Pennsylvania Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

US Legal Forms - one of the largest collections of legal documents in the United States - provides a variety of legal form templates that you can download or print.

By using the website, you can access thousands of forms for business and personal use, organized by categories, states, or keywords. You can find the most recent forms, such as the Pennsylvania Aseptic Techniques, within moments.

If you already hold a monthly membership, Log In to obtain the Pennsylvania Aseptic Techniques from the US Legal Forms collection. The Download button will appear on every form you view. You can access all previously acquired forms from the My documents section of your account.

Complete the payment process. Use your credit card or PayPal account to finalize the transaction.

Select the format and download the form to your device. Edit. Complete, modify, and print and sign the downloaded Pennsylvania Aseptic Techniques.

Each template added to your account has no expiration date and is yours indefinitely. Therefore, if you wish to download or print another copy, simply navigate to the My documents section and click on the form you need.

Gain access to the Pennsylvania Aseptic Techniques with US Legal Forms, the most extensive collection of legal document templates. Utilize a multitude of professional and state-specific templates that meet your business or personal needs and requirements.

- Make sure you have selected the correct form for your city/region.

- Click on the Preview button to review the form's content.

- Check the form summary to ensure you have chosen the right document.

- If the form does not meet your requirements, utilize the Search box at the top of the screen to find one that does.

- If you are satisfied with the form, confirm your selection by pressing the Purchase now button.

- Then, choose your preferred payment plan and provide your details to register for an account.

Form popularity

FAQ

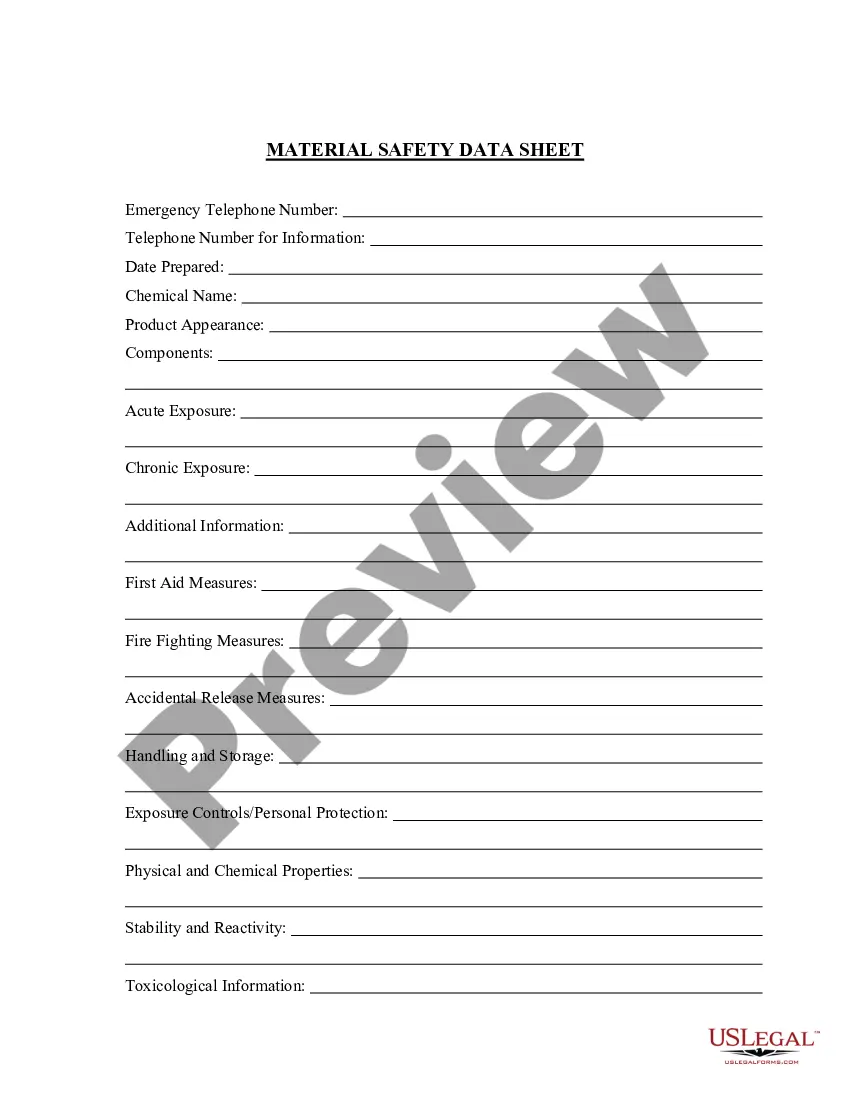

Aseptic techniques should be used in the following example situations: Inserting an invasive device (a urinary catheter) Dressing wounds healing by primary intention (surgical wounds) Dressing deep wounds that lead to a cavity or sinus. Minor surgery procedures.

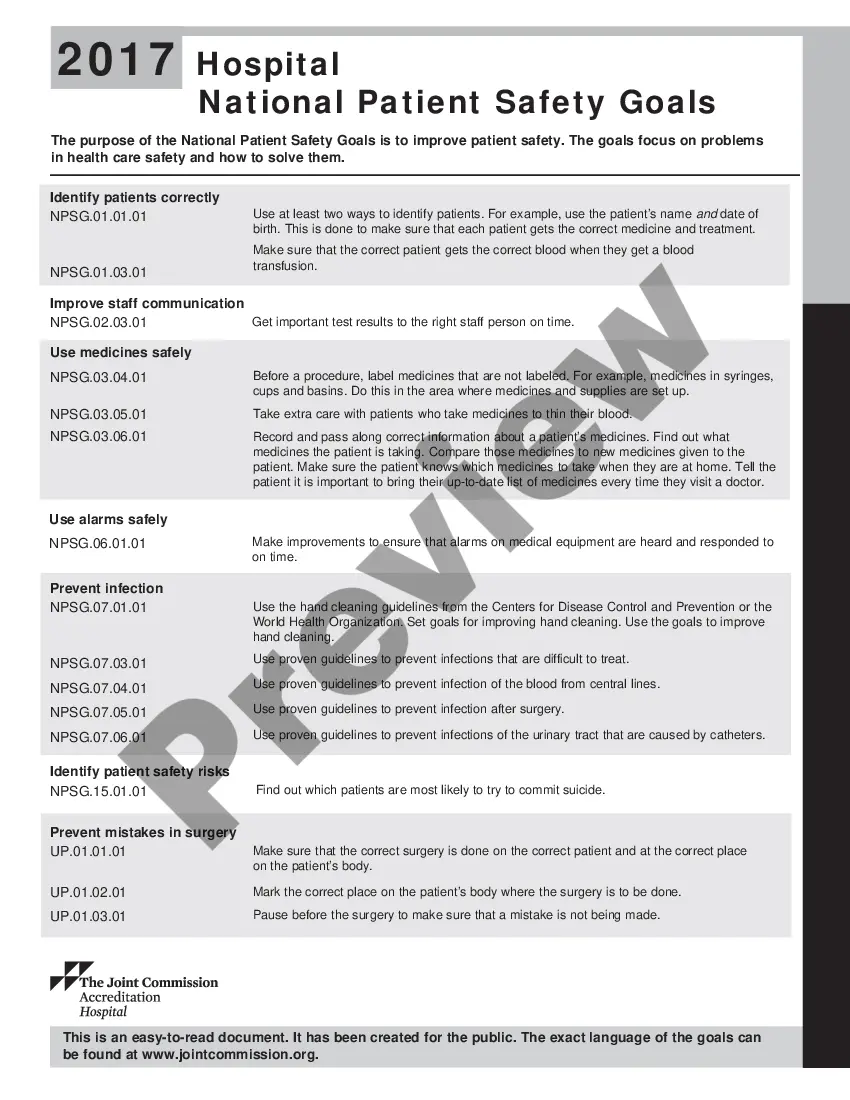

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

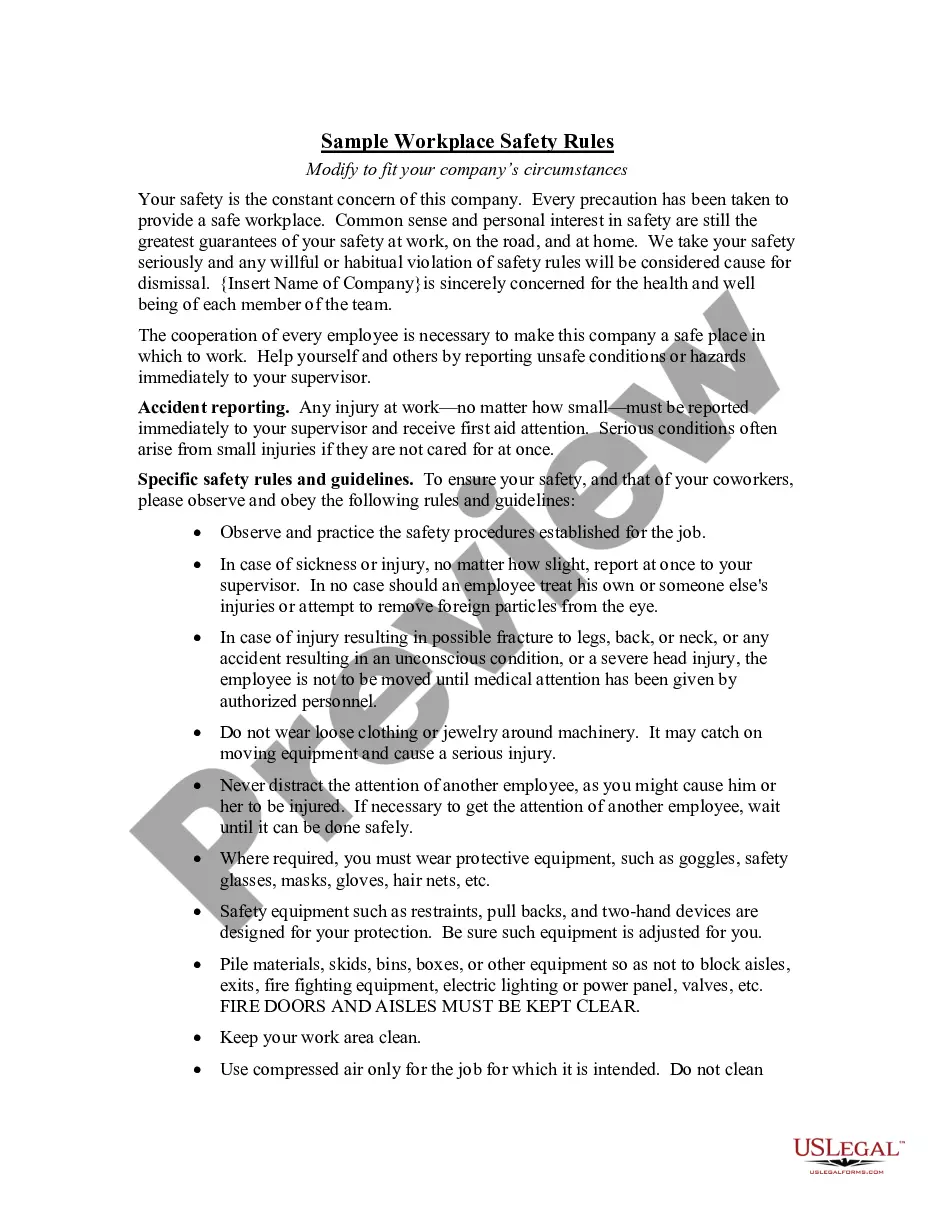

Do not sneeze, cough, laugh, or talk over the sterile field. Maintain a safe space or margin of safety between sterile and non-sterile objects and areas. Refrain from reaching over the sterile field. Keep operating room (OR) traffic to a minimum, and keep doors closed.

An aseptic technique is used to carry out a procedure in a way that minimises the risk of contaminating an invasive device, e.g. urinary catheter, or a susceptible body site such as the bladder or a wound.

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.25-Apr-2021

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

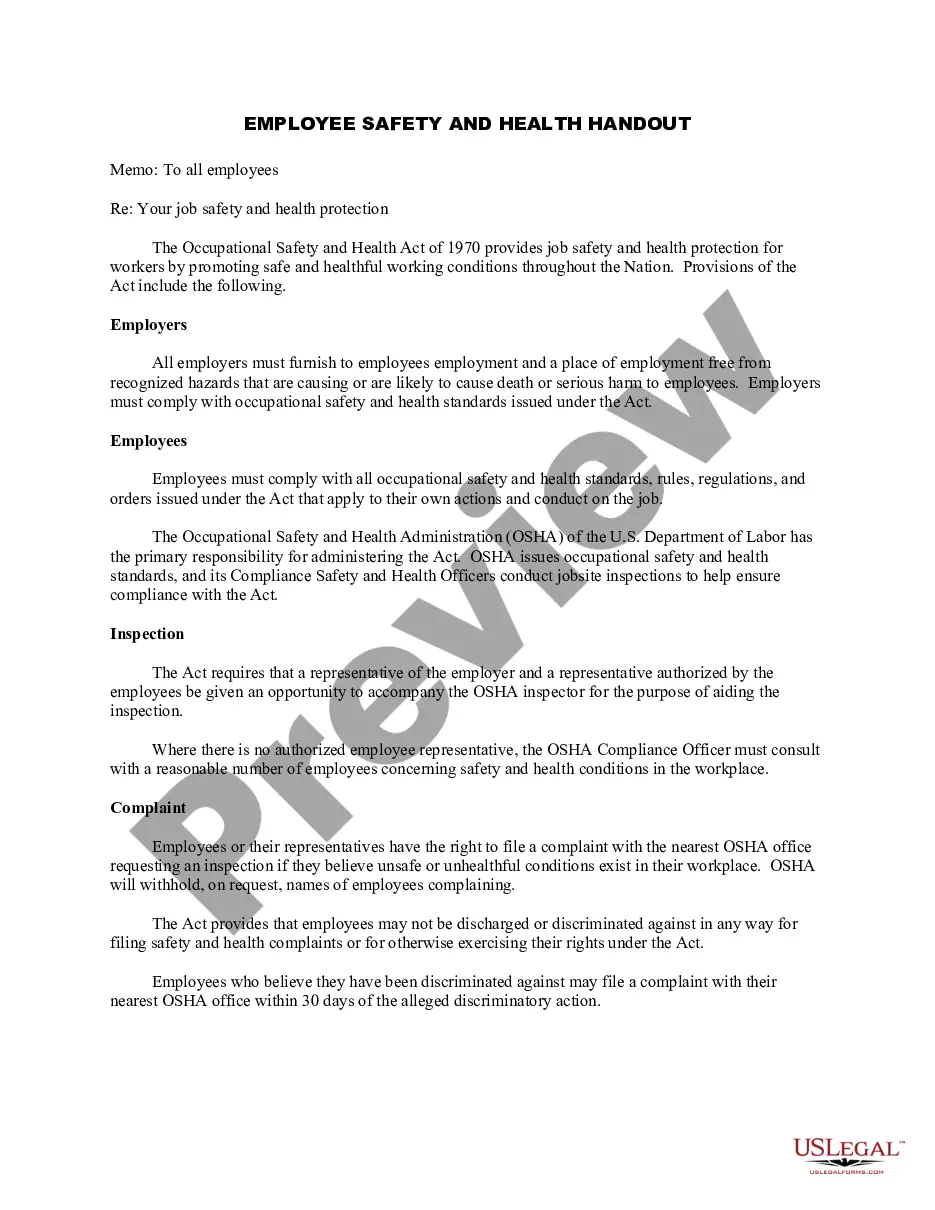

In the microbiology lab we use aseptic technique to: Prevent contamination of the specific microorganism we are working with. Prevent contamination of the room and personnel with the microorganism we are working with.

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.

Aseptic is most commonly applied in the context of techniques and procedures, while sterile is most commonly used to describe environments and instruments that have been cleaned (sterilized).