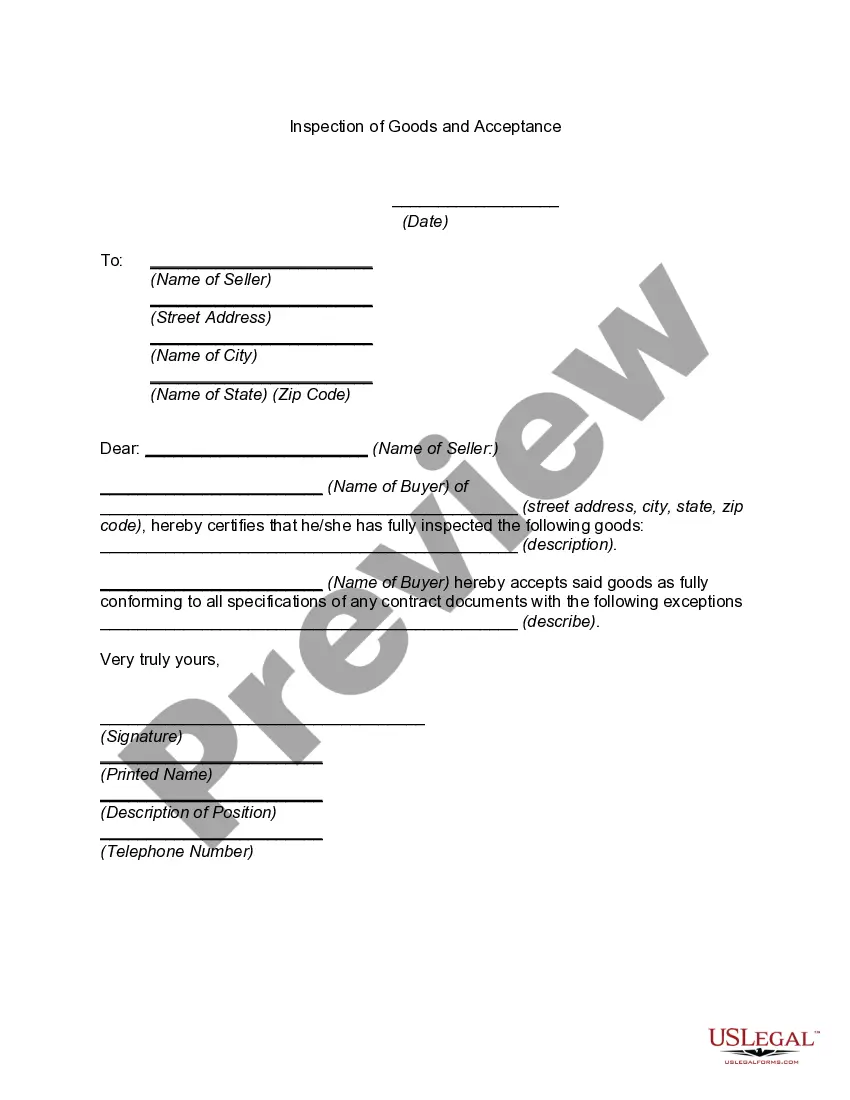

New York Inspection of Goods and Acceptance

Description

How to fill out Inspection Of Goods And Acceptance?

US Legal Forms - one of many most significant libraries of legal varieties in the USA - gives a wide array of legal papers templates you can down load or produce. While using web site, you can find thousands of varieties for business and specific reasons, categorized by groups, claims, or search phrases.You will discover the latest types of varieties such as the New York Inspection of Goods and Acceptance within minutes.

If you already possess a membership, log in and down load New York Inspection of Goods and Acceptance in the US Legal Forms local library. The Acquire button will appear on every single form you see. You gain access to all previously acquired varieties from the My Forms tab of your accounts.

If you wish to use US Legal Forms the very first time, listed below are basic recommendations to help you get started out:

- Be sure you have picked out the correct form for your metropolis/region. Click the Preview button to check the form`s articles. Read the form outline to actually have chosen the proper form.

- When the form doesn`t match your needs, use the Lookup industry towards the top of the screen to find the one who does.

- Should you be content with the shape, confirm your decision by simply clicking the Acquire now button. Then, select the rates program you want and provide your qualifications to register for an accounts.

- Process the purchase. Use your credit card or PayPal accounts to perform the purchase.

- Choose the format and down load the shape in your gadget.

- Make changes. Fill out, modify and produce and indication the acquired New York Inspection of Goods and Acceptance.

Every single template you included in your bank account does not have an expiry date and is also your own property permanently. So, if you want to down load or produce another duplicate, just visit the My Forms area and click on in the form you will need.

Gain access to the New York Inspection of Goods and Acceptance with US Legal Forms, one of the most substantial local library of legal papers templates. Use thousands of specialist and state-distinct templates that meet your company or specific demands and needs.

Form popularity

FAQ

One or more worn, damaged, or fouled sparkplugs are present. Catalytic converter is clogged, missing, or ineffective Malfunctioning oxygen sensor. Internal engine parts may be malfunctioning or damaged.

Ready? Have with you:A completed Vehicle Registration / Title Application (MV-82)Proof you own the vehicle.Proof of your identity and age.Proof you have NY automobile liability insurance.Payment for fees and taxes, or proof of payment or exemption.More items...

Upon inspection, the mileage appearing on the odometer shall be recorded upon the inspection sticker. IF A VEHICLE'S ANTI-LOCK BRAKE SYSTEM WARNING LIGHT IS ON, IT SHALL BE CONSIDERED GROUNDS FOR THE VEHICLE TO FAIL THE SAFETY INSPECTION PROVIDED IN THIS PARAGRAPH.

You can renew the registration only if your vehicle has had an emissions inspection within the last 12 months. If there is not an inspection report on file, you cannot renew your registration. You can renew your registration after your vehicle has passed the required emissions inspection.

What items does NY State Require be checked for the Safety Inspection?Seat Belts.Brakes.Steering, Front End, Suspension, Chassis, Frame and Wheel Fasteners.Tires (Except spare)Lights.Windshield and Other Glass.Windshield Wipers and Blades.Horn.More items...

Every 12 months, your vehicle needs a safety inspection from a DMV-licensed inspection station. In addition, an inspection is needed when there's a transfer of ownership. In other words, every time there's a vehicle title transfer.

First, determine if an expired out-of-state inspection is a violation of law in that state. Ask the authorities if a New York State inspection extension sticker prevents a ticket for the violation. The extension allows you 10 days from the date the vehicle returns to New York State to get an inspection.

In the state of New York, most things that make you a danger to other people on the road will cause you to fail the safety portion of your inspection. Some of these things can be obvious. You would already know that severely worn brakes or a ball joint worn enough to be a safety concern won't allow you to pass.

SAFETY ITEMS INSPECTED ON CARS AND LIGHT TRUCKSSeat Belts. Inspect for proper operation and anchorage.Brakes. At least one front wheel must be removed to inspect the brakes.Steering, Front End, Suspension, Chassis, Frame and Wheel Fasteners.Lights.Windshield and Other Glass.Windshield Wipers and Blades.Horn.Mirrors.More items...

All registrations, inspections, and non-driver IDs that expired in or after March, during the Coronavirus public health emergency, were extended by Executive Order but this extension will end on November 3. New Yorkers can quickly and easily renew a registration or renew a non-driver ID on the DMV website.