New Jersey Maintenance Engineer Checklist is a comprehensive and systematic guide that helps maintenance engineers ensure the proper functioning of equipment, machinery, and infrastructure in various industries and facilities across the state of New Jersey. This checklist is designed to guarantee a safe and efficient working environment, prolong the lifespan of assets, and minimize downtime. It covers several key areas to conduct inspections, identify defects, and perform necessary repairs and maintenance. Keywords: New Jersey, maintenance engineer checklist, equipment, machinery, infrastructure, industries, facilities, safe, efficient, working environment, lifespan, assets, downtime, inspections, defects, repairs. Types of New Jersey Maintenance Engineer Checklists: 1. Industrial Facility Maintenance Engineer Checklist: This checklist pertains to maintenance engineers working in manufacturing plants, warehouses, power plants, chemical facilities, and other industrial settings. It addresses a wide range of equipment, including boilers, pumps, generators, conveyor systems, HVAC units, air compressors, electrical panels, and more. 2. Building Maintenance Engineer Checklist: For maintenance engineers responsible for the upkeep of commercial buildings, residential complexes, offices, schools, hospitals, and other structures, this checklist caters to all aspects of the building's systems. It covers HVAC systems, fire safety equipment, plumbing, lighting, elevators, security systems, and other relevant areas. 3. Transportation Facility Maintenance Engineer Checklist: Maintenance engineers overseeing maintenance operations in transportation facilities such as airports, seaports, railways, and bus terminals can use this checklist. It focuses on safety equipment, navigation systems, fueling facilities, transport vehicles, gates, fences, signaling systems, and any other crucial components. 4. Energy Infrastructure Maintenance Engineer Checklist: For maintenance engineers involved in the maintenance of New Jersey's energy infrastructure, including power distribution grids, substations, solar farms, wind turbines, and power generation facilities, this checklist is essential. It addresses electrical systems, transformers, switchgear, protective relays, renewable energy sources, and related infrastructure. 5. Manufacturing Equipment Maintenance Engineer Checklist: Designed specifically for maintenance engineers working in manufacturing plants, this checklist focuses on various machinery and equipment used in the production process. It covers CNC machines, lathes, milling machines, presses, welding equipment, hydraulic systems, pneumatic systems, and other manufacturing equipment. These types of New Jersey Maintenance Engineer Checklists assist professionals in adhering to the industry standards, ensuring compliance with regulatory requirements, and maximizing the operational efficiency of equipment and systems. By employing these checklists, maintenance engineers can proactively identify and address potential issues, reducing the risk of breakdowns or accidents while optimizing the overall performance and longevity of the assets they are responsible for.

New Jersey Maintenance Engineer Checklist

Description

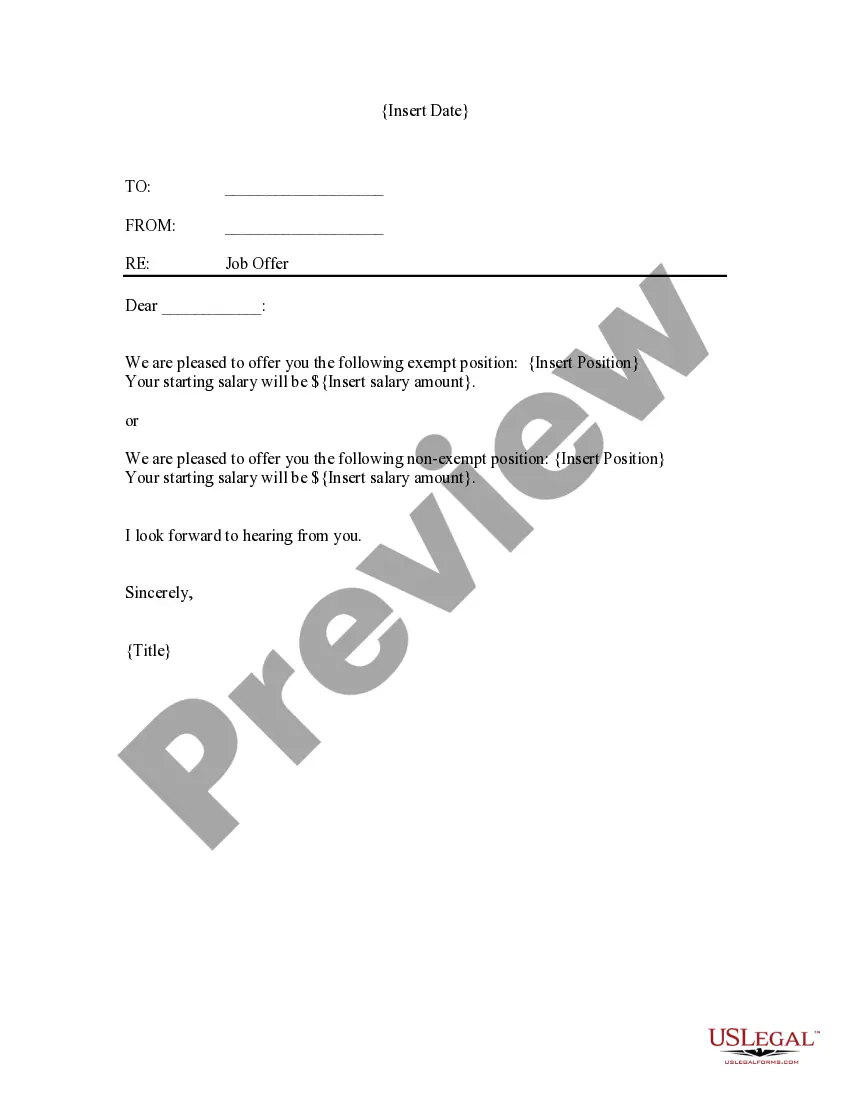

How to fill out Maintenance Engineer Checklist?

Have you been in a situation in which you need to have paperwork for sometimes enterprise or specific reasons nearly every day? There are plenty of authorized record layouts available online, but finding ones you can trust is not effortless. US Legal Forms offers a large number of type layouts, much like the New Jersey Maintenance Engineer Checklist, that are written to satisfy state and federal specifications.

When you are previously acquainted with US Legal Forms internet site and possess a merchant account, merely log in. Next, you can acquire the New Jersey Maintenance Engineer Checklist template.

Should you not come with an profile and need to start using US Legal Forms, adopt these measures:

- Get the type you want and ensure it is for your right city/state.

- Make use of the Preview option to analyze the shape.

- Browse the description to ensure that you have selected the correct type.

- In the event the type is not what you are seeking, make use of the Lookup area to find the type that meets your needs and specifications.

- Once you find the right type, click on Get now.

- Pick the costs program you desire, fill in the required information and facts to generate your money, and purchase the transaction utilizing your PayPal or credit card.

- Decide on a handy file formatting and acquire your version.

Find every one of the record layouts you possess bought in the My Forms menu. You can obtain a additional version of New Jersey Maintenance Engineer Checklist at any time, if possible. Just click on the essential type to acquire or print out the record template.

Use US Legal Forms, by far the most substantial variety of authorized kinds, to conserve efforts and prevent faults. The assistance offers skillfully manufactured authorized record layouts which you can use for a range of reasons. Produce a merchant account on US Legal Forms and start creating your way of life a little easier.