Nevada Workplace Safety Rules

Description

How to fill out Workplace Safety Rules?

Have you ever found yourself in a situation where you require documents for either business or personal purposes almost daily.

There are numerous legal document templates available online, but finding ones you can trust is not straightforward.

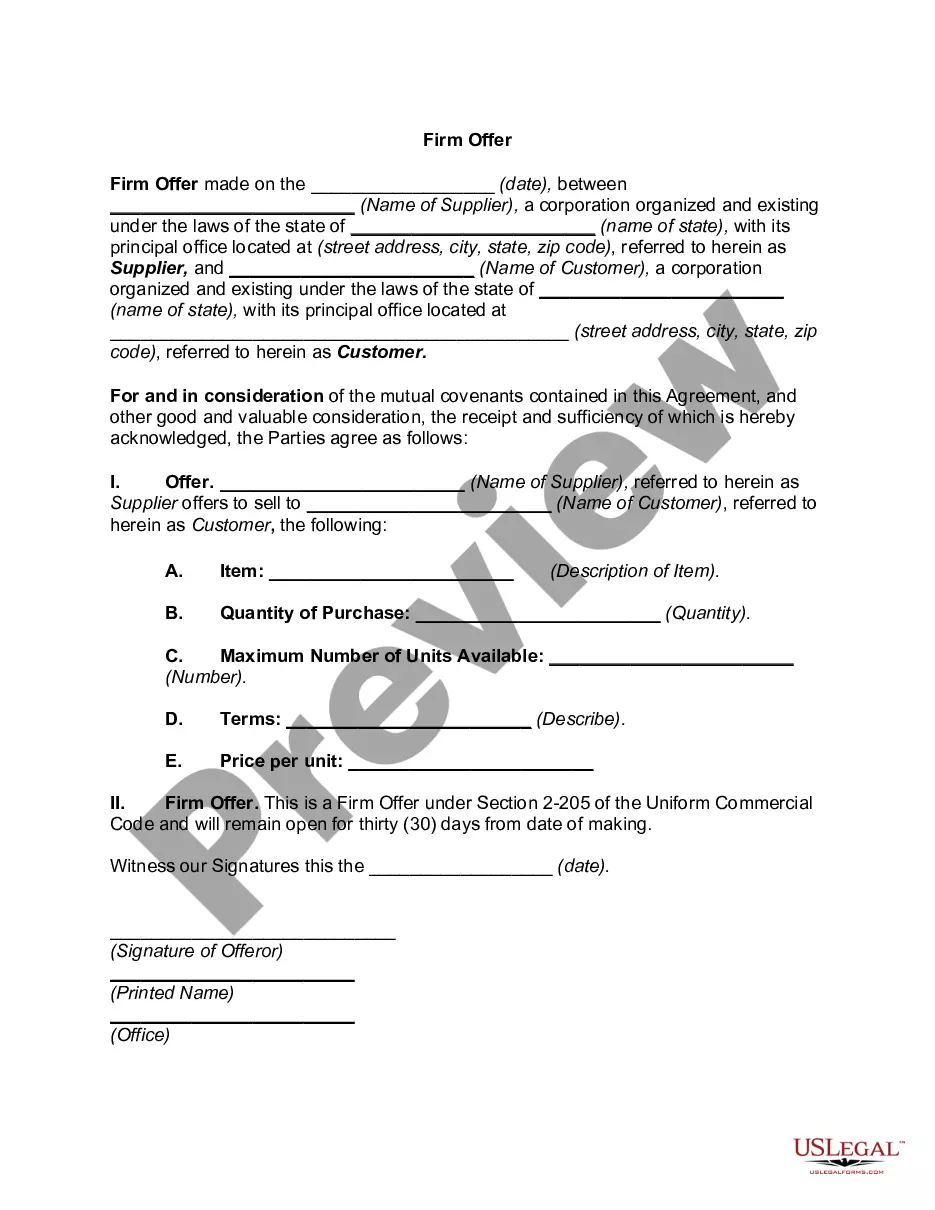

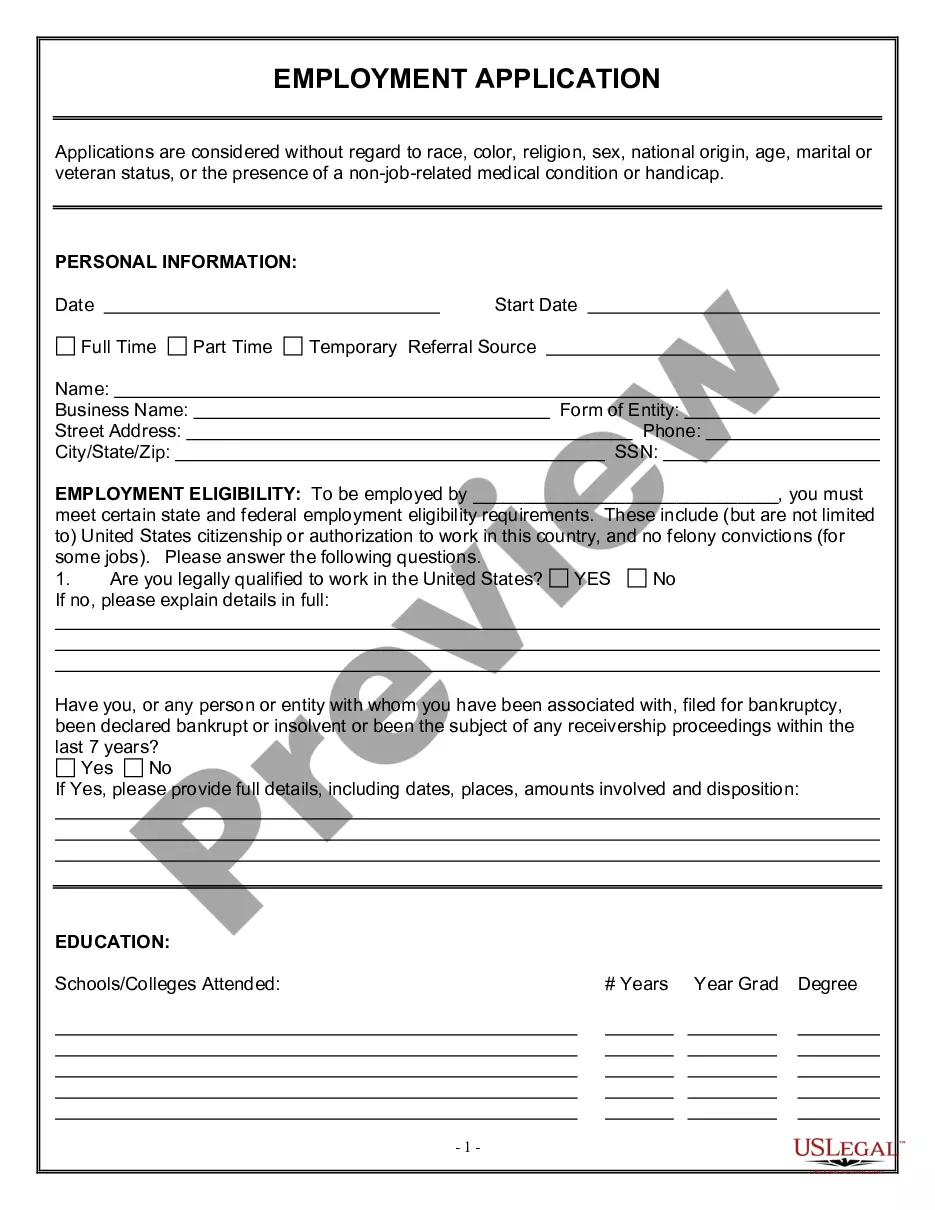

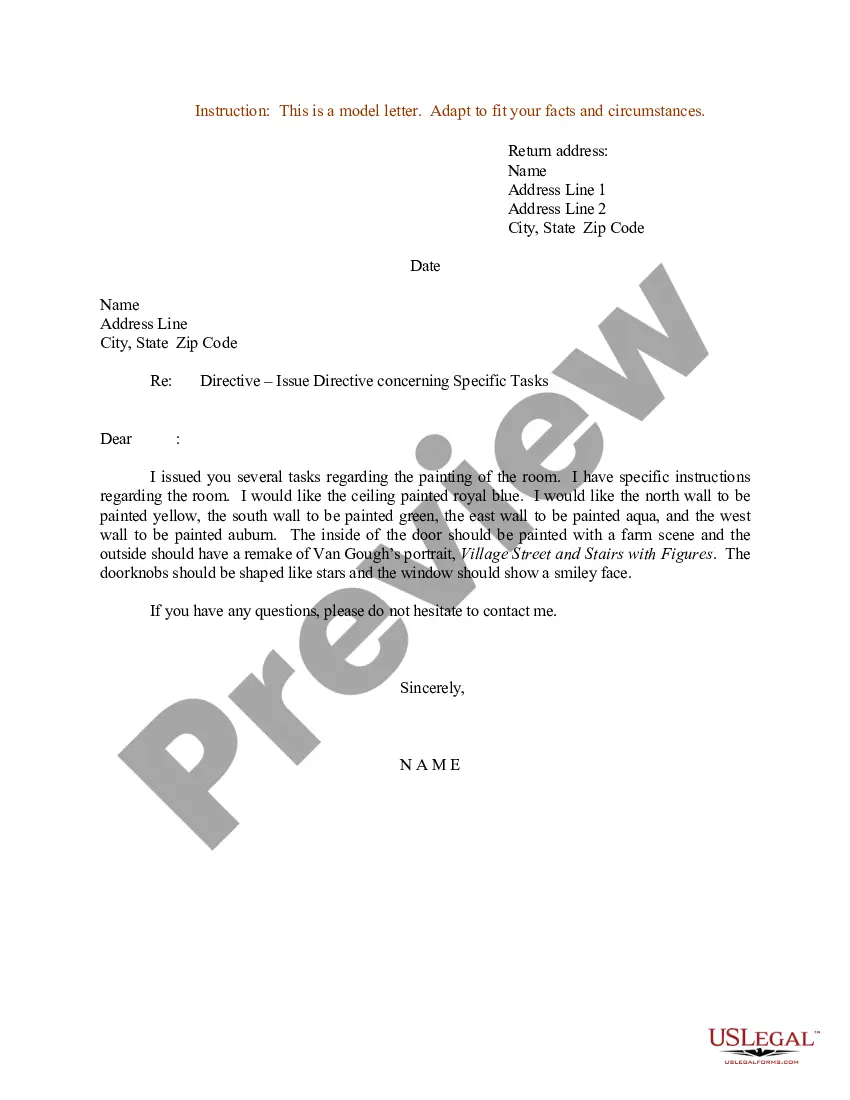

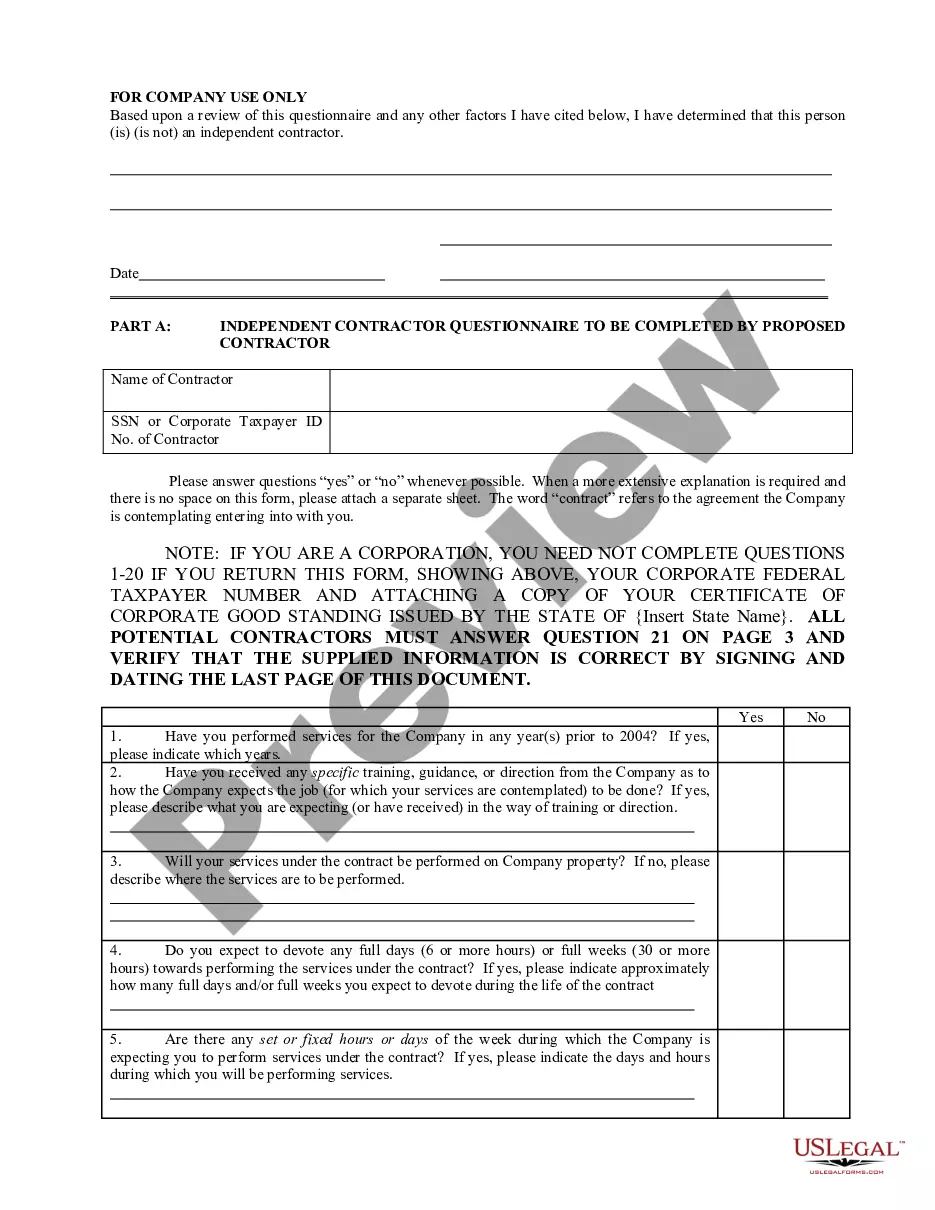

US Legal Forms offers a wide array of form templates, including the Nevada Workplace Safety Regulations, designed to comply with both state and federal standards.

Select the pricing plan you wish to use, complete the necessary information to set up your account, and finalize the order using your PayPal or Visa or Mastercard.

Choose a convenient file format and download your copy.

- If you are already acquainted with the US Legal Forms site and possess an account, simply Log In.

- Subsequently, you can download the Nevada Workplace Safety Regulations template.

- If you do not have an account and wish to start using US Legal Forms, follow these instructions.

- Identify the form you require and ensure it corresponds to your specific city/state.

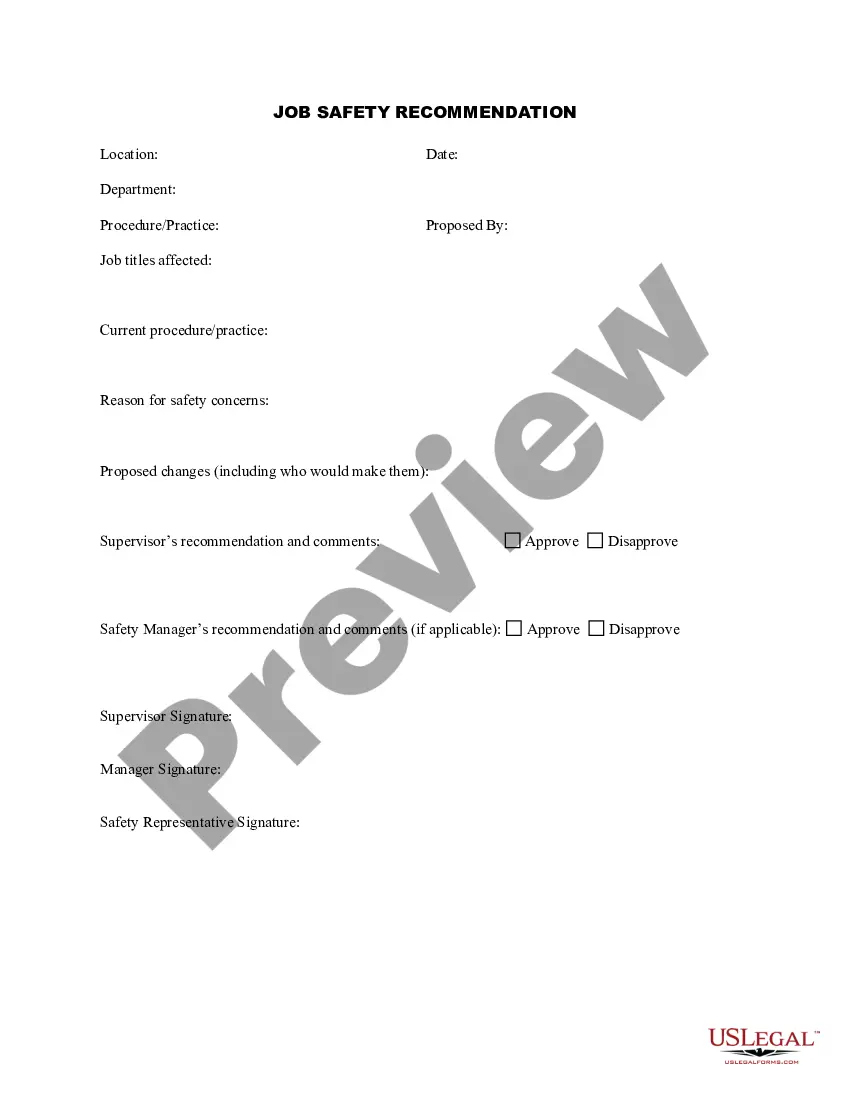

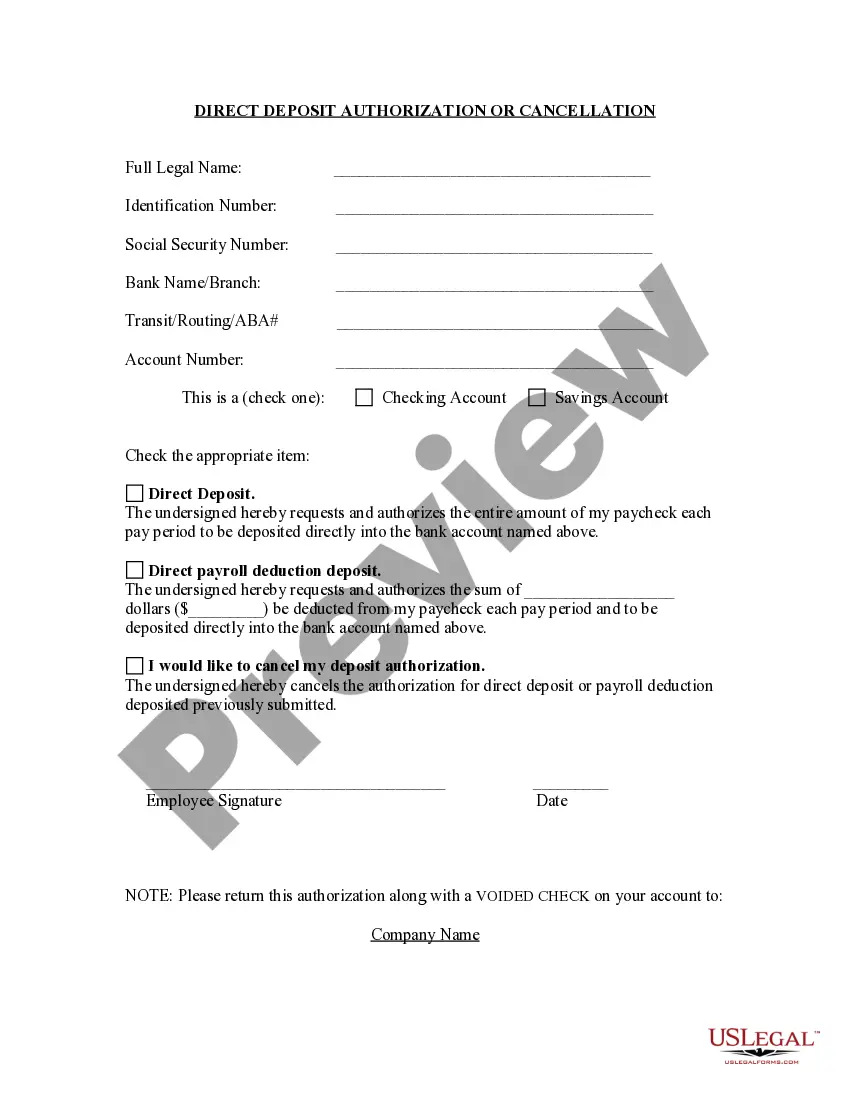

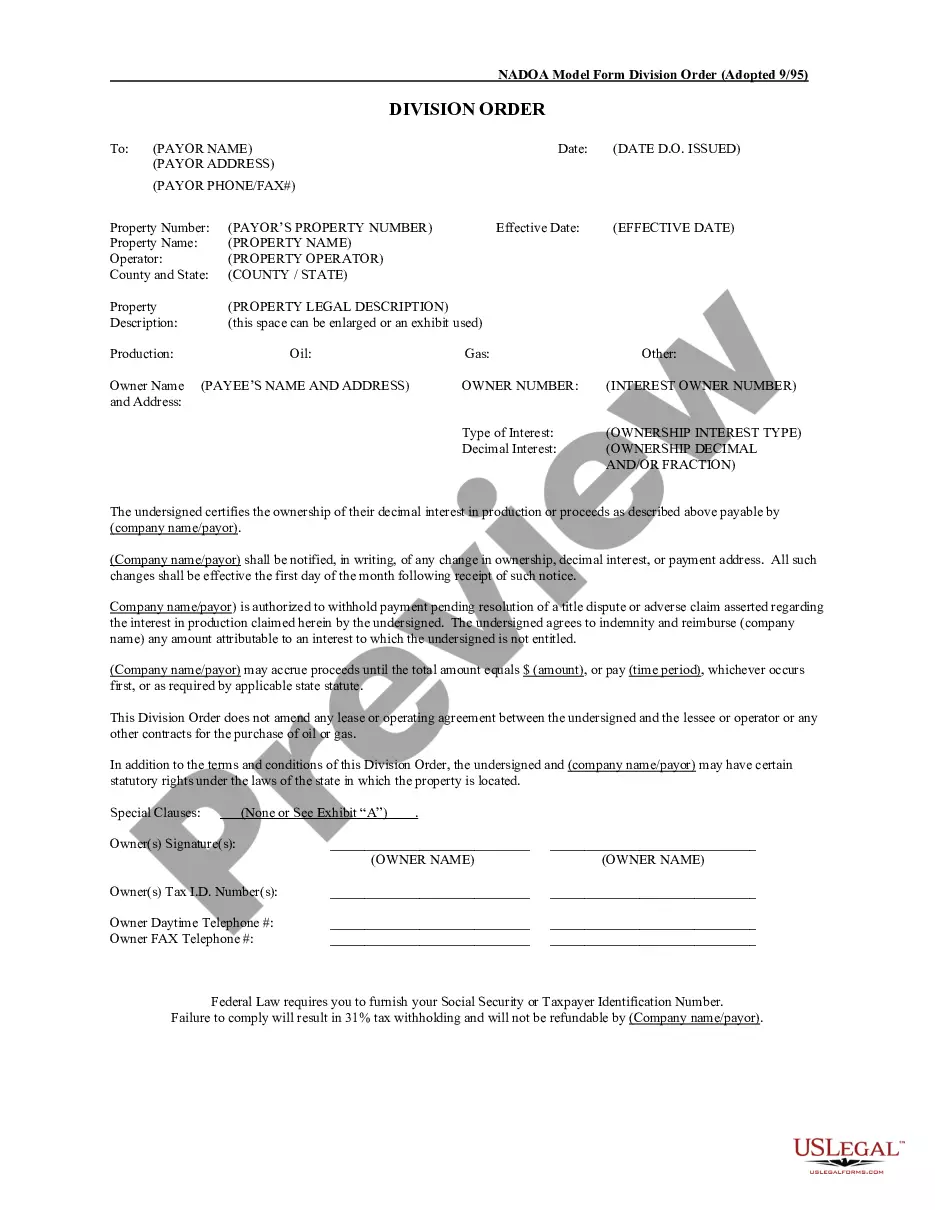

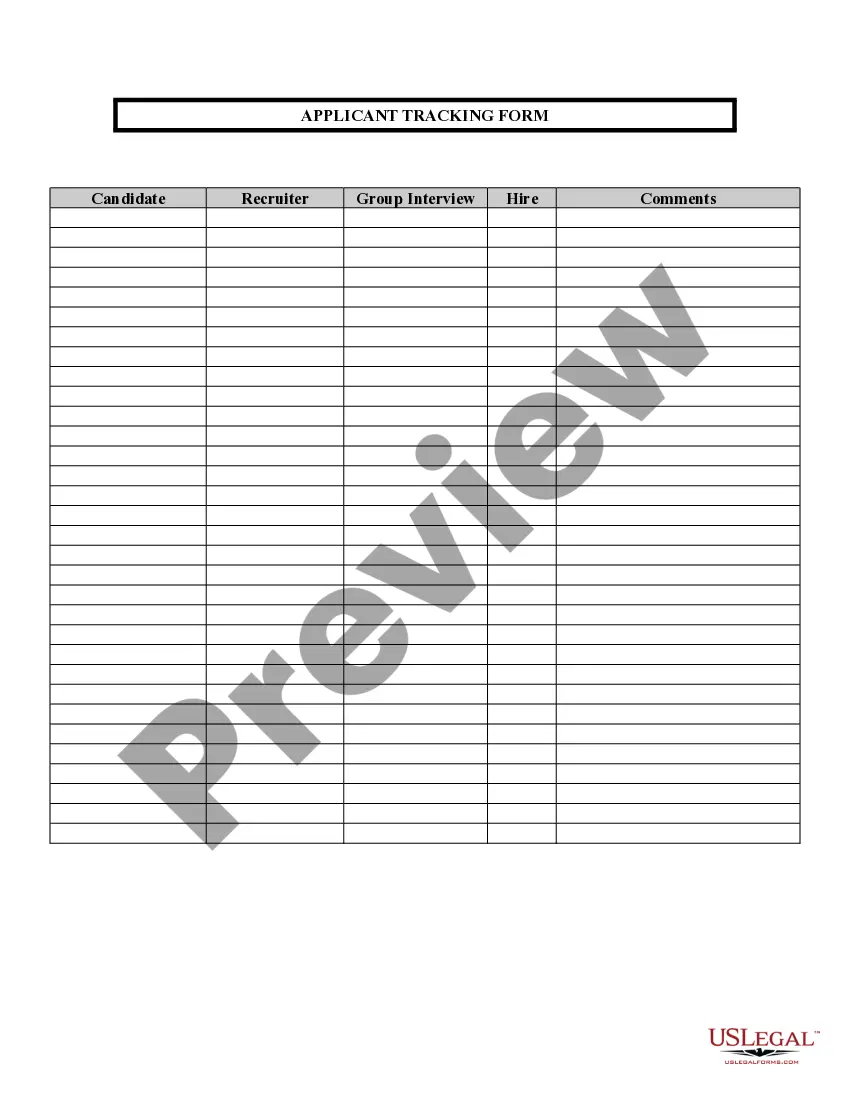

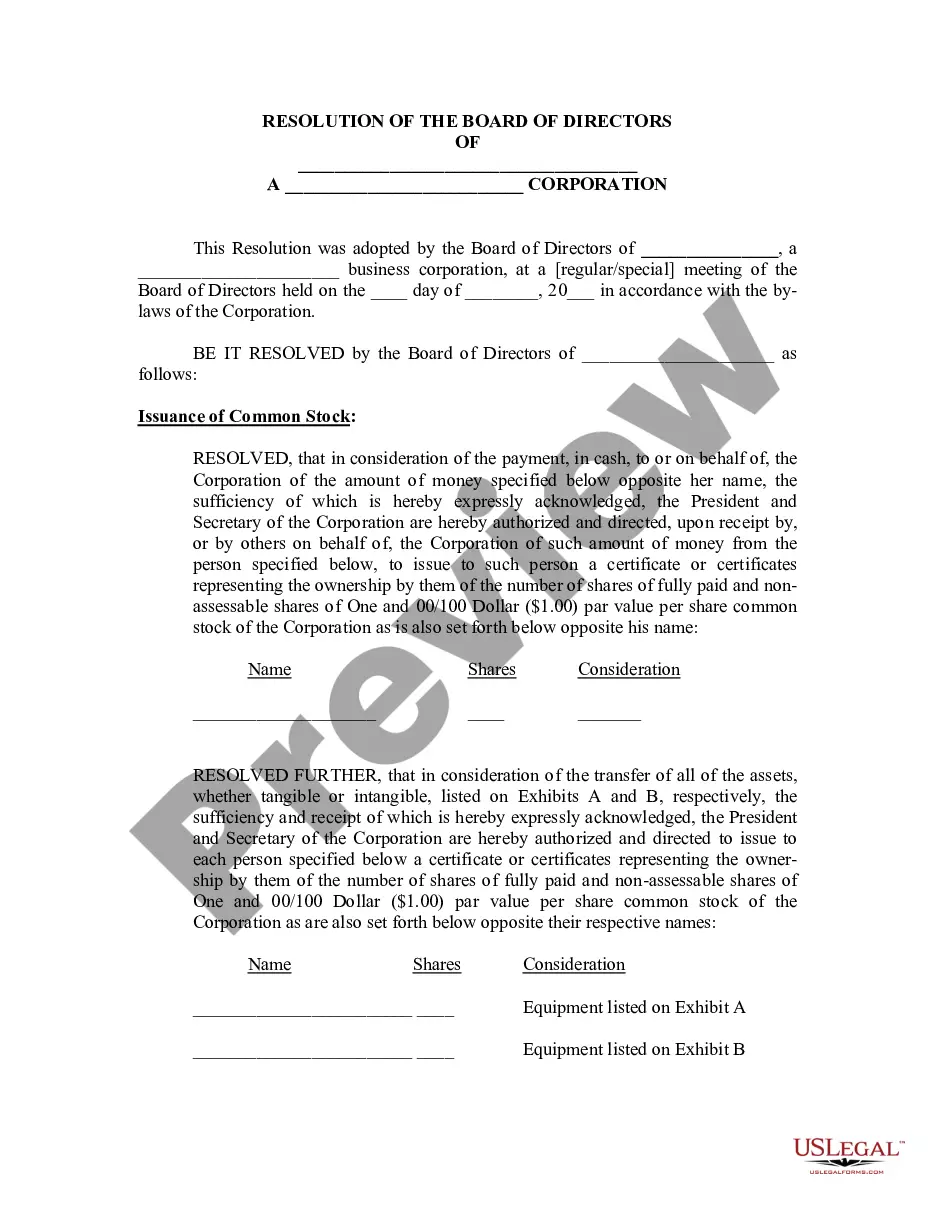

- Utilize the Review button to examine the document.

- Verify the details to ensure you have selected the correct form.

- If the form does not meet your expectations, use the Search field to locate a document that satisfies your needs.

- Once you find the suitable form, click on Buy now.

Form popularity

FAQ

The following 22 states or territories have OSHA-approved State Plans that cover both private and state and local government workers:Alaska.Arizona.California.Hawaii.Indiana.Iowa.Kentucky.Maryland.More items...

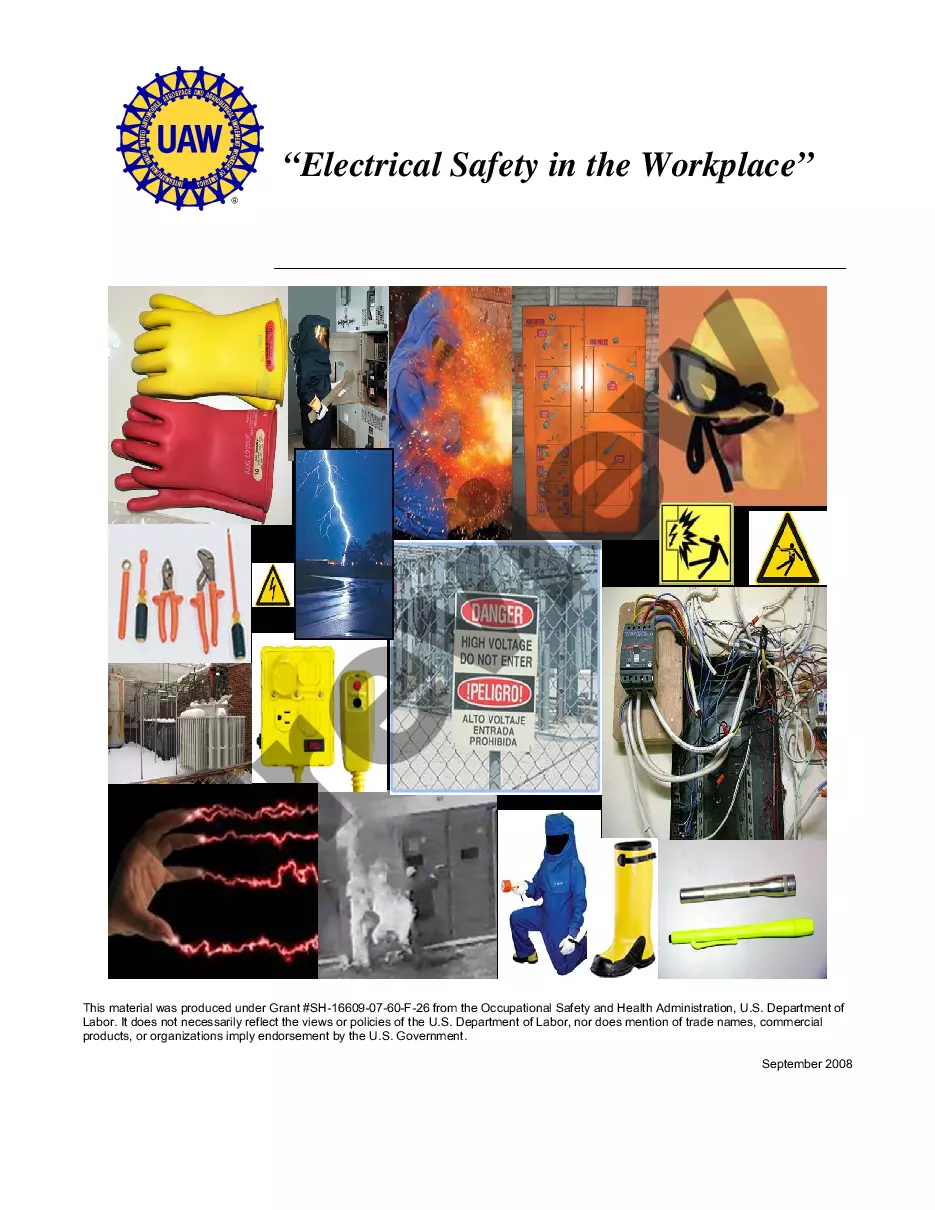

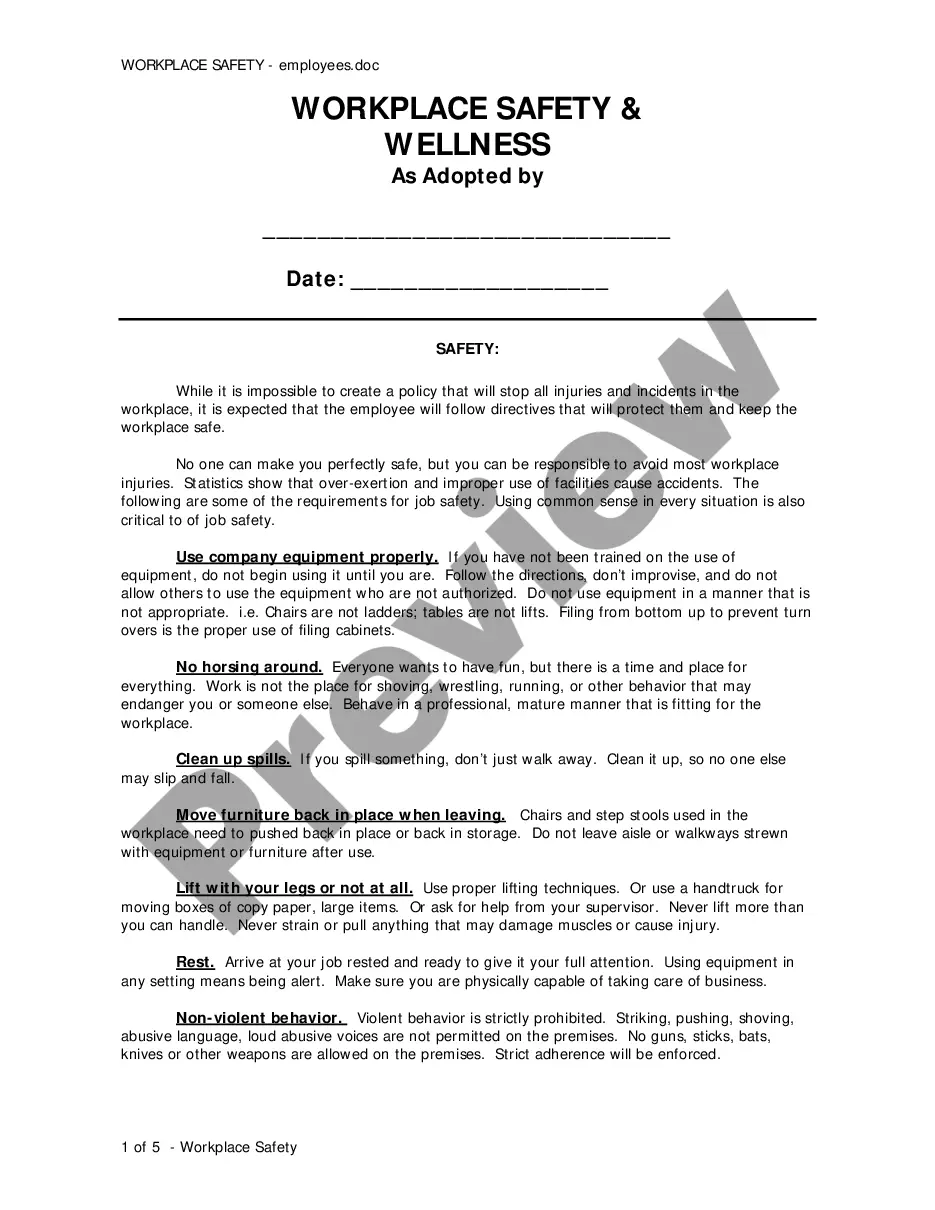

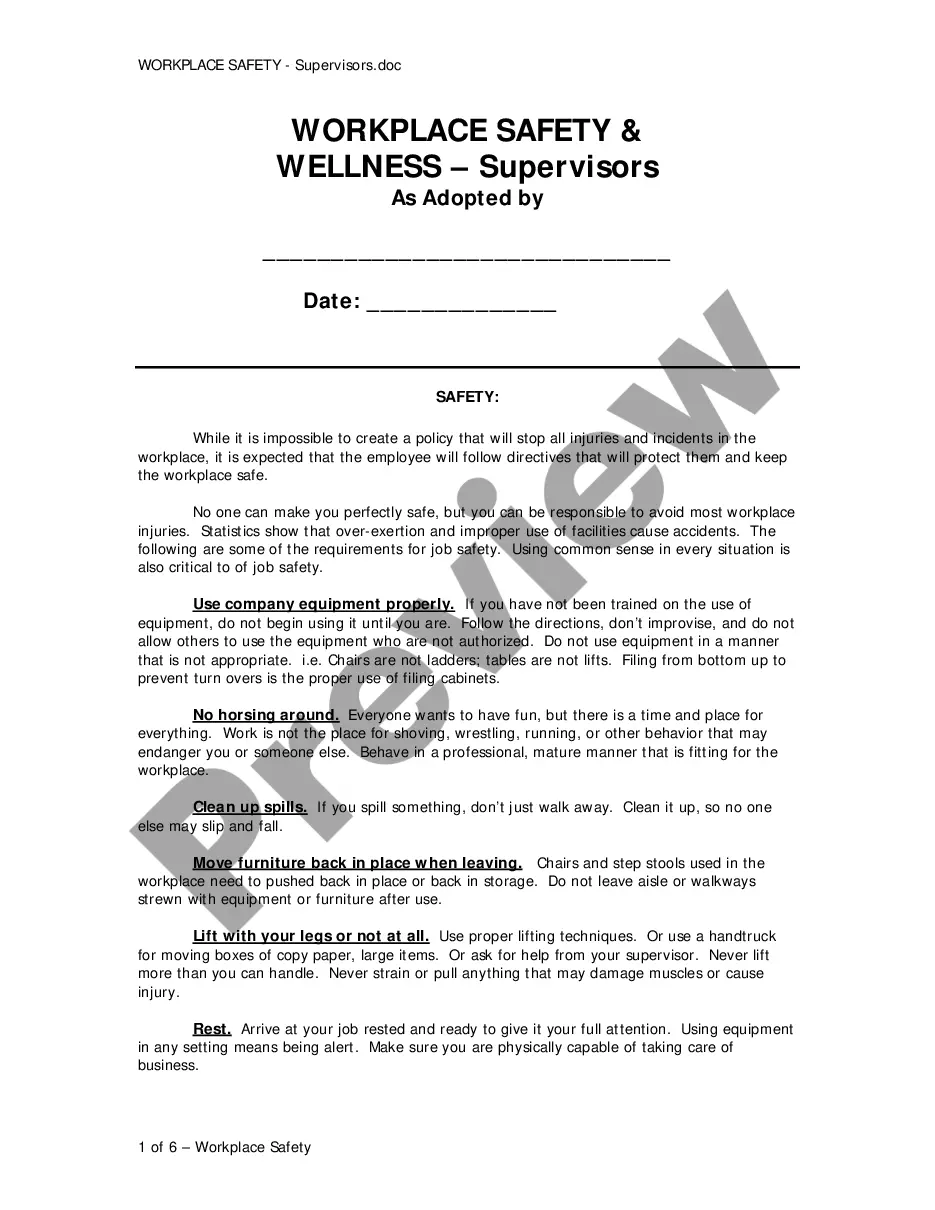

10 Daily Workplace Safety Tips in ManufacturingInform Supervisors of Unsafe Conditions.Use Equipment, Machines, and Tools Properly.Wear Safety Equipment (PPE)Prevent Slips and Trips.Keep Work Areas and Emergency Exits Clear.Eliminate Fire Hazards.Avoid Tracking Hazardous Materials.Prevent Objects from Falling.More items...?

Nevada State Plan Office Federal government employees, including those employed by the United State Postal Service, private sector maritime, employment on Indian Lands, and areas of exclusive federal jurisdiction, are covered under federal OSHA jurisdiction.

Workplace safety tipsUse tools, equipment and machinery properly.Report any unsafe conditions.Wear all necessary safety gear.Keep your workplace clear from clutter.Stay hydrated.Practice good posture when sitting or lifting.Take regular breaks.Be aware of your surroundings.More items...?

10 Rules for Workplace SafetyPreventing workplace incidents is everyone's job, and your personal safety is your responsibility.Dress appropriately, from clothing to footwear.Keep work areas neat and tidy.Follow the rules.Report workplace accidents or safety incidents.Know and follow emergency procedures.More items...?

Nevada OSHA is responsible for the enforcement of Nevada OSHA safety and health standards.

7 Safety Rules to Avoid Workplace InjuryUse the proper tool for the job.Always wear the proper PPE for the work task.Never work on live equipment.Make sure chemicals are properly labeled and stored.Communicate safety hazards to other personnel.Stop work when needed to address hazards.

You must:make sure your buildings are in good repair.maintain the workplace and any equipment so that it is safe and works efficiently.put right any dangerous defects immediately, or take steps to protect anyone at risk.take precautions to prevent people or materials falling from open edges, eg fencing or guard rails.More items...?

The Basics of SafetySTAY ALERT - and stay alive.WEAR THE RIGHT CLOTHES - work clothes should fit properly.USE THE RIGHT TOOLS - if you need a hammer, get a hammer.LEARN HOW TO LIFT - Lifting takes more than muscle; it is an art.More items...

Nevada. Nevada operates an OSHA-approved State Plan covering most private sector workers and all state and local government workers.