A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

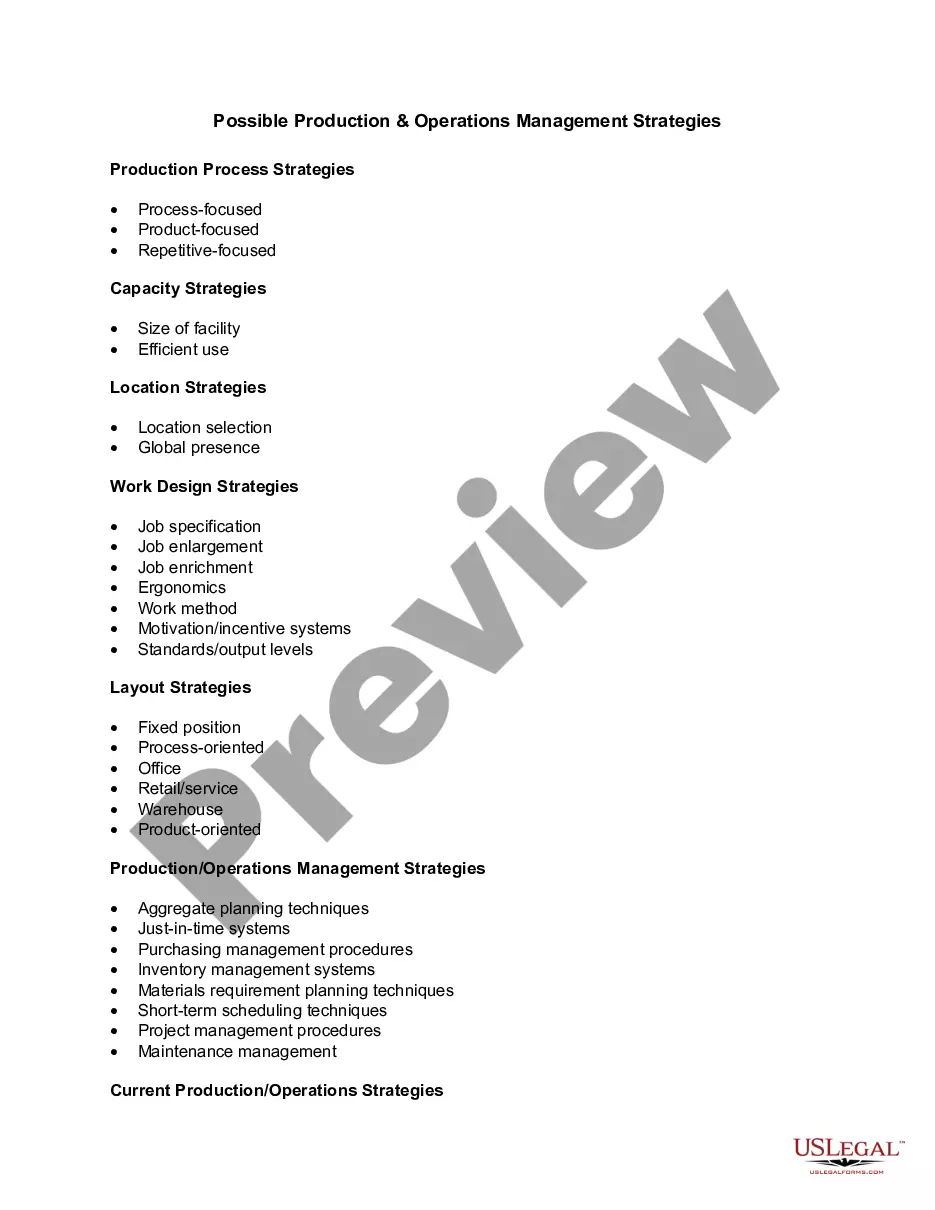

Nevada Possible Production and Operations Management Strategies refer to the various approaches and methods employed by businesses in Nevada to optimize their production processes and enhance overall operational efficiency. These strategies aim to streamline operations, reduce costs, improve quality, increase productivity, and meet customer demands effectively. Key focus areas for Nevada Possible Production and Operations Management Strategies may include supply chain management, inventory control, production planning, quality control, facility layout, and resource allocation. 1. Supply Chain Management: This strategy involves effectively managing all aspects of the supply chain, including procurement, transportation, and distribution, to ensure smooth flow of materials and products from suppliers to customers. It may involve implementing technology-driven solutions like logistics software, fostering strong supplier relationships, and adopting sustainable practices. 2. Lean Manufacturing: Lean manufacturing is a strategy emphasizing waste reduction and continuous improvement to maximize efficiency. It involves eliminating non-value-added activities, optimizing inventory control, and creating a culture of continuous improvement through techniques like 5S, Kaiden, and Just-in-Time (JIT) production. 3. Six Sigma: Six Sigma is a data-driven strategy that focuses on process improvement and defect reduction. It involves identifying and eliminating process variations, improving quality control measures, and minimizing defects through statistical analysis and rigorous problem-solving methods. 4. Total Quality Management (TQM): TQM is a comprehensive approach that emphasizes a commitment to quality in all aspects of operations. It involves establishing a customer-centric quality culture, implementing quality control techniques, and continuously improving processes to achieve customer satisfaction and enhance competitiveness. 5. Agile Manufacturing: Agile manufacturing is a flexible and responsive approach that enables rapid adaptation to market changes and customer demands. It involves quickly adjusting production processes, adopting technological advancements, fostering cross-functional collaboration, and employing modular and scalable production systems. 6. Green Operations: Green operations focus on sustainability and environmental consciousness. This strategy involves reducing waste, minimizing energy consumption, adopting eco-friendly practices, implementing green supply chain management, and incorporating sustainable product designs. 7. Outsourcing: Outsourcing involves delegating specific operations to external vendors or partners, enabling businesses to focus on their core competencies. It may include outsourcing manufacturing, logistics, or customer service functions to specialized companies to reduce costs or gain expertise. 8. Collaborative Planning, Forecasting, and Replenishment (CPR): CPR is a strategy that involves collaborative planning and information sharing between suppliers and customers to optimize production and inventory levels. It enhances supply chain efficiency, minimizes stock outs, and improves demand forecasting accuracy. By implementing these Nevada Possible Production and Operations Management Strategies, businesses in Nevada can achieve operational excellence, gain a competitive edge, and drive long-term success in today's dynamic marketplace.