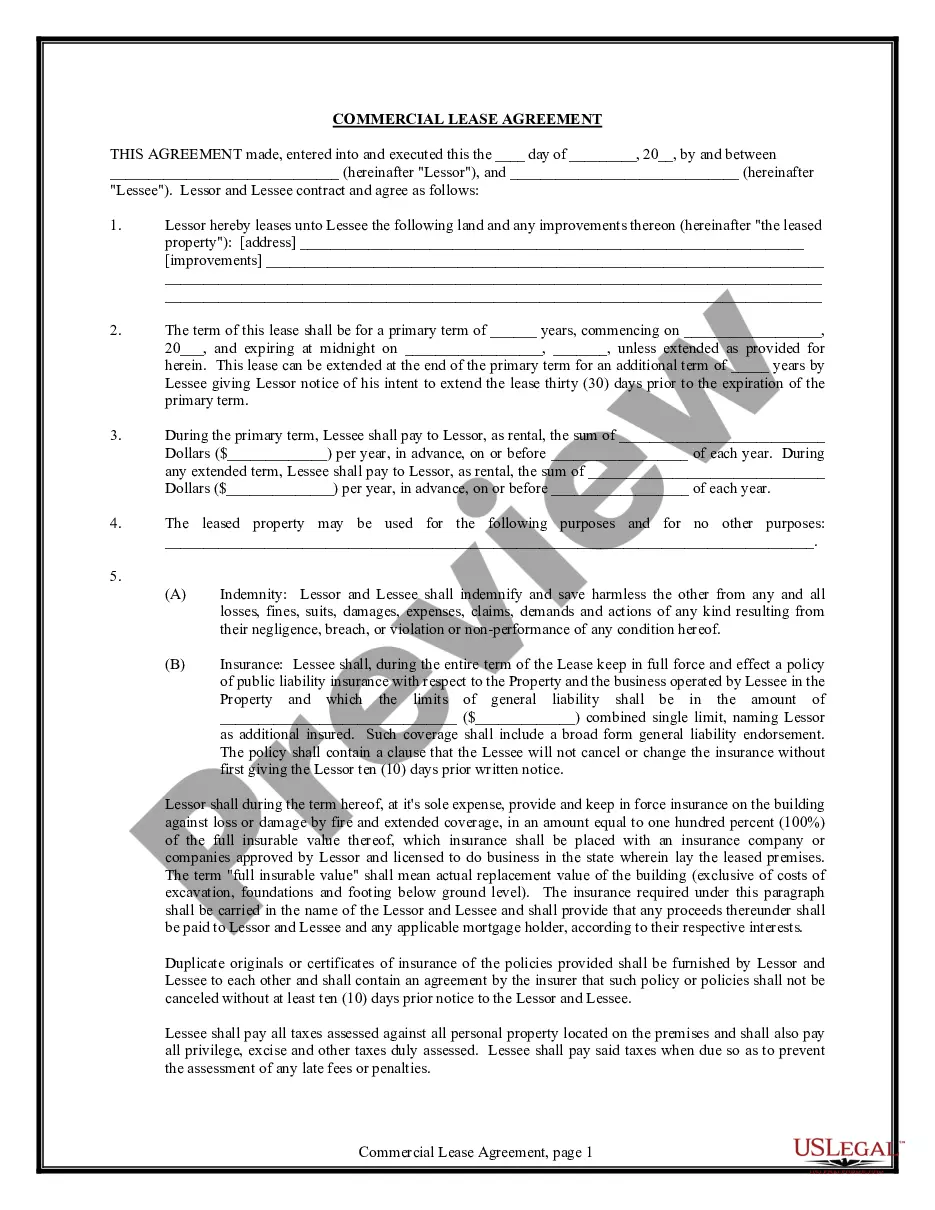

This office lease form states that the landlord shall install a freight elevator that will be adjacent to the tenant's exclusive loading dock. Upon completion of the installation of the tenant's freight elevator, the tenant, at its sole cost and expense, shall maintain the tenant's freight elevator in good working order.

Nevada Specification for Freight Elevator Service

Description

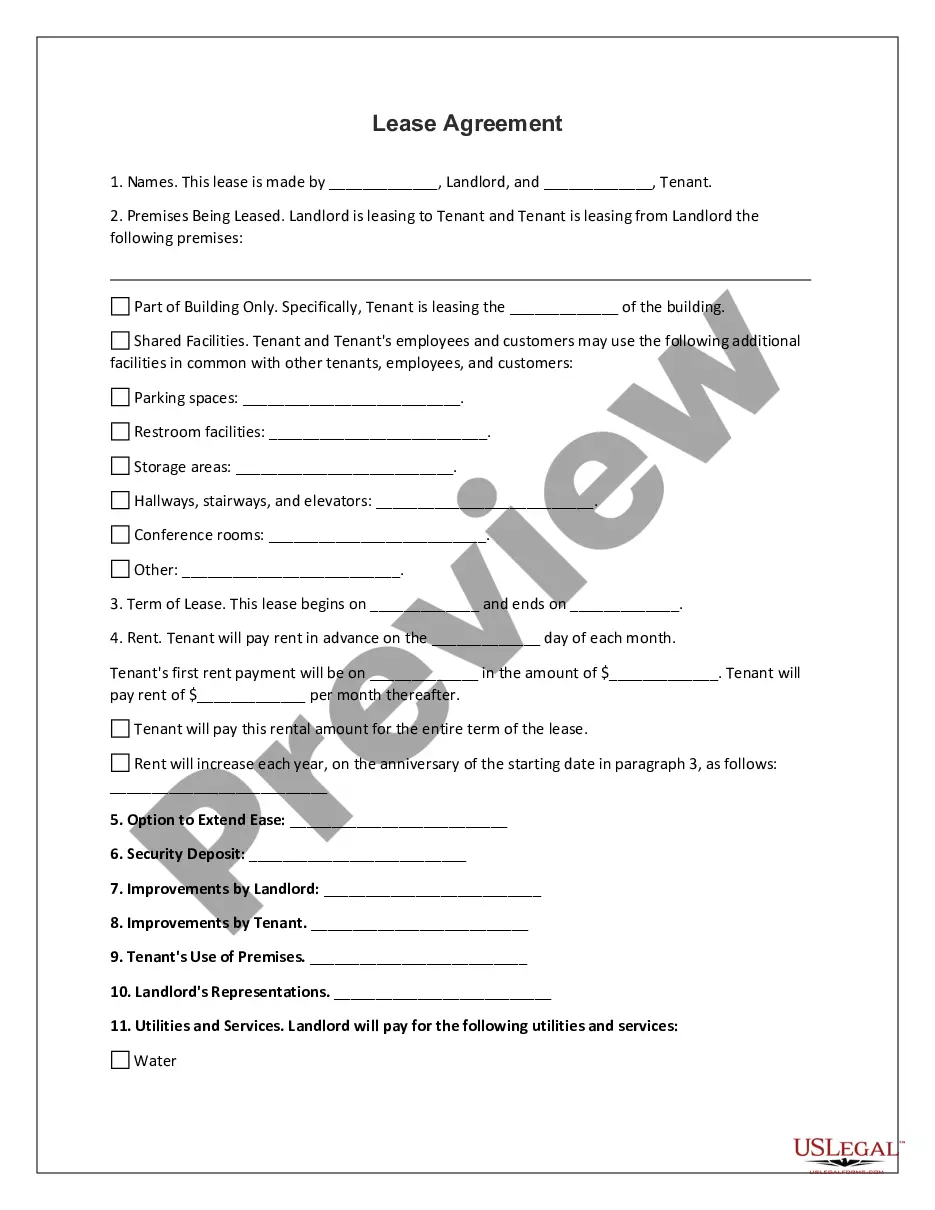

How to fill out Specification For Freight Elevator Service?

If you have to full, acquire, or print out legitimate papers web templates, use US Legal Forms, the largest variety of legitimate varieties, that can be found online. Make use of the site`s basic and practical search to obtain the paperwork you require. A variety of web templates for enterprise and person functions are sorted by types and states, or keywords. Use US Legal Forms to obtain the Nevada Specification for Freight Elevator Service in just a couple of click throughs.

In case you are already a US Legal Forms client, log in in your bank account and click the Obtain option to find the Nevada Specification for Freight Elevator Service. Also you can gain access to varieties you previously saved from the My Forms tab of your bank account.

If you use US Legal Forms for the first time, follow the instructions under:

- Step 1. Make sure you have selected the shape to the correct metropolis/land.

- Step 2. Utilize the Review method to check out the form`s information. Never overlook to read the explanation.

- Step 3. In case you are not happy with the kind, make use of the Lookup area towards the top of the display screen to discover other types in the legitimate kind template.

- Step 4. Once you have identified the shape you require, click the Buy now option. Pick the prices plan you like and put your accreditations to register for the bank account.

- Step 5. Approach the financial transaction. You should use your Мisa or Ьastercard or PayPal bank account to finish the financial transaction.

- Step 6. Find the structure in the legitimate kind and acquire it on the system.

- Step 7. Full, revise and print out or indicator the Nevada Specification for Freight Elevator Service.

Every legitimate papers template you buy is your own property eternally. You may have acces to every single kind you saved within your acccount. Click on the My Forms segment and select a kind to print out or acquire again.

Contend and acquire, and print out the Nevada Specification for Freight Elevator Service with US Legal Forms. There are thousands of specialist and status-particular varieties you may use for your enterprise or person needs.

Form popularity

FAQ

Its primary purposes are to provide reasonable safety for those persons who come in contact with elevators, escalators, dumbwaiters, moving walks, and material lifts by establishing minimum standards for design, installation, and maintenance, and for adoption by regulatory authorities throughout Canada.

ASME A17. 1/CSA B44-2016?one of ASME's most popular safety standards?addresses elevators, escalators, dumbwaiters, moving walks and material lifts. It provides requirements applying to the design, construction, installation, operation, testing, inspection, maintenance, alteration and repair of these conveyances.

ASME 17.1 is the "Safety Code for Elevators and Escalators." This includes the safety code requirements for elevators, escalators, dumbwaiters, moving walks, material lifts, and dumbwaiters with automatic transfer devices.

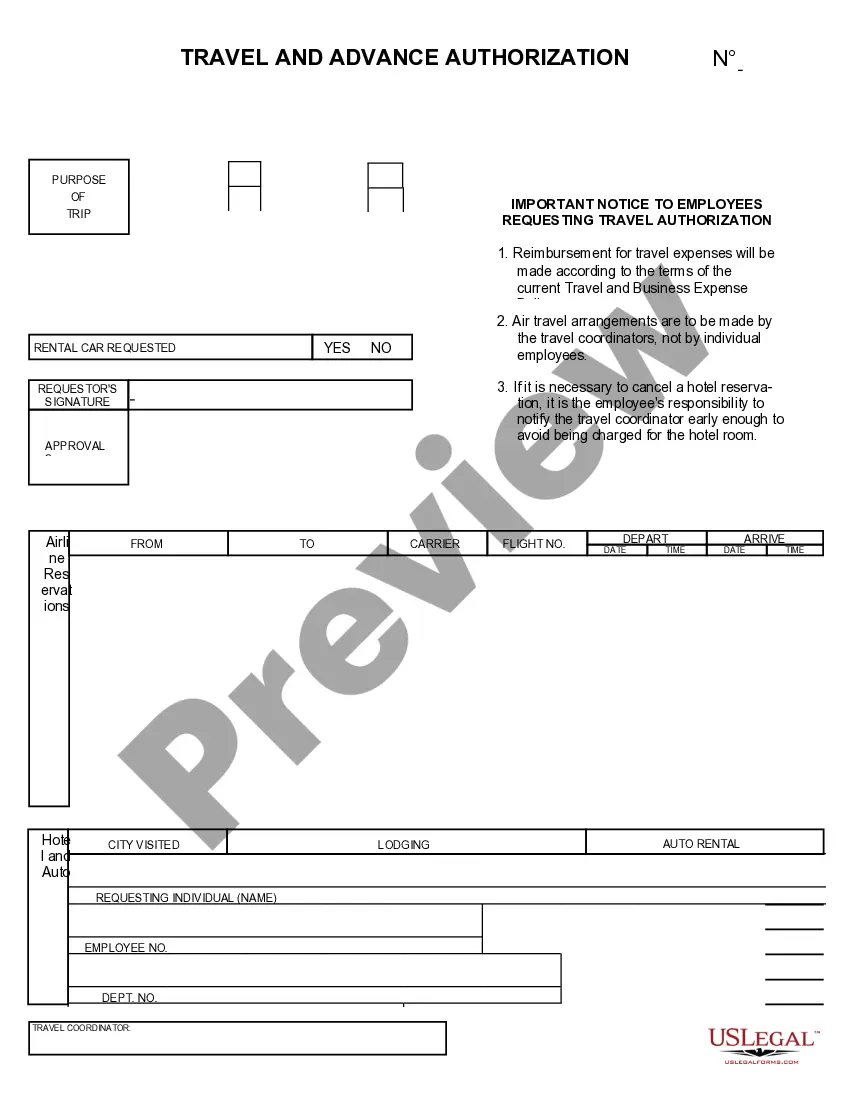

NAICS Code 333921 - Elevator and Moving Stairway Manufacturing sits in the 2-digit Manufacturing sector.

1. Standard Residential Elevator Sizes. Most home elevators have a cab depth of 36?-60?, width of 48?-60?, and height of at least 80?. Some variation occurs based on architectural features, the layout of your home, and local, state and federal residential building codes.

In compliance with ADA standards, the depth should have a minimum of 51 inches (1.30 m), width of 68 inches (1.73 m), and door width of 36 inches (. 91 m). The common elevator for office buildings are 6' wide by 5' deep (1.83 x 1.53 m). The doors of the elevator are typically 4' wide (1.22 m).

The Safety Code for Elevators ASME A17. 1-2022, as a code, is intended to provide safety of life and limb and promote public welfare. It covers not only elevators, escalators, moving walks, dumbwaiters, material lifts, and related equipment, but also their associated parts, rooms, spaces, and hoistways.

? The American Society of Mechanical Engineers (ASME) A17.3 Code for Existing Elevators and. Escalators is a retroactive elevator safety code, designed to make older elevator equipment as safe as possible.