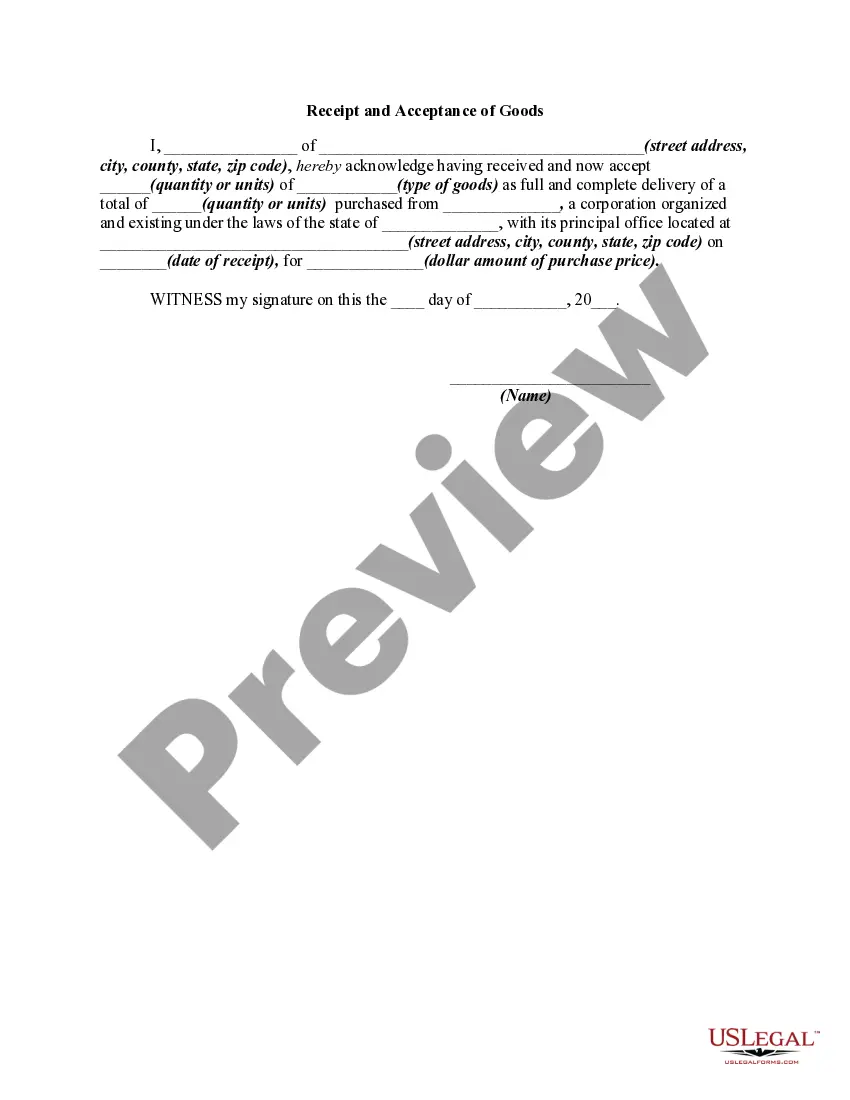

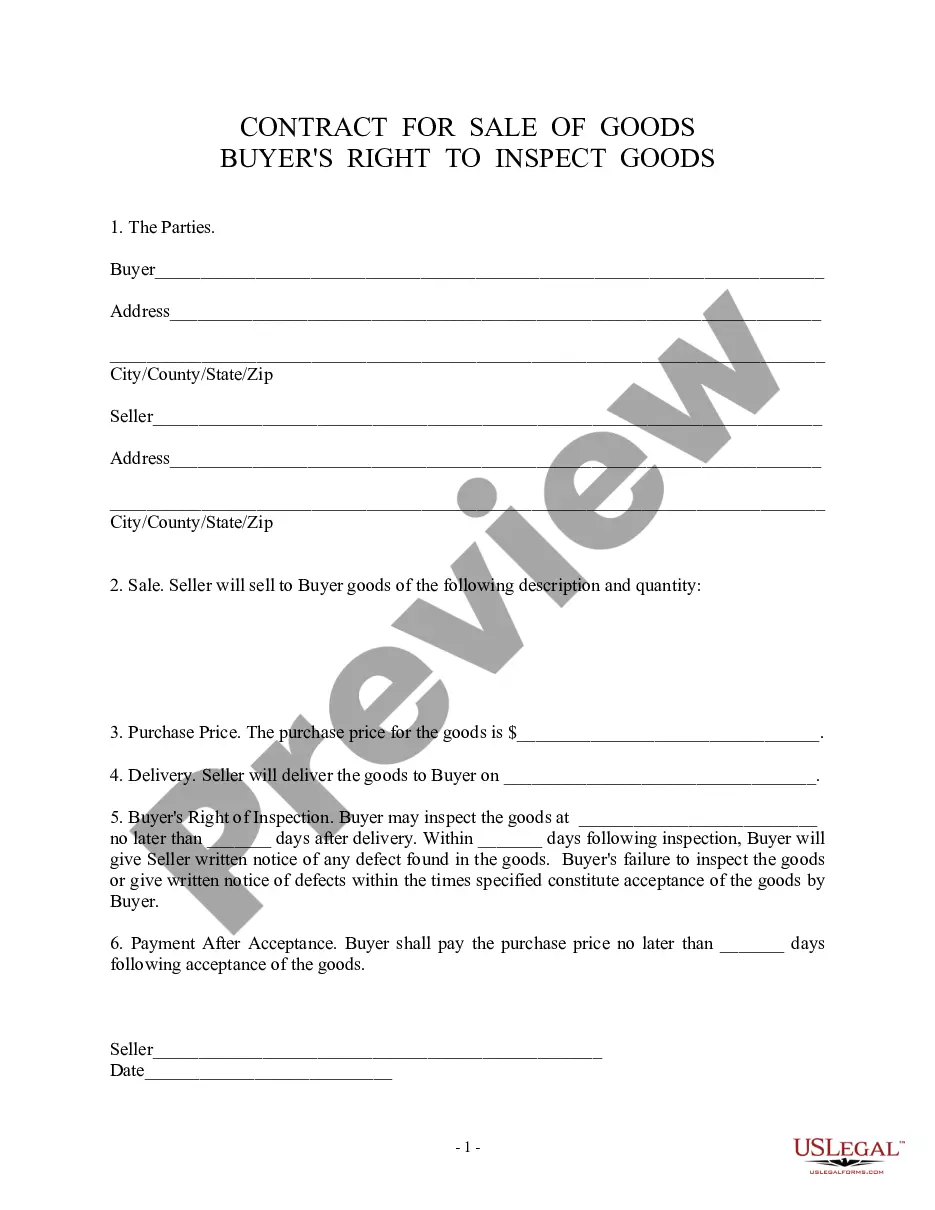

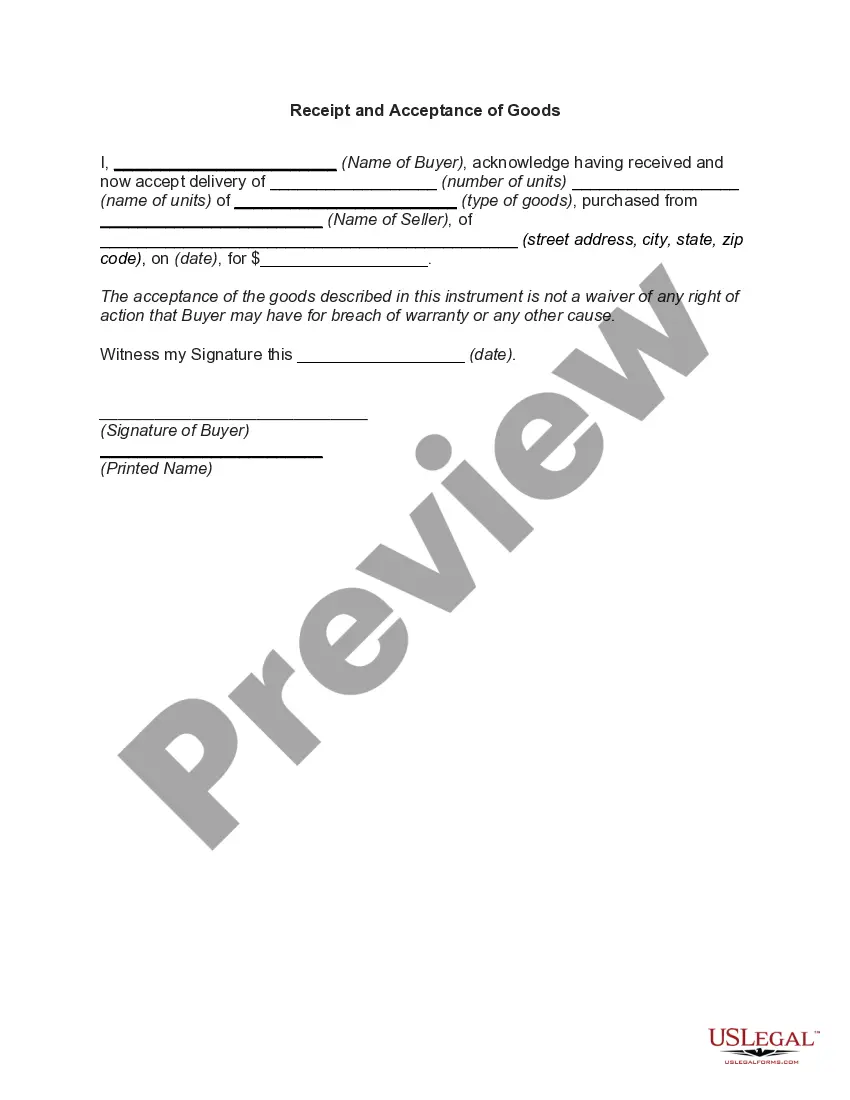

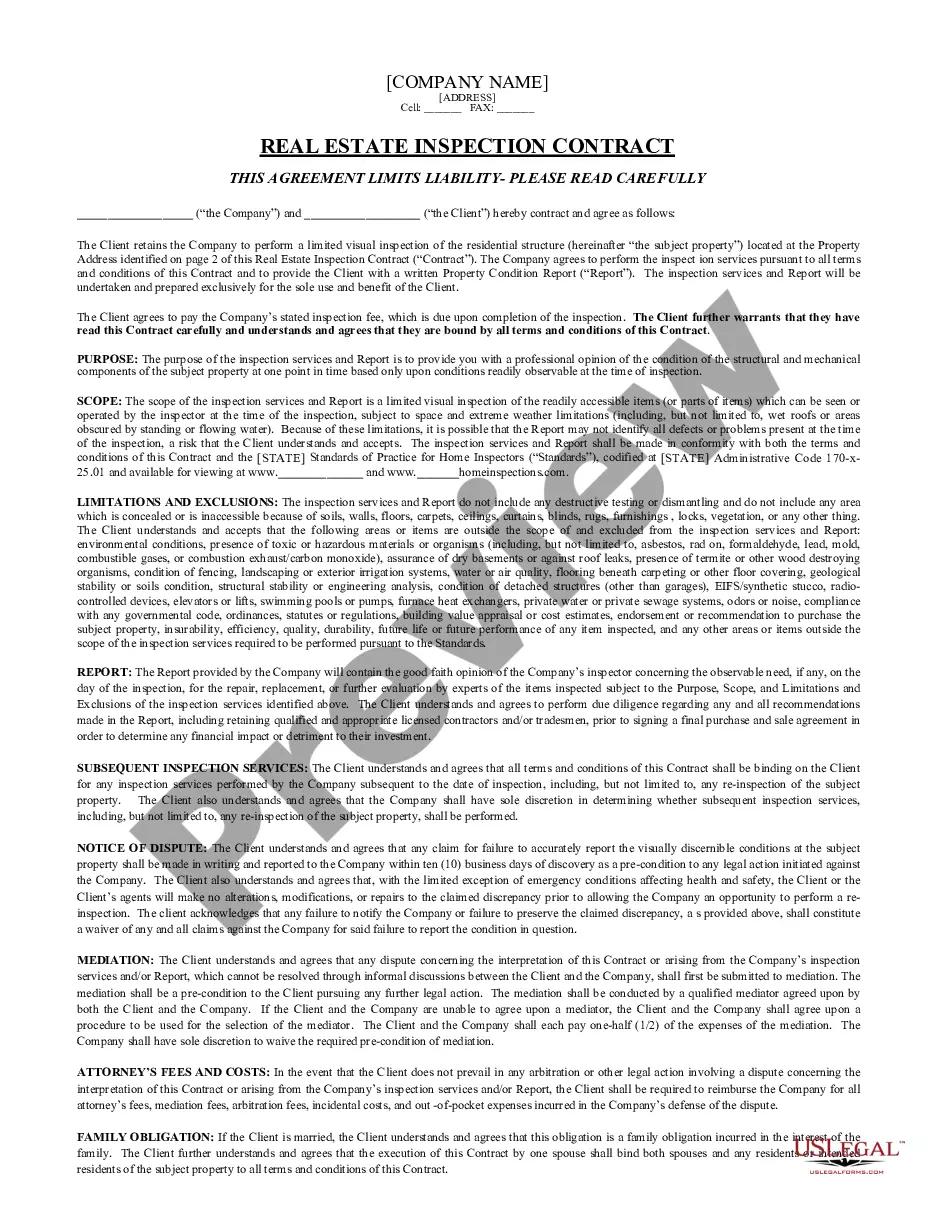

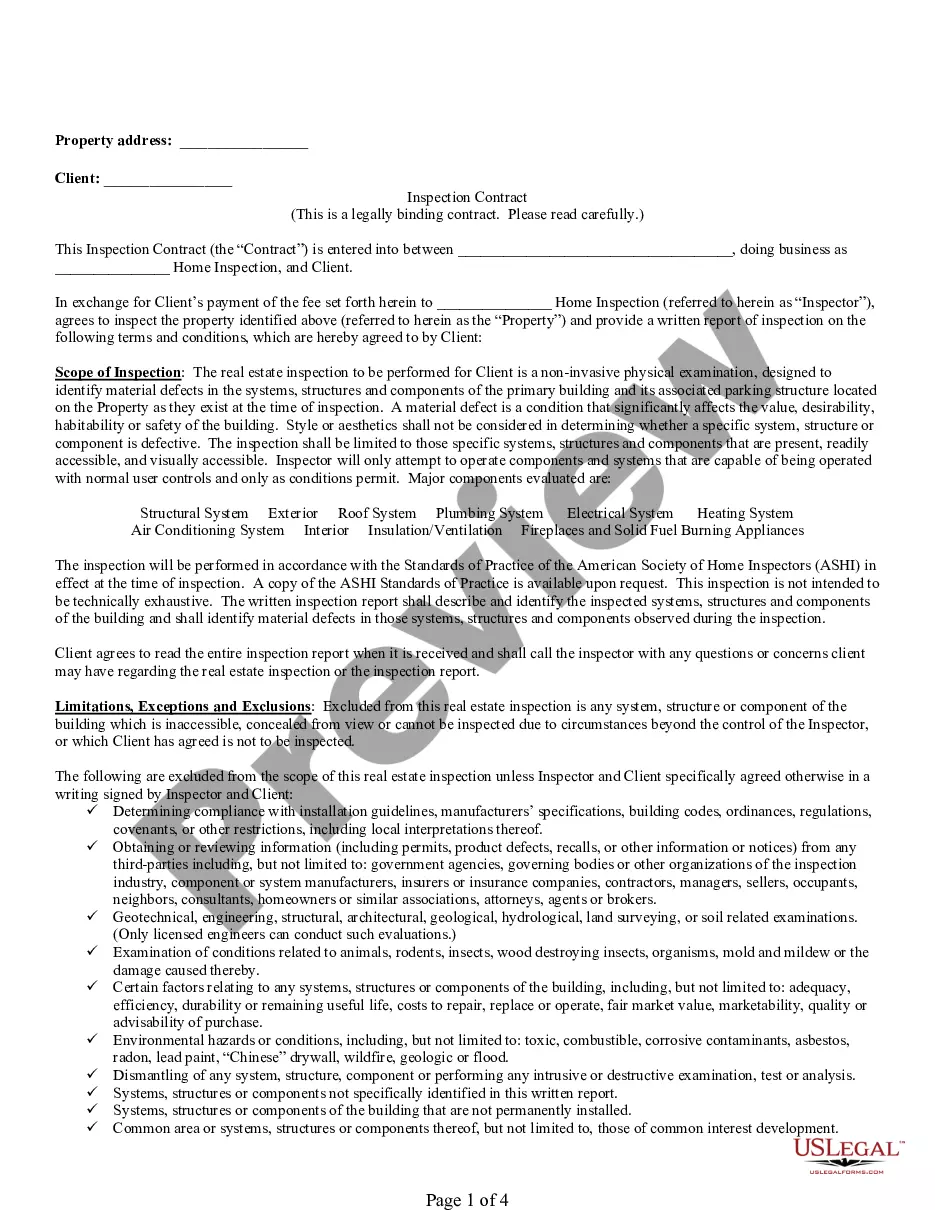

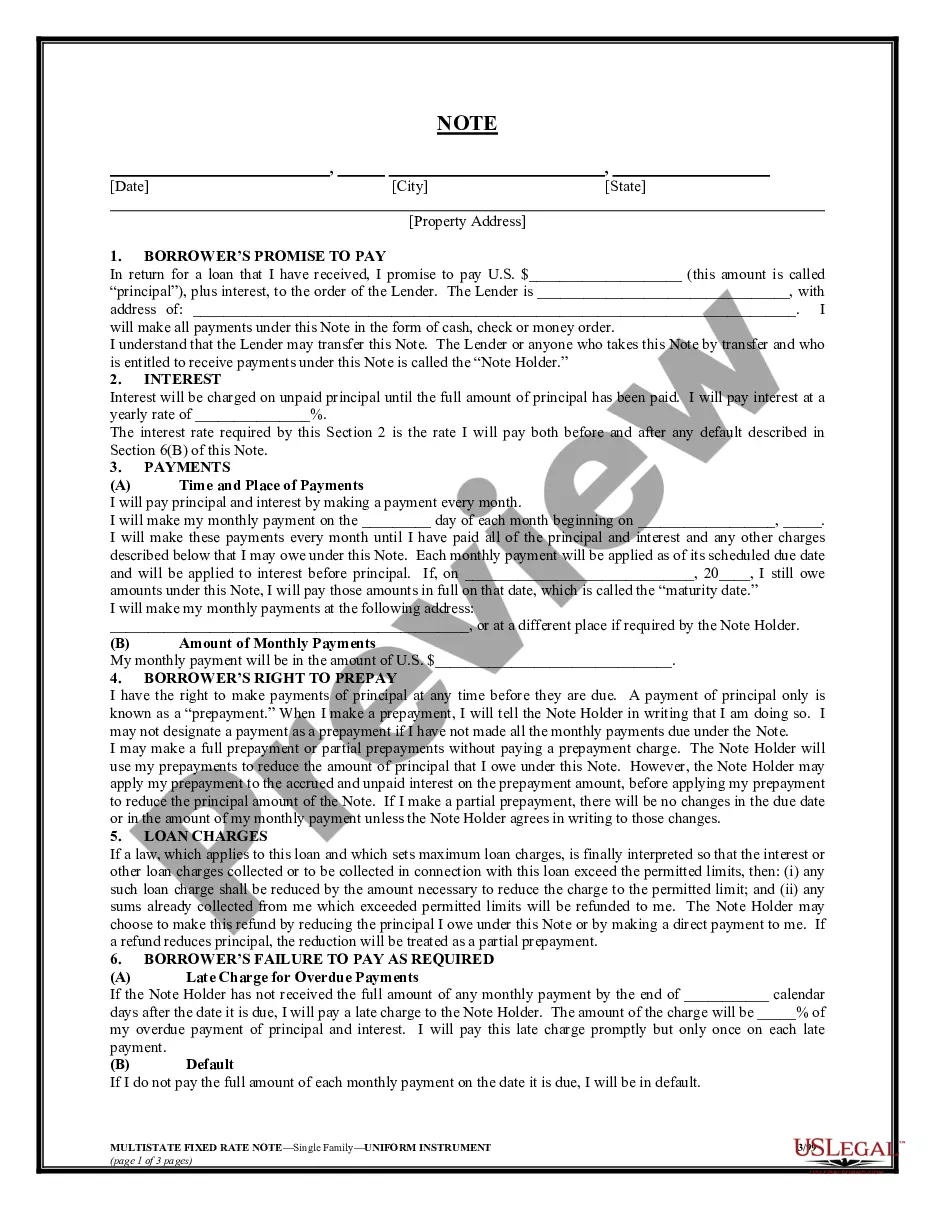

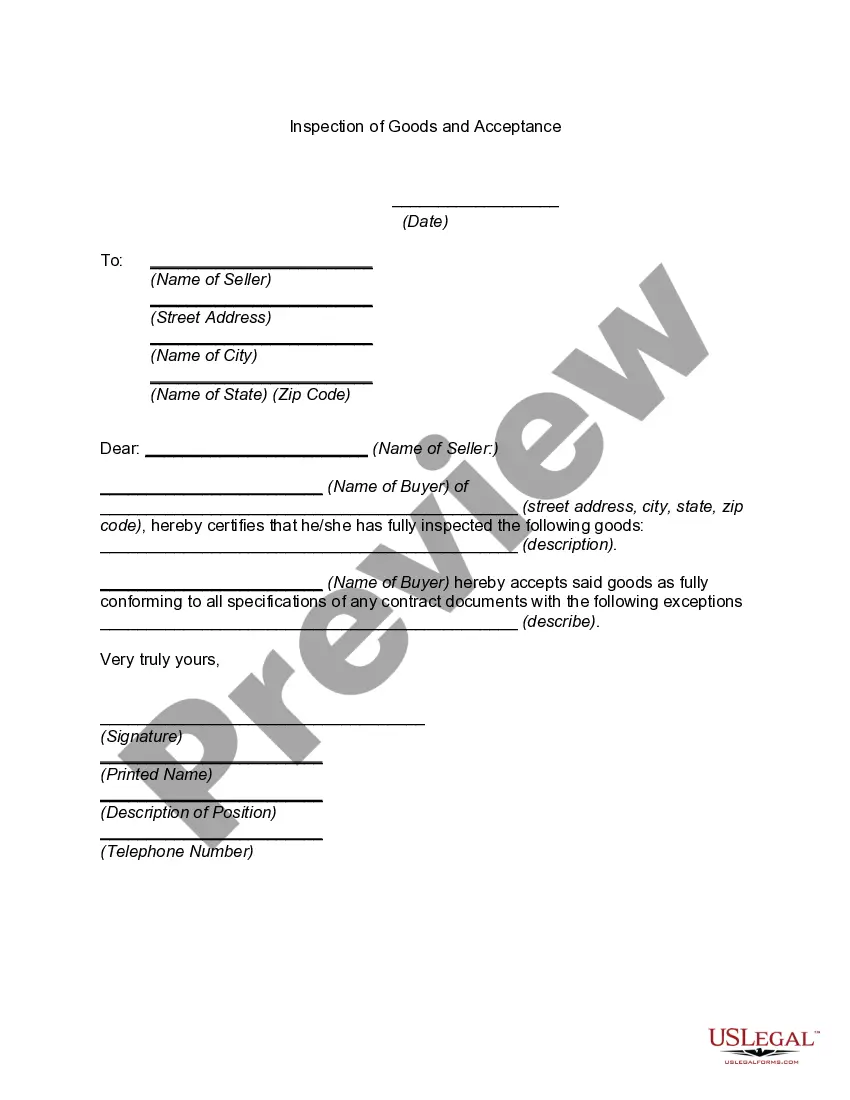

Pennsylvania Inspection of Goods and Acceptance

Description

How to fill out Inspection Of Goods And Acceptance?

If you require detailed, download, or print legal document templates, utilize US Legal Forms, the broadest range of legal forms available online.

Take advantage of the site's straightforward and convenient search feature to find the documents you need.

Various templates for business and personal purposes are organized by types and claims, or keywords.

Each legal document template you purchase is yours indefinitely. You can access any form you have downloaded in your account.

Click the My documents section to select a form for printing or downloading again. Be proactive and download, and print the Pennsylvania Inspection of Goods and Acceptance with US Legal Forms. There are various professional and state-specific forms available for your business or personal requirements.

- Use US Legal Forms to find the Pennsylvania Inspection of Goods and Acceptance with just a few clicks.

- If you are already a US Legal Forms client, Log In to your account and then select the Download option to access the Pennsylvania Inspection of Goods and Acceptance.

- You can also access forms you previously downloaded in the My documents section of your account.

- If you are using US Legal Forms for the first time, adhere to the following steps.

- Step 1. Ensure you have chosen the form for the correct city/state.

- Step 2. Utilize the Preview option to review the form's contents. Remember to read the description.

- Step 3. If you are not satisfied with the form, use the Lookup area at the top of the page to find other versions of the legal form template.

- Step 4. After you have found the form you need, click on the Get now option. Select your desired pricing plan and enter your credentials to sign up for an account.

- Step 5. Complete the transaction. You may use your credit card or PayPal account to finalize the payment.

- Step 6. Choose the format of the legal form and download it onto your device.

- Step 7. Fill out, edit, and print or sign the Pennsylvania Inspection of Goods and Acceptance.

Form popularity

FAQ

Yes. Vehicles will be exempt from the program if: 2022 the vehicle has been owned for one year and driven less than 5,000 miles in the prior year. However, motorists must go to an emissions inspection station to verify the vehicle's mileage and receive an exemption sticker.

Inspection and Safety RequirementsRear reflectors, headlamps, functional stop lamps (brake lights)Adequate braking system.Tires in safe operating condition.Rear wheel shields to bar substances from being thrown from the rear wheels at tangents exceeding 22.5 degrees from the road surface.Rear view mirror.Horn.More items...

A word about the PA State Inspection Emissions TestIf the check engine light is illuminated, it will fail emission inspection. A diagnostic and repair must be performed and the light must be reset before your car will pass the emission inspection.

Every car in Pennsylvania is required to undergo a vehicle safety and emissions inspection. These inspections are required by law to ensure that all vehicles on the road are safe to operate. These inspections can keep you and other drivers safe from dangerous and possibly fatal collisions.

Safety inspections for passenger cars and light-duty trucks require that the following items be checked: suspension components, steering, braking systems, tires and wheels, lighting and electrical systems, glazing (glass), mirrors, windshield washer, defroster, wipers, fuel systems, the speedometer, the odometer, the

From here, your mechanic will open the hood and inspect your engine and components for any leaks or damage. This inspection involves your exhaust, fuel, transmission, battery, coolant, and more. Your emissions system is also inspected.

Vehicle Safety InspectionA vehicle newly registered in Pennsylvania must have a safety inspection within ten (10) days of the registration date.

Pennsylvania requires vehicle safety inspections to ensure that vehicles are maintained for safe operation. Safety Inspections can prevent vehicle failure on the highways and crashes that may result in injuries or death.

There is a ten-day grace period after the expiration date. Still, you can only drive the car during that time if you can prove you have an appointment at a licensed PennDot inspection station and you are driving to that appointment.

Pennsylvania Car Inspection RequirementsSuspension. The car's ball joint movement can't exceed the manufacturer's specifications, along with shock absorbers that do not leak.Steering.Brakes.Tires and Wheels.Lighting and Electrical Systems.Glass and Mirrors.Windshield Washer, Defroster and Wipers.Fuel System.More items...