Oregon Maintenance Supervisor Checklist

Description

How to fill out Maintenance Supervisor Checklist?

US Legal Forms - one of the largest collections of legal documents in the USA - offers a broad selection of legal document templates available for download or printing.

While using the site, you can find thousands of forms for business and personal needs, categorized by groups, states, or keywords. You can discover the latest forms such as the Oregon Maintenance Supervisor Checklist in moments.

If you already have a monthly subscription, Log In to download the Oregon Maintenance Supervisor Checklist from the US Legal Forms catalog. The Download button will appear on every form you view. You'll have access to all previously acquired forms in the My documents tab of your account.

Process the transaction. Use a credit card or PayPal account to finalize your purchase.

Select the format and download the form to your device. Make edits. Fill in, amend, print, and sign the downloaded Oregon Maintenance Supervisor Checklist. Each template added to your account has no expiration date and is yours indefinitely. Therefore, if you wish to download or print another copy, simply go to the My documents section and click on the form you need. Access the Oregon Maintenance Supervisor Checklist with US Legal Forms, the most extensive collection of legal document templates. Utilize thousands of professional and state-specific templates that meet your business or personal requirements.

- Ensure you have selected the correct form for your jurisdiction.

- Click the Review button to examine the form's content.

- Read the form description to make sure you’ve picked the right one.

- If the form does not meet your requirements, utilize the Search field at the top of the screen to find the one that does.

- If you are satisfied with the form, confirm your choice by clicking the Buy now button.

- Then, choose the pricing plan you prefer and provide your information to create an account.

Form popularity

FAQ

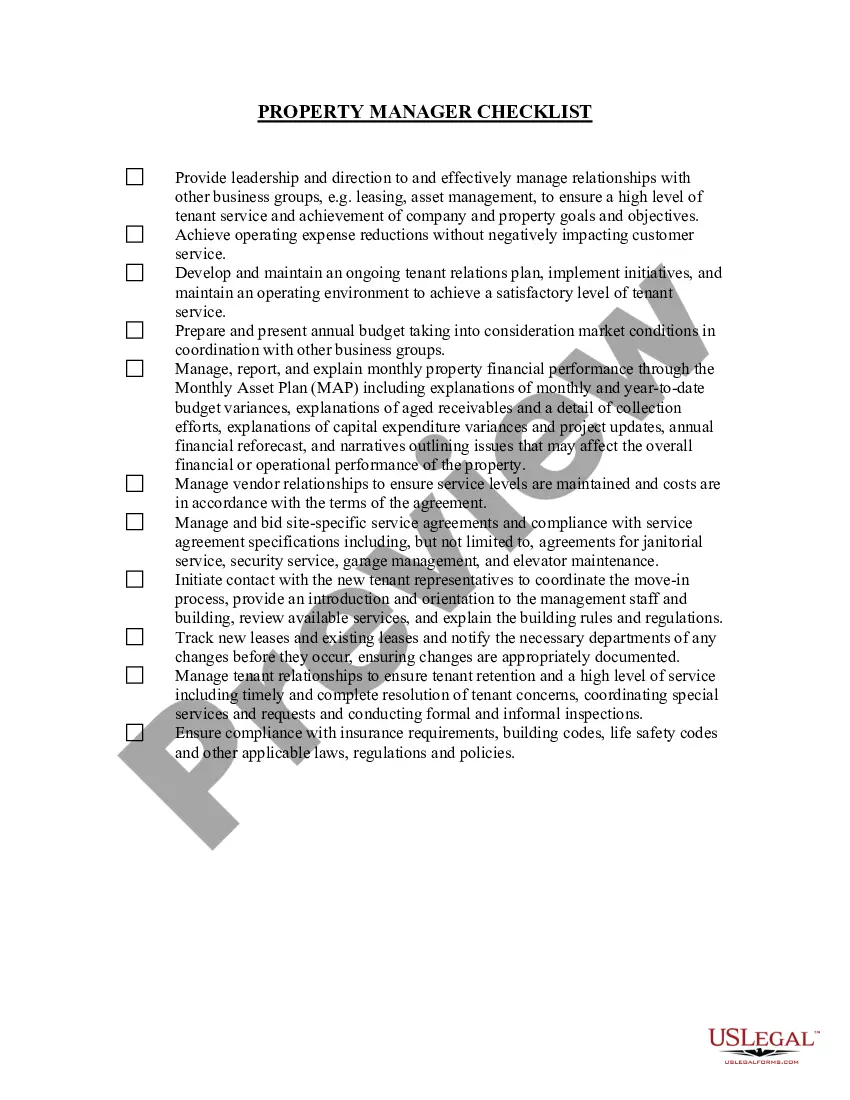

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.

A preventive maintenance checklist details the tasks that your technicians must complete during a maintenance check. A PM checklist will include both time-based (routine) and condition-based (non-routine) tasks, ensuring that critical issues are both prevented and corrected.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

Examples of routine maintenance Routine maintenance in a factory setting involves lubricating, cleaning, and adjusting machines, replacing equipment parts on a schedule, inspecting certain components, or performing conditioned monitoring exercises.

A preventive maintenance checklist is an itemized list of written tasks that guide technicians through a process of asset's preventive maintenance (PM).

Typical examples of routine maintenance include:Lubricating, cleaning, or adjusting machinery.Inspecting equipment to ensure proper operation and safety.Replacing parts that show deterioration.Checking, testing, and maintaining safety equipment, such as safety barriers, fire extinguishers, or alarm systems.More items...

Maintenance checklists and logbooks are tools used by technicians to document equipment maintenance inspections. Equipment maintenance involves the continuous process of checking, repairing, and servicing operating equipment to ensure businesses can operate without interruption.

A preventive maintenance checklist is a set of tasks that the technician needs to complete in order to close a preventive maintenance work order. A checklist gets all the steps and information out of a manual and into the hands of experienced technicians by standardizing PMs in your CMMS.