This form is a contract for the design and construction of a manufacturing facility that will be engaged in a particular manufacturing process. This form is a generic example that may be referred to when preparing such a form for your particular state. It is for illustrative purposes only. Local laws should be consulted to determine any specific requirements for such a form in a particular jurisdiction.

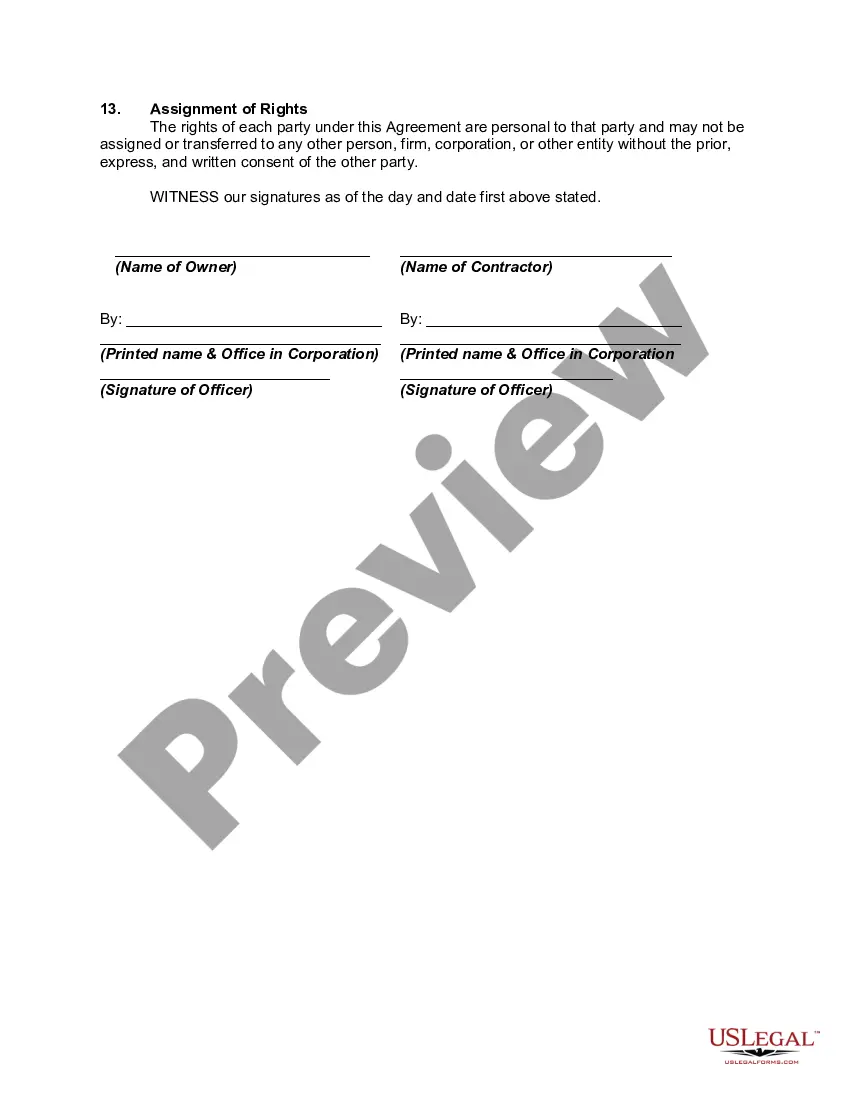

The Pennsylvania Contract for Design and Construction of Manufacturing Facility is a legally binding agreement that governs the construction and design process of manufacturing facilities in Pennsylvania. This contract outlines the obligations, responsibilities, and rights of both the owner and the contractor involved in the project. It ensures that all parties involved are protected and that the project is completed according to the agreed-upon specifications and timelines. This comprehensive contract includes various provisions, such as the scope of work, payment terms, project schedule, change orders, permits and licenses, guarantees, warranties, dispute resolution, and termination clauses. It also covers health and safety requirements, environmental considerations, and compliance with building codes and regulations. The Pennsylvania Contract for Design and Construction of Manufacturing Facility emphasizes the importance of thorough planning, accurate designs, and effective communication throughout the construction process. The contract is typically entered into by the owner, who is usually the manufacturer or the developer, and the contractor responsible for the design and construction of the facility. Different types of Pennsylvania Contracts for Design and Construction of Manufacturing Facility may include: 1. Lump Sum Contract: This type of contract establishes a fixed price for the entire project, regardless of any changes or modifications that may arise during the construction process. The contractor is responsible for completing the project within the specified budget and schedule. 2. Cost-Plus Contract: In this contract, the owner agrees to reimburse the contractor for the actual costs incurred during construction, including labor, materials, and overhead expenses. Additionally, a pre-determined markup or fee is added to cover the contractor's profit. 3. Design-Build Contract: Under this contract, the owner enters into a single agreement with a design-build entity, such as an architect or a construction firm. The design-build entity is responsible for both the design and construction aspects of the project, streamlining the process and potentially reducing costs and delays. 4. Unit Price Contract: In this contract, the project is divided into various units or components, each with a specific price per unit. The contractor is paid based on the quantities of each unit completed, providing greater flexibility and transparency in pricing. In conclusion, the Pennsylvania Contract for Design and Construction of Manufacturing Facility is a crucial document that ensures the successful completion of manufacturing facility projects in Pennsylvania. By addressing various aspects of the construction process, this contract protects the interests of both the owner and the contractor, promoting a smooth and efficient project execution.