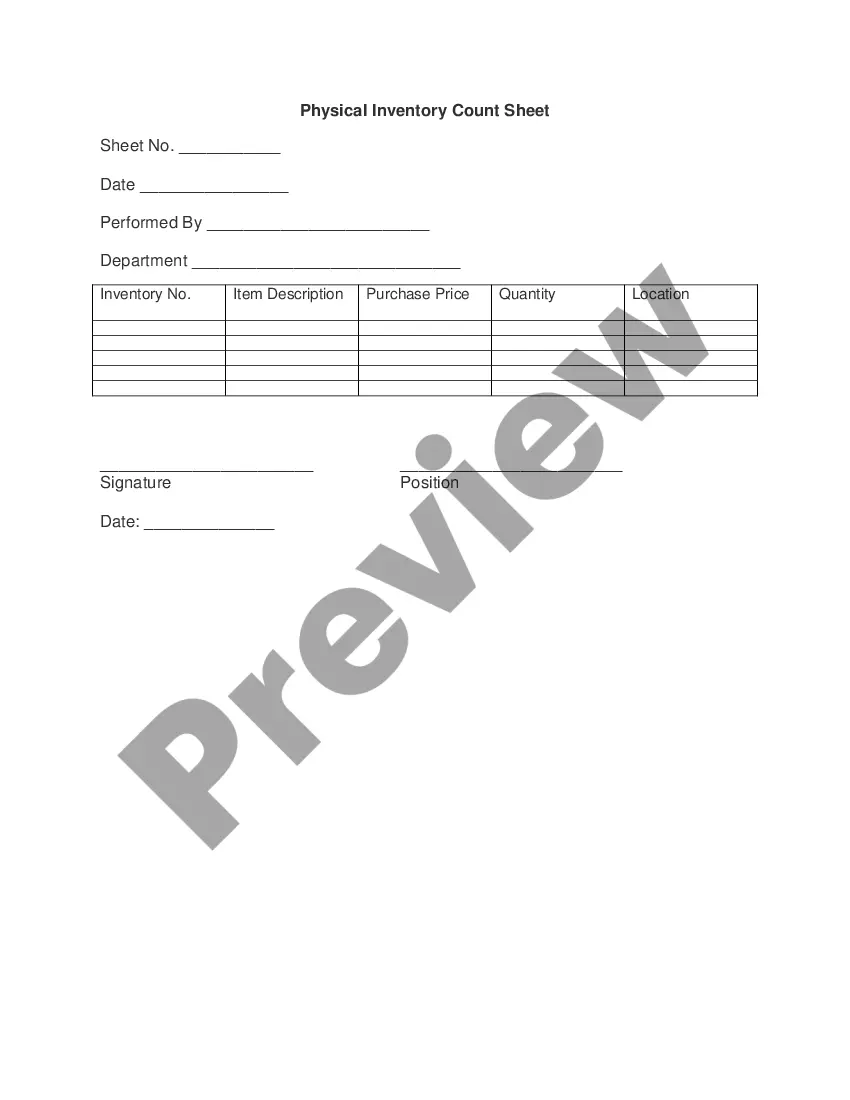

Creating a physical inventory document involves outlining each product's name, SKU, quantity, and location. You can use a North Dakota Physical Inventory Count Sheet for this purpose, as it provides a structured format for your data. Be sure to include spaces for notes on discrepancies or damaged items, making record-keeping more effective for future reference.

To conduct a physical inventory count, start by gathering all inventory items and a North Dakota Physical Inventory Count Sheet. Next, carefully count each product and record the numbers on the sheet. After completing the count, reconcile the results with your inventory records to identify any differences and establish clearer inventory management practices.

A physical inventory is usually taken at the end of a financial period to assess the quantity and value of inventory on hand. Many businesses in North Dakota utilize a Physical Inventory Count Sheet to facilitate this process, ensuring accuracy and consistency. This sheet helps to record each item's details, making it easier for businesses to track inventory levels and identify discrepancies.

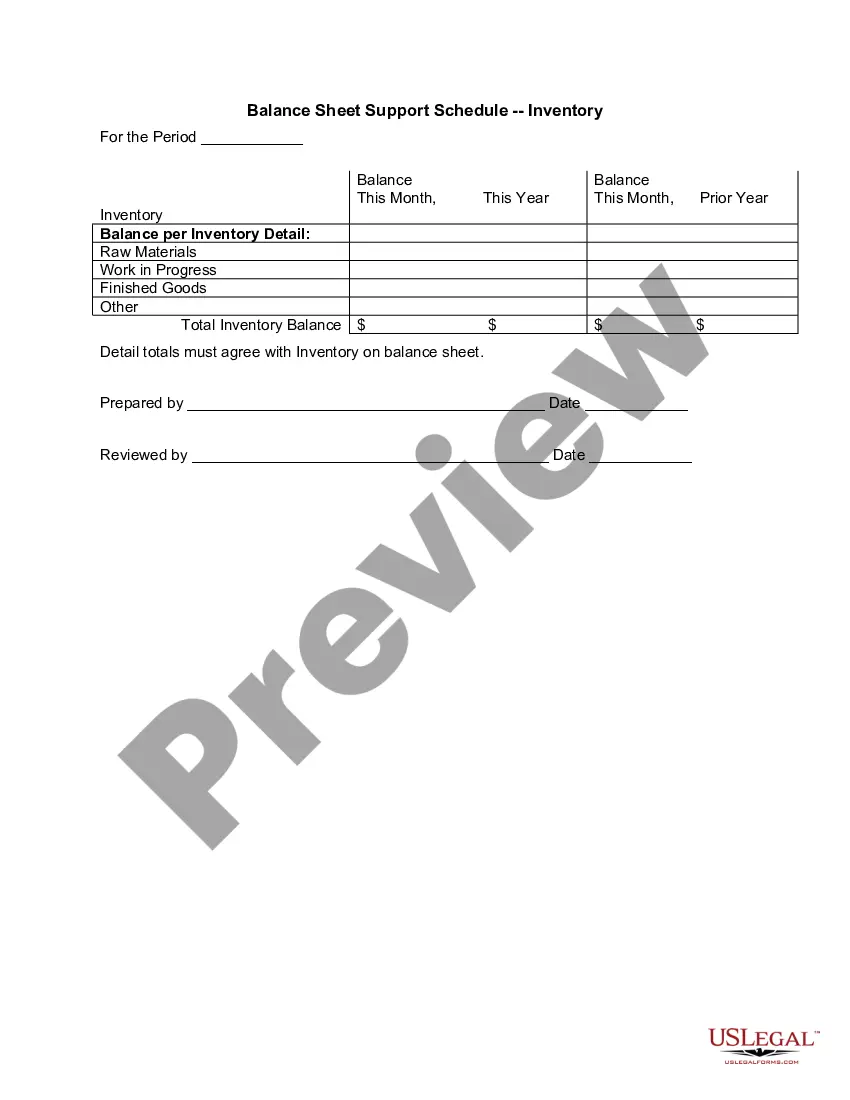

Yes, businesses in North Dakota can carry forward a net operating loss to offset future taxable income. This provision allows companies to recover some financial losses by applying them to profits in upcoming years. When you document your financial activities, including on your North Dakota Physical Inventory Count Sheet, remember to factor in any potential losses you might carry forward for strategic tax planning.

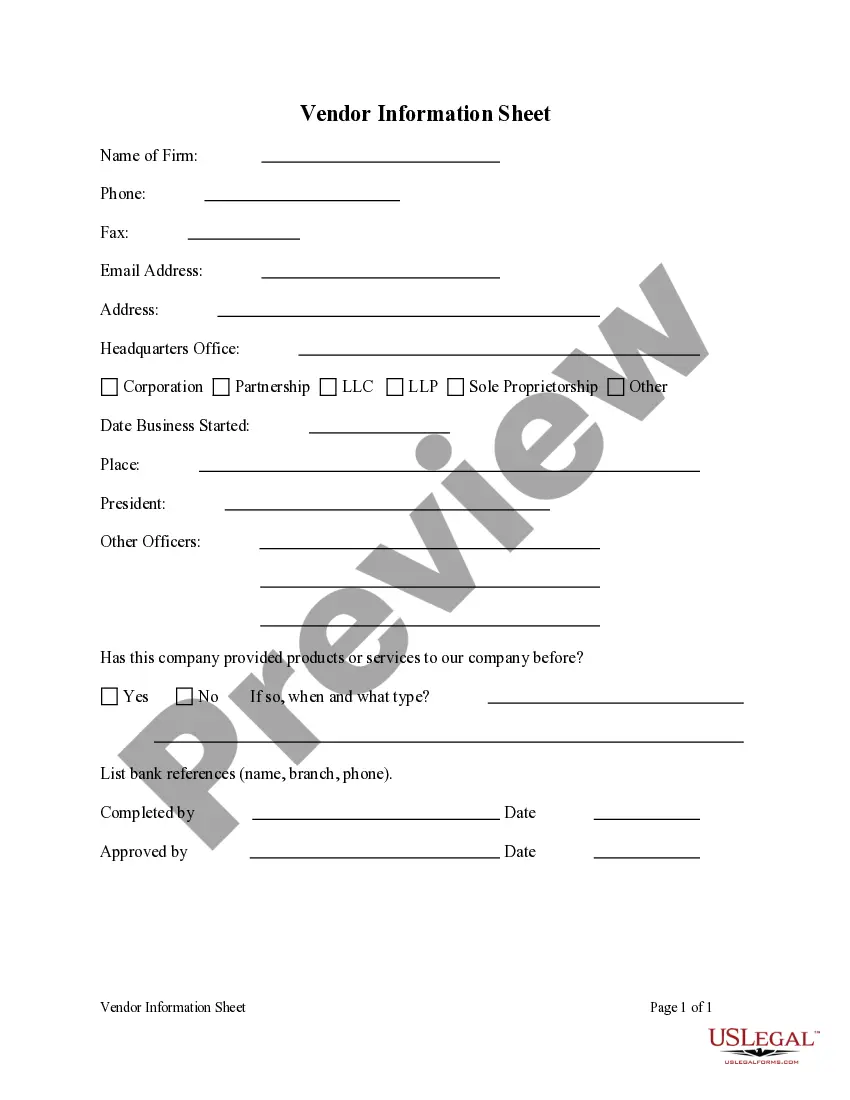

A North Dakota sales and use tax permit is a mandatory requirement for businesses that engage in retail sales or use taxable goods and services. Obtaining this permit enables businesses to collect tax from customers on behalf of the state. Completing your North Dakota Physical Inventory Count Sheet accurately can aid in managing sales tax obligations effectively.

The sales factor weighting election in North Dakota allows businesses to choose how to determine their sales factor for income apportionment. This option can significantly impact how your income is taxed, potentially offering a more beneficial tax approach. When preparing your North Dakota Physical Inventory Count Sheet, being mindful of this election can enhance your financial strategies.

The gross receipts tax in North Dakota is a tax applied to the total revenue generated by a business. This means that businesses must report their total income, regardless of expenses incurred. Understanding this tax can help you prepare your North Dakota Physical Inventory Count Sheet accurately, ensuring you account for all relevant financial activities.

Cycle counting should be performed regularly, typically every few months, depending on the size and complexity of your inventory. Regular checks using a North Dakota Physical Inventory Count Sheet help maintain accuracy over time. The frequency may increase based on how critical the inventory turnover is for your business.