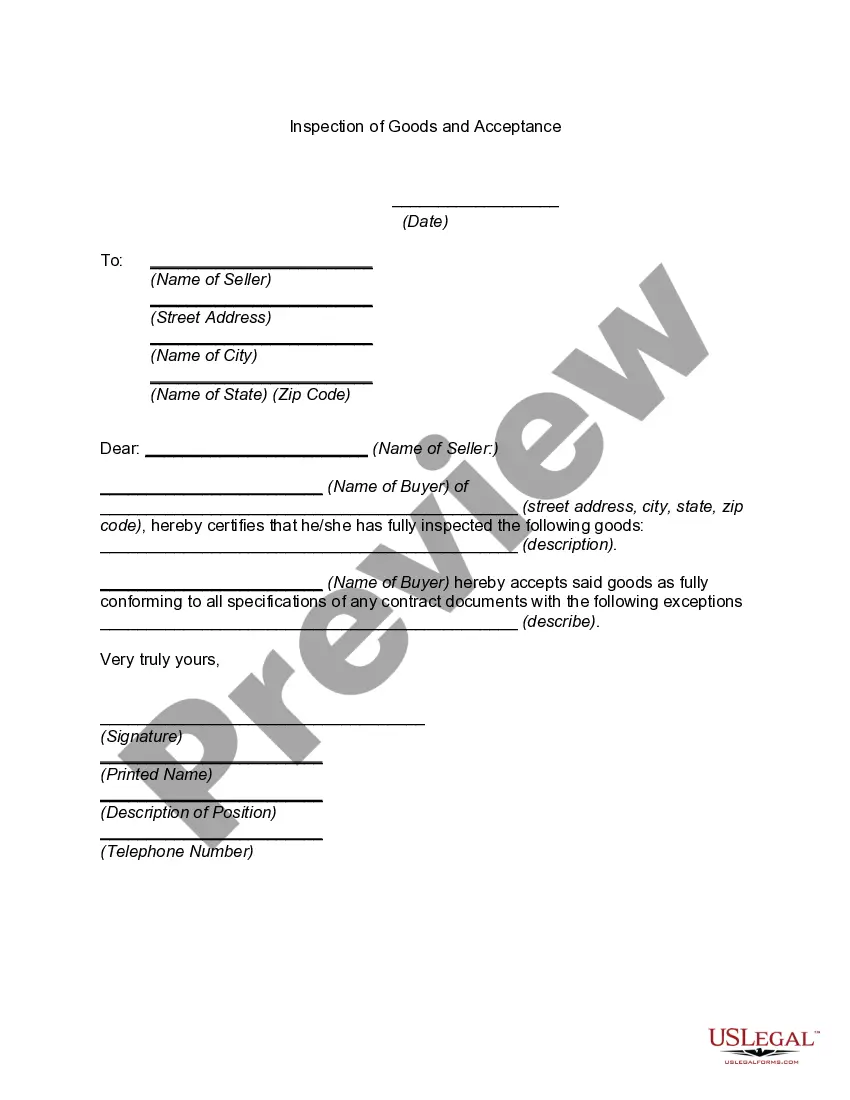

North Dakota Inspection of Goods and Acceptance is a process that ensures the quality and conformity of goods with the agreed-upon specifications before acceptance by the buyer. This is a crucial step in commerce, particularly in ensuring customer satisfaction, protecting both parties' interests, and maintaining a fair trading environment. The primary aim of the North Dakota Inspection of Goods and Acceptance is to prevent the sale and delivery of defective or substandard products. By conducting inspections, buyers can assess the goods' quality, quantity, packaging, labeling, and overall compliance with the relevant standards and specifications. There are several types of North Dakota Inspection of Goods and Acceptance that can take place depending on the nature of the goods and the specific agreements between the buyer and seller. These types include: 1. Pre-shipment Inspection: This inspection occurs before the goods are shipped to the buyer. It involves examining a representative sample from the whole batch to verify product quality, functionality, and adherence to specifications. 2. In-process Inspection: This inspection takes place during the manufacturing process and involves checking the quality, quantity, and integrity of the goods at different stages of production. It aims to identify and rectify any potential issues before completion. 3. Final Inspection: This inspection occurs after the goods have been manufactured and assembled, but before their shipment. It focuses on examining the end products thoroughly to ensure they meet the required standards and specifications agreed upon by both parties. 4. Random Sampling Inspection: In this type of inspection, a random sample is taken from the batch to evaluate the quality, functionality, and conformity of the goods. It is done to ensure representative assessment while saving time and costs compared to inspecting the entire batch. 5. Vendor Inspection: This inspection is conducted by an independent third-party inspector hired by the buyer to assess the goods' quality on-site at the manufacturer's or supplier's premises. 6. Receiving Inspection: This inspection takes place when the goods arrive at the buyer's location. It examines the packaging, quantity, and externally visible aspects of the goods to ensure they match the agreed-upon specifications before accepting the shipment. 7. Statutory Inspection: Certain goods fall under regulatory guidelines and standards that require inspection to comply with legal requirements. These inspections may be carried out by authorized agencies or government bodies to ensure public safety, health, and environmental standards are met. In summary, North Dakota Inspection of Goods and Acceptance encompasses various types of inspections carried out to evaluate the quality, conformity, and compliance of goods with agreed-upon specifications. By conducting these inspections, both buyers and sellers can mitigate potential risks, ensure customer satisfaction, and maintain trust and transparency in commercial transactions.

North Dakota Inspection of Goods and Acceptance

Description

How to fill out North Dakota Inspection Of Goods And Acceptance?

You can invest hrs on the Internet looking for the lawful document template that meets the federal and state demands you need. US Legal Forms provides 1000s of lawful varieties which can be reviewed by experts. It is possible to acquire or print the North Dakota Inspection of Goods and Acceptance from your support.

If you have a US Legal Forms accounts, you can log in and then click the Acquire option. Following that, you can total, revise, print, or indicator the North Dakota Inspection of Goods and Acceptance. Every single lawful document template you get is yours permanently. To acquire an additional copy associated with a purchased form, visit the My Forms tab and then click the related option.

Should you use the US Legal Forms web site the first time, follow the simple guidelines below:

- Very first, ensure that you have selected the proper document template for the state/city that you pick. See the form description to make sure you have picked the appropriate form. If accessible, take advantage of the Review option to look throughout the document template too.

- If you want to locate an additional edition of your form, take advantage of the Look for area to find the template that meets your needs and demands.

- Once you have identified the template you desire, simply click Purchase now to carry on.

- Select the rates strategy you desire, enter your references, and sign up for a free account on US Legal Forms.

- Complete the deal. You can utilize your Visa or Mastercard or PayPal accounts to pay for the lawful form.

- Select the formatting of your document and acquire it to the device.

- Make modifications to the document if necessary. You can total, revise and indicator and print North Dakota Inspection of Goods and Acceptance.

Acquire and print 1000s of document layouts while using US Legal Forms website, that offers the largest variety of lawful varieties. Use specialist and express-certain layouts to handle your organization or personal requirements.