Nevada Maintenance Engineer Checklist

Description

How to fill out Maintenance Engineer Checklist?

Locating the appropriate legal document template can be a challenge.

Of course, there are numerous formats available online, but how will you find the legal form you require? Utilize the US Legal Forms site.

The service offers a multitude of templates, such as the Nevada Maintenance Engineer Checklist, which can be used for both business and personal purposes. All templates are reviewed by experts and comply with federal and state regulations.

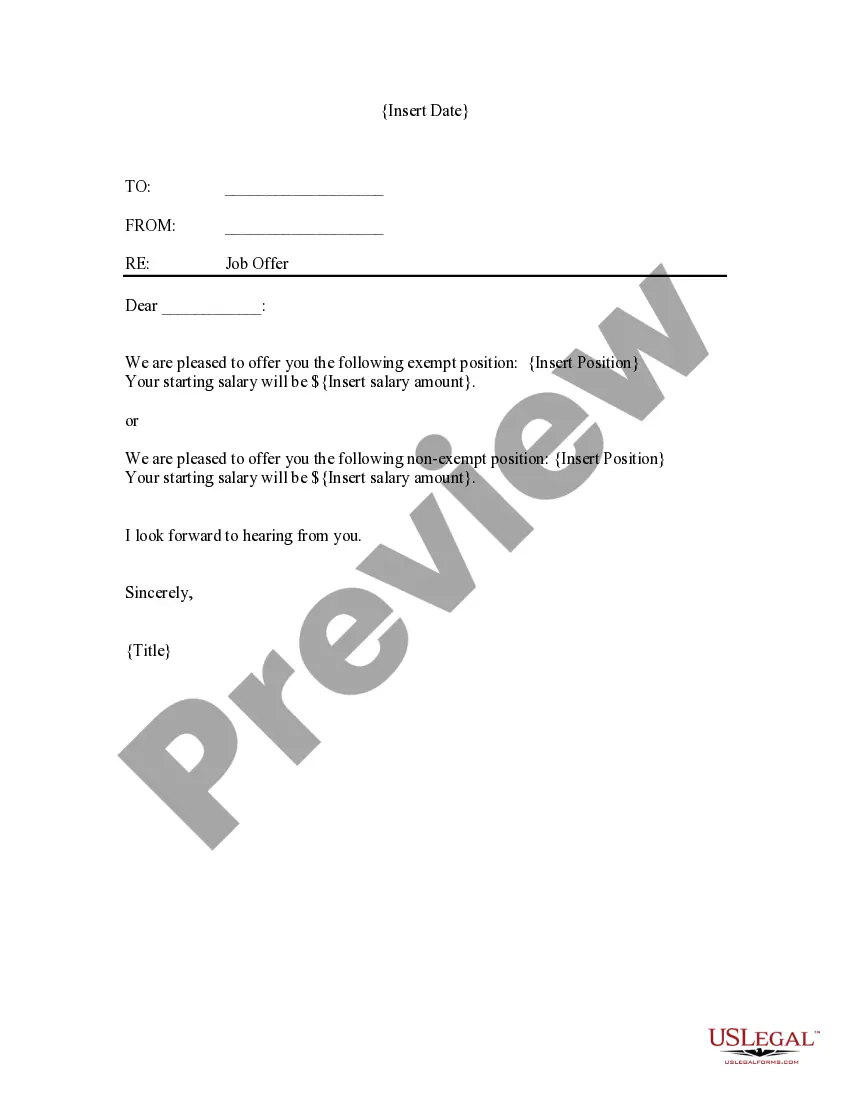

- First, ensure you have selected the correct form for your city/region.

- You can browse the form using the Review button and read the form description to confirm it is suitable for your needs.

- If the form does not meet your requirements, use the Search field to find the appropriate form.

- Once you are confident that the form is correct, select the Get now button to download the form.

- Choose the pricing plan you prefer and enter the necessary information.

- Create your account and pay for the transaction using your PayPal account or Visa or Mastercard.

Form popularity

FAQ

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

The maintenance plan's contents, which include the actual work, instructions, schedule, workers, spare parts, and contractors, guide all the maintenance work activities. Read on to learn what you need to include in the plan and how to make it efficient.

The Ultimate Preventive Maintenance ChecklistEnsure that machinery is clear of debris, before and after every shift.Wipe machine surfaces of lubricant, dirt and other loose debris each day.Regularly inspect tools for sharpness.Check for and replace worn or damaged tools.More items...

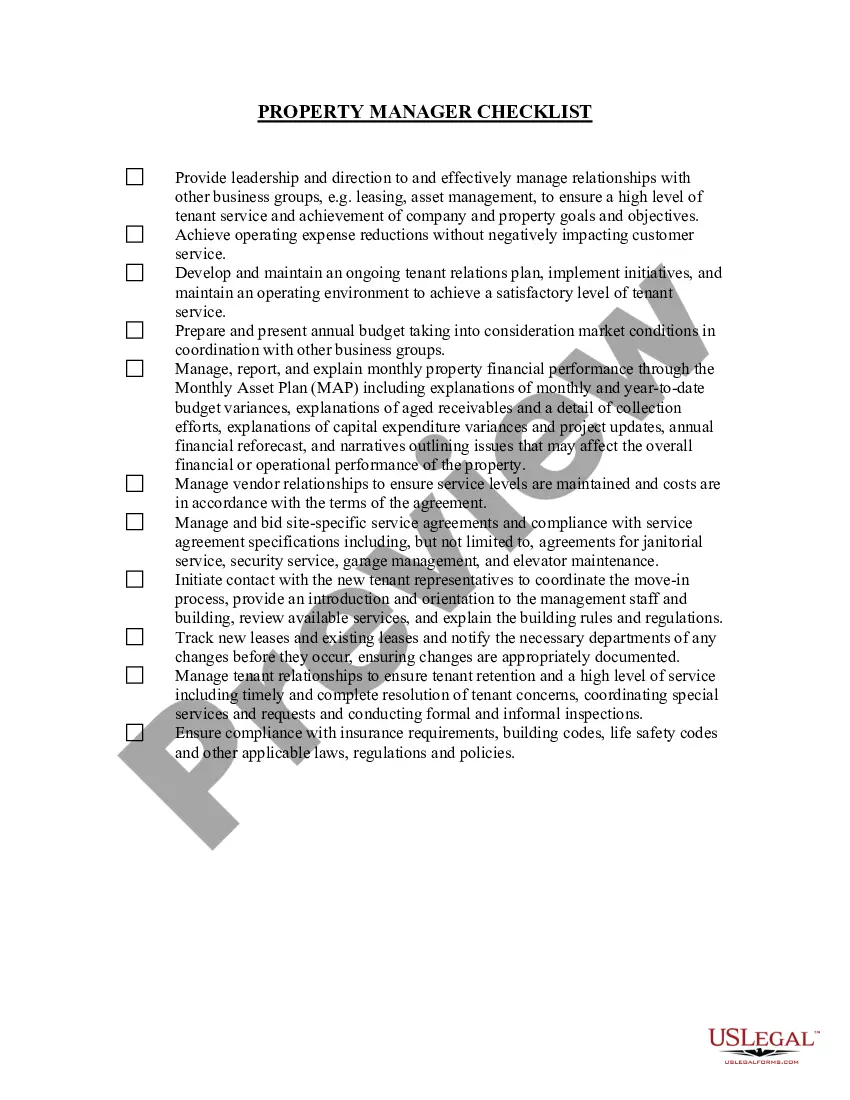

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

A preventive maintenance checklist is an itemized list of written tasks that guide technicians through a process of asset's preventive maintenance (PM).

An itemized list of discrete maintenance tasks that have been prepared by the manufacturers of the asset and/or other subject matter experts such as consultants. Checklists are the basic building blocks of a maintenance program.

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...