Nevada Maintenance Assistance - Technician Checklist

Category:

State:

Multi-State

Control #:

US-380EM

Format:

Word;

Rich Text

Instant download

Description

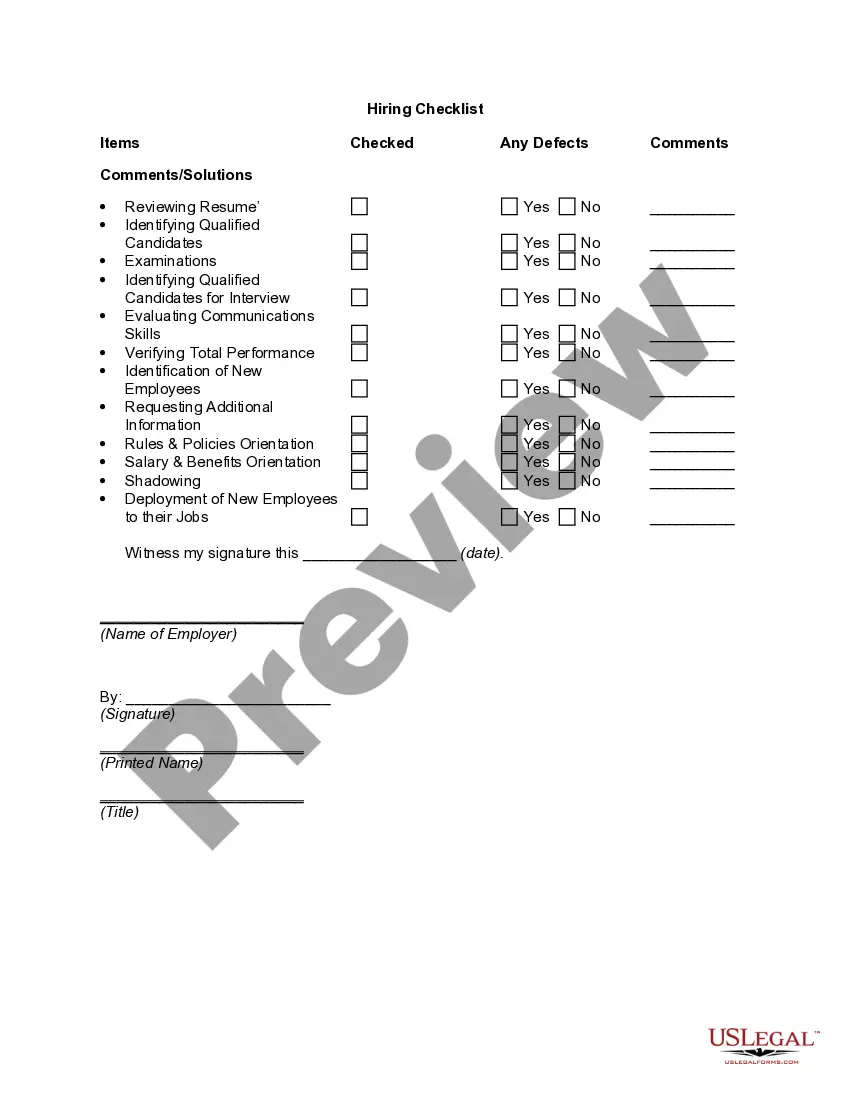

This form is used to list the potential duties of a maintenance assistant/technician.

How to fill out Maintenance Assistance - Technician Checklist?

US Legal Forms - one of the largest repositories of lawful templates in the USA - offers a range of legal document samples that you can download or print.

By utilizing the website, you can obtain thousands of forms for business and personal purposes, organized by categories, states, or keywords.

You can find the latest versions of forms such as the Nevada Maintenance Assistance - Technician Checklist in minutes.

Examine the form description to confirm that you have selected the right one.

If the form does not meet your requirements, use the Search field at the top of the screen to find one that does.

- If you have a monthly subscription, Log In and download the Nevada Maintenance Assistance - Technician Checklist from your US Legal Forms library.

- The Download button will appear on every form you view.

- You can access all of the previously downloaded forms from the My documents tab in your account.

- If you want to use US Legal Forms for the first time, here are simple instructions to help you get started.

- Ensure you have selected the correct form for your city/state.

- Click on the Preview button to review the form's details.