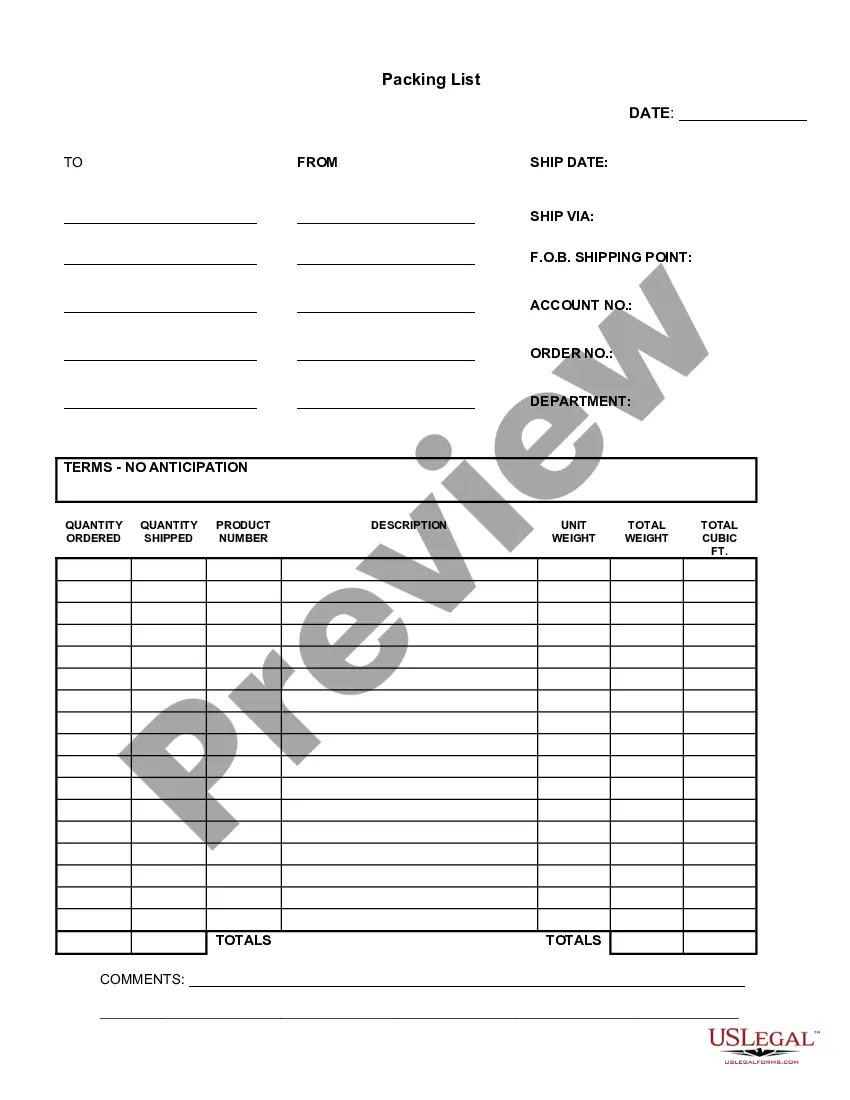

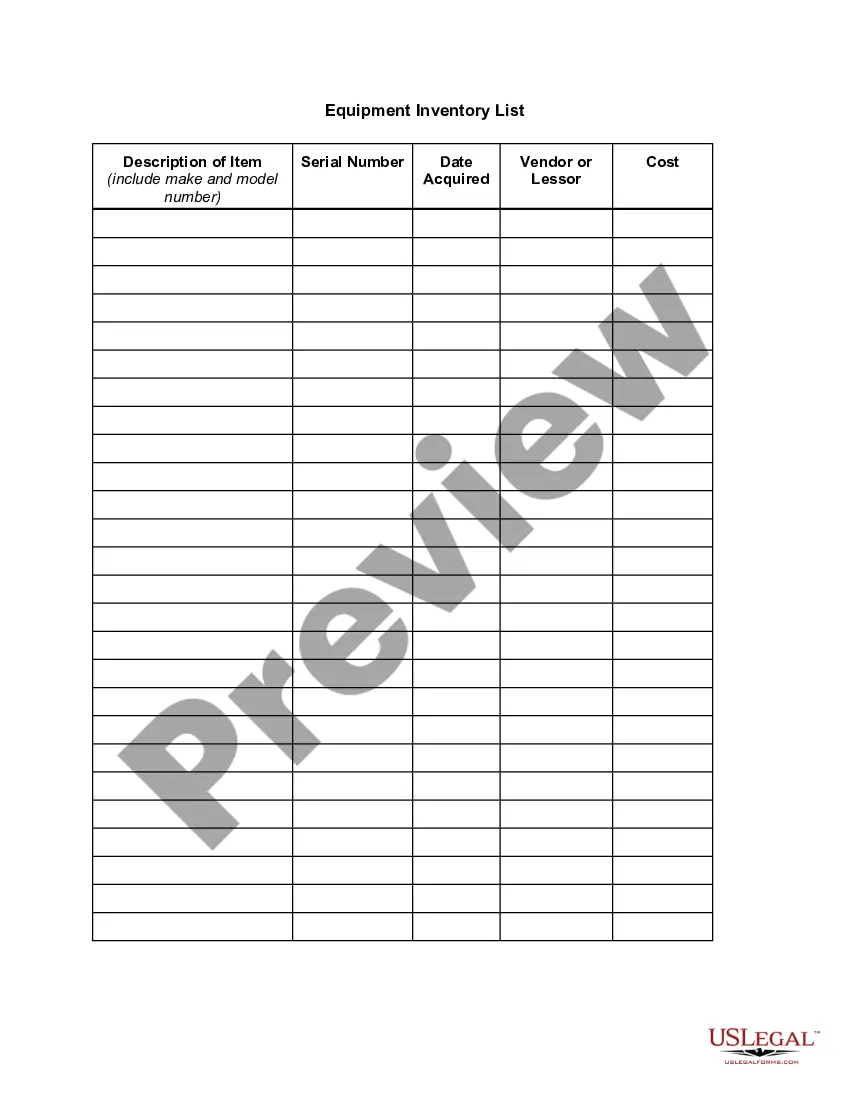

The New Jersey Equipment Inventory List is a comprehensive compilation of all the equipment and machinery owned by various entities in the state of New Jersey. It serves as a crucial tool for managing and organizing equipment assets, ensuring efficient maintenance, and facilitating proper resource allocation. This inventory list includes a wide range of equipment types, each serving a specific purpose in various industries. Some common equipment categories found on the New Jersey Equipment Inventory List include: 1. Construction Equipment: This category encompasses heavy machinery like excavators, bulldozers, cranes, loaders, and forklifts that are widely used in construction projects across New Jersey. 2. Transportation Equipment: In this category, you will find vehicles such as cars, trucks, vans, buses, ambulances, and utility vehicles used by government agencies, municipalities, and businesses for transportation purposes. 3. Manufacturing Equipment: It includes machinery like CNC machines, lathes, milling machines, 3D printers, and industrial robots utilized by manufacturing companies to facilitate the production process. 4. Medical Equipment: This category involves a wide range of medical devices, including diagnostic equipment, surgical tools, patient monitors, imaging machines, and other medical apparatus found in hospitals, clinics, and healthcare facilities. 5. Office Equipment: This category covers essential items used in office spaces, such as computers, printers, copiers, scanners, fax machines, telephones, and furniture, enabling smooth business operations and administrative tasks. 6. Communication Equipment: This includes devices like two-way radios, walkie-talkies, telephone systems, and network equipment required for communication in emergency services, law enforcement, public safety agencies, and organizations. 7. Agricultural Equipment: It encompasses farm machinery, including tractors, plows, tillers, sprayers, harvesters, and irrigation systems, which aid in crop cultivation and management in New Jersey's agricultural sector. 8. Scientific Equipment: This category involves laboratory equipment, research instruments, microscopes, spectrophotometers, centrifuges, and other tools utilized by educational institutions, research facilities, and scientific organizations. Additional types of New Jersey Equipment Inventory Lists might exist, specific to certain industries or organizations. For instance, there could be specialized inventories for the transportation department, public works, educational institutions, or any other entity in need of managing equipment resources efficiently. Keeping an accurate and up-to-date New Jersey Equipment Inventory List is crucial for both governmental and non-governmental organizations as it assists in tracking, maintaining, and budgeting equipment assets, reducing downtime, and optimizing overall operational efficiency.

New Jersey Equipment Inventory List

Description

How to fill out New Jersey Equipment Inventory List?

Are you presently within a place in which you will need files for either company or specific functions nearly every day time? There are a lot of authorized document themes available on the net, but locating versions you can rely isn`t easy. US Legal Forms gives a large number of type themes, much like the New Jersey Equipment Inventory List, that happen to be composed in order to meet federal and state demands.

When you are currently familiar with US Legal Forms web site and get an account, basically log in. Following that, it is possible to download the New Jersey Equipment Inventory List web template.

Unless you have an bank account and wish to begin using US Legal Forms, adopt these measures:

- Find the type you need and make sure it is for the right area/region.

- Take advantage of the Review key to review the form.

- Browse the description to actually have selected the appropriate type.

- In case the type isn`t what you`re searching for, make use of the Look for industry to discover the type that fits your needs and demands.

- If you obtain the right type, click Buy now.

- Pick the prices plan you need, submit the necessary information to make your bank account, and pay for the transaction utilizing your PayPal or bank card.

- Select a handy paper format and download your copy.

Discover all of the document themes you have bought in the My Forms menu. You may get a more copy of New Jersey Equipment Inventory List any time, if possible. Just select the needed type to download or print the document web template.

Use US Legal Forms, by far the most extensive selection of authorized forms, to save some time and prevent errors. The service gives appropriately created authorized document themes that you can use for a selection of functions. Make an account on US Legal Forms and commence creating your daily life a little easier.

Form popularity

FAQ

Here's a list of TAXABLE items you may encounter on your weekly trip to the store:Acne products cleansers or soaps (creams or lotions are exempt)Air fresheners.Alcoholic beverages.Aluminum foil.Ammonia.Antiperspirants, deodorants.Baby bath soaps, lotions, powder, shampoos.Bags (Plastic, cloth)More items...?

Tax Exempt ItemsFood for human consumption.Manufacturing machinery.Raw materials for manufacturing.Utilities and fuel used in manufacturing.Medical devices and services.

ST-3 (3-17) The seller must collect the tax on a sale of taxable property or services unless the purchaser gives them a fully completed New Jersey exemption certificate. State of New Jersey. Division of Taxation. SALES TAX.

How to Fill Out NJ Sales Tax Exempt Form ST-3?Name the seller of the merchandise, enter the seller's address, and the actual date of the transaction.Provide your taxpayer registration number.Describe the nature of goods or services you sell in an ordinary course of business.More items...

Goods that are subject to sales tax in New Jersey include physical property, like furniture, home appliances, and motor vehicles. The purchase of both prescription and non-prescription medicine, groceries, gasoline and clothing are tax-exempt.

Exempt items include most food sold as grocery items, most clothing and footwear, disposable paper products for household use, prescription drugs, and over-the-counter drugs.

Agencies of the federal government and the United Nations as well as the State of New Jersey and its political subdivisions are exempt from paying Sales Tax provided the agency making the purchase supplies the seller with a copy of a valid purchase order or contract signed by an authorized official.

Some examples of nontaxable goods and services are: Unprepared food for human consumption, clothing, certain professional and personal services, and real estate sales.

Form ST-4 makes it possible for businesses to purchase production machinery, packaging supplies, and other goods or services without paying Sales Tax if the way they intend to use these items is specifically exempt under New Jersey law.

The New Jersey sales and use tax exemption for manufacturers enables machinery, apparatuses, or equipment to be purchased without paying New Jersey sales and use tax.