A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

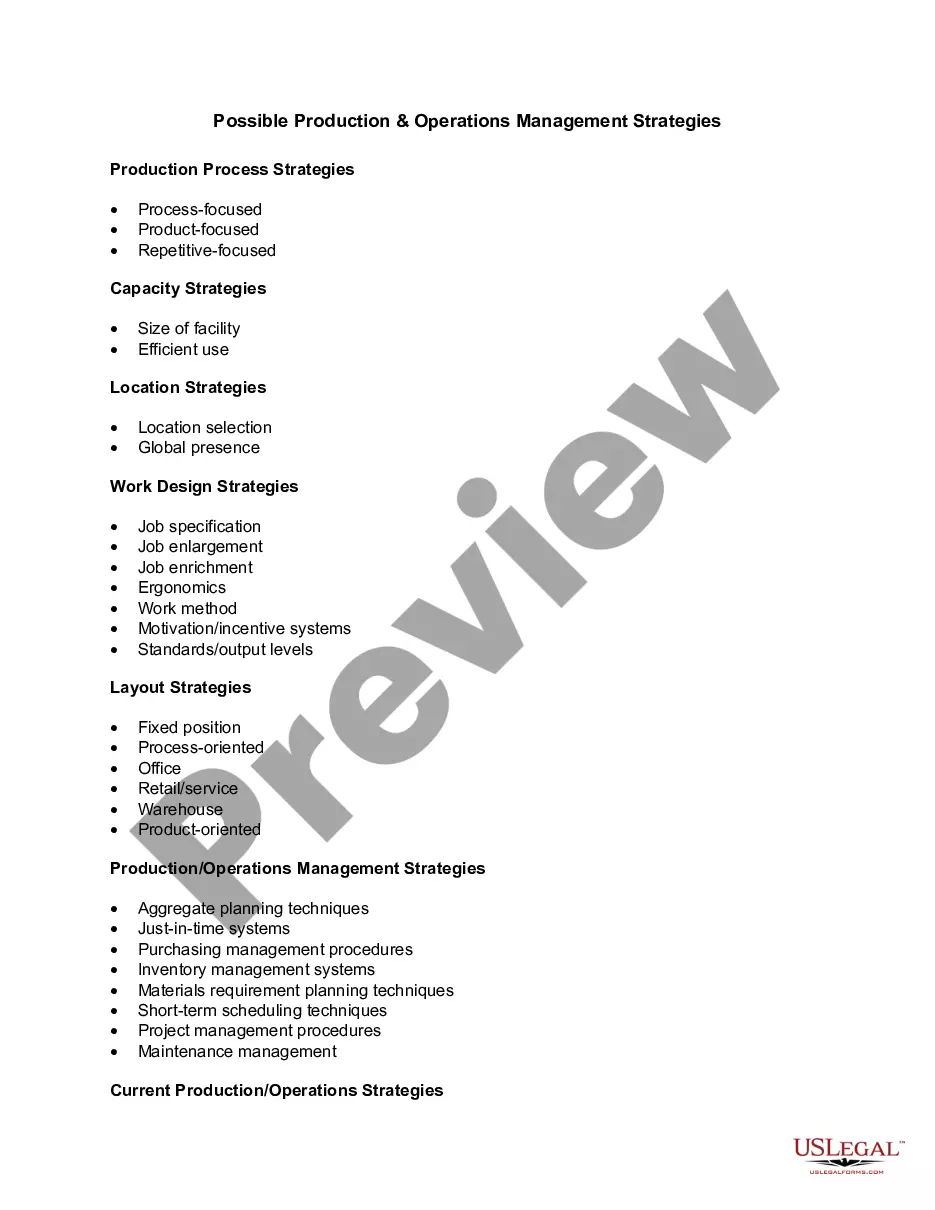

New Jersey Possible Production and Operations Management Strategies: A Comprehensive Overview New Jersey, located on the east coast of the United States, is known for its diverse industry landscape and robust economy. In order to remain competitive and maximize efficiency, businesses operating in New Jersey need to adopt effective production and operations management strategies. This detailed description aims to shed light on various possible production and operations management strategies relevant to New Jersey, focusing on key keywords such as lean manufacturing, supply chain optimization, technology integration, and environmental sustainability. 1. Lean Manufacturing: Lean manufacturing is a production strategy focused on minimizing waste, reducing costs, and improving overall productivity. New Jersey businesses can implement lean manufacturing principles to streamline their operations and increase efficiency. This may involve techniques such as just-in-time (JIT) production, continuous improvement, value stream optimization, and waste reduction practices. 2. Supply Chain Optimization: Given its strategic location and proximity to major transportation hubs, New Jersey serves as an ideal location for optimizing supply chain operations. Businesses in the state can implement strategies to enhance supply chain efficiency, including inventory management, demand forecasting, supplier collaboration, and adoption of e-commerce technologies. 3. Technology Integration: Embracing technological advancements can provide a competitive edge for New Jersey businesses. Incorporating advanced technologies like robotics, automation, data analytics, and artificial intelligence (AI) in production and operations management can enhance efficiency, reduce costs, and provide real-time insights for decision-making processes. 4. Environmental Sustainability: New Jersey recognizes the importance of sustainability and environmentally friendly practices. Adopting sustainable production and operations management strategies can not only minimize the negative impact on the environment but also appeal to conscious consumers. This may involve incorporating renewable energy sources, waste management practices, recycling, eco-friendly packaging, and compliance with environmental regulations. Differentiating between the types of New Jersey Possible Production and Operations Management Strategies: 1. Industry-Specific Strategies: New Jersey is home to a multitude of industries, including pharmaceuticals, biotechnology, healthcare, logistics, manufacturing, finance, and more. Each industry may require specialized production and operations management strategies tailored to its unique characteristics, such as regulatory compliance, quality control, supply chain complexity, and inventory management. 2. Small and Medium-Sized Enterprise (SME) Strategies: New Jersey has a thriving SME sector, which may require specific production and operations management strategies. These strategies often focus on resource optimization, scalable solutions, lean methodologies, and agile operations to compete with larger corporations while maintaining cost-effectiveness. 3. Service Industry Strategies: The service industry in New Jersey, including tourism, hospitality, and financial services, may require distinct production and operations management strategies. These strategies focus on areas such as service delivery optimization, customer relationship management, workforce management, and ensuring a seamless customer experience. In conclusion, New Jersey's bustling economy and diverse industry landscape provide ample opportunities for businesses to implement effective production and operations management strategies. By embracing lean manufacturing, optimizing the supply chain, integrating technology, and prioritizing environmental sustainability, businesses in New Jersey can drive efficiency, reduce costs, and stay ahead in the competitive marketplace.