Puerto Rico Aseptic Techniques refer to the specific methodologies, procedures, and practices employed within various industries and sectors to maintain a sterile and contamination-free environment. These techniques are crucial in industries such as pharmaceuticals, biotechnology, healthcare, food processing, and laboratory settings where the prevention of microbial contamination is paramount. The primary objective of Puerto Rico Aseptic Techniques is to prevent infection or spoilage of products, ensuring safety and quality. These techniques involve implementing rigorous protocols and following standard operating procedures (SOPs) to create and maintain a sterile environment throughout the production or testing process. There are several key components and procedures involved in Puerto Rico Aseptic Techniques: 1. Sterilization: The process of eliminating or reducing the number of microorganisms present on surfaces, equipment, or products. Common methods include heat sterilization (autoplaying), chemical sterilization, and filtration. 2. Clean room Design: Creating a controlled environment with low levels of airborne particles and microorganisms. This involves specialized ventilation systems, air filtration, positive pressure, and proper gowning procedures. 3. Gowning: Wearing appropriate Personal Protective Equipment (PPE) such as gloves, masks, gowns, and hair coverings to minimize the introduction of contaminants into the aseptic environment. 4. Hand Hygiene: Thorough handwashing using antibacterial soap or alcohol-based sanitizers before entering the clean room or handling sterile materials. 5. Aseptic Technique: The meticulous handling of sterile products or materials using sterile tools and equipment to prevent contamination. This includes techniques such as proper gloving, use of sterile wipes, and maintaining a sterile field. 6. Environmental Monitoring: Regular monitoring of air quality, surface contamination, and personnel hygiene to ensure the effectiveness of the aseptic techniques. This is done through air sampling, surface swabbing, and monitoring microbial counts. 7. Training and Validation: Training personnel on aseptic techniques, adhering to SOPs, and regularly validating the efficacy of the methods to ensure consistency and compliance with regulatory requirements. In addition to these general aseptic techniques, there are specialized variations that are utilized depending on the industry or specific requirements: 1. Pharmaceutical Aseptic Techniques: Strict guidelines governed by regulatory agencies like the FDA to maintain sterility during the manufacturing, packaging, and testing of pharmaceutical products. This often involves the use of isolators, laminar airflow hoods, and validated cleaning procedures. 2. Food Processing Aseptic Techniques: Techniques aimed at minimizing spoilage and contamination during the production, packaging, and storage of food products. This includes processes like high-temperature pasteurization, aseptic packaging, and enhanced sanitation practices. 3. Healthcare Aseptic Techniques: Techniques applied in healthcare settings like hospitals and clinics to prevent the spread of healthcare-associated infections. This involves hand hygiene, sterile procedures during surgeries, and proper disinfection of medical equipment. It is important to understand and implement appropriate Puerto Rico Aseptic Techniques in relevant industries to ensure the production of safe and high-quality products while safeguarding public health. Adhering to these techniques helps minimize the risk of contamination, maintain product integrity, and meet regulatory requirements.

Puerto Rico Aeseptic Techniques

Description

How to fill out Puerto Rico Aeseptic Techniques?

US Legal Forms - among the greatest libraries of legal kinds in the USA - gives a wide array of legal record templates you can down load or print. Using the site, you may get a huge number of kinds for business and person functions, categorized by classes, suggests, or key phrases.You can get the latest versions of kinds like the Puerto Rico Aeseptic Techniques in seconds.

If you currently have a monthly subscription, log in and down load Puerto Rico Aeseptic Techniques through the US Legal Forms local library. The Download key will show up on each kind you view. You have accessibility to all previously acquired kinds within the My Forms tab of your respective accounts.

If you would like use US Legal Forms for the first time, allow me to share simple instructions to help you started out:

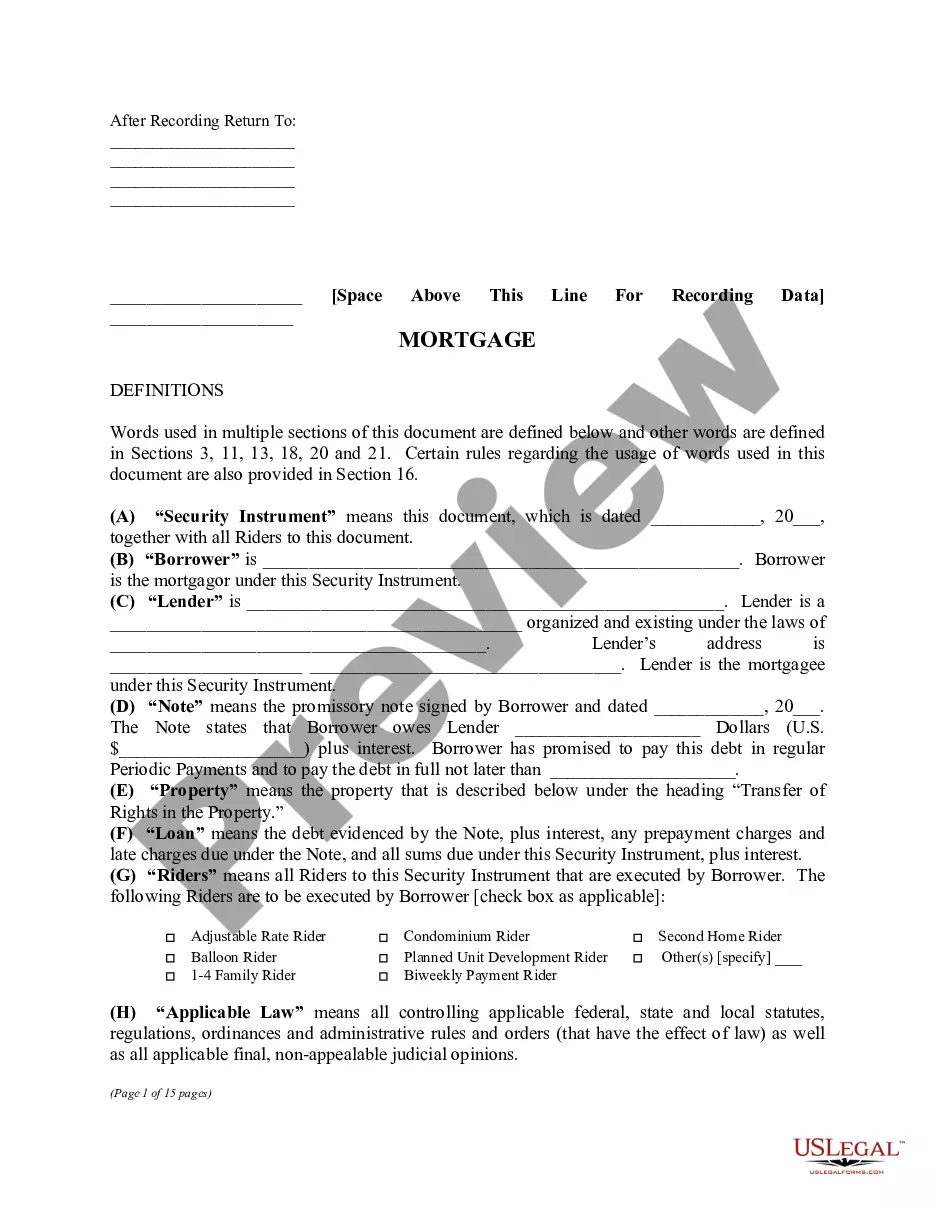

- Be sure you have picked the correct kind to your metropolis/county. Click on the Preview key to examine the form`s information. Read the kind outline to actually have chosen the correct kind.

- If the kind does not suit your demands, utilize the Lookup field near the top of the screen to get the the one that does.

- When you are satisfied with the shape, validate your decision by visiting the Purchase now key. Then, opt for the rates program you like and offer your references to register for the accounts.

- Procedure the transaction. Use your credit card or PayPal accounts to perform the transaction.

- Choose the structure and down load the shape on your own product.

- Make adjustments. Fill out, modify and print and indicator the acquired Puerto Rico Aeseptic Techniques.

Every web template you put into your money does not have an expiration time and is yours forever. So, if you want to down load or print one more duplicate, just proceed to the My Forms segment and then click in the kind you need.

Obtain access to the Puerto Rico Aeseptic Techniques with US Legal Forms, one of the most substantial local library of legal record templates. Use a huge number of skilled and condition-particular templates that meet up with your organization or person requirements and demands.