The Ohio Maintenance Engineer Checklist is a comprehensive document designed to guide maintenance engineers in performing their duties effectively and efficiently. This checklist acts as a roadmap for maintenance tasks and ensures that all necessary steps are completed to maintain the optimal functionality and safety of various systems and equipment within a facility. Keywords: Ohio, maintenance engineer, checklist, duties, tasks, functionality, safety, systems, equipment, facility. Different types of Ohio Maintenance Engineer Checklists may include: 1. Mechanical Systems Checklist: This checklist focuses on maintenance tasks related to mechanical systems like HVAC (heating, ventilation, and air conditioning) units, elevators, pumps, fans, boilers, and other similar equipment. It outlines tasks such as inspecting and cleaning filters, lubricating moving parts, checking for leaks, testing safety controls, and performing routine maintenance. 2. Electrical Systems Checklist: This checklist emphasizes maintenance tasks related to electrical systems, including panels, circuits, lighting fixtures, generators, motors, and other electrical equipment. It covers tasks like inspecting electrical connections, testing voltage levels, replacing bulbs, checking grounding systems, and maintaining backup power sources. 3. Plumbing Systems Checklist: This checklist is designed for maintenance engineers responsible for plumbing systems. It includes tasks such as inspecting pipes for leaks, repairing faucets and toilets, monitoring water pressure, flushing water heaters, testing backflow prevention devices, and maintaining sump pumps. 4. Fire Safety Systems Checklist: This checklist focuses on tasks related to maintaining fire safety systems, such as fire alarm systems, fire suppression systems, emergency exits, and fire extinguishers. It includes tasks like testing alarms and detectors, inspecting sprinkler systems, ensuring emergency lights are functional, checking fire doors, and maintaining fire extinguishers' validity. 5. Building and Asset Maintenance Checklist: This checklist encompasses general maintenance tasks related to the building's infrastructure and assets. It includes tasks like inspecting walls, ceilings, and floors for damages, lubricating doors and windows, maintaining parking lots, inspecting elevators and escalators, monitoring security systems, and conducting regular inspections of all areas within the facility. These various Ohio Maintenance Engineer Checklists play a critical role in ensuring that maintenance engineers cover all essential areas and tasks within their facility, contributing to its smooth and uninterrupted operation.

Ohio Maintenance Engineer Checklist

Description

How to fill out Ohio Maintenance Engineer Checklist?

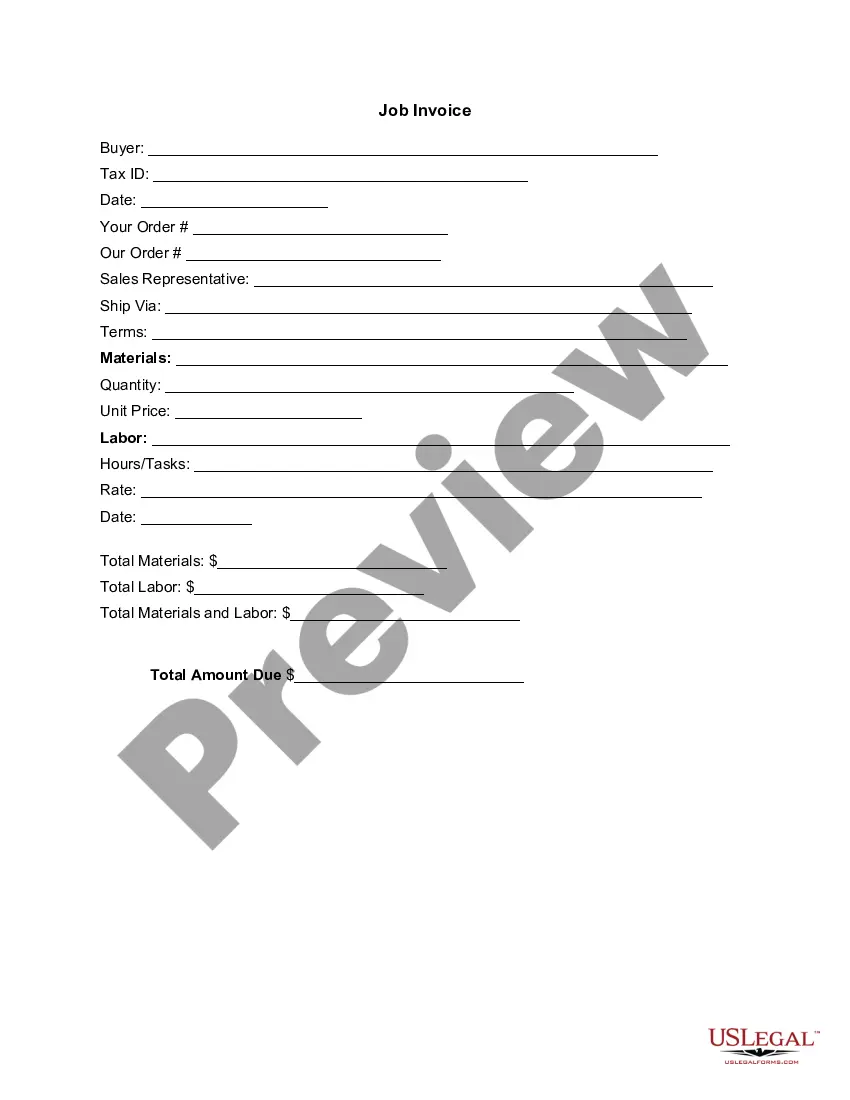

Discovering the right legitimate file format could be a struggle. Needless to say, there are plenty of themes available online, but how would you obtain the legitimate form you need? Take advantage of the US Legal Forms web site. The support provides a huge number of themes, for example the Ohio Maintenance Engineer Checklist, which can be used for organization and private needs. Each of the forms are inspected by specialists and satisfy state and federal needs.

In case you are currently authorized, log in for your accounts and then click the Download option to obtain the Ohio Maintenance Engineer Checklist. Make use of your accounts to appear with the legitimate forms you possess acquired in the past. Visit the My Forms tab of your own accounts and acquire another copy of your file you need.

In case you are a fresh customer of US Legal Forms, listed here are easy instructions so that you can comply with:

- Initially, make sure you have chosen the right form for the city/area. It is possible to examine the shape using the Preview option and look at the shape information to make sure it will be the best for you.

- In case the form does not satisfy your preferences, utilize the Seach area to obtain the proper form.

- When you are certain the shape would work, go through the Purchase now option to obtain the form.

- Select the pricing strategy you would like and enter the required details. Design your accounts and pay money for the order using your PayPal accounts or credit card.

- Select the data file file format and download the legitimate file format for your gadget.

- Total, change and produce and indicator the received Ohio Maintenance Engineer Checklist.

US Legal Forms is the most significant local library of legitimate forms for which you can see numerous file themes. Take advantage of the service to download appropriately-manufactured papers that comply with condition needs.