Oklahoma Manufacturer Analysis Checklist

Description

How to fill out Manufacturer Analysis Checklist?

US Legal Forms - one of the most extensive collections of legal documents in the United States - offers a broad range of legal paper templates that you can download or print.

Through the website, you can obtain thousands of forms for business and personal purposes, organized by categories, states, or keywords. You can access the latest forms such as the Oklahoma Manufacturer Analysis Checklist within minutes.

If you already have a subscription, sign in and download the Oklahoma Manufacturer Analysis Checklist from the US Legal Forms library. The Download button will appear on every form you review. You can access all previously downloaded forms in the My documents section of your account.

Process the payment. Use your credit card or PayPal account to complete the transaction.

Select the format and download the form to your device. Make modifications. Fill out, edit, and print and sign the downloaded Oklahoma Manufacturer Analysis Checklist. Each template you added to your account does not expire and is yours indefinitely. Therefore, if you need to download or print another copy, just go to the My documents section and click on the form you require. Access the Oklahoma Manufacturer Analysis Checklist with US Legal Forms, the most comprehensive collection of legal document templates. Utilize thousands of professional and state-specific templates that meet your business or personal needs and requirements.

- Ensure you have selected the correct form for your locality/state.

- Click on the Review button to evaluate the form's content.

- Examine the form summary to confirm you have chosen the right one.

- If the form doesn’t meet your requirements, use the Search box at the top of the screen to find the one that does.

- When you are satisfied with the form, confirm your choice by clicking on the Download now button.

- Next, select the pricing plan you prefer and provide your information to create an account.

Form popularity

FAQ

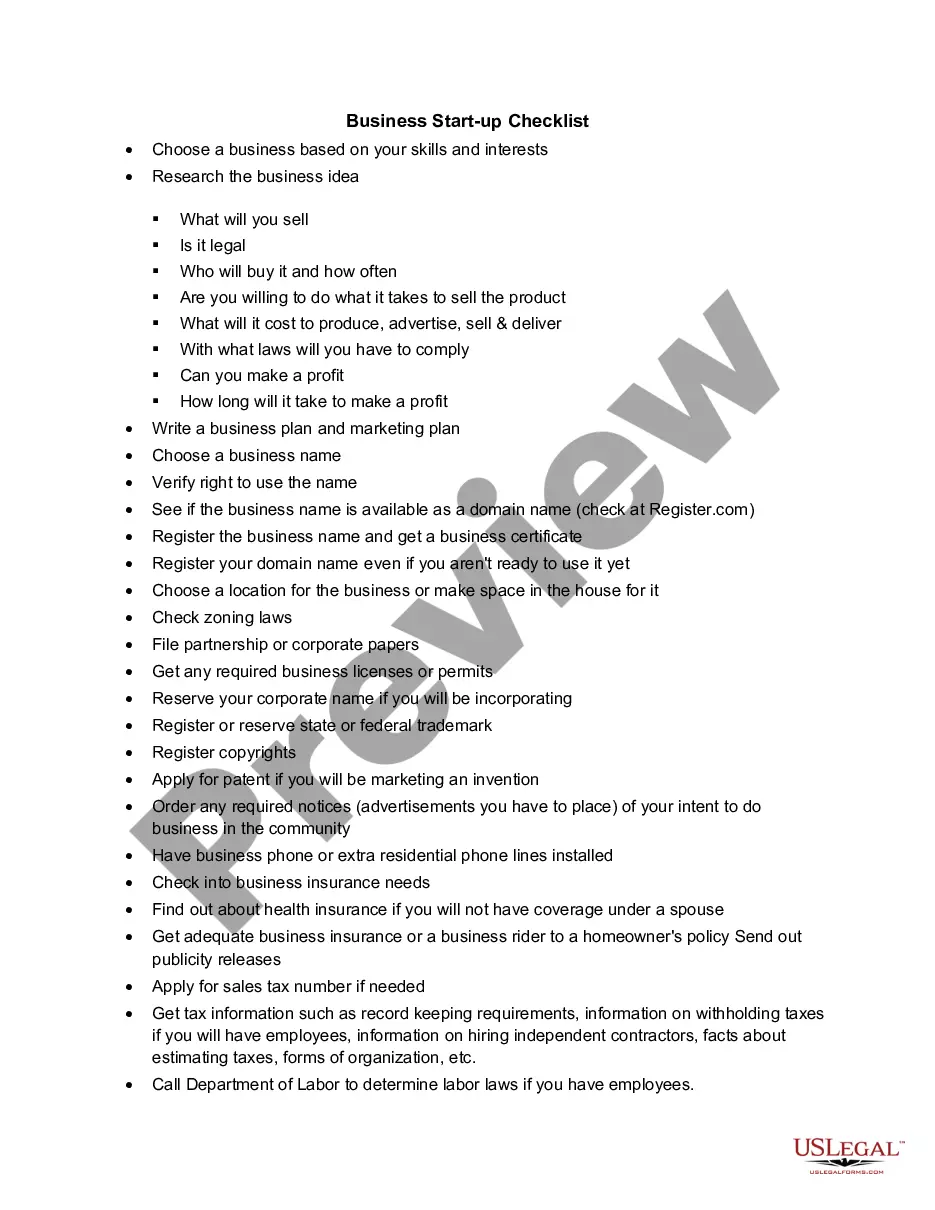

To become a vendor for the state of Oklahoma, you need to register your business and comply with procurement guidelines. This often involves filling out an application and providing relevant documentation. By using resources like the Oklahoma Manufacturer Analysis Checklist, you can navigate the vendor process more efficiently and understand the requirements for successful bidding.

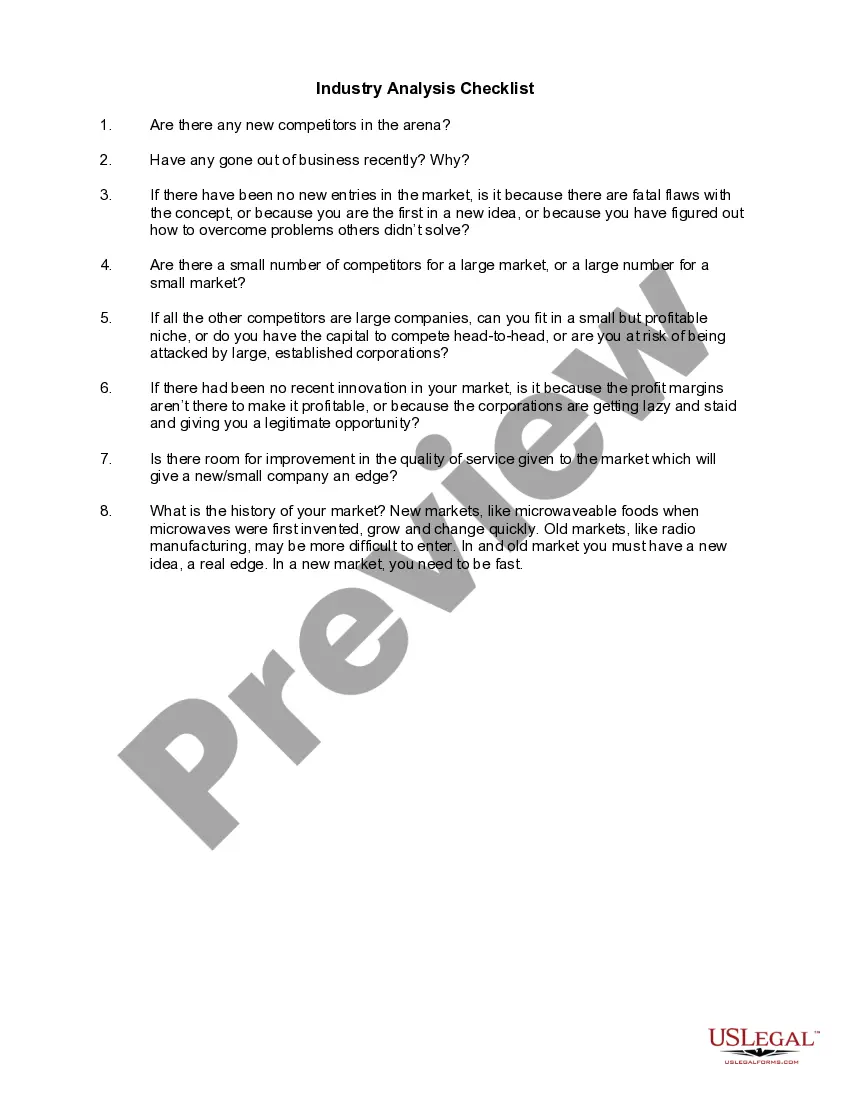

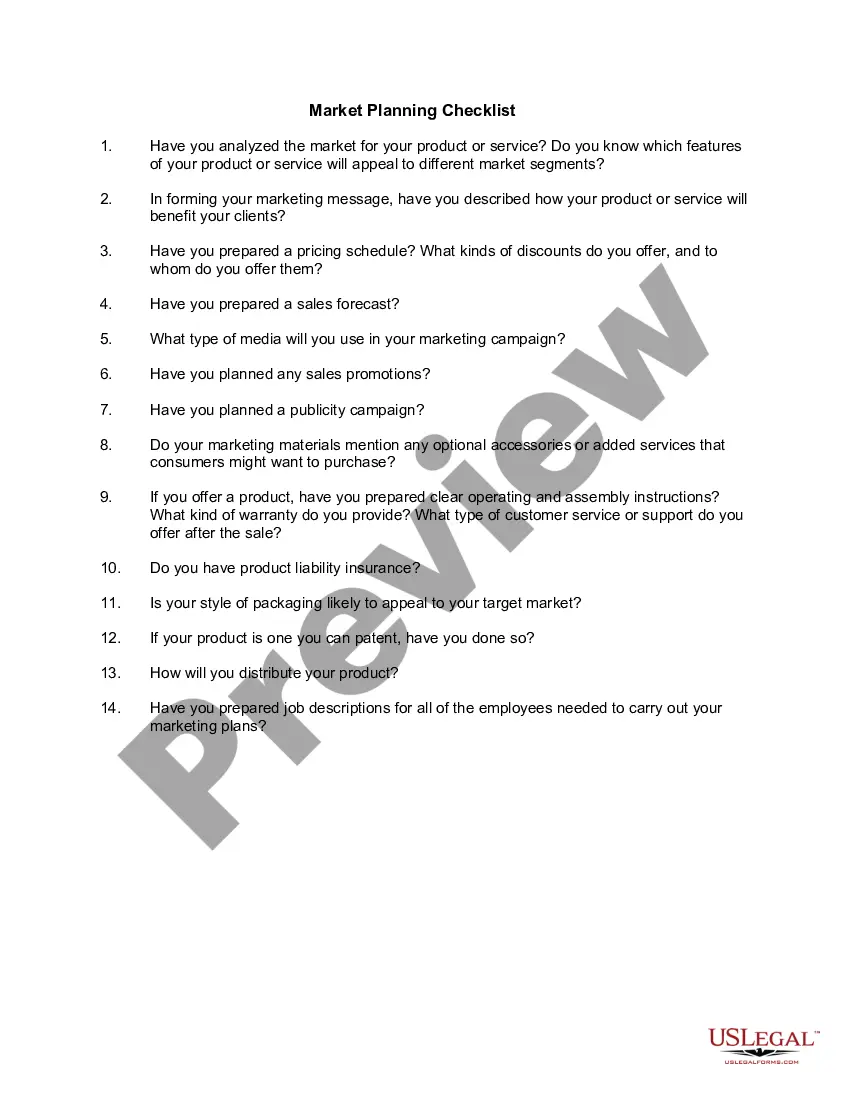

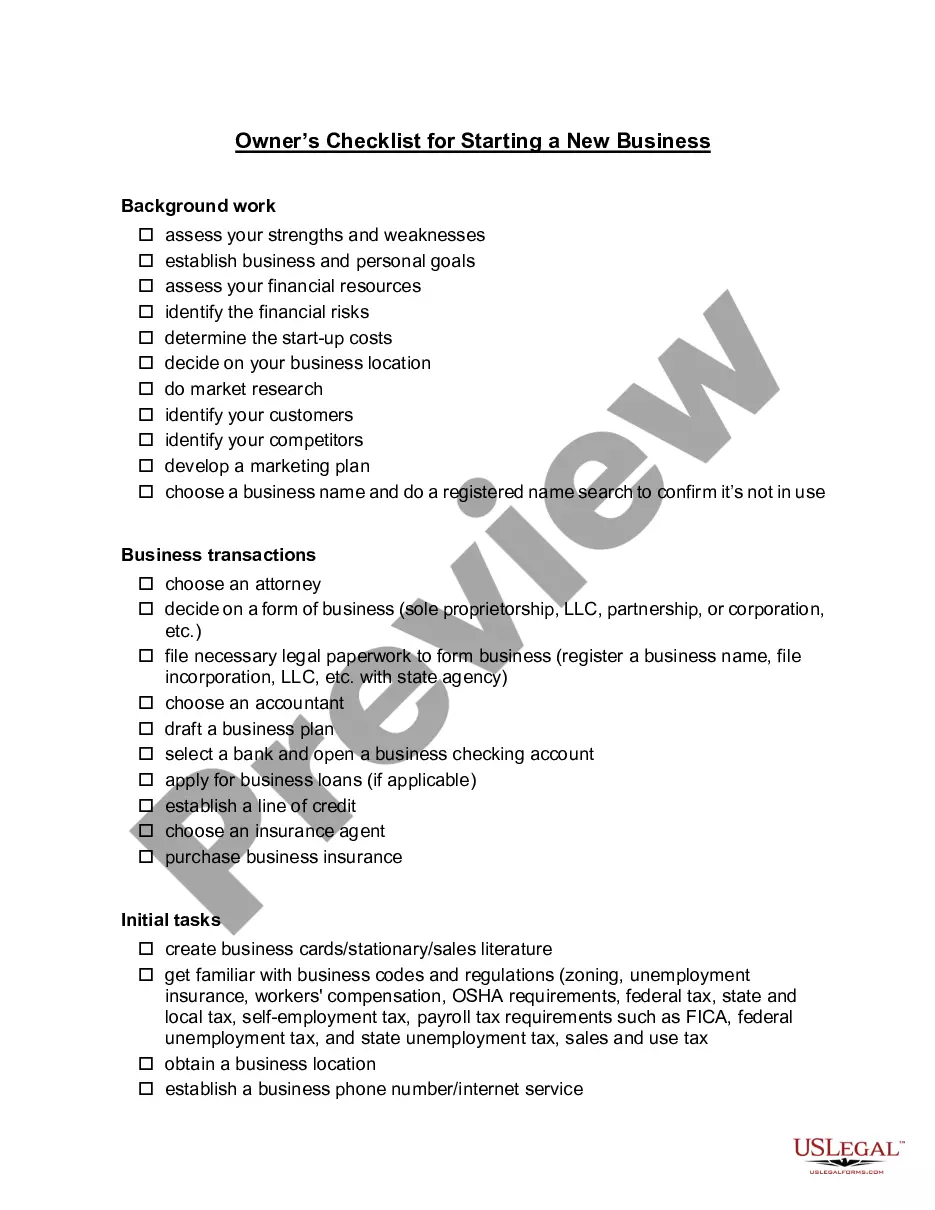

An example of a checklist could include a daily maintenance checklist for manufacturing equipment. This list might cover tasks such as inspecting machinery, checking fluid levels, and ensuring safety guards are in place. By adopting the Oklahoma Manufacturer Analysis Checklist, businesses can create tailored options that suit their specific manufacturing needs.

A checklist in industry serves as a critical tool to manage complex workflows and ensure compliance with safety and quality standards. It provides a structured approach for employees to follow, minimizing the risk of oversight during production. Implementing the Oklahoma Manufacturer Analysis Checklist can empower your team to achieve operational excellence.

The purpose of a checklist is to enhance organization and consistency by providing a clear roadmap for tasks that need completion. It reduces the risk of errors, ensuring that all components are addressed systematically. By incorporating the Oklahoma Manufacturer Analysis Checklist, businesses can gain greater visibility into their operations and refine their processes.

A production checklist is a specific type of checklist tailored to the various stages of the manufacturing process. It serves to guide staff through tasks, ensuring they follow established protocols and meet production targets. Utilizing the Oklahoma Manufacturer Analysis Checklist can enhance communication among team members and improve overall productivity.

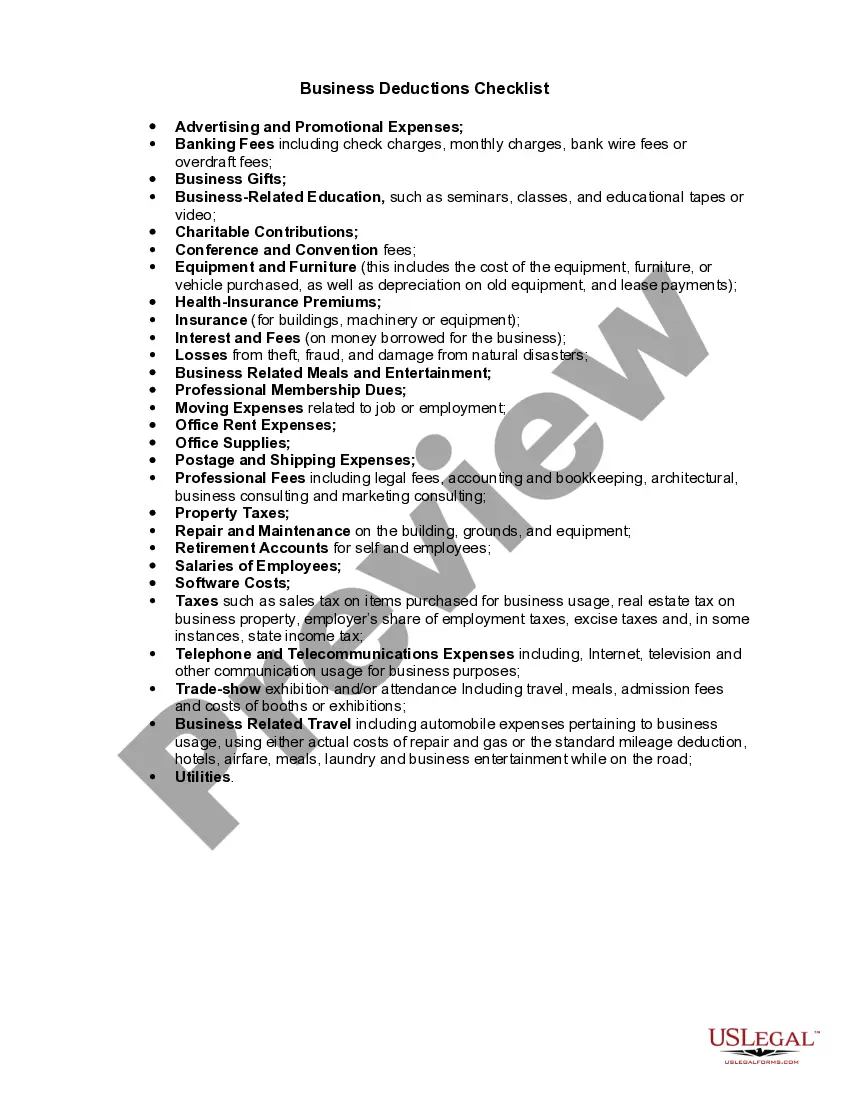

A checklist in manufacturing is a systematic tool used to ensure all necessary steps are completed during production processes. It helps maintain quality control by outlining essential tasks and verifying that nothing is overlooked. When implementing the Oklahoma Manufacturer Analysis Checklist, manufacturers can boost efficiency and streamline operations.

The five responsibilities of quality control involve developing quality standards, conducting inspections, recording data, analyzing results, and implementing corrective measures. Quality control personnel must ensure that all products comply with established guidelines. Using an Oklahoma Manufacturer Analysis Checklist can help quality control teams stay accountable for these critical responsibilities.

The five essentials of a quality control checklist include clarity, completeness, relevance, organization, and accessibility. Each item on the checklist should be clear and directly related to quality standards. By incorporating these essentials into an Oklahoma Manufacturer Analysis Checklist, businesses can improve their quality assurance processes.

A quality control checklist is a tool used to document the steps and parameters needed to verify product quality. It helps teams stay organized and focused during evaluation processes. Utilizing an Oklahoma Manufacturer Analysis Checklist can enhance quality control efforts by clearly defining criteria for assessment.

An inspection checklist outlines the essential items and processes that need to be evaluated during an inspection. This checklist helps ensure that all necessary inspections occur consistently and effectively. For manufacturers looking to streamline their inspection process, an Oklahoma Manufacturer Analysis Checklist can serve as a comprehensive guide to what should be inspected.