Oregon Aeseptic Techniques

Description

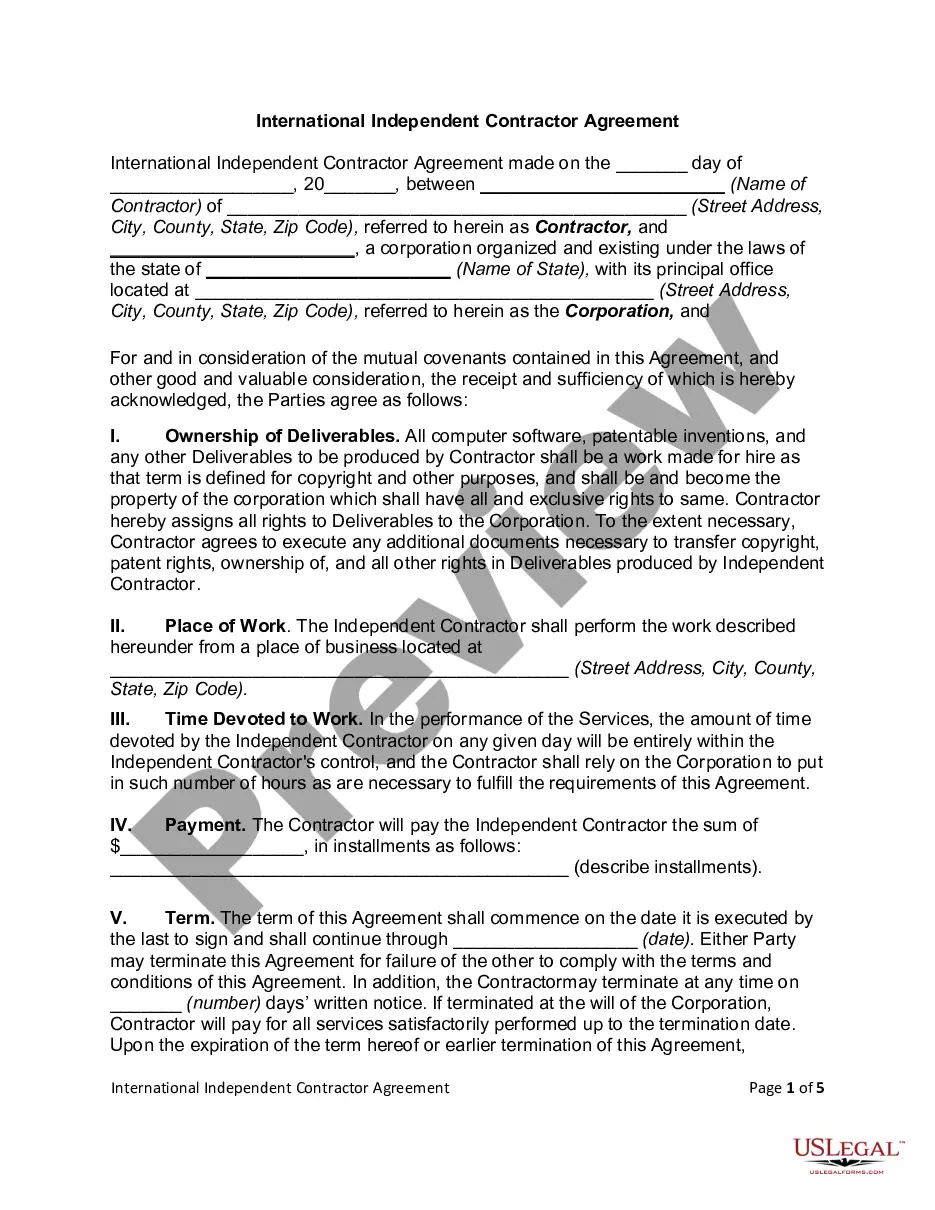

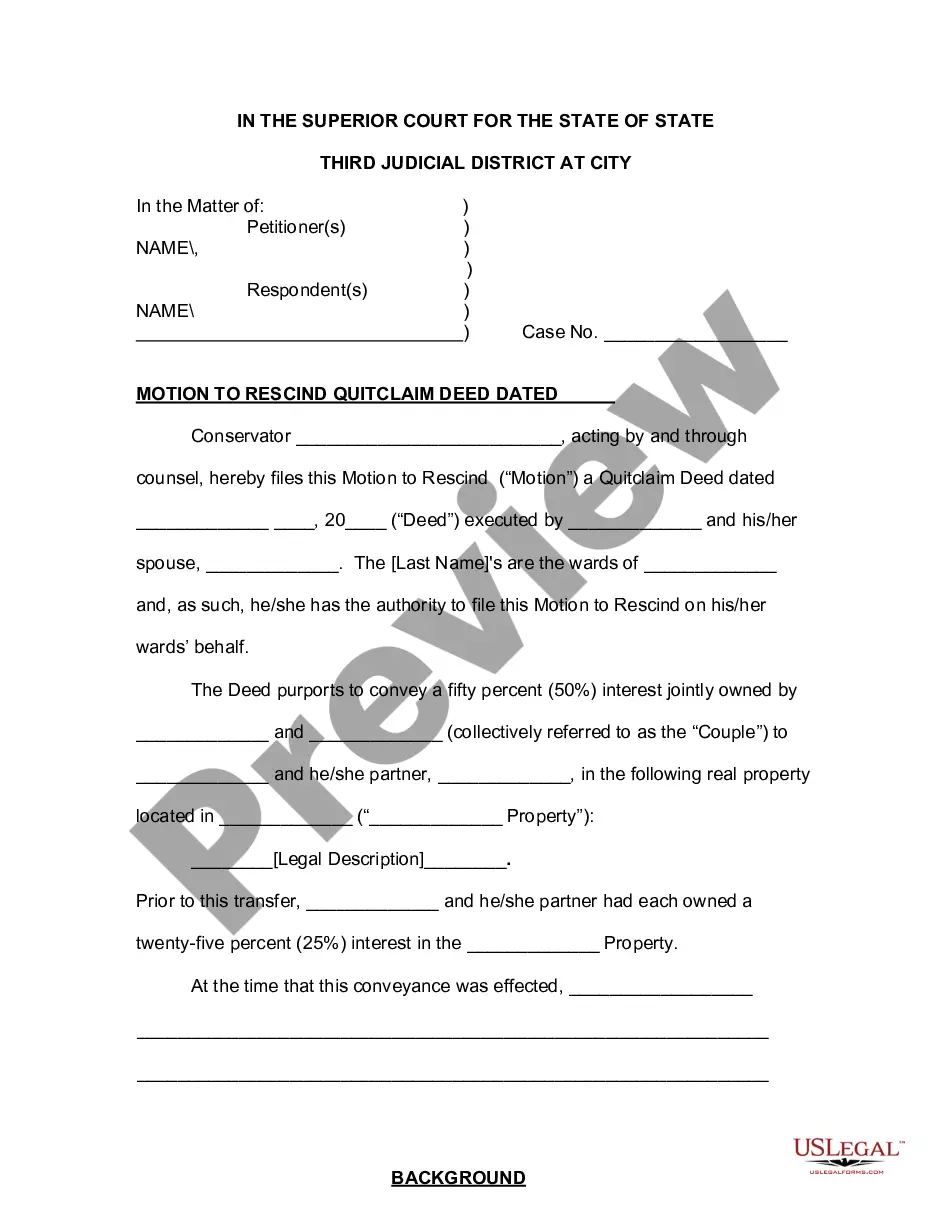

How to fill out Aeseptic Techniques?

If you require comprehensive, download, or printing legal document templates, utilize US Legal Forms, the most extensive collection of legal forms available online.

Take advantage of the site's straightforward and user-friendly search to find the documents you need.

A variety of templates for business and individual purposes are organized by categories and states, or keywords.

Step 4. Once you find the form you need, select the Buy now button. Choose the payment plan you prefer and enter your credentials to create an account.

Step 5. Process your purchase. You can use your credit card or PayPal account to complete the transaction.

- Utilize US Legal Forms to locate the Oregon Aseptic Techniques in just a few clicks.

- If you are currently a US Legal Forms customer, Log In to your account and click the Download button to access the Oregon Aseptic Techniques.

- You can also reach forms you previously downloaded in the My documents section of your account.

- If you are using US Legal Forms for the first time, follow the instructions below.

- Step 1. Ensure you have selected the form for the correct city/state.

- Step 2. Utilize the Preview function to review the form’s content. Don’t forget to read the explanation.

- Step 3. If you are not satisfied with the form, use the Search area at the top of the screen to find other versions of the legal form template.

Form popularity

FAQ

Don't worry about clearing out fridge space for one of our drums of fruit puree. Not only are they shelf-stable for up to 18 months aseptic packaging means that they also don't require refrigeration and can still stay fresh during their shelf life.

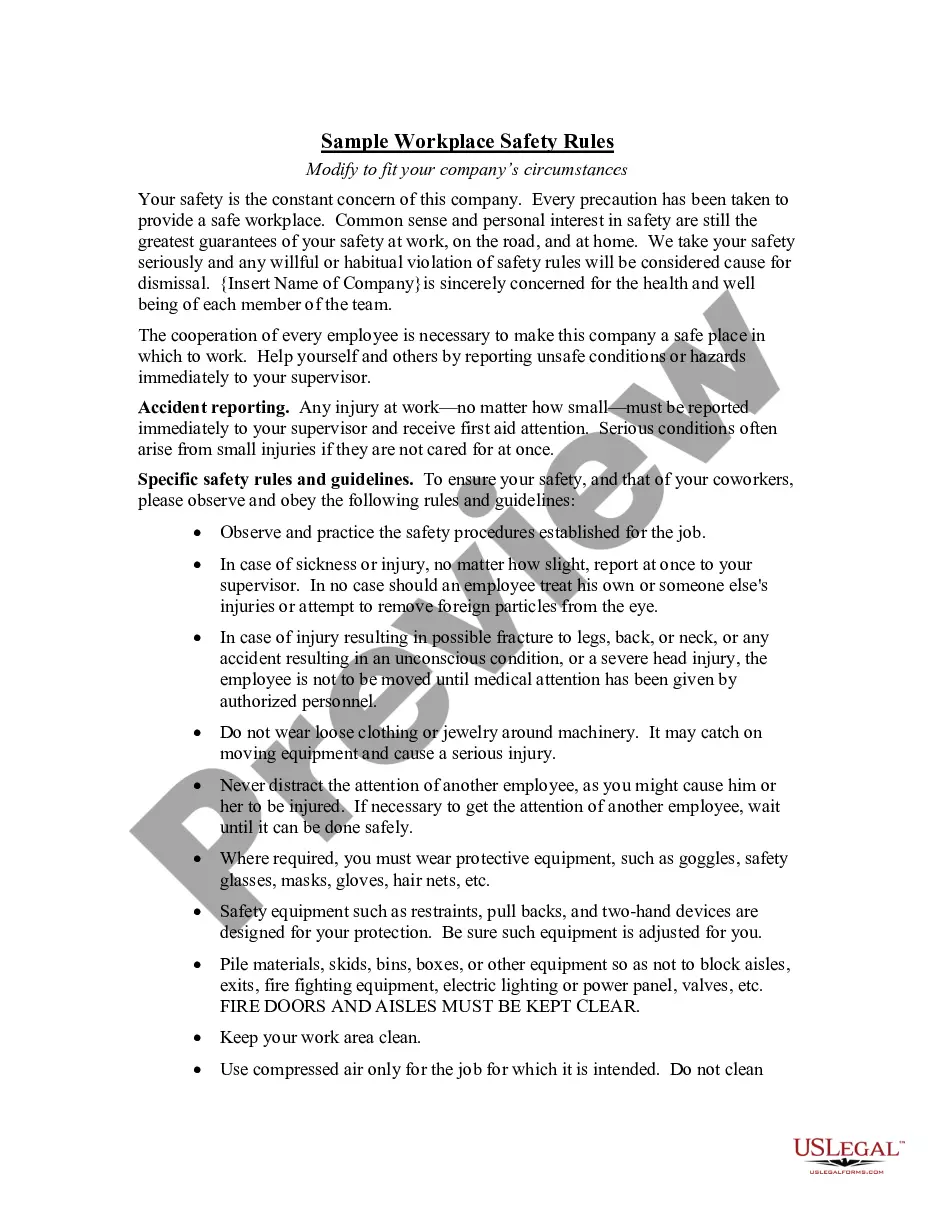

Injection safety, or safe injection practices, is a set of measures taken to perform injections in an optimally safe manner for patients, healthcare personnel, and others.

Step 1: A clean workspace.Step 2: Hand hygiene.Step 3: Sterile, safety-engineered syringe.Step 4: Sterile medication vial and diluent.Step 5: Disinfecting skin.Step 6: Appropriate sharps disposal.Step 7: Appropriate waste management.

What are safe injection practices? Safe injection practices are intended to prevent transmission of infectious diseases between one patient and another, or between a patient and dental health care personnel (DHCP) during preparation and injection of medications.

Why Surveillance in providing safer injections? Unsafe injections pose a major risk to the patients, of contracting unwanted infections during the process of care or investigations. These infections can result into productivity losses frequently, and are also lethal at times.

How long is your product good after best use date? As a guideline, Oregon Fruit cans have a shelf-life of about 2 to 3 years from the date of production, establishing a Best Buy date listed on the can. The predicted shelf life assumes the can isn't dented or damaged, and the product is stored under normal conditions.

WE BREW BEER USING FRUIT PUREE AS AN INGREDIENT FOR OUR COMMERCIAL BREWERY. TO PROPERLY PRODUCE FRUIT BEERS WITH PROPER FRUIT CHARACTER, HOW MUCH PUREE SHOULD WE USE TO BREW WITH? Our customers typically use 1/2 - 2 pounds of puree per gallon of finished beer.

Oregon Fruit Canned Fruit Purees consist of real fruit, minimally processed to a smooth texture to ensure the best fresh fruit flavor, aroma, and color. They contain no added sugar or preservatives and are pasteurized and canned for shelf stability for up to 18 months.

When is the optimal stage of brewing to add fruit puree/concentrate? The optimal stage to add fruit purees is during primary/secondary. Adding fruit at this time maximizes flavor and aromatic potential in the final product, while reducing contamination potential (discussed below).