Oregon Equipment Maintenance Agreement with a Manufacturer

Description

How to fill out Equipment Maintenance Agreement With A Manufacturer?

Have you been inside a position where you will need paperwork for possibly organization or individual functions nearly every day time? There are a variety of legitimate file web templates available online, but finding ones you can depend on is not straightforward. US Legal Forms gives a large number of type web templates, much like the Oregon Equipment Maintenance Agreement with a Manufacturer, which can be created in order to meet federal and state needs.

If you are presently knowledgeable about US Legal Forms site and have a merchant account, simply log in. After that, it is possible to download the Oregon Equipment Maintenance Agreement with a Manufacturer web template.

Should you not offer an accounts and want to begin using US Legal Forms, follow these steps:

- Obtain the type you want and make sure it is for your proper metropolis/state.

- Use the Review option to examine the shape.

- Read the explanation to actually have chosen the appropriate type.

- If the type is not what you are searching for, utilize the Search field to discover the type that fits your needs and needs.

- If you discover the proper type, simply click Get now.

- Choose the rates prepare you desire, complete the necessary information and facts to create your money, and purchase an order utilizing your PayPal or charge card.

- Decide on a hassle-free file format and download your backup.

Get all the file web templates you may have bought in the My Forms menus. You can aquire a more backup of Oregon Equipment Maintenance Agreement with a Manufacturer any time, if needed. Just go through the necessary type to download or print out the file web template.

Use US Legal Forms, one of the most extensive assortment of legitimate types, to conserve some time and stay away from mistakes. The assistance gives professionally made legitimate file web templates which you can use for a variety of functions. Produce a merchant account on US Legal Forms and start making your daily life easier.

Form popularity

FAQ

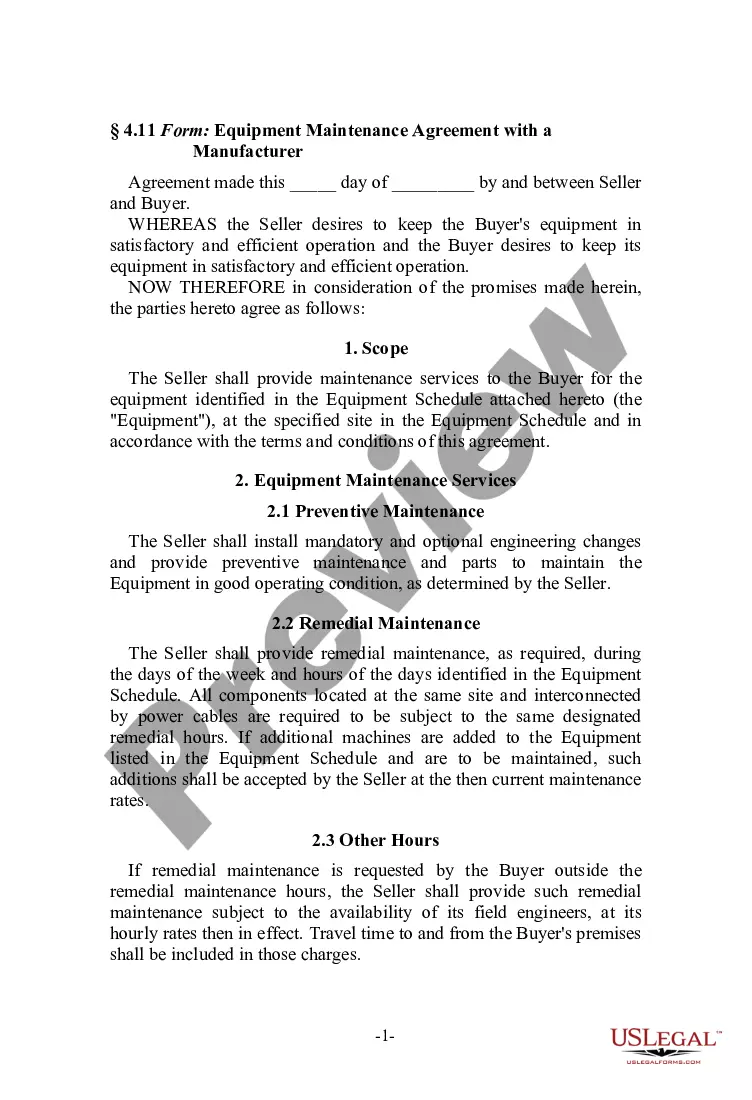

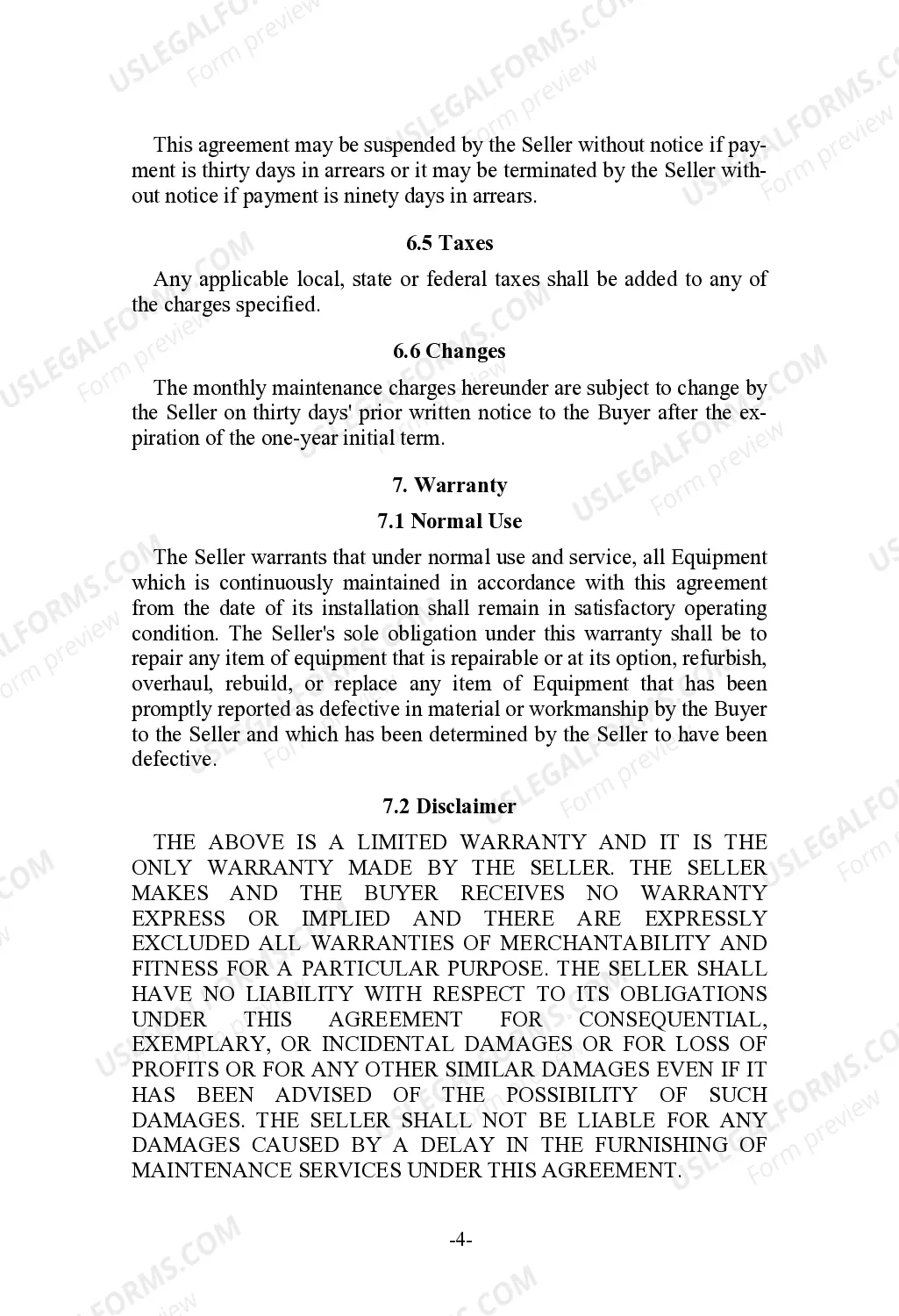

By Practical Law Commercial. A B2B agreement in which the supplier agrees to provide a maintenance and support service for equipment. The agreement is drafted to be broadly neutral between the parties. To access this resource, sign in below or register for a free, no-obligation trial.

A maintenance agreement (contract), sometimes called a service agreement (contract), is an agreement which requires specific performance of repairing, cleaning, altering, or improving tangible personal property on a regular or irregular basis to ensure the product's continued satisfactory operation.

The contract should clarify the type of maintenance you need, whether it's on-demand, preventive, or condition based, for example. For the scope of the work, expect to see a clear outline of the services the provider is going to perform, making sure to describe the jobs explicitly to avoid any ambiguity in the future.

Maintenance agreements typically include clauses referencing: Responsibility: A description of the contractor's responsibilities for the term of the agreement. Timescale: The length of the agreement and how it can be terminated. Payment: Payment terms and amounts.

How to Create a Planned Maintenance Contract Full name and details of service provider and client. The type of maintenance. A disclosed scope of work. A service schedule. Payment terms. Warranties and guarantees. Information regarding legal disputes. Details on contract termination.

What Should A Maintenance Agreement Include? Names and other details of both parties involved. Date and term of the agreement. Define what will be maintained. Specific maintenance tasks. The SOP. Subcontracting clause. Compensation T & C. Breach/ termination.

A maintenance contract is an agreement between you and your service provider that outlines the tasks, schedules, and frequency of the maintenance services they provide.

A maintenance agreement is a contract between two parties ? usually a maintenance company and a company or individual ? laying out the terms and conditions for scheduled maintenance services.