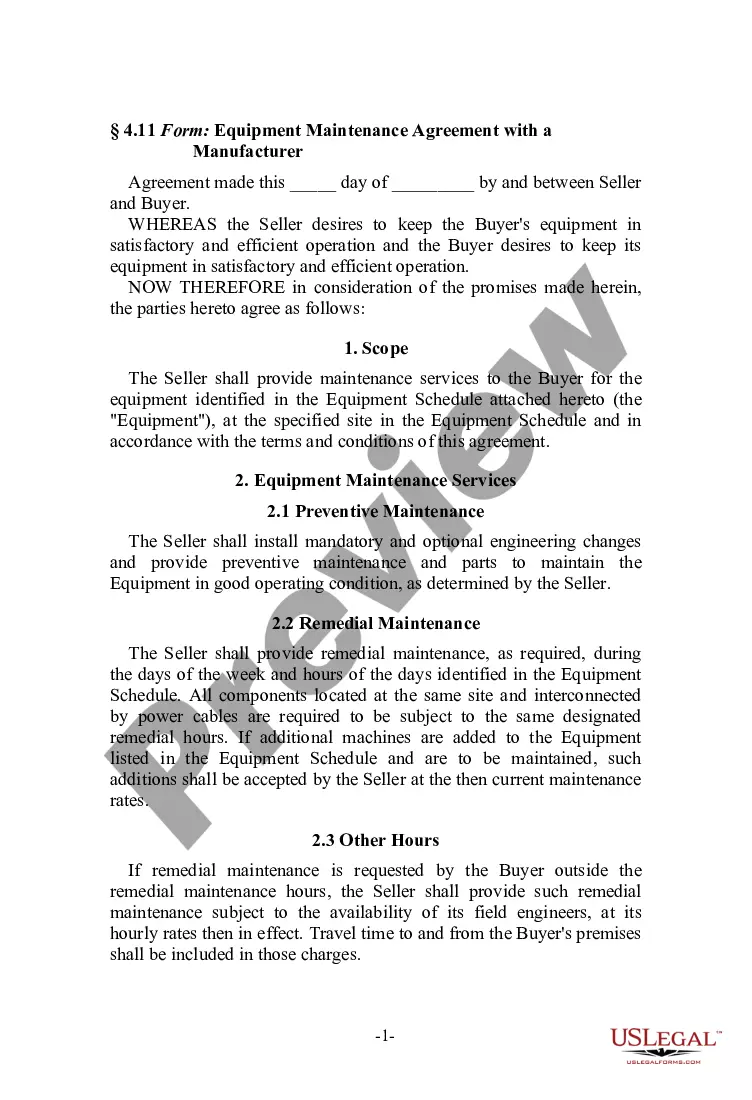

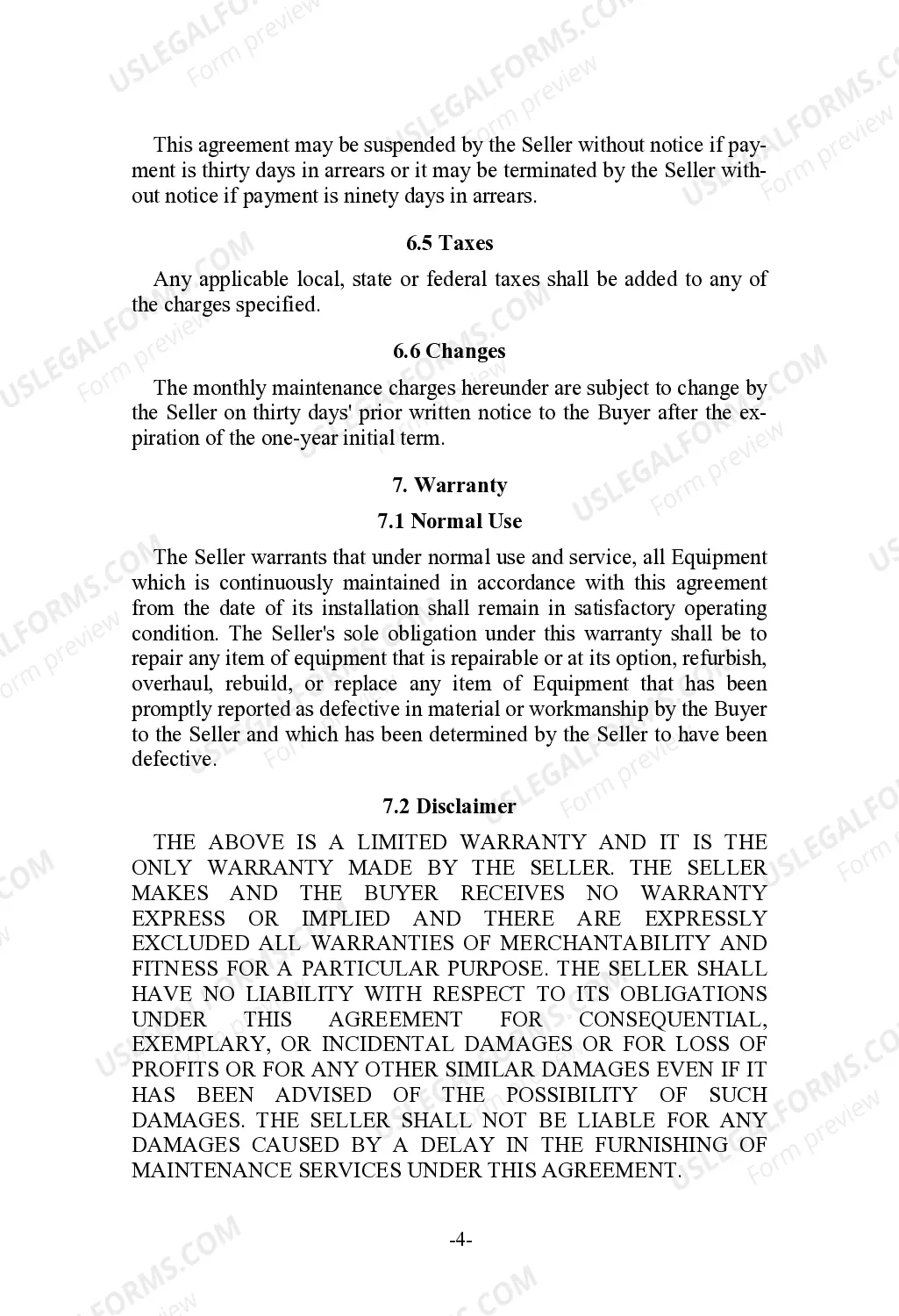

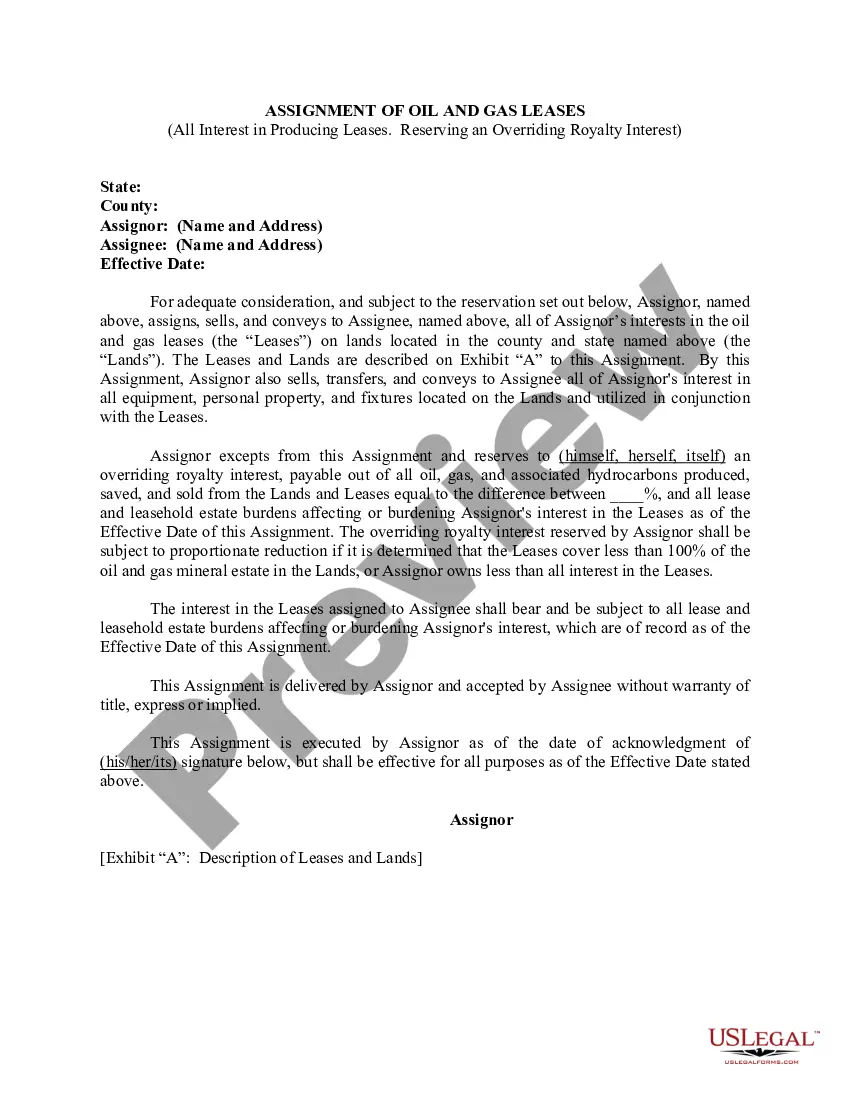

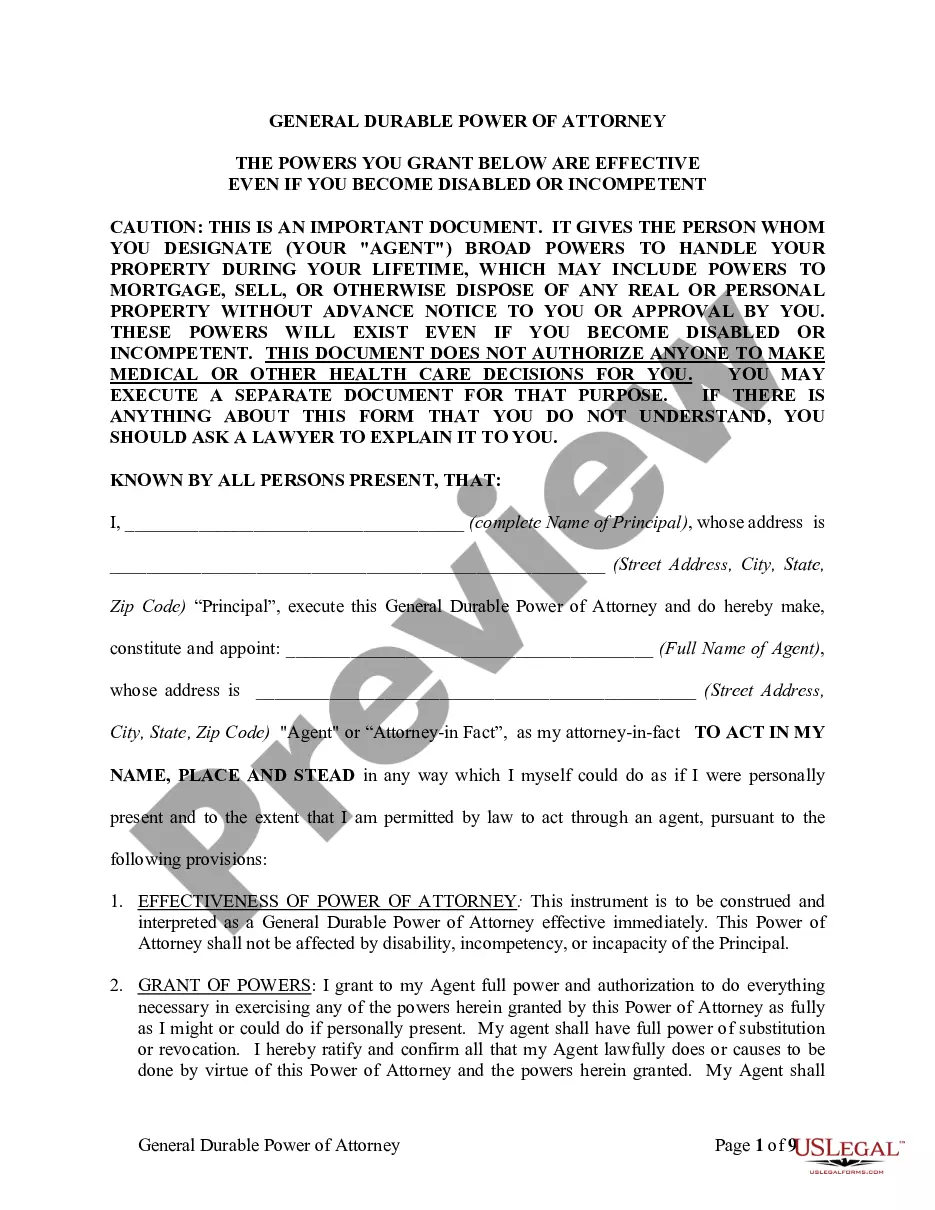

Pennsylvania Equipment Maintenance Agreement with a Manufacturer: A Comprehensive Overview In Pennsylvania, an Equipment Maintenance Agreement (EMA) with a Manufacturer is a legally binding contract that governs the maintenance and service obligations between a manufacturer and a customer for a piece of equipment. These agreements are crucial to ensure the efficient functioning and longevity of equipment, ranging from heavy machinery to complex industrial systems. Such agreements are tailored to meet the unique requirements of different industries and businesses in Pennsylvania. Some notable types of Equipment Maintenance Agreements with Manufacturers in Pennsylvania include: 1. Preventive Maintenance Agreement: This type of agreement focuses on regular inspections, adjustments, and cleaning of equipment to prevent potential malfunctions or breakdowns proactively. Through scheduled maintenance, the manufacturer aims to optimize the performance, reliability, and safety of the equipment while minimizing the probability of unexpected downtime or major repairs. 2. Corrective Maintenance Agreement: In situations where equipment already faces critical issues or breakdowns, Corrective Maintenance Agreements address the repair and restoration of the affected system to its optimal working condition. These agreements specify the manufacturer's responsibilities to promptly deploy qualified technicians, source replacement parts, and perform necessary repairs, aiming to minimize the disruption to the customer's operations. 3. Comprehensive Maintenance Agreement: A Comprehensive Maintenance Agreement combines preventive and corrective maintenance services into a single package. It covers both routine inspections and repairs, offering customers a holistic solution to ensure the continuous operation of their equipment under the manufacturer's requisite care. Key Elements and Benefits of a Pennsylvania Equipment Maintenance Agreement: 1. Scope of Services: The agreement specifies the types of maintenance services or repairs that the manufacturer will provide, including routine inspections, emergency repairs, software updates, or equipment upgrades. It also outlines any exclusions or limitations regarding the covered equipment or parts. 2. Service Levels and Response Time: Manufacturers often describe the guaranteed response time for attending to service requests, especially during emergencies or unexpected breakdowns. This ensures that customers have a clear understanding of the support they can expect during critical situations. 3. Maintenance Schedule: The agreement typically delineates the recommended maintenance schedule, based on the equipment's usage, operational conditions, and manufacturer's guidelines. This helps in planning downtime, reducing impacts on daily operations, and maximizing the equipment's lifespan. 4. Spare Parts and Consumables: To streamline repairs, the agreement specifies how the manufacturer will manage spare parts inventory and their availability. It may explain whether the manufacturer will deliver the parts directly or make them accessible through authorized suppliers or service centers. 5. Payment Terms: The agreement outlines the payment structure, including any upfront fees, periodic service charges, or additional costs incurred for repairs or replacements. It also mentions any applicable warranties or extended coverage plans. 6. Termination and Renewal: The agreement typically stipulates the termination conditions, notice periods, and circumstances that allow either party to end the contract. It also mentions provisions for automatic renewal, renegotiation, or possible equipment buyouts at the end of the agreement's term. Pennsylvania Equipment Maintenance Agreements with Manufacturers serve as a safeguard against unexpected equipment failures while minimizing downtime and expensive repairs. By entering into such agreements, businesses can benefit from the expertise and support of the manufacturer to optimize equipment performance, ensure compliance with regulations, and maintain a competitive edge in their respective industries.

Pennsylvania Equipment Maintenance Agreement with a Manufacturer

Description

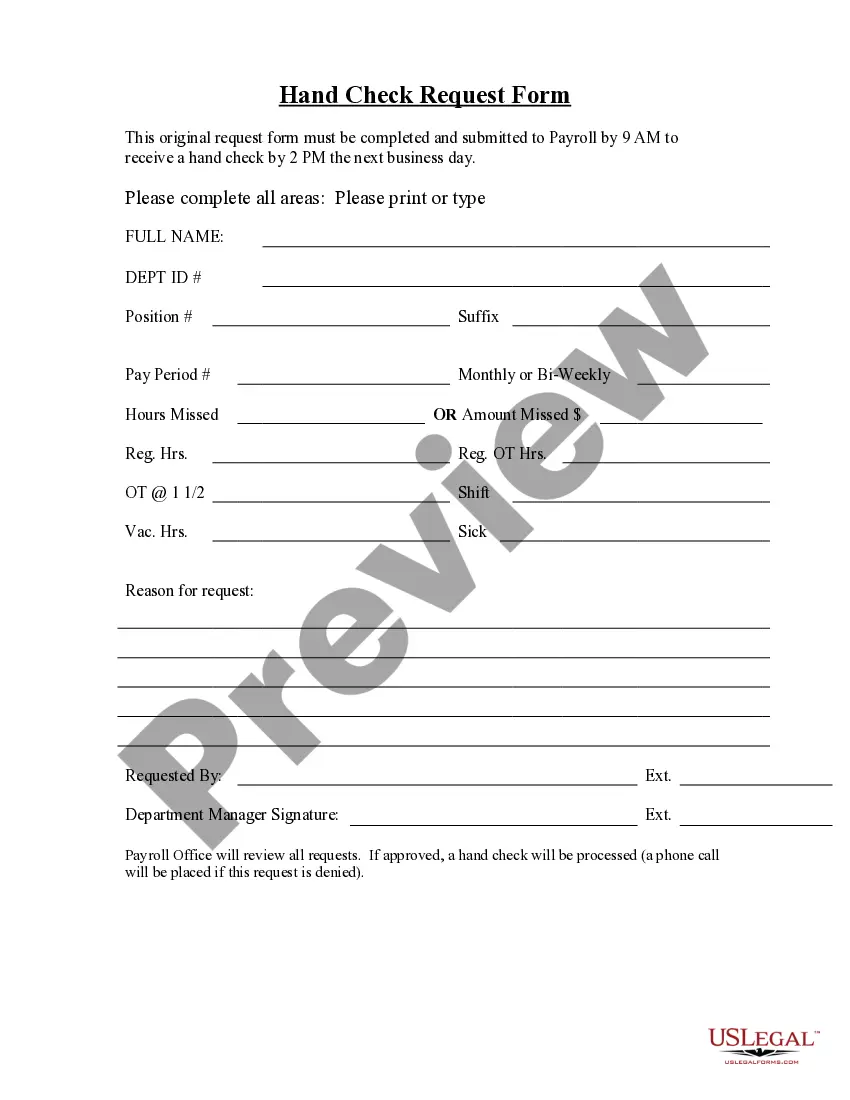

How to fill out Pennsylvania Equipment Maintenance Agreement With A Manufacturer?

Choosing the best lawful papers format could be a battle. Needless to say, there are tons of themes available on the Internet, but how would you discover the lawful form you require? Use the US Legal Forms web site. The services provides 1000s of themes, such as the Pennsylvania Equipment Maintenance Agreement with a Manufacturer, that you can use for company and personal requirements. All of the kinds are checked by pros and fulfill state and federal specifications.

Should you be already listed, log in in your profile and click on the Acquire button to find the Pennsylvania Equipment Maintenance Agreement with a Manufacturer. Utilize your profile to check from the lawful kinds you might have acquired earlier. Go to the My Forms tab of your own profile and obtain another duplicate in the papers you require.

Should you be a brand new customer of US Legal Forms, listed here are simple recommendations so that you can adhere to:

- Initial, make certain you have chosen the appropriate form for your city/region. You may examine the form utilizing the Review button and browse the form outline to guarantee this is the best for you.

- When the form is not going to fulfill your preferences, use the Seach area to discover the right form.

- Once you are sure that the form is acceptable, select the Get now button to find the form.

- Select the pricing plan you would like and enter the needed details. Design your profile and pay for your order making use of your PayPal profile or Visa or Mastercard.

- Pick the data file formatting and acquire the lawful papers format in your product.

- Full, edit and produce and indication the obtained Pennsylvania Equipment Maintenance Agreement with a Manufacturer.

US Legal Forms may be the biggest collection of lawful kinds where you will find a variety of papers themes. Use the company to acquire skillfully-made files that adhere to status specifications.

Form popularity

FAQ

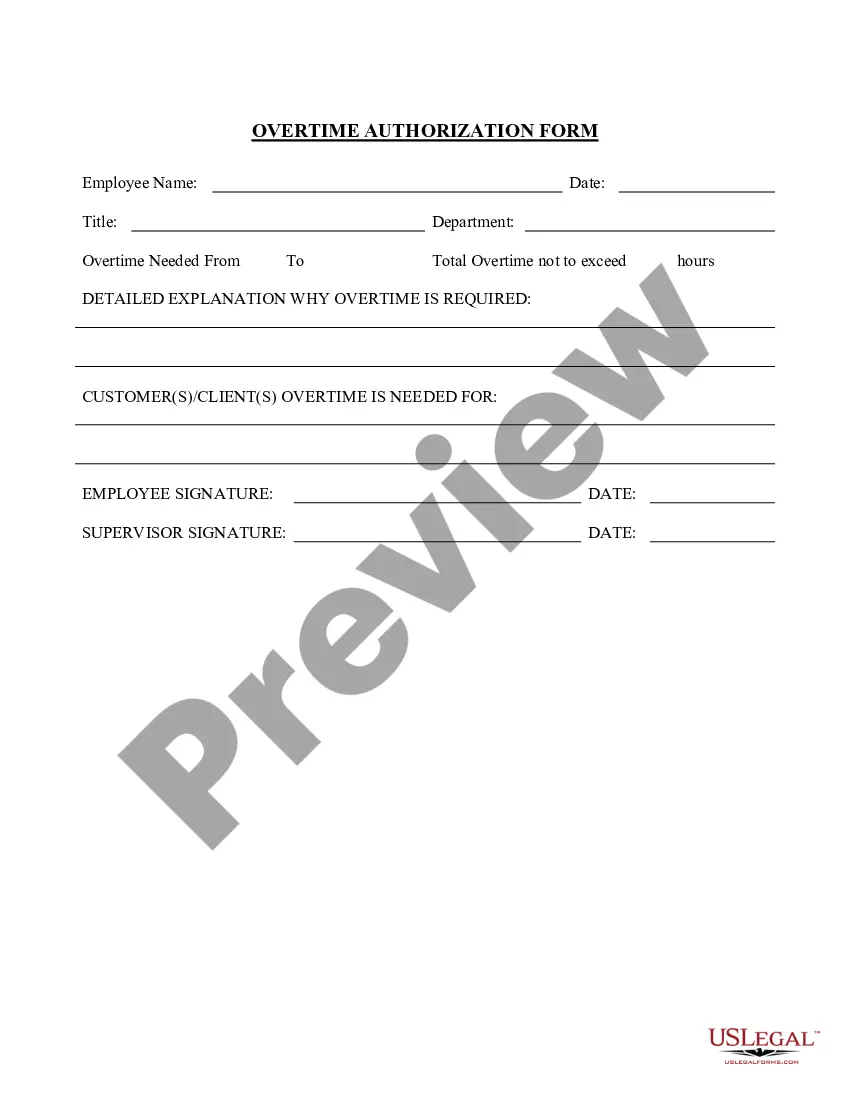

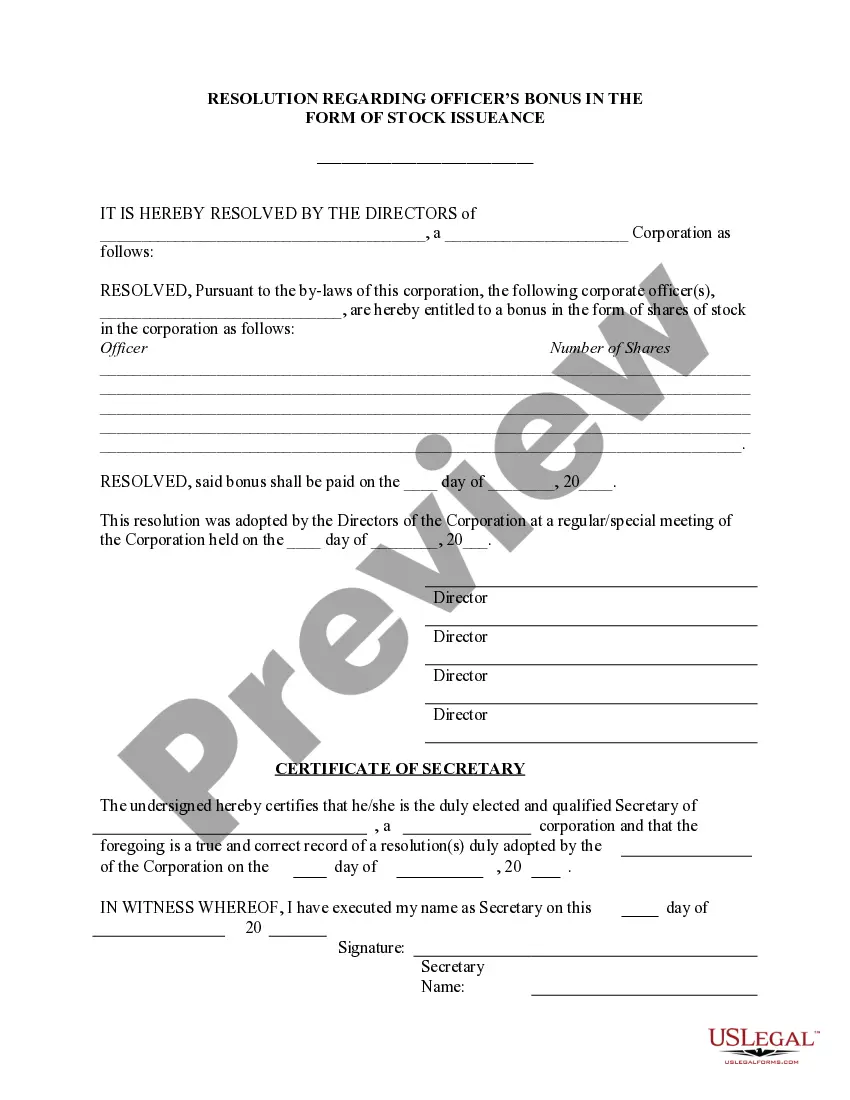

A facilities or building maintenance contract should contain: Full names and details of both parties. Types of maintenance. Scope of the work. Equipment details. Service schedules. Response times. Service completion times. Payment terms.

A maintenance agreement (contract), sometimes called a service agreement (contract), is an agreement which requires specific performance of repairing, cleaning, altering, or improving tangible personal property on a regular or irregular basis to ensure the product's continued satisfactory operation.

In your maintenance agreement, you will need to include: A section that defines both the provider and the client including their full legal names and any terms that need to be defined in the contract. A list of the services that will be performed in detail. Make sure all possible services as included.

This Pennsylvania sales tax exemption for manufacturing also applies to repair parts for machinery and equipment, as well as supplies that are directly used or consumed in the manufacturing or processing operation.

A maintenance contract is a legal agreement between your organization and a maintenance service provider that outlines the work they're going to do, when they're going to do it, how quickly, and to what standard.

Do you have to pay sales tax on an extended warranty? Yes. The sale at retail or use of maintenance, service and warranty contracts constitutes prepayment for services to tangible personal property and is subject to tax.

Maintenance contracts include service level parameters such as response time and performance of the equipment to be maintained (99 percent network availability, for example). Other provisions of these agreements may include the timeliness and timeframe of services to be rendered and the annual or monthly fee.

How to Create a Planned Maintenance Contract Full name and details of service provider and client. The type of maintenance. A disclosed scope of work. A service schedule. Payment terms. Warranties and guarantees. Information regarding legal disputes. Details on contract termination.