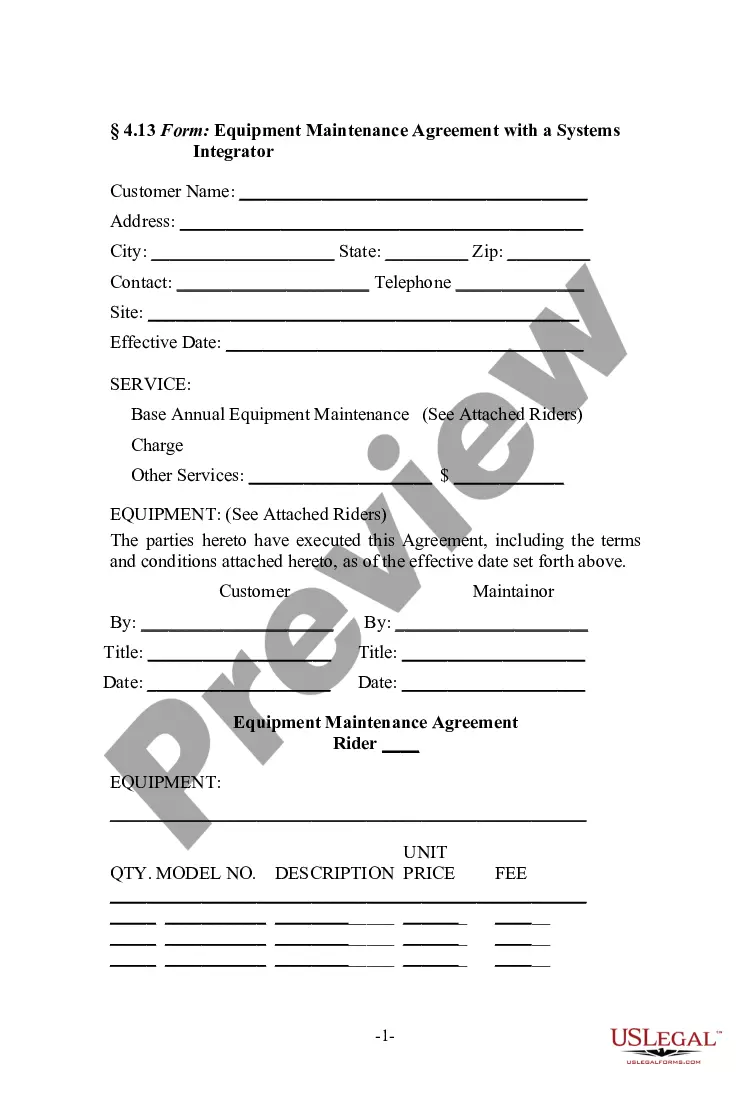

Oklahoma Equipment Maintenance Agreement with a Manufacturer

Description

How to fill out Equipment Maintenance Agreement With A Manufacturer?

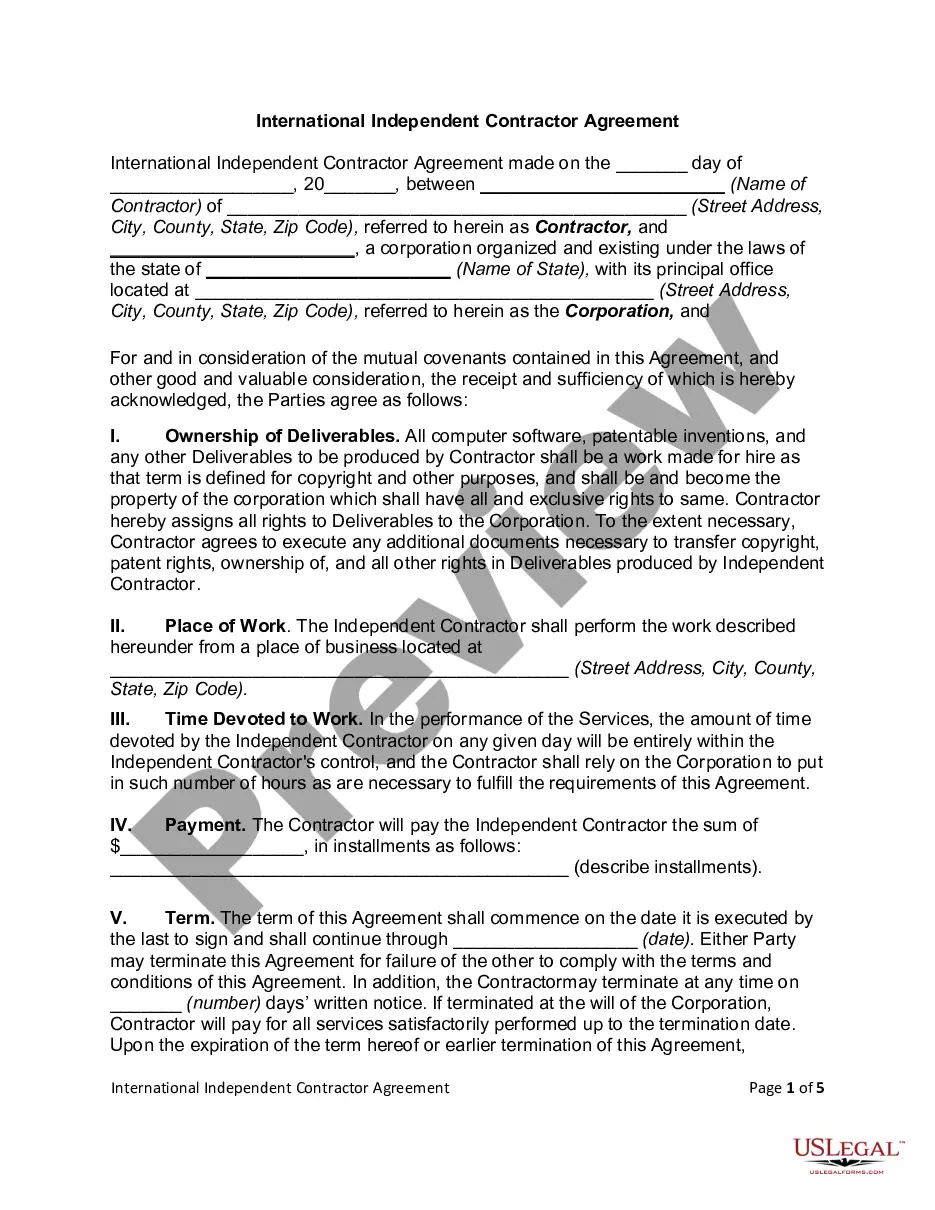

You can spend hours online trying to locate the correct legal document template that meets state and federal requirements you need.

US Legal Forms offers a vast selection of legal forms which are vetted by professionals.

You can obtain or print the Oklahoma Equipment Maintenance Agreement with a Manufacturer from my service.

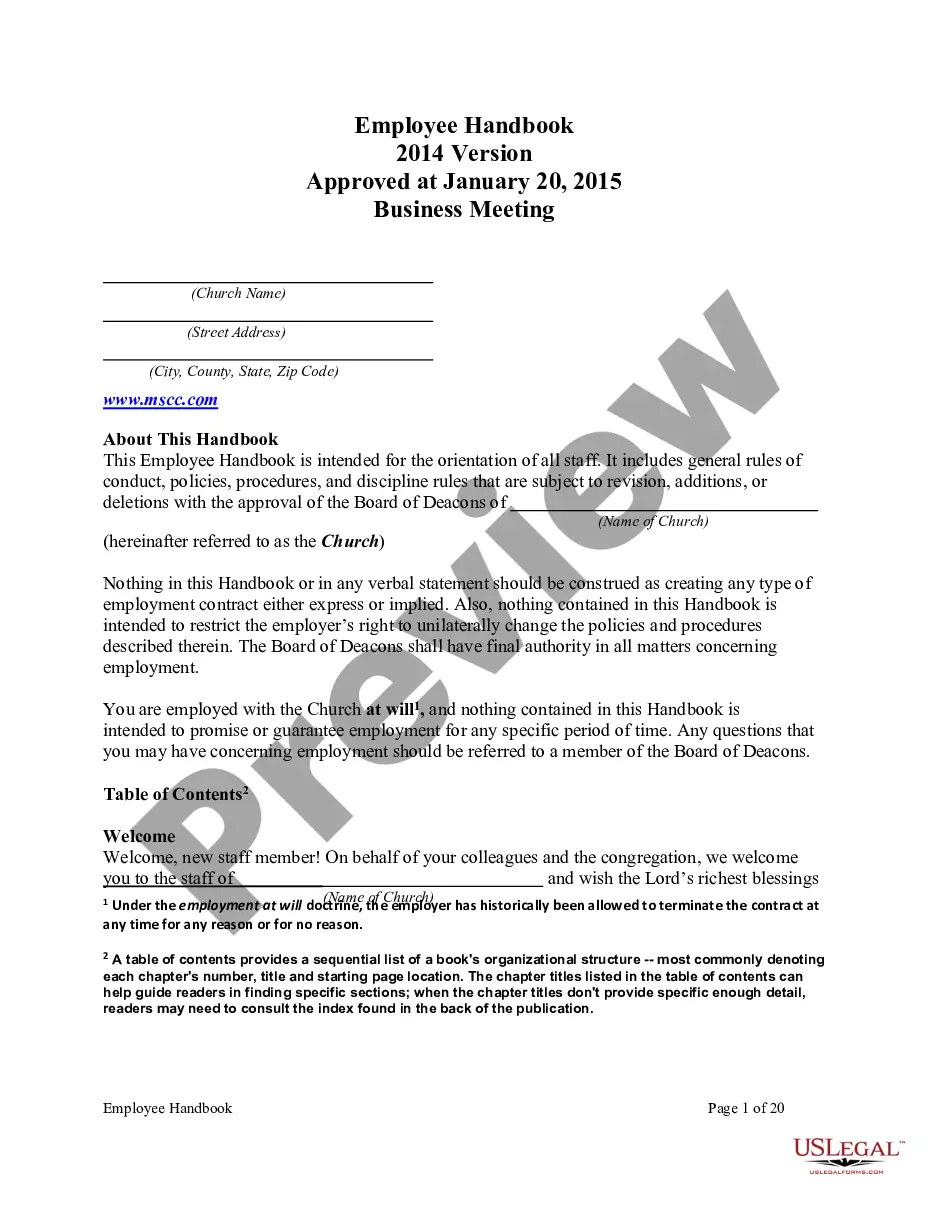

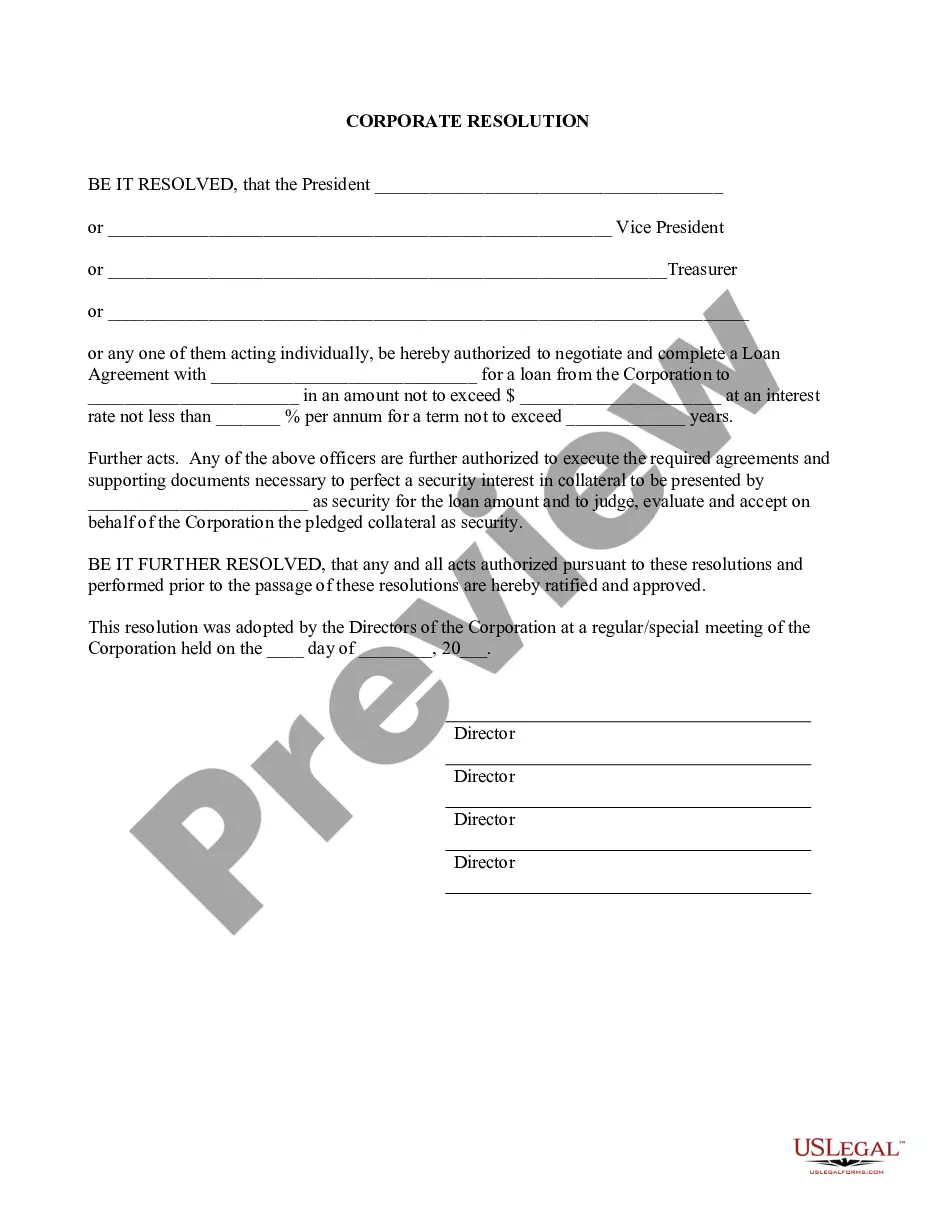

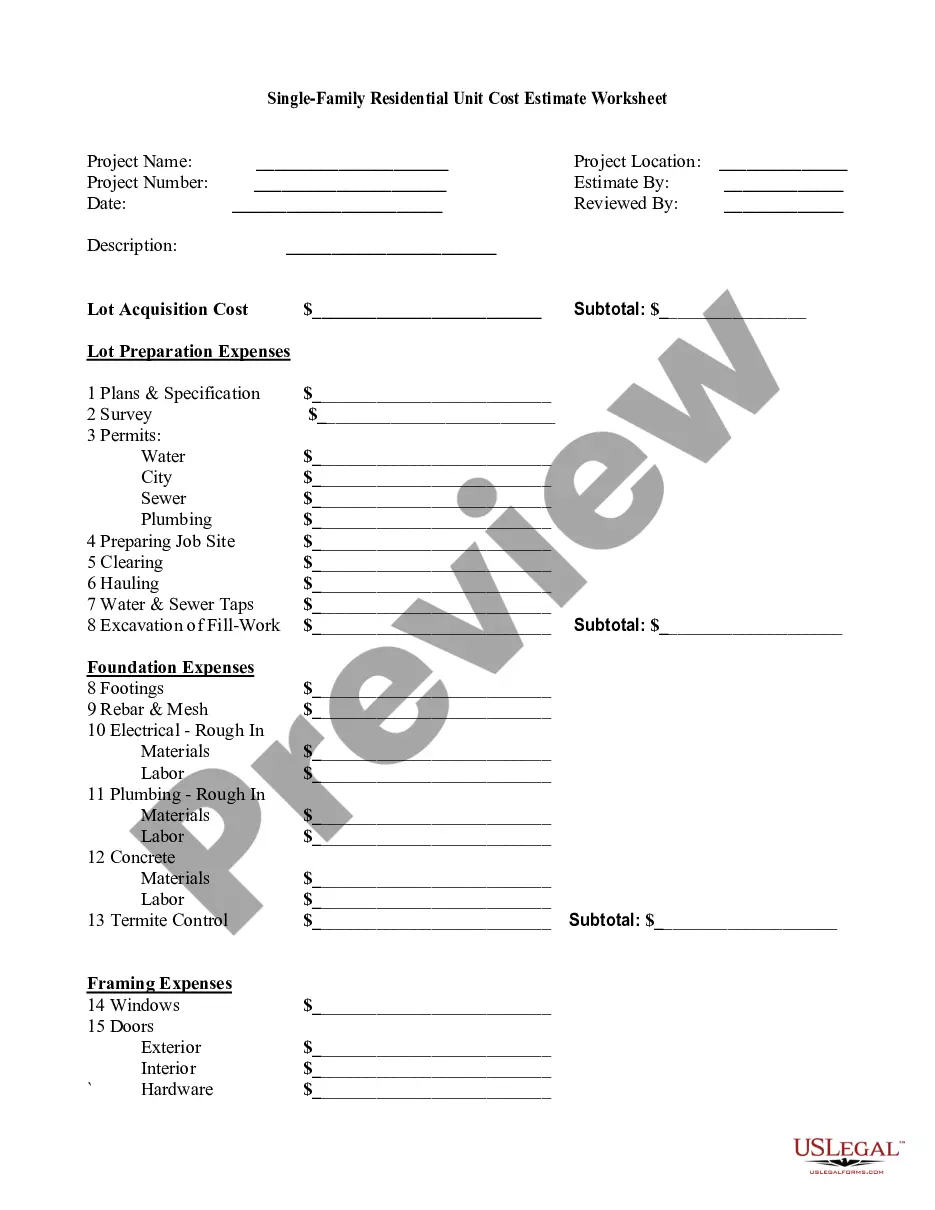

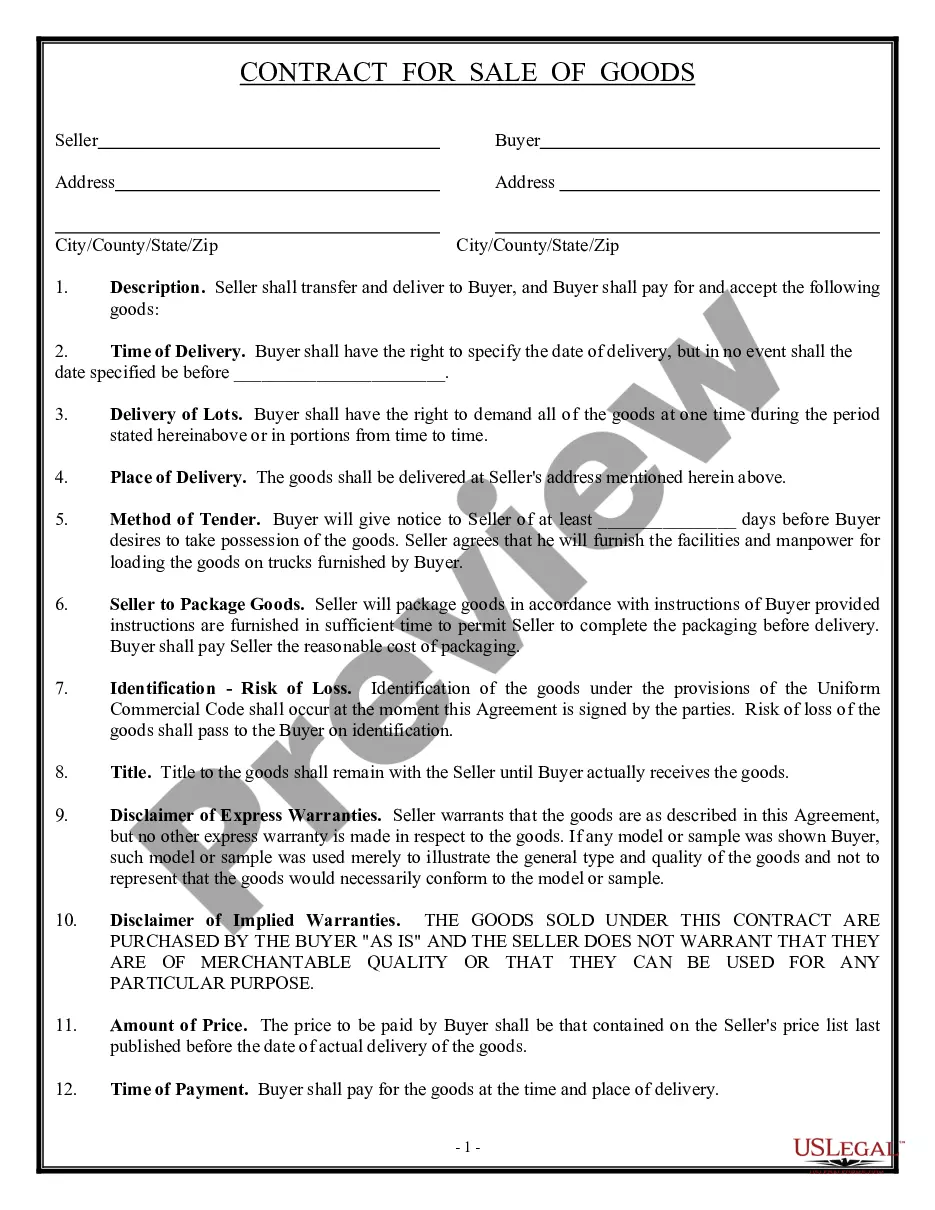

If available, use the Preview option to view the document template as well.

- If you have a US Legal Forms account, you can Log In and click the Download option.

- Then, you can complete, edit, print, or sign the Oklahoma Equipment Maintenance Agreement with a Manufacturer.

- Every legal document template you purchase is yours permanently.

- To obtain another copy of a purchased form, go to the My documents tab and click the appropriate option.

- If you're using the US Legal Forms website for the first time, follow the simple instructions below.

- First, ensure you have selected the correct document template for the region/city you choose.

- Read the form description to make sure you have chosen the right form.

Form popularity

FAQ

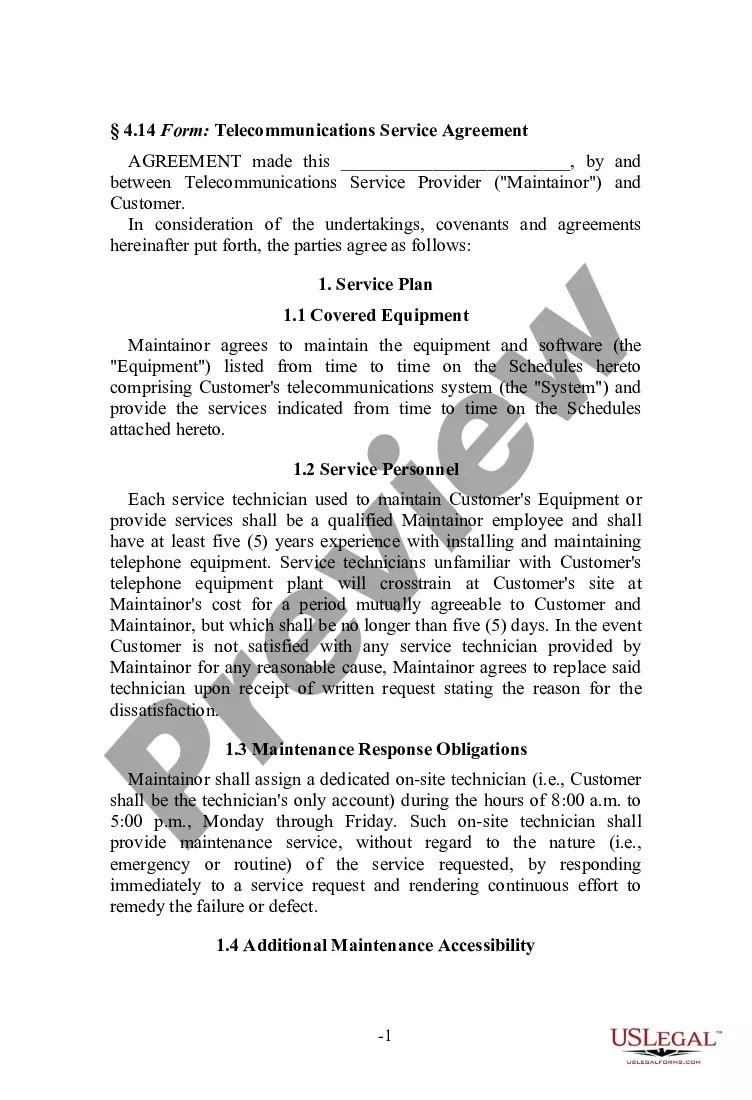

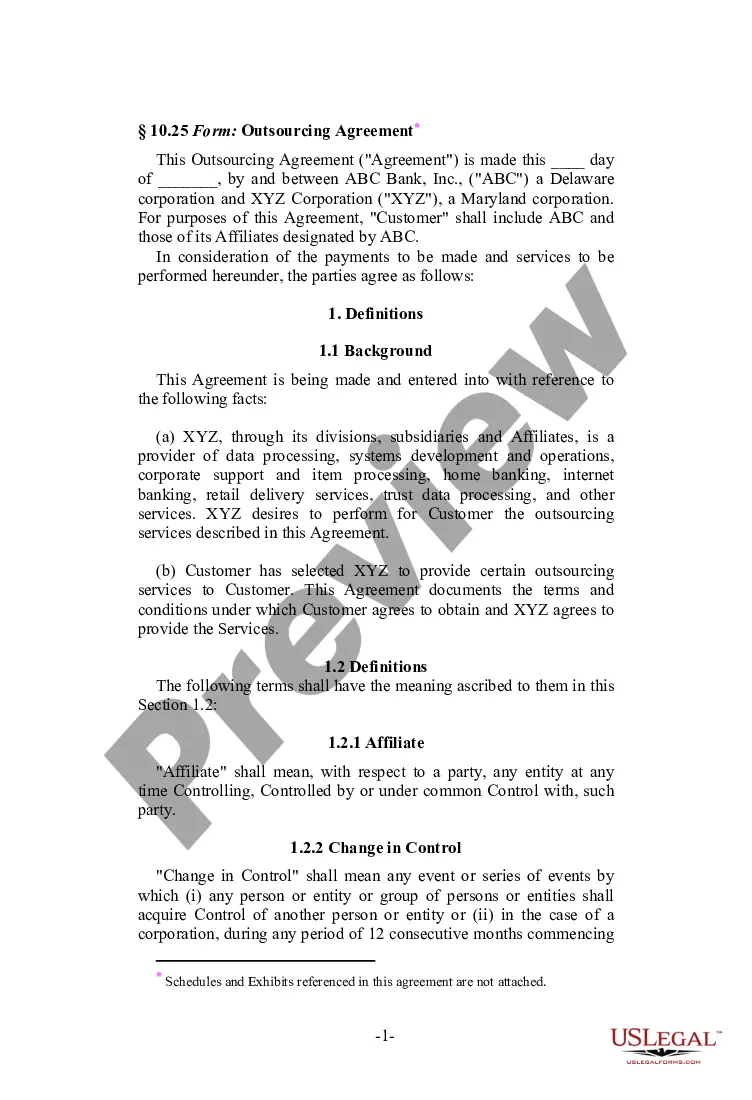

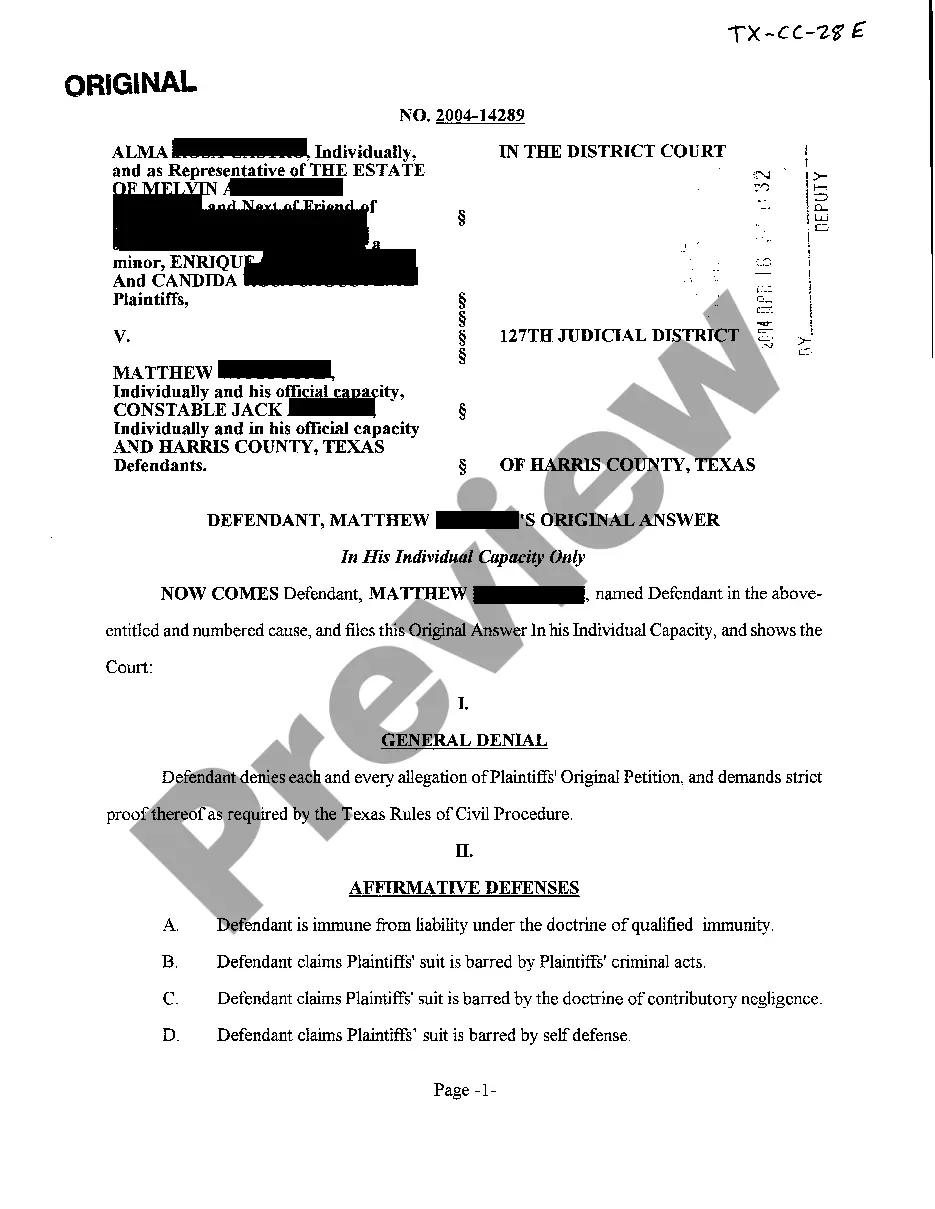

A service maintenance contract is a legal agreement between a company and a maintenance service provider. It specifies the terms and conditions of the agreement between the two parties.

When writing a contract for an independent maintenance contractor, include the hourly pay rate, methods of payment, and any provisions for additional compensation. With contracts for larger service providers, include all agreed-upon provisions such as compensation, price discounts or early payment, and credit terms.

What is an Equipment Service Agreement? An Equipment Service Agreement is a program of pre-scheduled maintenance calls for your HVAC or Plumbing equipment based on a contract between Indoor Elements Mechanical and you, our valued customer.

In your maintenance agreement, you will need to include:A section that defines both the provider and the client including their full legal names and any terms that need to be defined in the contract.A list of the services that will be performed in detail.The compensation for the agreed upon services.More items...

Essentially, maintenance is what you get regularly done on your vehicle to make sure it stays in fighting form. Maintenance is something that's scheduled like an oil change whereas service is when you need something specific fixed or tuned up that's outside of your regular maintenance schedule.

Maintenance agreements provide routine maintenance, access to emergency repairs, and constant upgrades to software and your system's hardware. More importantly, the agreement make you a priority and allows you to build a relationship with your maintenance provider.

A maintenance agreement outlines the steps one party will undertake to insure the upkeep, repair, serviceability of another party's property. Maintenance contracts are commonly used by companies that take care of vehicle fleets, industrial equipment, office and apartment buildings, computer networks, etc.

Draw up a section for official definitions at the beginning of the contract.Lay out the maintenance services to be performed early in the contract.Discuss the compensation structure agreed upon for services.Draft a section discussing any warranties or promises made by either party.More items...

The name and address of the involved parties, usually a business and the company providing the service. Price of the contract. Annual maintenance contract terms and conditions. Penalties for breaking contract or contract termination.